1. The unit includes electronic devices and solenoid valve, please do not knock.

2. Caution for connecting line when disassembling the unit.

3. Please wipe it using soft cloth with neutral detergent when cleaning the product.

Next wipe detergent and dirt by the wrung—out soft cloth, then using dried soft

cloth to dry.

4. Please do not washing with watering or using some detergent with particle such

as scouring powder and laundry detergent, also do not using diluent, detergent

with high acid or Nylon brush to clean this product, lest to damage surface or

erode internal electronic components, especially be careful not to damage

transparent cover which placed induction window to avoid decrease the

effectiveness of reaction. Tips: Ensure the distance between sensing window and

counter top is above 35cm When installing on stainless steel counter top.

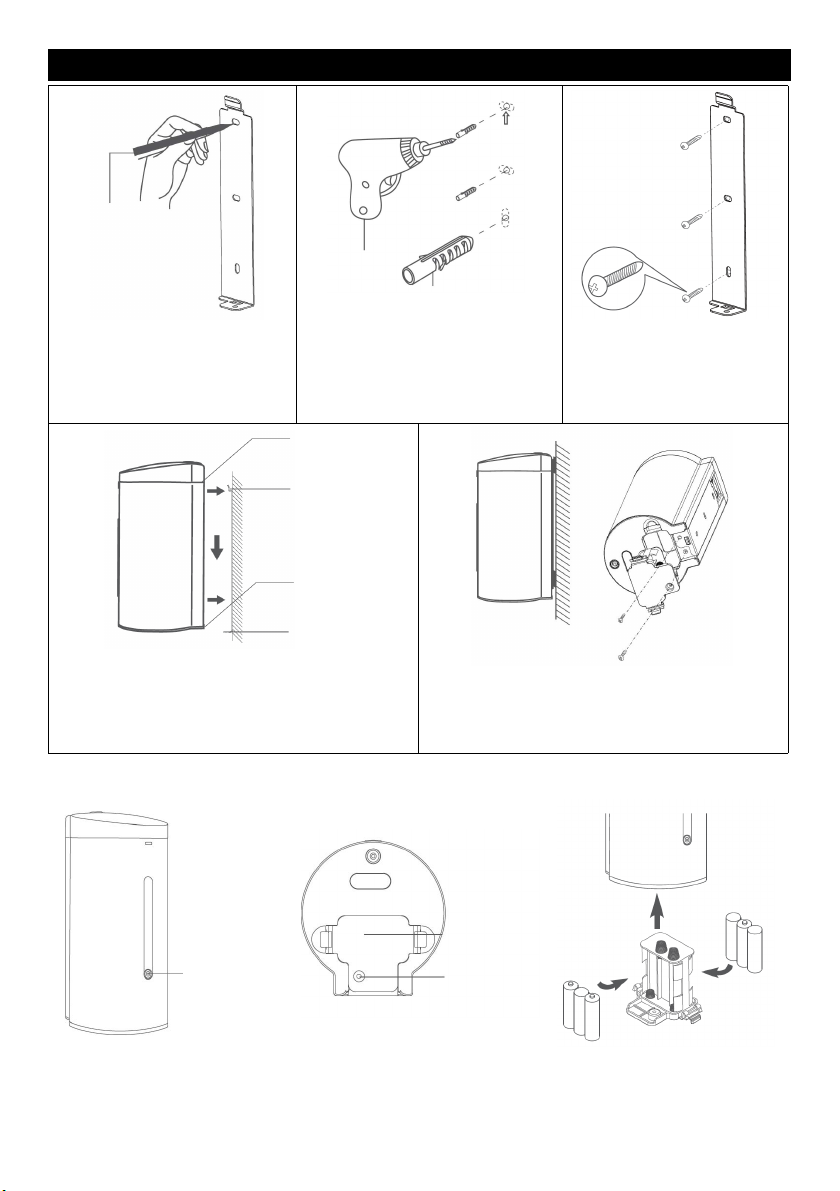

Installation.

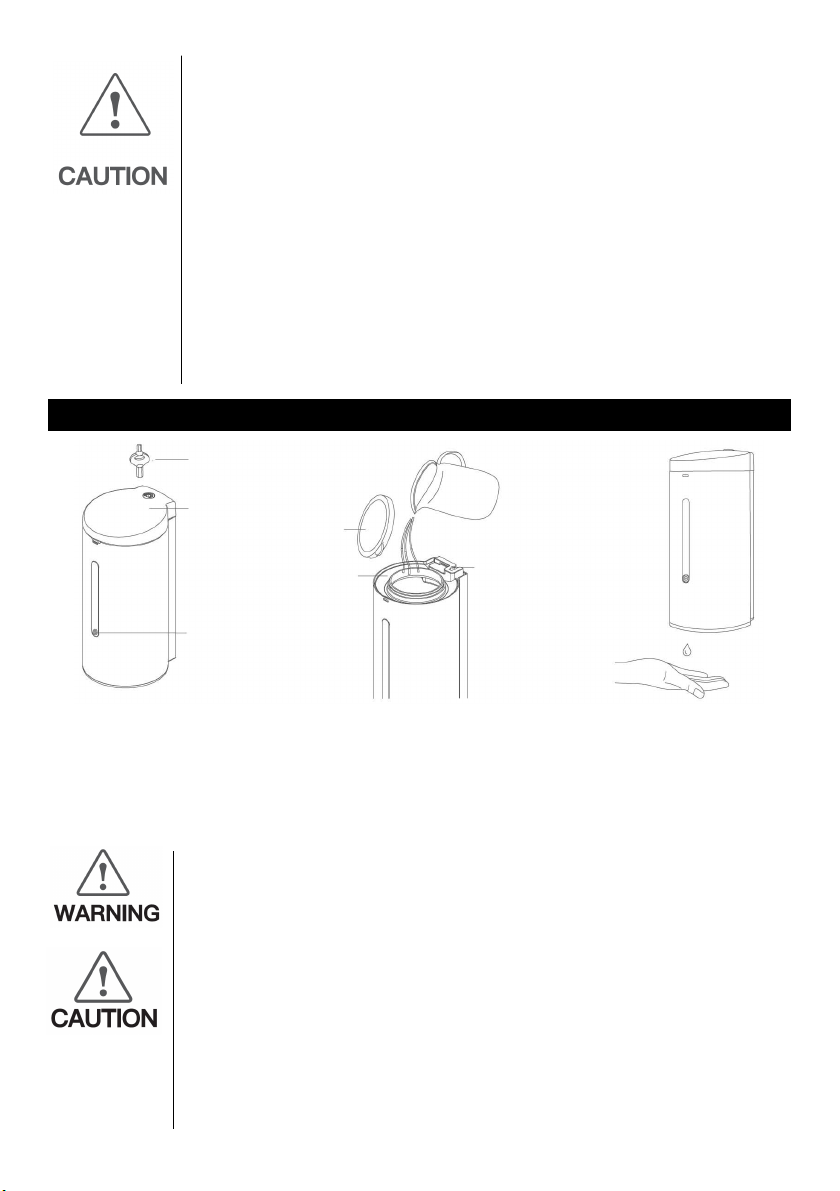

How To Use

Put your hand under the sensor

until the liquid sprayed out.

Open the sealing cap and pour the

liquid soap, remove the extra over

wing, and recover it.

Insert the key into the lock to

open the top cover after install

the battery Long press the setting

button for about 3 seconds, then

the LED light on with flashing 3

times.

Children should be used under adult supervision to prevent accidentally eating! Please

don’t throw away discarded batteries, recycling used batteries by correct way!

The unit has been designed with microcomputers & electronic circuit etc. Do not splash

water.

1. After installing the batteries, long press the setting button for about 3 seconds, then

the LED light on with a flashing, after 3 times flashing will the unit stay in standby,

long press the setting button to switch between turning the machine standby Status

and dormant status.

2. The unit is suggested to install batteries even if you don’t use it, so that the unit will

run automatically every 72 hours to avoid the catheter pressure adhesion.

3. Some of unit had installed batteries and in dormant status before delivery. Keep

press setting buttons for more than 3 seconds, the indicator will flash 3 times turning

into standby status. Whereas if the unit turn to dormant status after keeping press

the setting button.

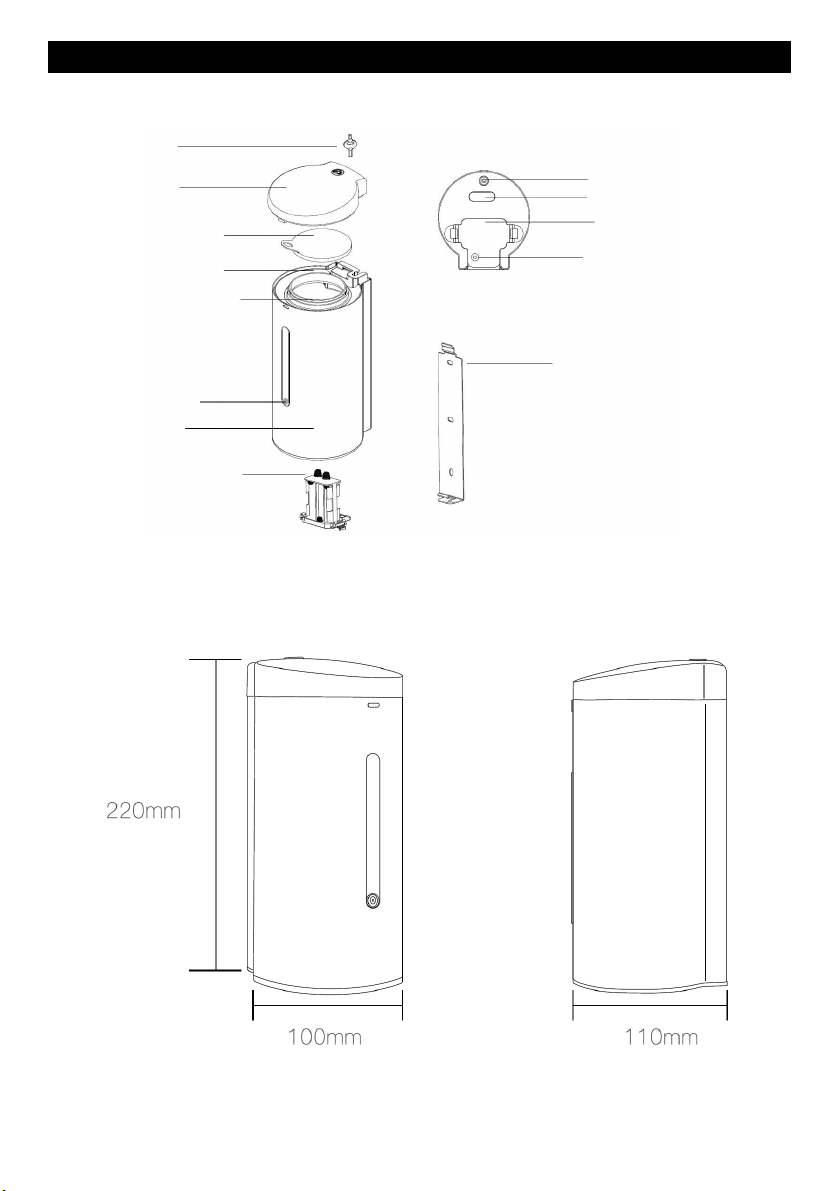

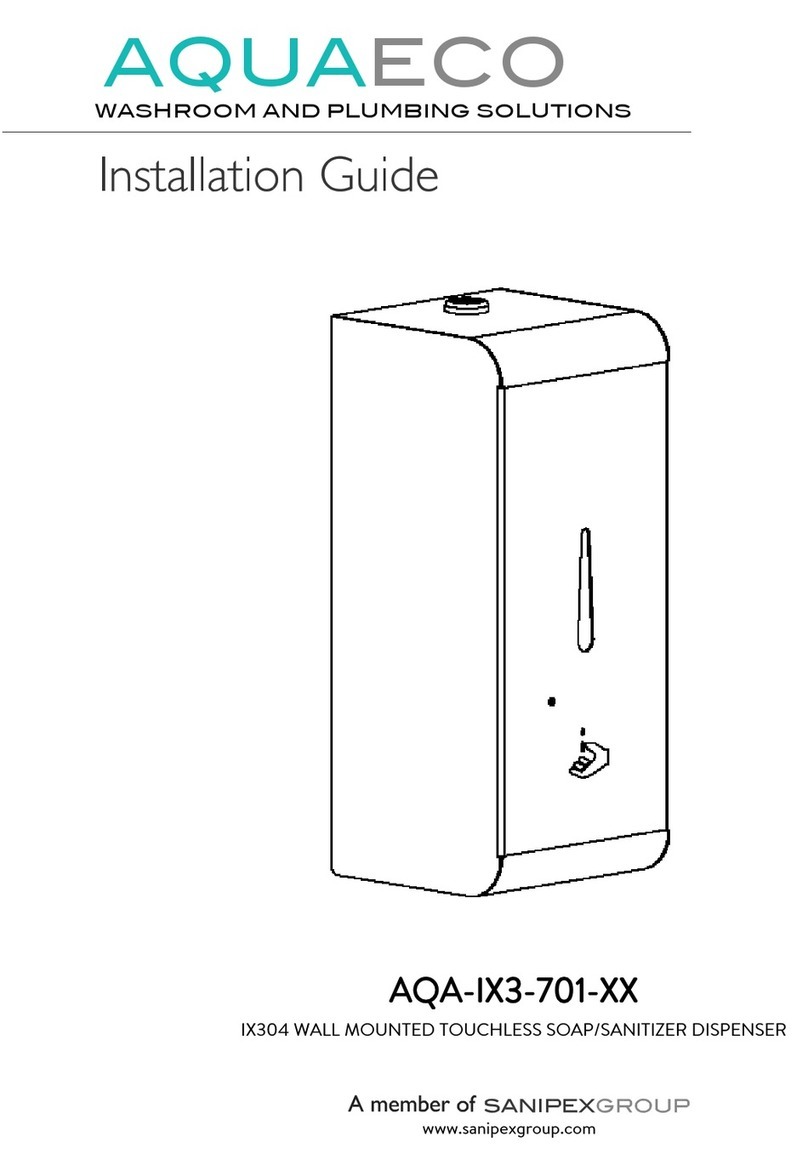

Liquid Button

Indicator

Fixed Bracket

Sealing Cap

Cap

Key