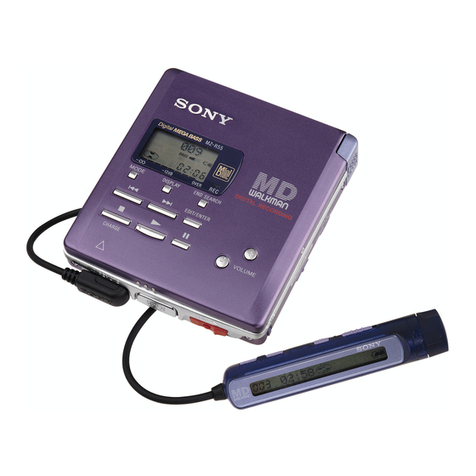

Audio

System: MiniDisc digital audio system

Laser: Semiconductor laser (=780 nm)

Sampling frequency: 44.1 kHz

Coding: Adaptive Transform Acoustic Coding

(ATRAC)

No. of channels: 2 (left and right, stereo)

1 (monaural)

Frequencyresponse: 20 Hz-20 kHz (+0 dB, -6dB)

Wowand flutter: Belowmeasurable limit

General

Input terminal

OPT/LINE IN jack

Impedance: 47k

Input level: SENS H:178mV

SENS L:500mV

MIC jack

Impedance: 600

Input level: 0.4mV

Output terminal

Output Jack: Phones, 22

Power output: 3.5 mW+3.5 mW

Power supply

Rechargeable battery: DC 1.2V

(included rechargeable battery)

Battery: DC 1.5V (One LR6, AA, UM-3 battery)

AC adaptor: DC 1.8V (included AC adaptor)

Dimensions (WxHxD)

Cabinet dimensions: 78.2x71.6x16.8

mm

incl.projecting parts: 79.9x73.6x18.6

mm

Weight: 120 g (with

battery)

94 g (without battery)

Playtime

(When used in hold mode, at 25°C, on a flat, stable surface)

Batterytype:PlaytimeRecord time

Rechargeable: About 15 hoursAbout 7 hours

Panasonic alkaline: About 21 hoursAbout 3 hours

Both together: About 38 hoursAbout 15 hours

Charger

Input: AC 220 V (GH) / AC220-230 V (EG) /

AC 230-240V (EB), 50/60 Hz 8W

Recharging time: About 3 hours

2