Panasonic PT-40LC12 User manual

Other Panasonic Monitor manuals

Panasonic

Panasonic TH-50BT300U User manual

Panasonic

Panasonic TH-84LQ70U User manual

Panasonic

Panasonic TH50PH10UKA - 50" Plasma Panel User manual

Panasonic

Panasonic TH-42PF30W User manual

Panasonic

Panasonic TH-58PF12UK User manual

Panasonic

Panasonic WVCM1420 - COLOR MONITOR User manual

Panasonic

Panasonic Viera TH-42PWD4 User manual

Panasonic

Panasonic TH32LRT12U - HD LCD DISPLAY User manual

Panasonic

Panasonic TH-55LFV50 Guide

Panasonic

Panasonic TH-50LFB70W User manual

Panasonic

Panasonic TH-85PF12W User manual

Panasonic

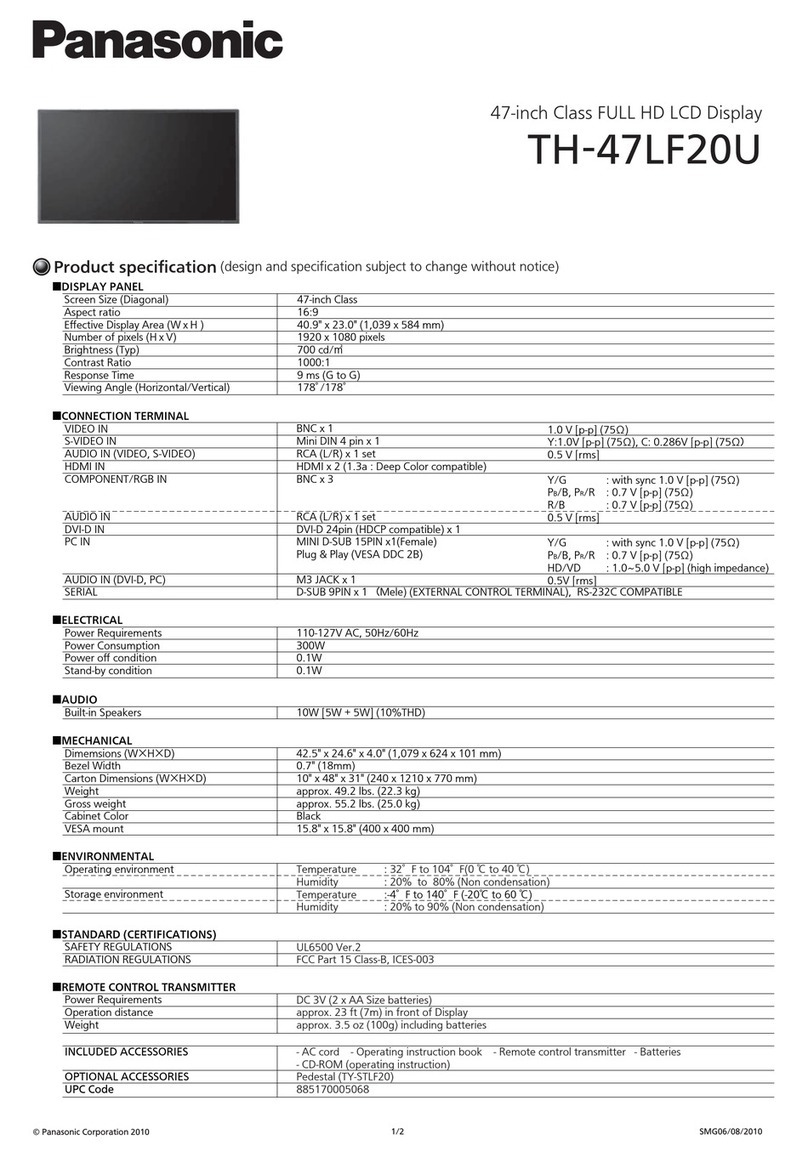

Panasonic TH47LF20U - 47" HD LCD TV User manual

Panasonic

Panasonic TH-47LFV5W User manual

Panasonic

Panasonic TH-65PHD8EK User manual

Panasonic

Panasonic TH-103PF10UK - 103" Plasma Panel User manual

Panasonic

Panasonic TH-50VX100U User manual

Panasonic

Panasonic TH37PR10U - 37" PLASMA TELEVISION User manual

Panasonic

Panasonic BT-H1700BMC User manual

Panasonic

Panasonic TH-70LF50E User manual

Panasonic

Panasonic TH-37PW7BX User manual