Safety

2

1.2 Safety precautions

Welding power source

Observe the following instructions to

prevent the hazard.

(1)Never use the welding power source for other than

welding purpose. (e.g. Never attempt to use the

welding power source for pipe thawing.)

(2)It is very important to comply with all instructions,

safety warnings, cautions and notes mentioned.

Failure to do so can result in serious injury or even

death.

(3)Work of driving source at the input side, selecting

work site, handling, storage and piping of high

pressure gas, storage of welded products and also

disposal of waste should be performed according to

the operating instructions and national, state and

local codes and regulations.

(4)Prevent any unauthorized personnel to enter in and

around the welding work area.

(5)Pacemaker wearers should consult their doctor

before going near arc welding. Magnetic fields can

affect pacemakers.

(6)Only educated and/or skilled persons who well

understand this welding power source should

install, operate, maintain and repair the unit.

(7)Only educated and/or skilled persons who well

understand the operating instructions of the unit

and are capable of safe handling should perform

operation of the unit.

Against electric shock

Observe the following instructions to

prevent the hazard.

(1)Do not touch live parts.

(2)Grounding of the case of the welding power and

base metal or a jig electrically connected to the

base metal must be performed by educated and/or

skilled persons.

(3)Before installation or maintenance work, turn off

power at the power box, wait it for at least five

minutes to discharge capacitors. Significant voltage

may exist on capacitors after turning off power at

the power box so it is imperative to check to make

sure that no charged voltage present at capacitors

before touching any parts.

(4)Do not use undersized, worn, damaged or bare

wired cables.

(5)Connect cables firm and insulate connection parts.

(6)Keep all cases, panels and covers securely in

place.

(7)Do not handle the welding power source with torn

or wet gloves.

(8)Wear safety harness in case of working above floor

level.

(9)Turn off all equipment when not in use.

(10)Perform periodic checks without fail and repair or

replace any damaged parts before using the power

source.

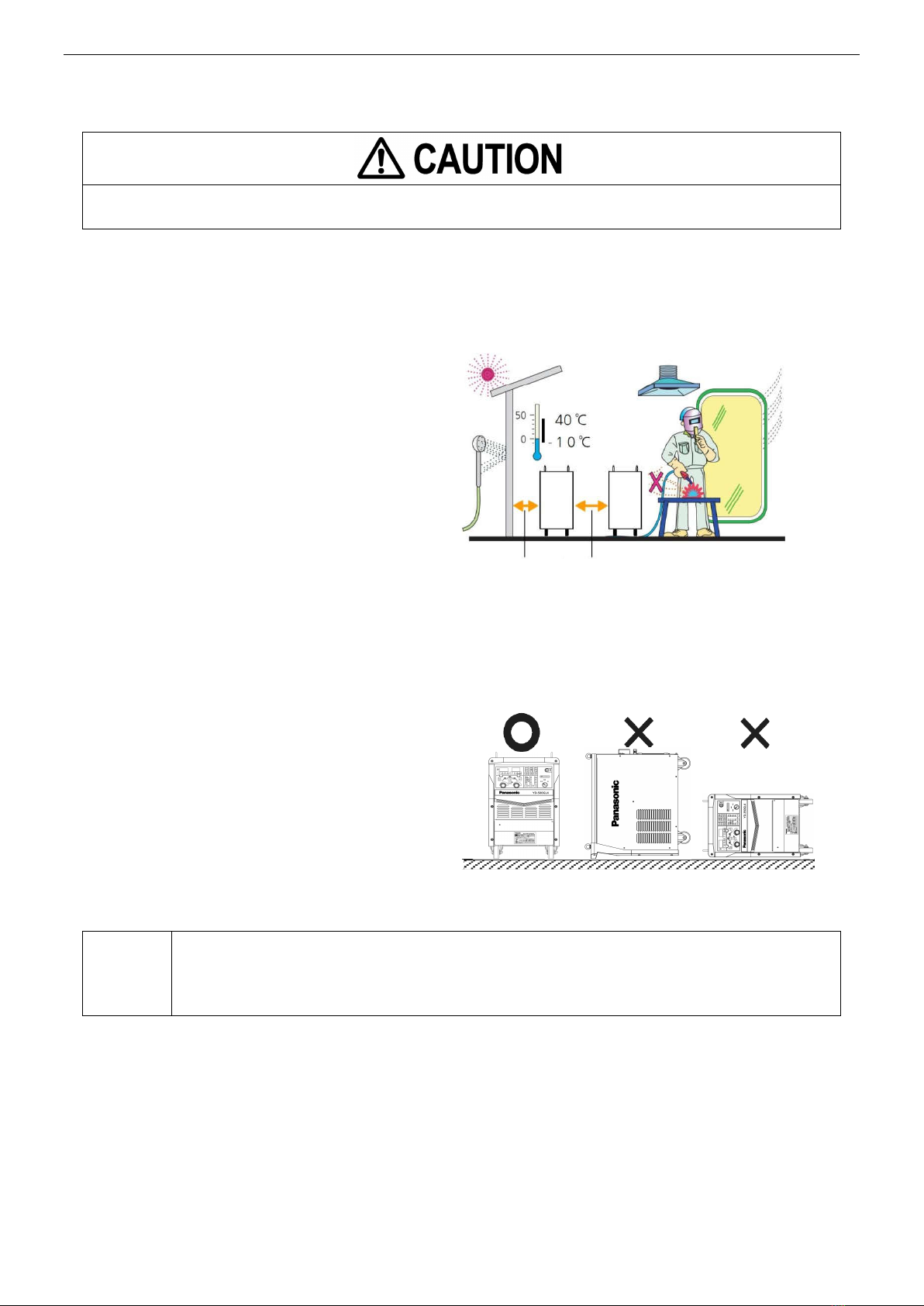

Ventilation and protective equipment

Oxygen deficit, fume and gas

generated during welding can be

hazardous.

(1)When conducting welding in the bottom of the tank,

boiler or hold as well as legally-defined sites, use a

local exhauster specified by the applicable laws and

regulations (occupational safety and health

regulation, rules on preventing suffocation or etc.)

or wear protective breathing gear.

(2)To prevent dust injury or poisoning by the fume

generated during welding, use a local exhauster

specified by the applicable law (occupational safety

and health regulation, rules on preventing injury by

inhaled dust or etc.), or wear protective breathing

gear.

(3)When conducting welding in a confined area, make

sure to provide sufficient ventilation or wear

protective breathing gear and have a trained

supervisor observe the workers.

(4)Do not conduct welding at a site where degreasing,

cleaning or spraying is performed. Conducting

welding near the area where any of these types of

work is performed can generate toxic gases.

(5)When welding a coated steel plate, provide

sufficient ventilation or wear protective breathing

gear. (Welding of coated steel plates generates

toxic fume and gas.)

Against fire, explosion or blowout

Observe the following cautions to

prevent fires explosion or

blowout.

(1)Remove any combustible materials at and near the

work site to prevent them from being exposed to

the spatter. If they cannot be relocated, cover them

with a fireproofing cover.

(2)Do not conduct welding near combustible gases.

(3)Do not bring the hot base metal near combustible

materials immediately after welding.

(4)When welding a ceiling, floor or wall, remove all

flammables including ones located in hidden

places.

(5)Properly connect cables and insulate connected

parts. Improper cable connections or touching of

cables to any electric current passage of the base

metal, such as steel beam, can cause fire.

(6)Connect the base metal cable at a section closest

to the welding part.

(7)Do not weld a sealed tank or a pipe that contains a

gas.

(8)Keep a fire extinguisher near the welding site for

an emergency.