8.5 Storing the shoes when not being used .................................................................................61

9. Workhead Fastclip Oset.................................................................................. 62

9.1 Offset workhead .....................................................................................................................62

9.2 Adjustment for clipping/de-clippingtool (offset).......................................................................62

10. Troubleshooting...................................................................................................63

10.1 Clips are being installed before sleeper is fully lifted .............................................................63

10.2 Clips are not being fully installed............................................................................................63

10.3 Clips are being over driven.....................................................................................................63

10.4 Clipping shoe rides over clip on one side ..............................................................................63

10.5 The tools are stuck to the rail .................................................................................................63

11. Warranty and Service ......................................................................................... 64

11.1 Warranty.................................................................................................................................64

11.2 Service ...................................................................................................................................64

12. Contact ....................................................................................................................64

13. Maintenance.......................................................................................................... 65

13.1 DenitionofMaintenanceTerms ...........................................................................................65

13.2 Categories of Work ................................................................................................................66

13.2.1 Scheduled Work .......................................................................................................................66

13.2.2 Arising Work .............................................................................................................................66

13.3 Remounting/Assembling ........................................................................................................66

13.4 Fasteners ...............................................................................................................................66

13.5 Maintenance and service .......................................................................................................68

13.5.1 Maintenance Supplies ...............................................................................................................68

13.5.2 Maintenance intervals................................................................................................................68

13.5.3 Job letter allocation....................................................................................................................68

13.5.4 Function code ............................................................................................................................69

13.5.5 Job code example......................................................................................................................69

13.5.6 Safety code................................................................................................................................69

13.5.7 Maintenance Schedule ..............................................................................................................70

13.6 Maintenance Job List .............................................................................................................72

CH01V Safety labels and warnings signs – Visual check .....................................................................72

CH02V Paint work – Visual check.........................................................................................................74

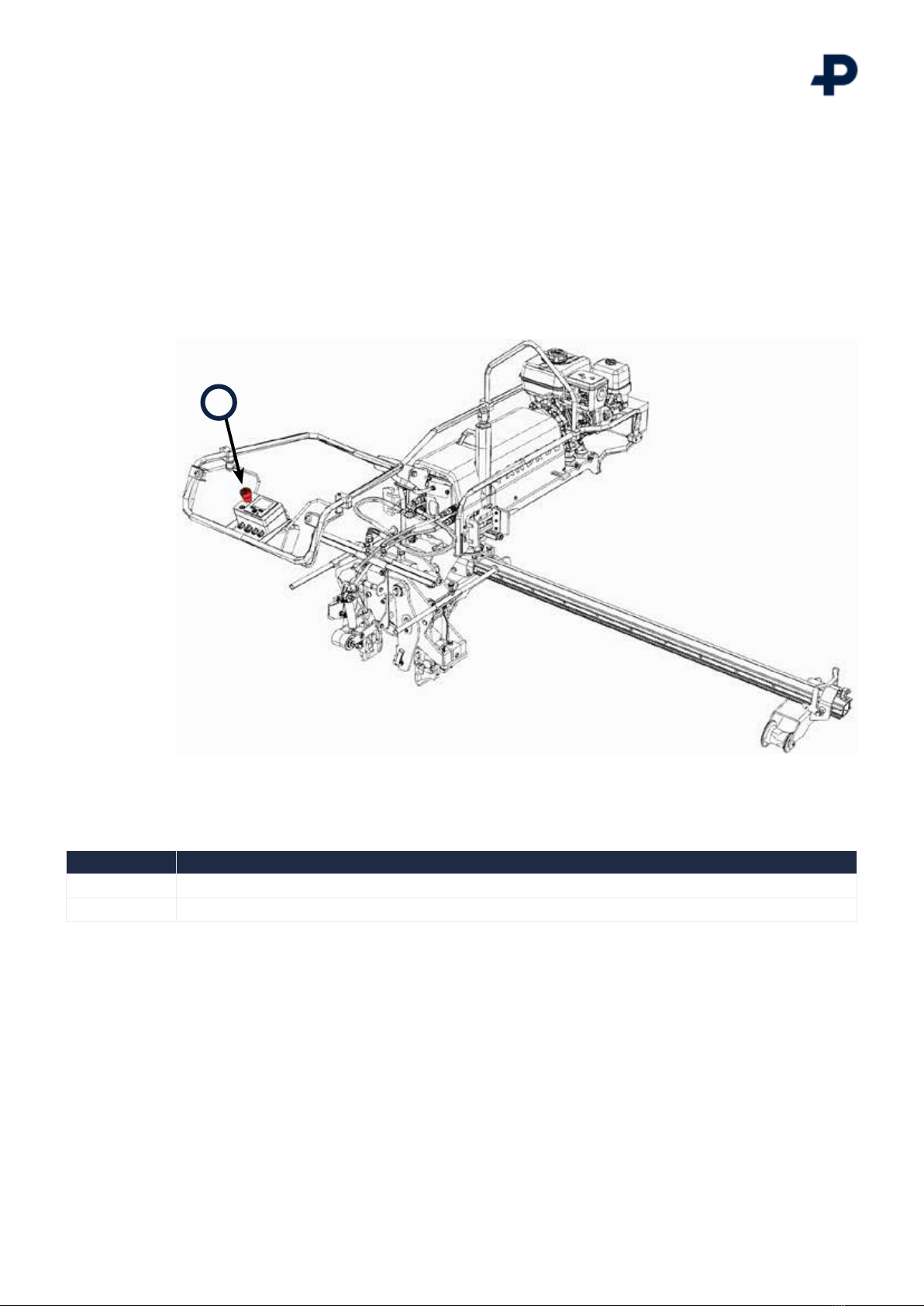

CH03V Frame – Visual check ...............................................................................................................75

CH04V Sign of leakage – Visual check.................................................................................................76

CH05C Abnormal sounds – Check........................................................................................................77

CH06C Tighten bolts – Check...............................................................................................................78

CH07L Lubrication, tool.........................................................................................................................79

REMARK: e-Clip too has no lubrication points/grease nipples. ...........................................................79

CH08C FE/FC tool – Check ..................................................................................................................80

4 av 118

OPERATION AND MAINTENANCE MANUAL I ENG_OMM_CD200IQ_P03 I 11 February 2022

@Pandrol 2022