Introduction

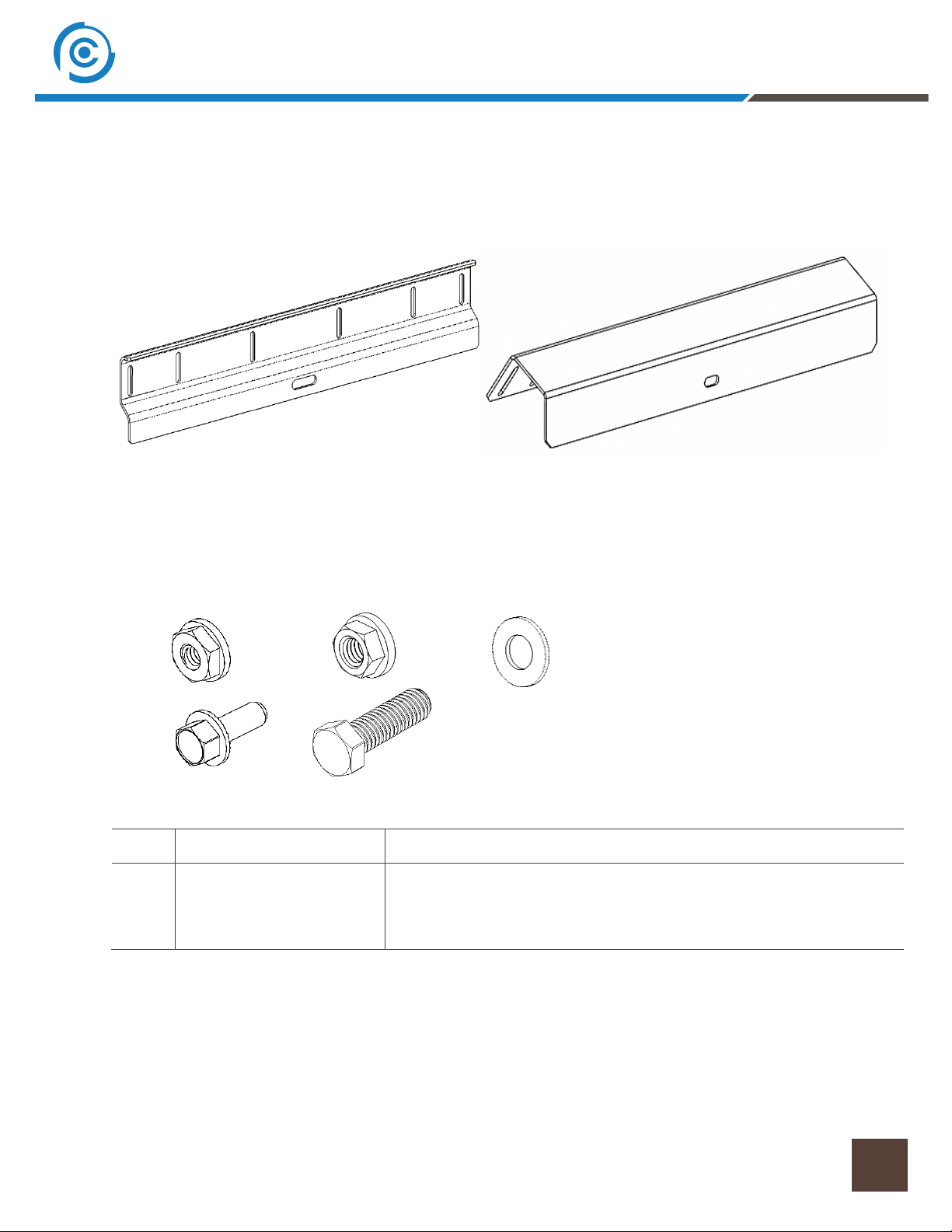

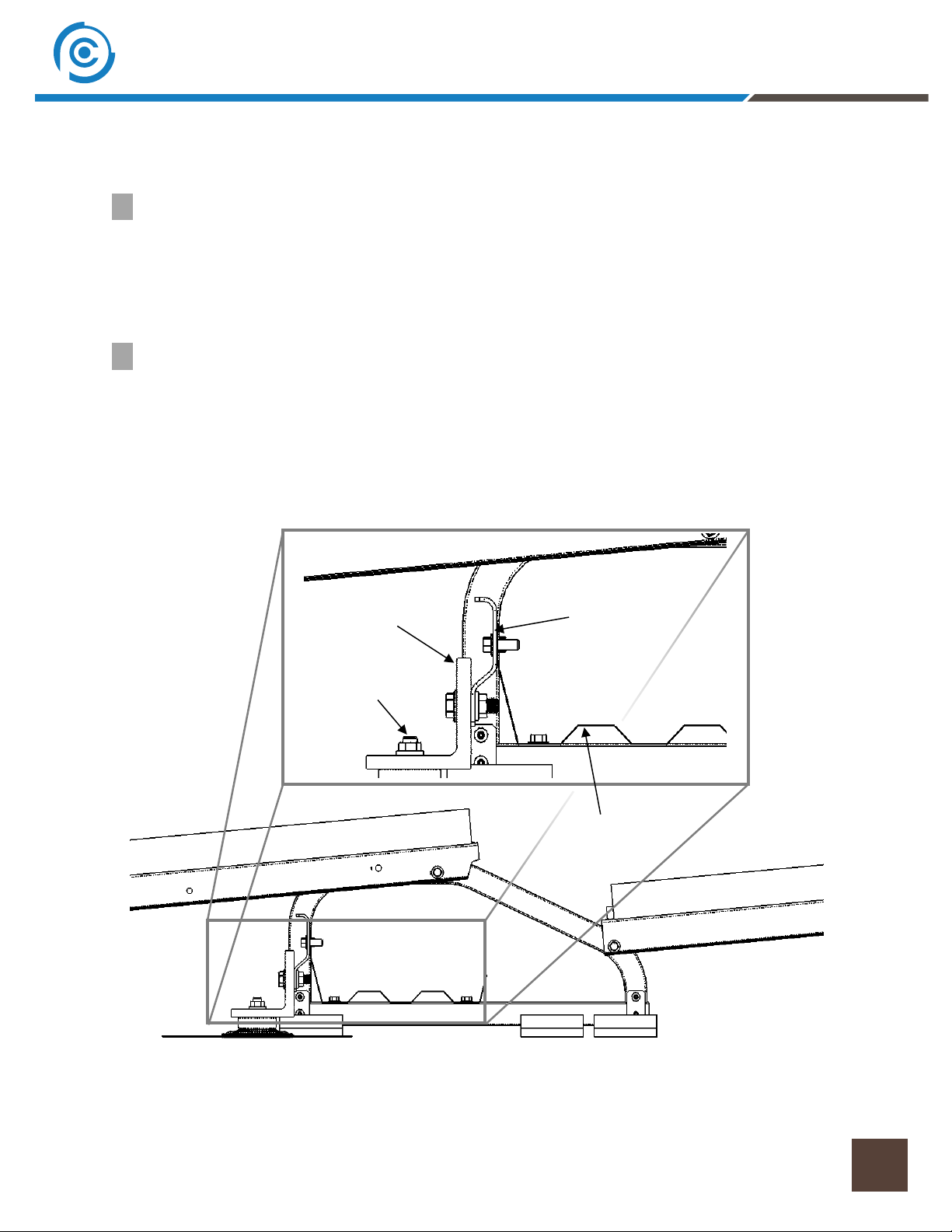

The PanelClaw Mechanical Attachment Bracket is an option for PanelClaw’s Polar Bear® III HD flat roof

photovoltaic mounting systems. The PanelClaw Mechanical Attachment Bracket is designed to enable

installers to seamlessly connect EcoFasten Solar®, OMG® Roofing Products and Anchor Products™

Mechanical Attachments to PanelClaw’s Polar Bear III HD system. This installation manual demonstrates

the proper connection of EcoFasten, OMG and Anchor products to Polar Bear III HD components.

THIS INSTALLATION MANUAL DOES NOT COVER SELECTION OF OR INSTALLATION OF ANY MATERIALS

USED TO SEAL A MECHANICAL ATTACHMENT TO THE ROOF. FOR THESE INSTRUCTIONS PLEASE SEE OEM

PROVIDER INSTALLATION MANUALS AND RELATED LITERATURE. A LIST OF OEM PROVIDERS IS SHOWN

BELOW.

THIS INSTALLATION MANUAL DOES NOT COVER SELECTION OF OR INSTALLATION OF FASTENERS

REQUIRED TO FASTEN A MECHANICAL ATTACHMENT TO THE ROOF STRUCTURE ITSELF. FOR THESE

INSTRUCTIONS, PLEASE SEE OEM PROVIDERS INSTALLATION MANUALS AND RELATED LITERATURE. A

LIST OF OEM PROVIDERS IS SHOWN BELOW.

ANY QUESTIONS RELATED TO MECHANICAL ATTACHMENT ROOF PATCHES, PATCH SELECTION, PATCH

COMPATIBILITY WITH ROOF MEMBRANE, PATCH COMPLIANCE WITH ROOF MEMBRANE

MANUFACTURER WARRANTIES, OR ANY QUESTIONS RELATED TO MECHANICAL ATTACHMENTS AND

ROOF WARRANTIES, MUST BE DIRECTED TO RESPECTIVE MECHANICAL ATTACHMENT OEM PROVIDER

SHOWN BELOW.

PANELCLAW IS NOT RESPONSIBLE FOR THIRD PARTY MECHANICAL ATTACHMENT PRODUCTS OR THEIR

RESPECTIVE INSTRUCTIONS, MANUALS, WARRANTIES, OR SUPPORT.

OEM MECHANICAL ATTACHMENT PROVIDERS:

•Anchor Products: www.anchorp.com

•OMG Roofing Products: www.omgroofing.com

•ECOFasten Solar: www.ecofastensolar.com

Safety Overview

Safety is an essential part of every photovoltaic (PV) installation and every construction site. It is

imperative to plan ahead for any safety concerns and hazards to promote safe work practices during

installation. This section does not claim to address or Support all safety concerns that may arise during

the installation of PanelClaw mounting systems or any other aspect of the work being performed. Before

beginning work, installers should refer to all local and federal safety, health, and regulatory

requirements to assure compliance. Refer to OSHA Part 1926 and its related Subparts for federal

construction related regulations and standards.

The section in Appendix A: Safety outlines some of the obvious / major hazards that could exist during

the installation of PanelClaw products, and are divided to bring a level of clarity to such hazards. Some

sections do not apply to all PanelClaw product lines and such exclusions are noted within each section.

PRIOR TO INSTALLATION, READ THE SAFETY PROVISIONS ATTACHED IN APPENDIX A AND REVIEW

THE INSTALLATION MANUAL IN ITS ENTIRETY.