3

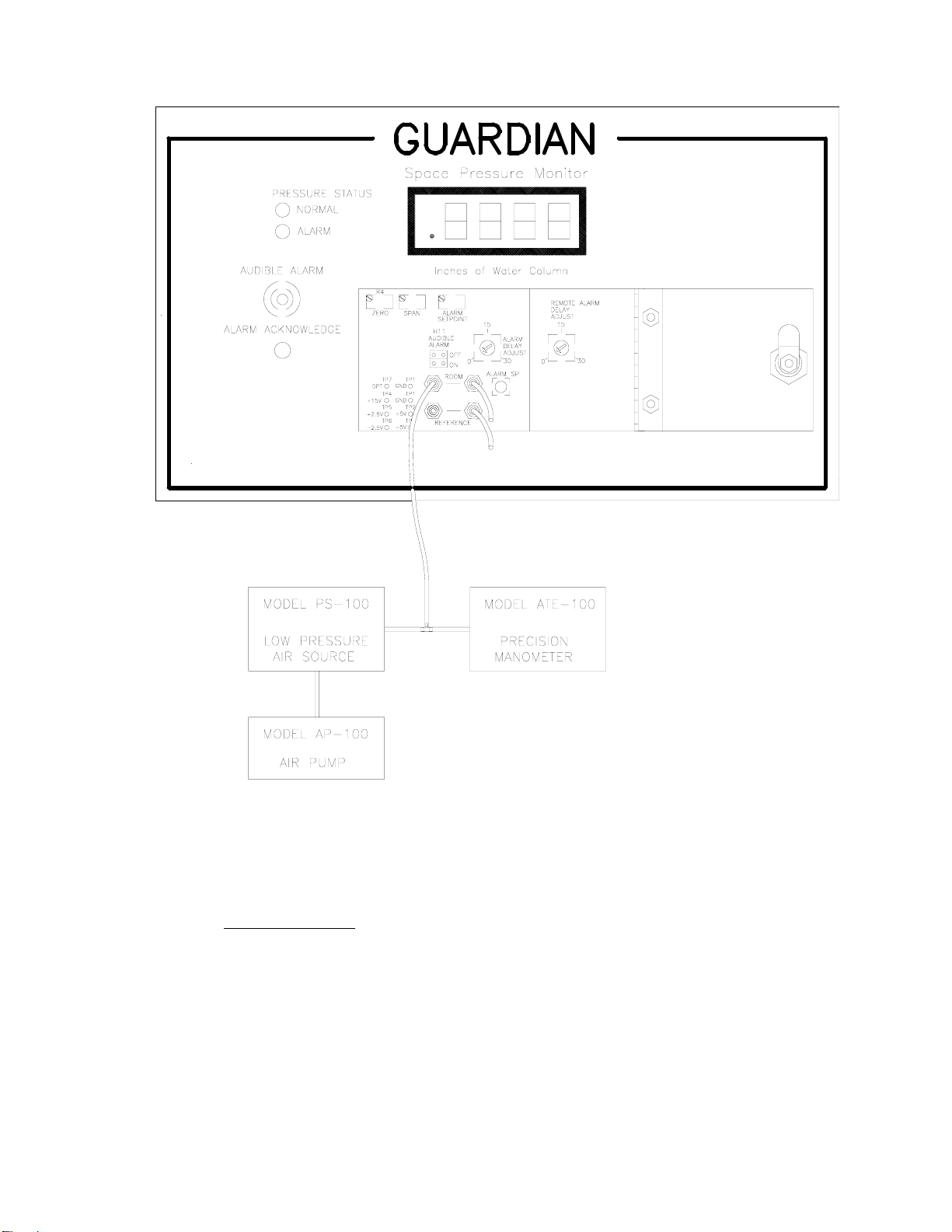

1.0 BASIC OPERATION

The Guardian is a complete system package consisting of space and reference pressure sensors and the

central signal processing module. The central module measures and displays the pressure differential

with a resolution of up to one ten thousandth of an inch water column. The LED display can be factory

set for engineering units of either Inches Water Column or Pascals. An analog output which is linear to

the pressure differential is provided for remote monitoring, control and data logging. An alarm

condition will occur when the space pressure falls outside the preset operating range. During an alarm

condition a local LED will illuminate, a local audible alarm circuit will be enabled, and an alarm relay

shall energize for remote alarming purposes. An optional remote auxiliary alarm is available with an

adjustable delay which will activate a local LED and the audible alarm. A key locked front panel

allows for controlled access to the field configurable functions of the Guardian. These functions

include pressure alarm setpoint adjustment, audible alarm on/off selection, adjustable delay of the

pressure alarm to prevent nuisance alarms which would occur due to normal foot traffic, and

differential pressure transducer calibration.

2.0 GUARDIAN FEATURES

2.1 POWER SUPPLY

The Guardian utilizes an isolated linear type power supply generating +15vdc and ∀5vdc to

power the pressure transducer sensor, scaling and digit circuitry. Input power to the Guardian

is 24VAC. The power supply is fused with a 3/8 Amp Slow Blow Pico fuse, located near the

input power terminal.

2.2 ALARM STATUS

Both Normal and Alarm operating status is locally indicated via LED•s on the Guardian face

plate.

2.3 ALARM SELECTION

The Guardian can be field configured to provide either Positive or Negative room pressure

alarming function. In the Positive mode the alarm activates when space pressure falls below

the alarm setpoint value. When in the Negative mode the alarm activates when space pressure

rises above the setpoint value.

2.4 AUDIBLE ALARM ACKNOWLEDGE

Muting of the local audible alarm during a loss of the required pressurization level. The

audible alarm circuit shall be reset once the monitored pressurization level is within the

acceptable operating range.

2.5 REMOTE ALARM RELAY

A single-pole double-throw relay is energized whenever the space pressurization level is

outside of the acceptable operating range.

2.6 REMOTE ROOM PRESSURE SELECT

The Room Pressure Monitor can be configured for positive or negative room monitoring

remotely by the closure of a dry contact.

2.7 REMOTE AUXILIARY ALARM