Parallax ELEV-8 V2 User manual

Web Site: www.parallax.com

Learn: learn.parallax.com

Forums: forums.parallax.com

Sales: [email protected]

Technical: [email protected]

Office: (916) 624-8333

Fax: (916) 624-8003

Sales: (888) 512-1024

Tech Support: (888) 997-8267

EDU Hotline: (916) 625-6801

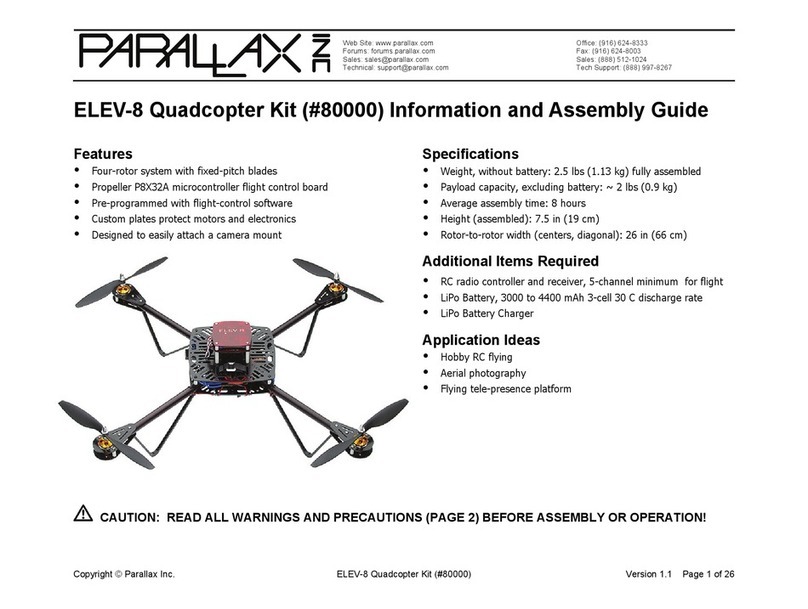

ELEV-8 V2 Quadcopter Assembly

Guide

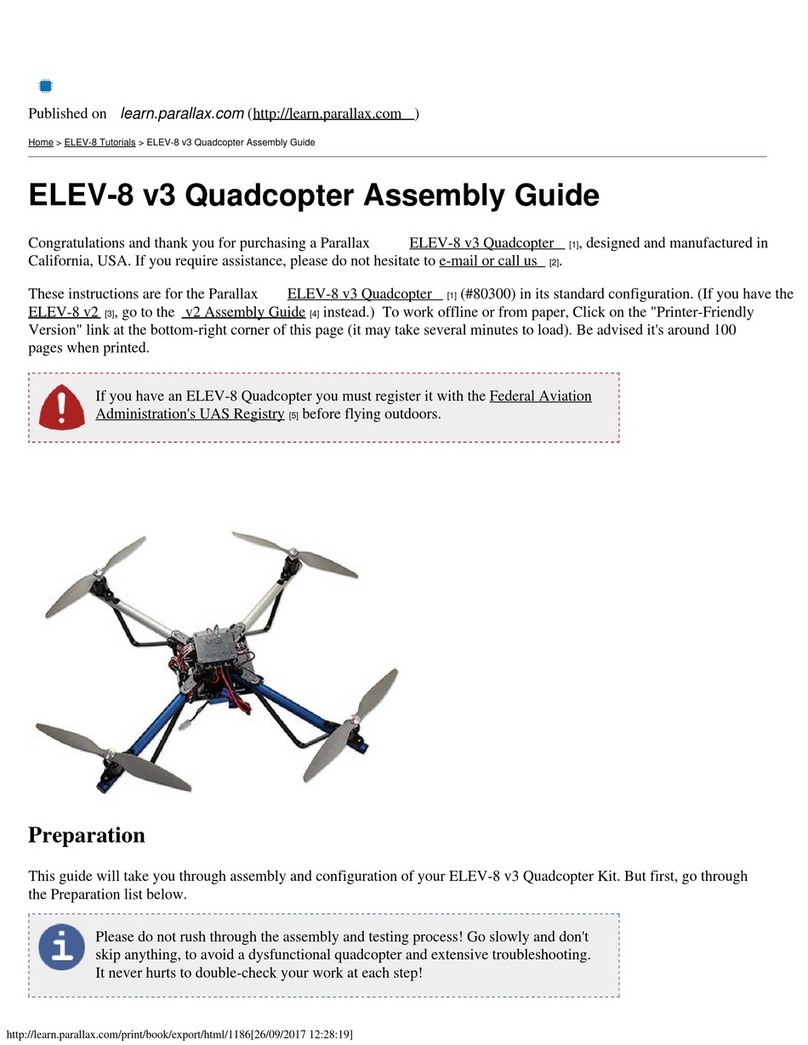

Congratulations and thank you for purchasing a Parallax ELEV-8 Quadcopter, designed and

manufactured in California, USA. We at Parallax pride ourselves on producing high-quality

products with industry-leading documentation and support. These instructions are for

assembling the Parallax ELEV-8 Quadcopter Version 2 (#80200 or #80202) in its most standard

configuration.

If you have an ELEV-8 Quadcopter you must register it with the Federal Aviation

Administration's UAS Registry before flying outdoors.

Do not use any assembly instructions or guides other than those provided by Parallax Inc. for

your exact part number. Doing so may result in hardware failure and/or personal injury. Also

note that there are small but extremely important differences between Version 1 (#80000) and

Version 2 (#80200/#80202) of the ELEV-8; do not use this web guide for assembling Version 1.

This assembly guide assumes your ELEV-8 V2 kit contains a flight controller (#80200). If you

bought the ELEV-8 V2 No Flight Controller kit (#80202), sections regarding the programming

and installation of the HoverFly Open will not apply to you. Watch for special announcements

on these pages as you progress through assembly.

This guide consists of thirty-nine discrete assembly steps, organized into nine sections. The

introduction page of each section will explain what will be done in the steps within and why, and

list all of the tools and parts you will need for that particular section. If you prefer to work from a

printed version of these instructions, please be advised - this PDF assembly guide is

extremely long and will take a large amount of paper when printed.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Preparation

1. Read the important Safety Information sheet included with your kit. Building a

Quadcopter is a rewarding but potentially dangerous undertaking, so it is critical that you

have an understanding of the risks involved to maximize enjoyment and minimize

danger. Please always wear eye protection when assembling, soldering, or operating

your ELEV-8.

2. Carefully cross-check the contents of your kit with the enclosed Bill of Materials (BOM). If

you are missing any components, e-mail or call our sales department (888-512-1024).

(Note: Because this product is discontinued, some parts may no longer be available.

Parallax is not responsible for replacing parts from kits purchased from a source other

than our webstore or through our sales team, or if the kit is no longer within the warranty

period.

)

3. Read the entire assembly instructions before beginning. Assembly and testing takes 6

–12 hours, depending on skill level, equipment, and work space. If you do not have prior

experience soldering, we recommend you take some time to learn and practice before

beginning this project.

4. Gather your kit and all of the additional items and tools required in a well-lit and

comfortable work area.

5. After educating yourself on the safe and proper use of Lithium-Polymer (LiPo) batteries,

charge your LiPo battery.

Please do not rush through the assembly and testing process. If you go slowly, and exactly

follow these instructions, you should experience few or no issues with your ELEV-8. But if you

accidentally overlook any part of these steps, you may end up with a dysfunctional quadcopter

that could require considerable troubleshooting before it can fly. It never hurts to double-check

your work at each step!

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Additional Items Required

● Radio Control Transmitter and Receiver; 5-channel minimum required for flight. We

recommend (and will provide instruction for) the Spektrum DX6i transmitter and

matching Spektrum AR610 receiver (or OrangeRX R615); this setup will accommodate

simple projects requiring one extra servo. If you anticipate building more sophisticated

projects, such as controlled camera gimbals, we recommend the Spektrum DX8 and

matching Spektrum AR8000 receiver (or OrangeRC R800X) and Spektrum TM1000

telemetry transmitter. While this equipment is somewhat expensive, it is high-quality and

will accommodate both your current and future needs.

● Lithium Polymer (LiPo) battery with 3000 to 4400 mAh capacity and minimum 20C

discharge rate, such as Parallax product #752-00010.

● “LiPo Balance Charger” (packaging should have those exact words), such as Parallax

product #752-00009. Using a charger not designed for LiPo batteries will cause the

battery to flame and release toxic smoke.

● A LiPo Low-Voltage Alarm, such as Parallax product #752-00014. These will alert you

with a very loud buzzer when your battery voltage gets low, significantly reducing the risk

of damaging your battery or crashing your ELEV-8.

We recommend you acquire the ELEV-8 Crash Pack (#80080). Crashes are an inevitable part

of the learning process, and having to wait around for replacement parts is always a bummer.

Tools Required

● Safety Eyewear (#700-10003)

● Wire Strippers/Cutters (12-16 AWG)

● Ruler or Measuring Tape

● Soldering Iron (We recommend the Parallax Basic Soldering Kit, #700-10011)

● Rosin-Core Solder, see note in Section 1 (Also in the Parallax Basic Soldering Kit)

● Work-Holding Vise (Also in the Parallax Basic Soldering Kit)

● Rosin Soldering Flux Paste (optional

)

● Metal or Wood Block with 5/32” (4 mm) hole (optional)

● Electrical Tape or Heat-Shrink Tubing

● Heat Gun, Hair Dryer, or Soldering Iron

● Small Flat-Head Screwdriver

● #1 Philips Head Screwdriver

● Pencil

● Permanent Marker

● Scissors

● 1/4” Wrench, 1/4" Socket, or Adjustable Wrench

● Diagonal Cutters ("Dikes")

● Sharp Knife, Razor Blade, or Sandpaper (between 80 and 200 grit)

● 5/16" Wrench, 5/16" Socket, or Adjustable Wrench

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

● Flat-Nose Pliers

Loctite and 242 are trademarks or registered trademarks of Henkel Corporation, U.S.A. Spektrum is a trademark or registered trademark of

Horizon Hobby, Inc. and Bachmann Industries, Inc. Hoverfly is a registered trademark of Hoverfly Technologies, Inc. Futaba is a registered

trademark of Futaba Denshi Kogyo Kabushiki Kaisha Corporation of Japan. Hitec is a trademark or registered trademark of Hitec RCD USA,

Inc.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Section 1: Soldering the Connections

All steps in Section 1 will focus on the ELEV-8 V2 electrical connections. All of the high-current

connections between components will be made using gold-plated bullet connectors (“male” and

“female” on the left and right of the below image, respectively), which must be soldered onto the

wires and covered with heat-shrink tubing. This will ensure a reliable connection while providing

flexibility to change motor polarity and replace or upgrade components as desired.

You will have to make an educated decision on whether to use leaded vs. lead-free solder.

Traditionally, solder was composed mostly of tin and lead. As it has become known that lead is

a toxin harmful to humans (only if ingested, in any form), lead-free solder has risen in popularity.

Many people still prefer to use leaded solder for its superior ability to create strong solder joints,

while others prioritize safety over performance and choose lead-free. There is an abundance of

material available on the subject, and we suggest you conduct your own research and make

your own choice.

These six steps will take approximately 2 to 6 hours, depending on your skill level and

equipment.

Tools Needed in this Section

● Wire Strippers/Cutters (12-16 AWG)

● Ruler or Measuring Tape

● Soldering Iron

● Rosin-Core Solder

● Work-Holding Vise

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

● Metal or Wood Block with 5/32” (4 mm) hole (optional)

● Rosin Soldering Flux Paste (optional

)

Parts Needed in this Section

● 1 – 16 AWG Silicone Wire, Blue (#750-00061)

● 4 – 1050 kV Brushless Motor and Accessories (#750-90008)

● 20 – 3.5 mm “Male” Bullet Connector (#450-00050)

● 24 – 3.5 mm “Female” Bullet Connector (#450-00050)

● 4 – 30A Electronic Speed Controller (ESC) (#750-90009)

● 1 – EC3 "Male/Female" Connector Pair (#452-00088)

● 1 – LiPo Battery (Not Included)

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Step 1: Prepare Extension Wires

In this step, you will cut to length and strip the Extension Wires to be used to connect the Motors

to the Electronic Speed Controllers.

Tools Needed

● Wire Strippers/Cutters (12-16 AWG)

● Ruler or Measuring Tape

Parts Needed

● 15' – 16 AWG Silicone Wire, Blue (#750-00061)

Instructions

1. Using the ruler or measuring tape and wire cutter, measure and cut 12 lengths of wire,

each 12 inches (30.5 cm) long.

2. Using the wire strippers, remove 1/8” (3 mm) of insulation from both

ends to expose the

metal wire.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

3. Repeat for the 11 remaining wires.

At the end of this step, you should have some extra wire. You may want to cut a few short

pieces from it and strip the ends. You can use it to practice soldering in the next step.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Step 2: Soldering Motor Bullet Connectors

Over the course of the remaining Section 1 steps, you will solder all of the electrical connections

for the ELEV-8. Here, you will be soldering “male” bullet connectors to the Motors’ wire leads.

Watch the video for this assembly step on our YouTube channel

(https://www.youtube.com/watch?v=tGsjf-s-J_o) before getting started.

Warning!

Risk of severe burns. Soldering iron tips become extremely hot when used. NEVER touch the

iron tip.

Risk of lung irritation. Avoid direct inhalation of solder fumes; always solder in a

well-ventilated area.

Regardless of your choice of solder, do not eat or drink in your work area, and wash your

hands thoroughly after soldering.

Tools Needed

● Soldering Iron

● Rosin-Core Solder

● Work-Holding Vise

● Metal or Wood Block with 5/32” (4 mm) hole (optional)

● Rosin Soldering Flux Paste (optional)

Parts Needed

● 4 – 1050 kV Brushless Motor (# 750-90008)

● 12 – 3.5 mm "Male" Bullet Connectors (# 450-00050)

When you remove the motors from their packaging, keep all of the included accessories. You

will need to use the bullet connectors, heat-shrink tubing, and propeller adapters

w/screws included with each motor in later steps.

Instructions

If you have never soldered bullet connectors before, use some extra wire mentioned in the note

at the end of the previous step and a few bullet connectors to practice with (you have extra of

both).

1. Take the wire at the tip of each motor lead and twist it using your fingers to bring all of

the individual wires together.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

2. Clamp one of the wires into the vise so that the exposed metal wire is pointing upwards.

3. After cleaning the tip of the soldering iron, apply a small amount of solder to the tip to

"tin" it (this will provide better heat conduction from the iron to the connection).

4. Apply a small amount of solder to the tip of the wire. You want to see the wire "absorb"

the solder and become covered in a thin layer of molten solder before removing the

soldering iron. It may take some time (up to 15 seconds), but it should be clear when the

solder suddenly starts to "flow" around the tip of the wire. If you have difficulties tinning

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

your leads, dipping your wire into rosin soldering flux paste (optional, not included) first

might make the process easier. Repeat this "tinning" process with every wire.

5. Place a Male bullet connector into the vise, with the shallow “cup” end facing up. If you

are using the block, clamp it into the vise and seat the bullet connector into the hole.

6. Hold the soldering iron to the small hole on the side of the “cup” of the bullet connector,

and apply solder slowly into the “cup” until it is half full. Put the solder down.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

7. Continuing to hold the soldering iron to the hole, slowly insert a Motor lead fully into the

“cup” and continue to hold the soldering iron to the hole for approximately 15 seconds.

This will help to prevent a "cold" solder joint (poor quality, where the solder has not

properly fused to both surfaces).

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

8. Remove the soldering iron, but hold the motor lead until the solder has cooled and set,

approximately 10 seconds. A good solder joint should appear as shown in the image

below; you can always re-do a joint if you are not satisfied.

9. Repeat this process to solder a "male" bullet connector to each of the three leads on

each Motor, for a total of twelve connections.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Step 3: Soldering Extension Wire Bullet Connectors

You’ll be using the same soldering techniques you learned in Step 2 to solder "male" and

"female" bullet connectors to opposite ends of the extension wires.

Tools Needed

● Soldering Iron

● Rosin-Core Solder

● Work-Holding Vise

● Metal or Wood Block with 5/32” (4 mm) hole (optional)

● Rosin Soldering Flux Paste (optional)

Parts Needed

● 12 – Extension Wires, prepared in Step 2

● 12 – 3.5 mm "Male" Bullet Connectors (#450-00050)

● 12 – 3.5 mm "Female" Bullet Connectors (#450-00050)

Instructions

1. Prepare the wires for soldering by twisting and tinning them. (same procedure as in Step

2)

a. Take the wire at the end of each wire and twist it using your fingers to bring all of

the individual wires together.

b. Clamp one of the wires into the vise so that the exposed metal wire is pointing

upwards.

c. After cleaning the tip of the soldering iron, apply a small amount of solder to the

tip to "tin" it (this will provide better heat conduction from the iron to the

connection).

d. Apply a small amount of solder to the tip of the wire. You want to see the wire

"absorb" the solder and become covered in a thin layer of molten solder before

removing the soldering iron. It may take some time (up to 15 seconds), but it

should be clear when the solder suddenly starts to "flow" around the tip of the

wire. If you have difficulties tinning your leads, dipping your wire into rosin

soldering flux paste (optional, not included) first might make the process easier.

e. Repeat this process with every wire.

2. Solder a "male" bullet connector to one

end of each of the twelve extension wires (same

procedure as in Step 2);

a. Place a bullet connector into the vise, with the shallow “cup” end facing up. If you

are using the block, clamp it into the vise and seat the bullet connector into the

hole.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

b. Hold the soldering iron to the small hole on the side of the “cup” of the bullet

connector, and apply solder slowly into the “cup” until it is half full. Put the solder

down.

c. Continuing to hold the soldering iron to the hole, slowly insert the end of an

extension wire fully into the “cup” and continue to hold the soldering iron to the

hole for approximately 15 seconds. This will help to prevent a "cold" solder joint

(poor quality, where the solder has not properly fused to both surfaces).

d. Remove the soldering iron, but hold the motor lead until the solder has cooled

and set, approximately 10 seconds.

3. Solder a "female" bullet connector to the other end of each of the twelve extension wires,

using the same procedure.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Step 4: Soldering ESC Bullet Connectors

In this step, you’ll again be using the same soldering techniques you learned in Step 2, but this

time to solder "male" and "female" bullet connectors to opposite ends of the ESCs.

Tools Needed

● Soldering Iron

● Rosin-Core Solder

● Work-Holding Vise

● Metal or Wood Block with 5/32” (4 mm) hole (optional)

● Rosin Soldering Flux Paste (optional)

Parts Needed

● 4 – 30A Electronic Speed Controller (ESC) (#750-90009)

● 8 – 3.5 mm "Male" Bullet Connectors (#450-00050)

● 12 – 3.5 mm "Female" Bullet Connectors (#450-00050)

Instructions

1. Prepare the wires for soldering by twisting and tinning them. (same procedure as in Step

2)

a. Take the wire at the end of each wire and twist it using your fingers to bring all of

the individual wires together.

b. Clamp one of the wires into the vise so that the exposed metal wire is pointing

upwards.

c. After cleaning the tip of the soldering iron, apply a small amount of solder to the

tip to "tin" it (this will provide better heat conduction from the iron to the

connection).

d. Apply a small amount of solder to the tip of the wire. You want to see the wire

"absorb" the solder and become covered in a thin layer of molten solder before

removing the soldering iron. It may take some time (up to 15 seconds), but it

should be clear when the solder suddenly starts to "flow" around the tip of the

wire. If you have difficulties tinning your leads, dipping your wire into rosin

soldering flux paste (optional, not included) first might make the process easier.

e. Repeat this process with every wire.

2. Solder "male" bullet connectors to the red and black input leads on each ESC (same

procedure as in Step 2);

a. Place a bullet connector into the vise, with the shallow “cup” end facing up. If you

are using the block, clamp it into the vise and seat the bullet connector into the

hole.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

b. Hold the soldering iron to the small hole on the side of the “cup” of the bullet

connector, and apply solder slowly into the “cup” until it is half full. Put the solder

down.

c. Continuing to hold the soldering iron to the hole, slowly insert the end of an input

lead into the “cup” and continue to hold the soldering iron to the hole for

approximately 15 seconds. This will help to prevent a "cold" solder joint (poor

quality, where the solder has not properly fused to both surfaces).

d. Remove the soldering iron, but hold the motor lead until the solder has cooled

and set, approximately 10 seconds.

3. Solder "female" bullet connectors to the to the blue output leads on each ESC, using the

same procedure.

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Step 5: Soldering Power Breakout EC3 Connector

The last of the soldering for ELEV-8 assembly is soldering EC3 connectors (image below) to the

Power Breakout Cable (this Step) and battery leads (Step 6). This is one of the most difficult

assembly steps, so we strongly suggest you take your time and do some research of your own

(watch some videos on "soldering EC3 connectors", etc).

An EC3 Connector presents an issue when trying to identify the "gender" of each side of the

connection. The housing at left in the above image is inserted into the housing on the right, so

one would be inclined to call the left housing "male" and the right housing "female". However,

the housing at left is for "female" contacts (bullet connectors) and the housing at right is for

"male" contacts. Since the gender of a plug is defined by the gender of the contacts, the plug to

the left is "female" and to the right is "male."

Tools Needed

● Wire Strippers/Cutters (12-16 AWG)

● Ruler or Measuring Tape

● Soldering Iron

● Rosin-Core Solder

● Work-Holding Vise

● Metal or Wood Block with 5/32” (4 mm) hole (optional

)

● Rosin Soldering Flux Paste (optional

)

● Small Flat-Head Screwdriver

● Flat-Nose Pliers

Parts Needed

● 1 - Power Breakout Cable (#800-00006)

● 1 – "Male"/"Female" EC3 pair w/cover and bullet connectors (not interchangeable with

other bullet connectors) (#452-00088)

Copyright © Parallax Inc.

ELEV-8 V2 Assembly Guide

07/26/2018

Other manuals for ELEV-8 V2

1

Table of contents

Other Parallax Quadcopter manuals