Paramount Fitness VANTAGE IN-FLOOR CLEANING SYSTEM User manual

Other Paramount Fitness Swimming Pool Cleaner manuals

Paramount Fitness

Paramount Fitness MDX User manual

Paramount Fitness

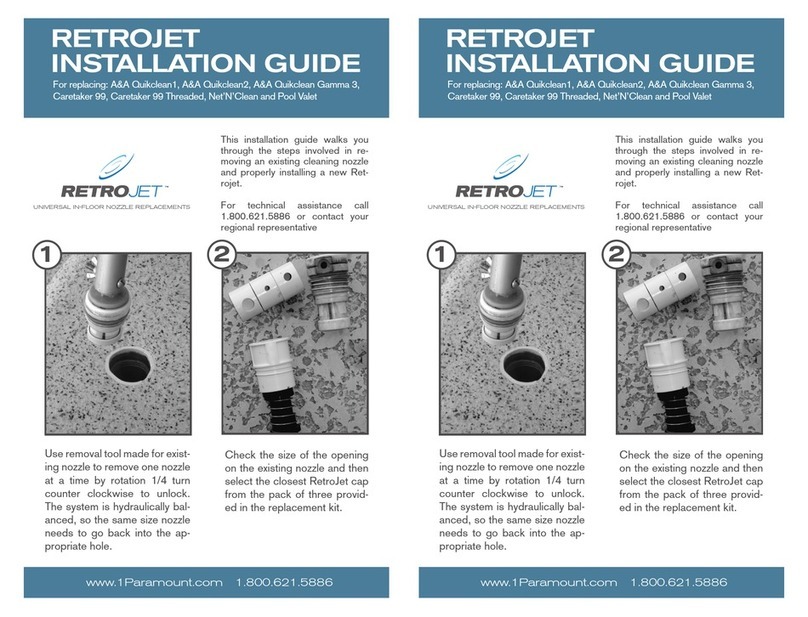

Paramount Fitness RetroJet User manual

Paramount Fitness

Paramount Fitness SwingJet User manual

Paramount Fitness

Paramount Fitness MDX User manual

Paramount Fitness

Paramount Fitness PCC2000 User manual

Paramount Fitness

Paramount Fitness PCC2000 User manual