5

MDX WINTERIZATION

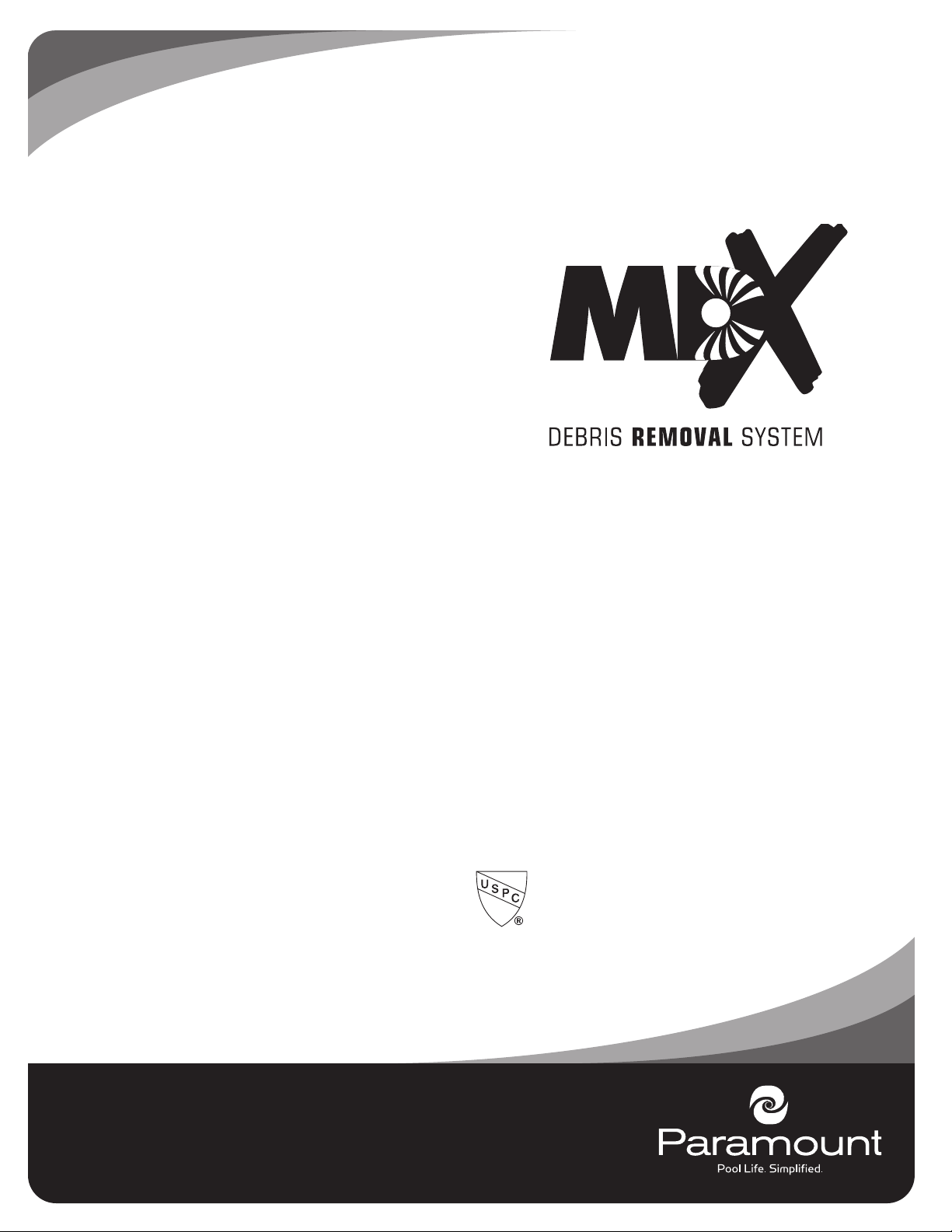

WITH CANISTER WITHOUT CANISTER

If vacuum relief suction outlets are located below freeze

line skip steps 1 and 2.

1. Remove grate from second suction and install blow

through plug and blow line to achieve airlock.

2. If 3rd suction line is installed remove grate, install 3"

blow-through plug and blow line to achieve airlock.

3. o to canister instructions step 1 - 4 below.

4. If vent tube is installed, install blow through plug and

blow line to achieve airlock. Repeat vacuum out

canister. Then complete canister step 5.

If vacuum relief suction outlets are located below freeze

line skip steps 1 and 2.

1. Remove grate from second suction and install blow

through plug and blow line to achieve airlock.

2. If 3rd suction line is installed remove grate, install 3"

blow-through plug and blow line to achieve airlock.

3. If vent line is installed in main suction line, plug vent

line and install blow through plug in pump inlet and

blow line to achieve airlock.

4. Lastly, blow vent line to achieve airlock.

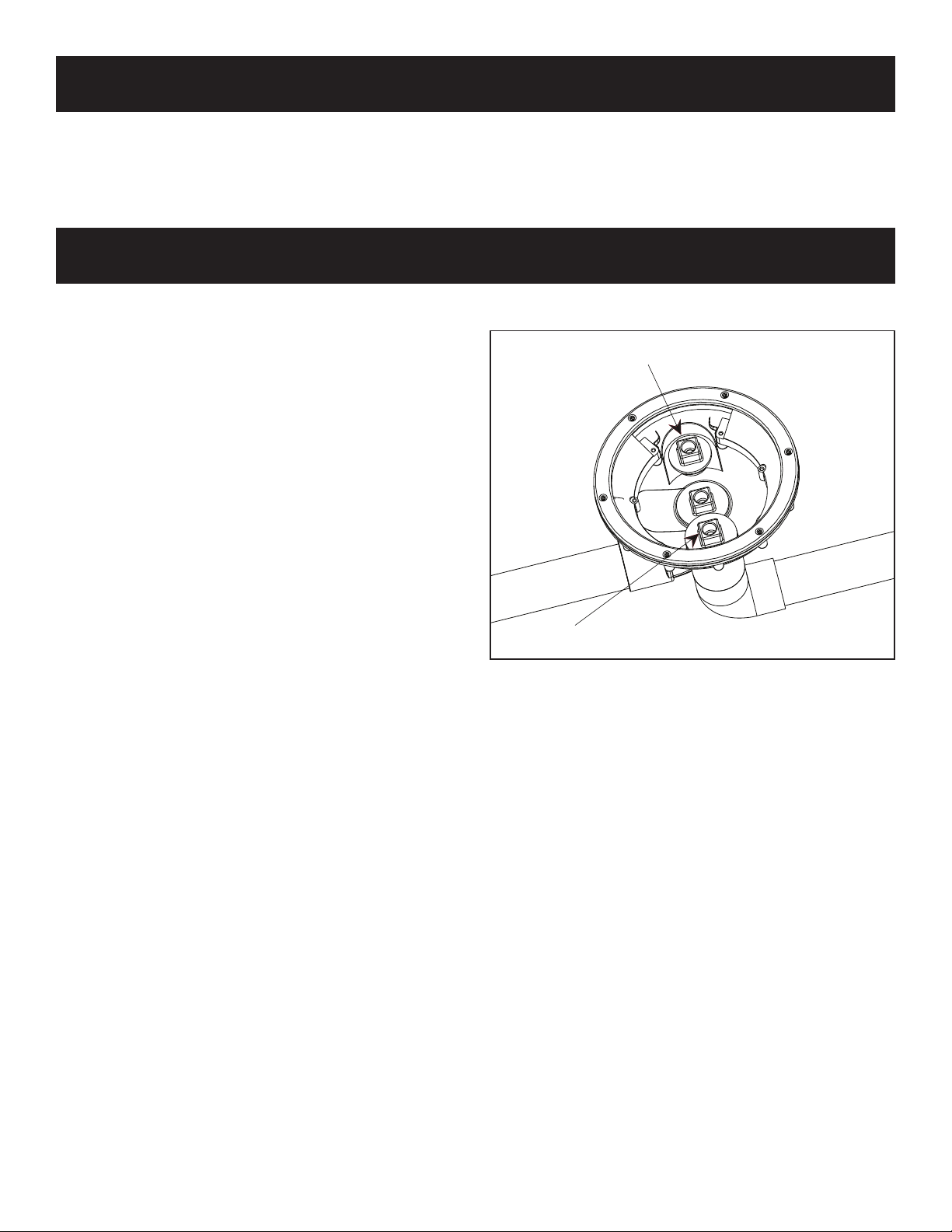

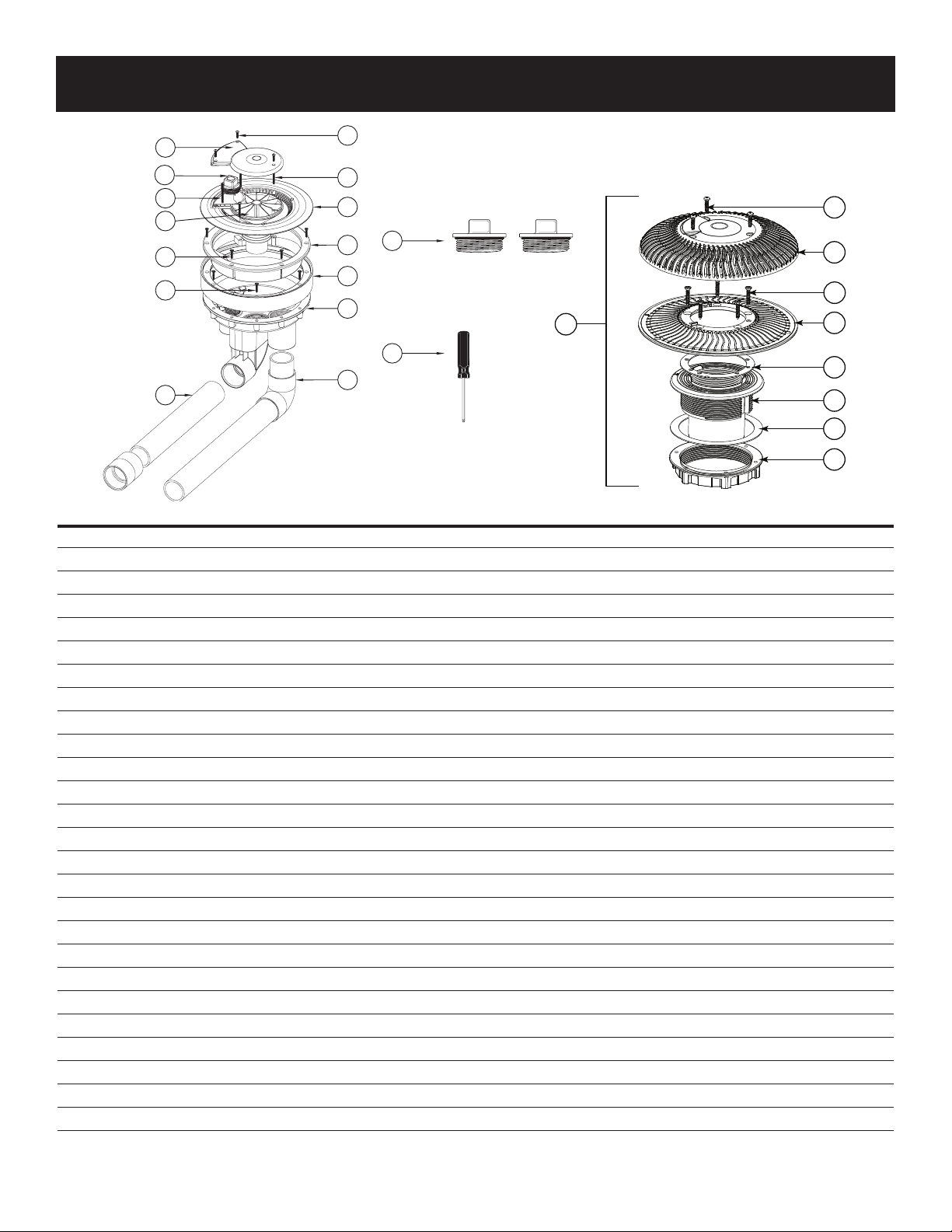

1. Remove outer lid, inner lid and basket, clean and dry

off, and store in same area as modules

2. Install and secure regular winterization plug in

equalizer line of canister to pool at poolside.

3. Install and secure Schrader plug or blow out plug

from canister to main drain. Blow out and obtain air

lock as previously described, if skimmer is tied into

canister, repeat procedure to skimmer.

4. Bottom port of canister to pump may require an

extended pipe for ease of blowing out. Install and

blow out line from canister to pump. Install and

secure plug in pump. Using shop vac, remove all

water from within canister components.

5. Extension pipe can be removed and replaced with

plug or izmo type container if izmo not used. Be

sure to install device to absorb ice expansion in

canister area. Failure to do this may result in potential

ice freeze damage to canister.

WWiinntteerriizzaattiioonn aannttii--ffrreeeezzee iiss ttoo bbee uusseedd aass nneecceessssaarryy oorr

wwhheenn rreeqquuiirreedd..

Additional questions should be forwarded to Paramount’s

corporate office at 1.800.621.5886.

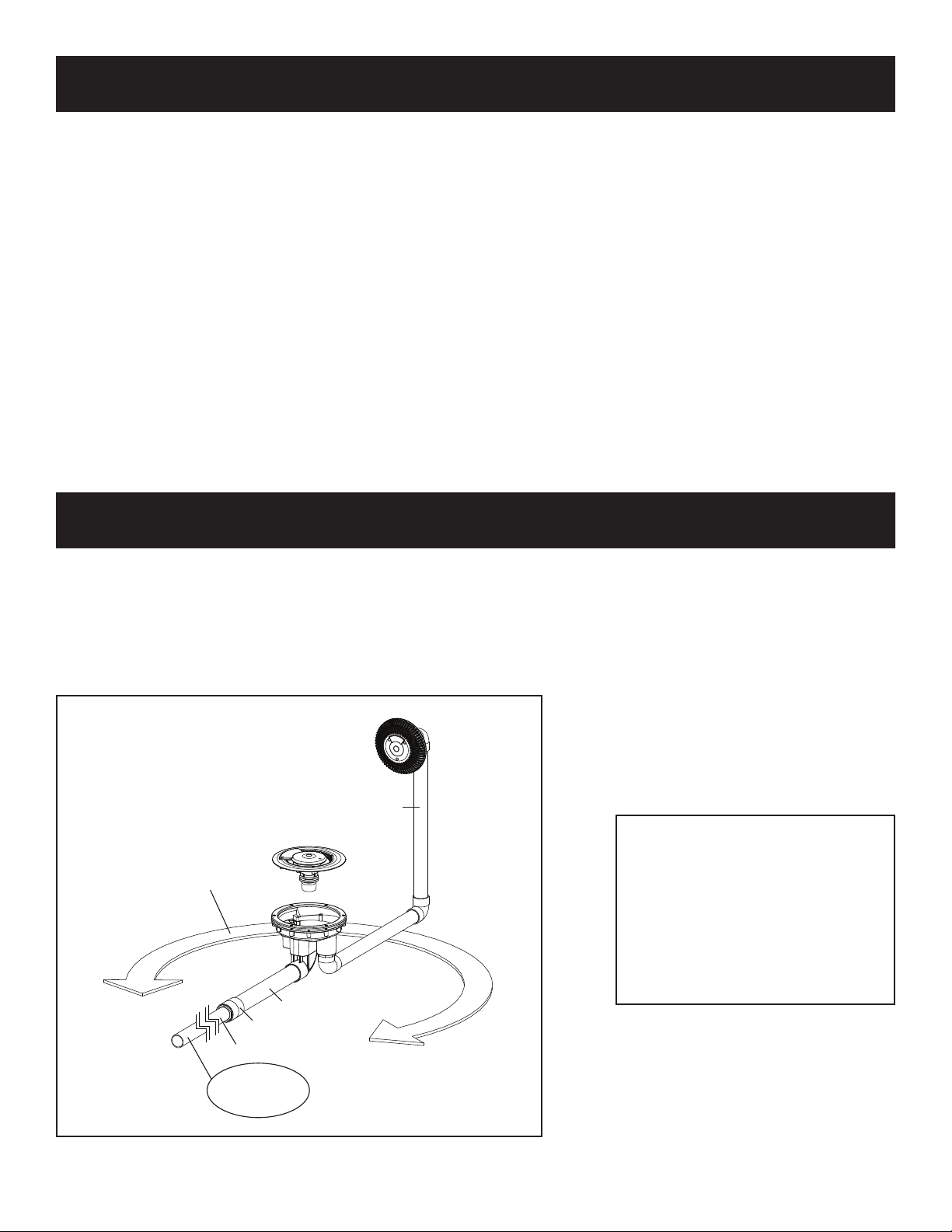

ARAMOUNT CANISTER WINTERIZATION

TEST PLUGS

2" GALV.

SQ. HEAD

BALANCE LINE

TO MAIN

DRAIN

TO OPTIONAL SKIMMER

OR VENT LINE

USE STANDARD

SKIMMER PLUG

WRENCH