Paratec GmbH

Next H / C

Issue II

04-2005

Owner‘s Manual

5

Inspection Procedures

Carry out inspection proceedures at assembly, before every repack and after

emergency use.

According to the manufacturer‘s regulation, every NEXT rig must be inspec-

ted by qualified personel, before it is used for the first time, before every re-

pack, no matter if it was used or not and after it was handled in an improper

way such as after water jumps etc. The periodic inspection and repack cycle

for this Harness Container Sytem is 12 months. Other countries may have

different regulations, so please check with your responsible organisation.

Read the instructions in this manual completely before you begin.

Points of Inspection Inspect for

Main lift web damaged edges, velcro damage, broken

stitches, ravelled stitches

Reserve ripcord, ripcord pocket, cable

housing

tight fit in pocket, bent pin, enough

excess cable, worn out velcro, broken

stitches, loose tacking on MLW and / or

reserve flap

Chest and leg straps damaged edges, velcro damage, broken

stitches, ravelled stitches, worn out ela-

stic keepers

Cutaway pad, cables, cutaway housings velcro damage, nicks in cables, damaged

cables, dirty cables,

Container flaps broken plastic stiffeners

Grommets sharp edges, bad or improper setting,

AAD set up according to manufacturer‘s installation,

damaged cables

Main riser velcro damage, bent rings, damaged

closing loop,

hardened webbing on 3-ring, good togg-

le fit,

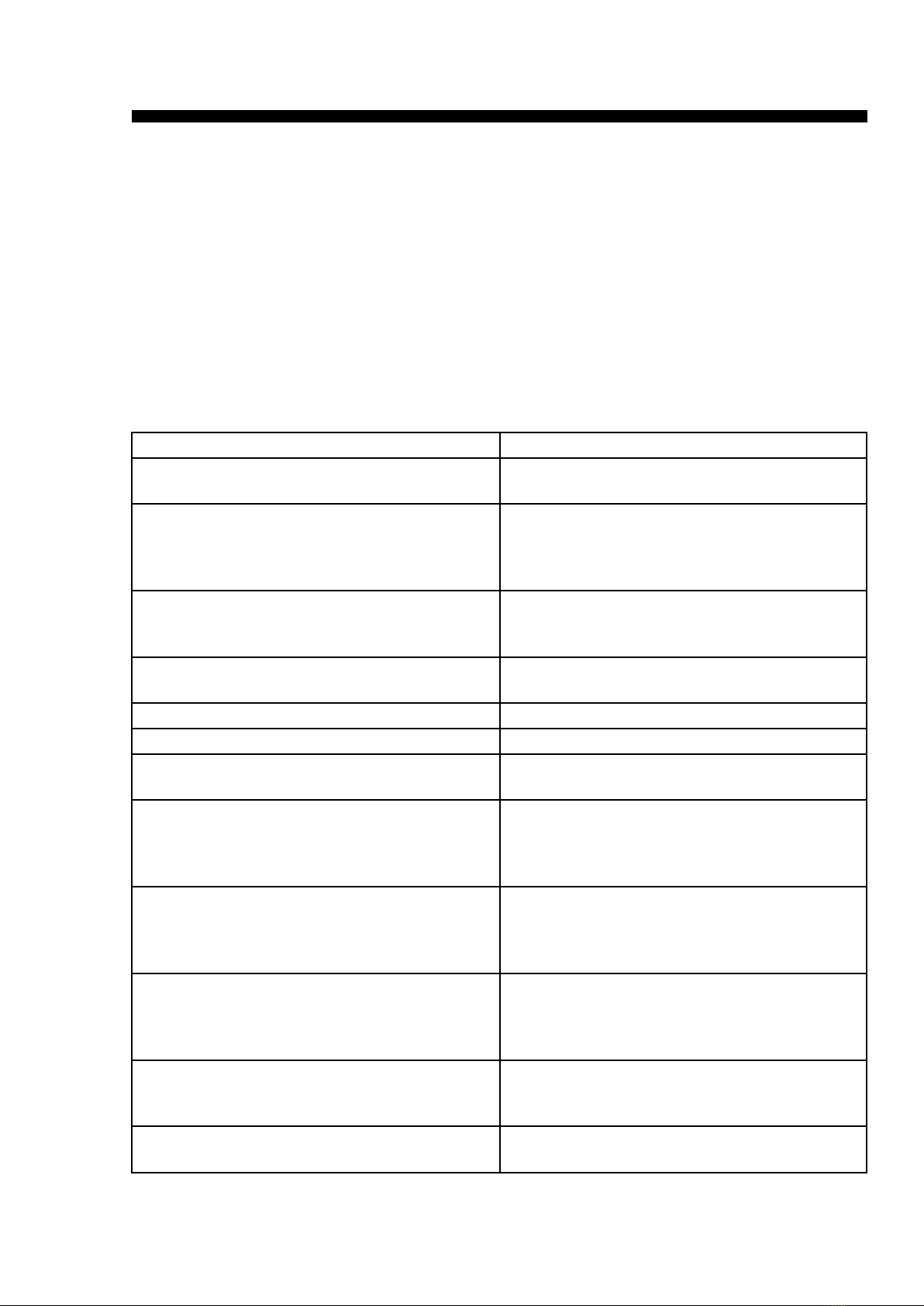

Free bag and pilot chute grommets for sharp edges, all seams

of bag, velcro in good condition, safety

stow, bridle seams, damages on pilot

chute fabric, spring force sufficient

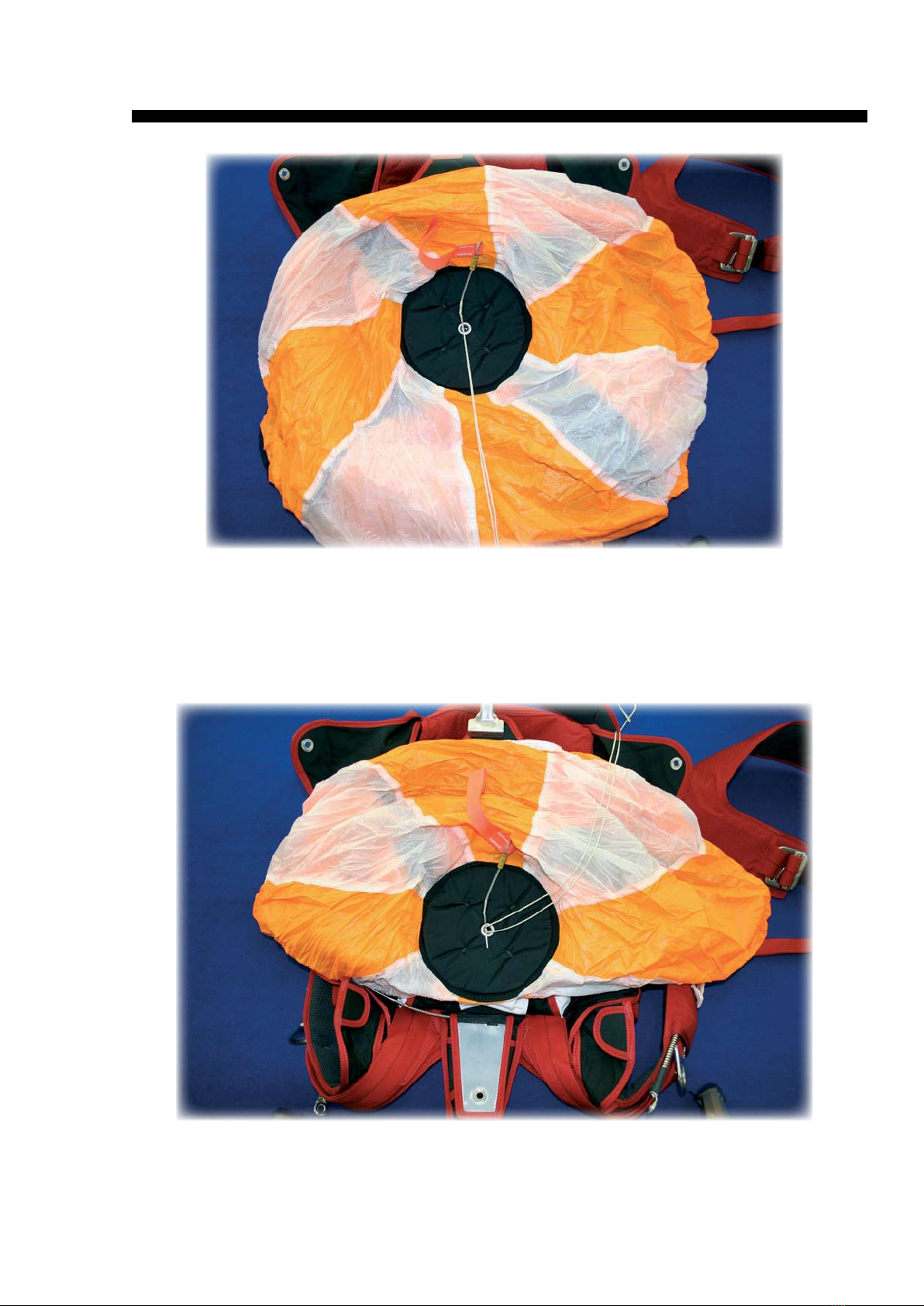

Main deployment bag and pilot chute damaged grommets, old rubber bands,

retract system of P/C in good condition,

Pilot Chute fabric for porosity

Closing loops proper length, not frayed, general conti-

tion, proper type for AAD used

Entire hardware rust, sharp edges, cracks, correct instal-

lation