Elsner KNX AQS/TH-B-UP Series Guide

Installation and Adjustment

KNX AQS/TH-B-UP

Combined Indoor Sensor

Elsner Elektronik GmbH Control and AutomationTechnology

Herdweg 7

D – 75391 Gechingen Phone +49 (0) 70 56 / 93 97-0 info@elsner-elektronik.de

Germany Fax +49 (0) 70 56 / 93 97-20 www.elsner-elektronik.de

Item numbers 40239 (white), 40240 (aluminium-coloured), 40241 (anthracite), 40242 (stainless steel coloured)

EN

1 Contents

Elsner Elektronik GmbH • Herdweg 7 • D-75391 Gechingen • Germany

Sensor KNX AQS/TH-B-UP • from software version 0.3.3, ETS programme version 3.1

Status: 24.09.2014 • Subject to technical changes. Errors excepted.

1. Description ........................................................................................... 5

1.0.1. Scope of delivery .......................................................................................... 6

1.1. Technical specifications ........................................................................................... 6

1.1.1. Accuracy of the measurement ..................................................................... 7

2. Installation and commissioning ........................................................... 8

2.1. Installation notes ...................................................................................................... 8

2.2. Installation position .................................................................................................. 8

2.3. Composition ............................................................................................................. 9

2.3.1. Housing .......................................................................................................... 9

2.3.2. Rear view of sensor board with connections ........................................... 10

2.4. Assembly of the sensor ......................................................................................... 10

2.5. Notes on mounting and commissioning .............................................................. 10

3. Display and operation at the device .................................................. 11

3.1. Mode display and manual temperature controller .............................................. 11

3.2. Change ambient temperature with the buttons .................................................. 12

4. Transfer protocol ............................................................................... 14

4.1. List of all communications objects ....................................................................... 14

5. Parameter setting .............................................................................. 23

5.1. Behaviour on power failure/ restoration of power .............................................. 23

5.2. General settings ..................................................................................................... 23

5.3. Measured values: Temperature, humidity, CO2 .................................................. 23

5.4. Threshold values: Temperature, humidity, CO2 .................................................. 24

5.4.1. Threshold value 1, 2, 3, 4: Temperature, humidity, CO2 ......................... 24

Threshold value ........................................................................................... 24

Switching output .......................................................................................... 26

Block .............................................................................................................. 26

5.5. Temperature PI control .......................................................................................... 27

5.5.1. General set point values ............................................................................. 29

Set point Comfort ........................................................................................ 29

Set point for standby ................................................................................... 30

Eco set point ................................................................................................. 30

Set point values for frost/heat protection (building protection) .............. 31

General variables ......................................................................................... 31

5.5.2. Heating control level 1/2 ............................................................................. 31

5.5.3. Cooling control level 1/2 ............................................................................. 34

5.6. Humidity PI control ................................................................................................ 36

General control ............................................................................................ 36

Controller target value ................................................................................. 36

Dehumidification and/or humidification .................................................... 37

5.7. Dewpoint temperature ........................................................................................... 38

5.7.1. Coolant temperature monitoring ............................................................... 39

Minimum coolant temperature threshold value ....................................... 39

Switching output .......................................................................................... 39

Block .............................................................................................................. 40

2 Contents

Elsner Elektronik GmbH • Herdweg 7 • D-75391 Gechingen • Germany

Sensor KNX AQS/TH-B-UP • from software version 0.3.3, ETS programme version 3.1

Status: 24.09.2014 • Subject to technical changes. Errors excepted.

5.8. Absolute humidity .................................................................................................. 40

5.9. Comfort field ........................................................................................................... 41

5.10.CO2 PI control ........................................................................................................ 41

General control ............................................................................................ 42

Controller target value ................................................................................. 42

Ventilation control ....................................................................................... 43

5.11.Variable comparator .............................................................................................. 44

5.11.1. Control variable comparator 1/2 ................................................................ 44

5.12.Logic ........................................................................................................................ 45

AND logic ...................................................................................................... 45

OR logic ........................................................................................................ 45

5.12.1. AND and/or OR logic 1/2/3/4/5/6/7/8 .......................................................... 45

Block .............................................................................................................. 46

5.12.2. AND logic connection inputs ..................................................................... 47

5.12.3. Connection inputs of the OR logic ............................................................. 48

5.13.Display settings ...................................................................................................... 49

5.14.Pushbutton ............................................................................................................. 51

5.14.1. Pushbutton interface 1/2 ............................................................................ 52

5.14.2. Control modes for drive control ................................................................ 54

3 Clarification of signs

This manual is amended periodically and will be brought into line with new software

releases. The change status (software version and date) can be found in the contents footer.

If you have a device with a later software version, please check

www.elsner-elektronik.de in the menu area "Service" to find out whether a more up-to-

date version of the manual is available.

Clarification of signs used in this manual

Installation, inspection, commissioning and troubleshooting of the device

must only be carried out by a competent electrician.

Safety advice.

Safety advice for working on electrical connections, components,

etc.

DANGER! ... indicates an immediately hazardous situation which will lead to

death or severe injuries if it is not avoided.

WARNING! ... indicates a potentially hazardous situation which may lead to

death or severe injuries if it is not avoided.

CAUTION! ... indicates a potentially hazardous situation which may lead to

trivial or minor injuries if it is not avoided.

ATTENTION! ... indicates a situation which may lead to damage to property if it is

not avoided.

ETS In the ETS tables, the parameter default settings are marked by

underlining.

4 Clarification of signs

5 Description

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

1. Description

The Sensor KNX AQS/TH-B-UP measures CO2concentration, temperature and

humidity and calculates the dew point. The sensor can receive external measured

values via the bus and process them with the own data to overall vealues (mixed

values, e. g. room average). The KNX AQS/TH-B-UP offers two push buttons that may

be used for changing the ambient temperature (target value), for switching between

operating modes or as free programmable bus push buttons.

The KNX AQS/TH-B-UP provides switching outputs with adjustable threshold values.

The switching outputs and further communication objects can be linked by AND and

OR logic gates. Additionally, an integrated actuating variable comparator can compare

and output values that are received via communication objects.

Integrated PI controllers allows for control of a ventilation (depending on CO2

concentration and air humidity) and a heating/cooling system (depending on

temperature). The KNX AQS/TH-B-UP can can emit a warning to the bus as soon as

the area of optimum comfort (according to DIN 1946) is left.

The integrated display shows the own values and data received from the bus (e. g.

date, time). The housing is completed with a frame of the switching series installed in

the building and thus merges with the interior.

Functions:

• Measurement of CO2concentration of the air, of temperature and air

humidity (absolute and relative), calculation of the dew point

•Mixed values from own measured values and external values (proportions

can be set in percentage)

•Display 1-3 rows (own values or values received from the bus) or display of

temperature control (see Mode display and manual temperature controller,

page 11)

•2 push buttons. Configuration as bus push button or for changing ambient

temperature and switching between operating modes (see Change ambient

temperature with the buttons, page 12)

•PI controller for heating (one or two step) and cooling (one or two step)

depending on temperature. Control according to separate target values or

basic target temperature

•PI controller for ventilation depending on humidity and CO2concentration:

dehumidification/humidification (one step) or dehumidification (one or two

step)

•Switching outputs with adjustable threshold values: 3 × temperature, 2 ×

humidity, 4 × CO2. Threshold values can be set by parameter or via

communication objects

•8 AND and 8 OR logic gates with each 4 inputs. Every switching incident as

well as 8 logic inputs in the form of communication objects, may be used as

inputs for the logic gates. The output of each gate may optionally be configured

as 1 bit or 2 x 8 bits

6 Description

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

•2 actuating variable comparators for output of minimum, maximum or

avarage values. Each with 5 inputs (for values received via communication

objects)

Configuration is made using the KNX software ETS. The product file, the data sheet

and the manual can be downloaded from the Elsner Elektronik homepage on

www.elsner-elektronik.de in the “Service” menu.

1.0.1. Scope of delivery

• Housing with display, buttons and sensor board

•CO

2sensor unit

• Base plate

You will need in addition (not supplied):

• Socket Ø 60 mm, 42 mm deep

• Frame (for element 55 x 55 mm), suitable for the switching programme used in

the building

1.1. Technical specifications

Housing Plastic material (partly lacquered)

Colours • White glossy (similar to RAL 9016 Traffic White)

• Aluminium matt

• Anthracite matt

• Stainless steel

• Special colours on request

Mounting In-wall (in socket Ø60 mm, 42 mm deep)

Protection category IP 20

Dimensions Housing approx. 55 x 55 (W x H, mm),

mounting depth approx. 15 mm,

base plate approx. 71 x 71 (W x H, mm)

Total weight approx. 72 g

Ambient temperature Operation -10…+50°C, storage -20…+60°C

Ambient air humidity max. 95% R. H., avoid bedewing

Operating voltage KNX bus voltage

Bus current max. 10 mA

Data output KNX +/- bus terminal plug

BCU type Own micro controller

PEI type 0

Group addresses max. 254

Allocations max. 254

Communication objects 253

CO2 measurement range 0...2000 ppm

CO2resolution 1 ppm

CO2accuracy* ± 50 ppm ± 3% of the measuered value

7 Description

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

* Mind the notes on Accuracy of the measurement, page 7

The product conforms with the provisions of EC guidelines

• EMC Directive 2004/108/EC

• Low Voltage Directive 2006/95/EC

The following standards and/or technical specifications have been applied:

• EN 50491-5-1: 2010

• EN 50491-5-2: 2011

• EN 60730-1: 2011

1.1.1. Accuracy of the measurement

Measurement variations from sources of interference (see chapter Installation

position) must be corrected in the ETS in order to ensure the specified accuracy of the

sensor (offset). To ensure a correct CO2measurement, the device must be installed in

a windproof socket.

The indicated accuracy of the CO2measurement will be achieved after a run-in

period of 24 hours (without interruption of the bus voltage) if the sensor has been in

contact with fresh air (350…450 ppm) at least once in this period.

After this, the CO2sensor will recalibrate every two weeks by defining the lowest

measured value captured during that period (without interruption of the bus voltage)

as a reference for fresh air.

The guarantee the accuracy on a sustained basis, the sensor should be provided with

fresh air at least once in two weeks. This occurs normally during room ventilation.

When measuring temperature, the self-heating of the device is considered by the

electronics. The heating is compensated by reducing the measured temperture by the

self-heating of 1.8°C. The indicated indoor temperature measured value approches the

actual room temperature during a 2 hours heating period.

Temperature measurement

range

-30…+60°C

Temperature resolution 0.1°C

Temperature accuracy* ± 0,9°C at 25°C

Humidity measurement

range

0…100%

Humidity resolution 0.1%

Humidity accuracy 0…20 % = ± 5% R. H.

20…80 % = ± 3% R. H.

80…100 % = ± 5% R. H.

Humidity drift ± 0.5% R. H. per year in normal air

8 Installation and commissioning

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

2. Installation and commissioning

2.1. Installation notes

Installation, testing, operational start-up and troubleshooting should

only be performed by an electrician.

CAUTION!

Live voltage!

There are unprotected live components inside the device.

• National legal regulations are to be followed.

• Ensure that all lines to be assembled are free of voltage and take

precautions against accidental switching on.

• Do not use the device if it is damaged.

• Take the device or system out of service and secure it against

unintentional use, if it can be assumed, that risk-free operation is no

longer guaranteed.

The device is only to be used for its intended purpose. Any improper modification or

failure to follow the operating instructions voids any and all warranty and guarantee

claims.

After unpacking the device, check it immediately for possible mechanical damage. If it

has been damaged in transport, inform the supplier immediately.

The device may only be used as a fixed-site installation; that means only when

assembled and after conclusion of all installation and operational start-up tasks and

only in the surroundings designated for it.

Elsner Elektronik is not liable for any changes in norms and standards which may occur

after publication of these operating instructions.

2.2. Installation position

The Sensor KNX AQS/TH-B-UP will be installed concealed within a socket (Ø 60 mm,

42 mm deep).

May be installed and operated in dry interior rooms only.

Avoid condensation.

For monitoring of the CO2content of the room air choose an installation position in

height of head (standing or sitting, according to utilization of room). The CO2

concentration in indoor rooms is highest near the floor and decreases towards the

ceiling.

9 Installation and commissioning

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

When selecting an installation location, please ensure that the measurement results

are affected as little as possible by external influences. Possible sources of interference

include:

• Direct sunlight

• Drafts from windows and doors

• Draft from ducts which lead from other rooms or from the outside to the

junction box in which the sensor is mounted

• Warming or cooling of the building structure on which the sensor is mounted,

e.g. due to sunlight, heating or cold water pipes

• Connection lines and ducts which lead from warmer or colder areas to the

sensor

Measurement variations from such sources of interference must be corrected in the

ETS in order to ensure the specified accuracy of the sensor (offset).

To ensure a correct CO2measurement, the device must be installed in a windproof

socket.

2.3. Composition

2.3.1. Housing

Fig. 1

1 Base plate

2 Catches

3 Openings for air circulation

4 Push button

5 Programming LED (recessed)

6 Programming button

(recessed) for teaching device

7 Push button

8 Openings for air circulation

(LOWER)

3

24

6

7

5

8

1

10 Installation and commissioning

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

2.3.2. Rear view of sensor board with connections

2.4. Assembly of the sensor

First of all fit the windproof socket with connection. Also seal inlet pipes to avoid

infiltration.

Screw the base plate onto the socket and position the frame of the switching

programme. Connect the CO2sensor unit and the bus line +/- (black-red plug) to the

terminals provided on the board.

Pin the sensor with the notches on to the metal frame, so that sensor and frame are

fixed.

2.5. Notes on mounting and commissioning

Never expose the device to water (e.g. rain) or dust. This can damage the electronics.

You must not exceed a relative humidity of 95%. Avoid condensation.

After the bus voltage has been applied, the device will enter an initialisation phase

lasting a few seconds. During this phase no information can be received via the bus.

Fig. 2

1 KNX terminal BUS +/-

2Notches

3SlotforCO

2sensor unit

4 Plug of CO2 sensor unit

5CO

2sensor unit

Lenght of cable approx. 110 mm

a Hole centre distance approx. 43 mm

b Diameter of diaphragm

approx. 18 mm

2

1

34 5

a

b

Place the CO2sensor unit in the socket. The side with the sensor

membrane must face to front.

Fig. 3

11 Display and operation at the device

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

3. Display and operation at the device

Specifications for the display are set in the ETS and the use of the push buttons is

permitted or disabled.

Basically the display can show a two-row or three-row text (e. g. for measured values)

or a tempertuare controller. You can switch between the two types by pressing one of

the buttons, if this has not been disabled in the ETS.

3.1. Mode display and manual temperature

controller

Depending on the ETS setting selected, the mode display will only display show the

current target value, or the base target value setting with scale display. The manually

adjustable range can be set in the ETS.

The following display options are available:

Fig. 4

Mode display with current target value and/or base

target value

Fig. 5

Mode display with scale display for adjusting the base

target value.

The control position in the image reads "Base target

value reduced".

Fig. 6

Mode display with scale display and number.

Shows the set target value change.

The control position in the image reads "Base target

value reduced to 1.0°".

Fig. 7

Mode display with scale display and range.

Shows the possible adjustment range (as set in the ETS).

The control position in the image reads "Base target

value reduced".

12 Display and operation at the device

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

Symbols

Priority (points)

One point: Priority 1/priority control. It is not possible to adjust the temperature

automation system manually. Neither the target temperature nor the operating modes

can be changed using the buttons on the unit.

Two points: Priority 2. The target temperature and operating mode can be changed

using the buttons.

3.2. Change ambient temperature with the

buttons

If the mode display is active, the target ambient temperature and the operating mode

can be changed manually using the buttons. The button functions can be blocked in

the ETS or be suppressed for Priority 1 operating modes. The individual operating

modes can also be locked for manual selection in the ETS.

Comfort mode.

Comfort (present) target

temperature will be used.

Standby mode.

Standby (absent during day)

target temperature will be used.

Eco mode.

Night target temperature will be

used.

Building protection mode.

Building protection target

temperature will be used. The

symbol will blink when the

mode has been activated but the

activation delay has not yet

expired.

Heating mode.

Heating will be provided.

Cooling mode

Cooling will be provided.

Fig. 8

Mode display with scale display, range and number.

Displays the possible adjustment range (as set in the

ETS) and the set target value change.

The control position in the image reads "Base target

value reduced to 1.0°".

Fig. 9

In "HVAC mode with 2x 8 bits" control mode, points are

shown under the symbol, to indicate the running priority

of the current mode.

13 Display and operation at the device

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

Decrease target

temperature (-)

briefly press

left button

Ambient temperature in the current

mode is decreased.

The sep-size is defined in the ETS

(0.1°C to 5°C).

Increase target

temperature (+)

briefly press

right button

Ambient temperature in the current

mode is increased.

The sep-size is defined in the ETS

(0.1°C to 5°C).

Change mode press

left or right button

longer than 2 secs.

Changes between the operating

modes Comfort, Standby, Eco and

Building Protection (if deblocked in

the ETS).

Extend Comfort

mode

in Eco mode:

press both buttons

at the same time

longer than 2 secs.

Switches from Eco to Comfort mode

again for a certain time (e. g. if the

rooms are used longer in the

evening).

The period is defined in the ETS (up

to 10 hours). The time remaining in

Comfort mode is displayed.

14 Transfer protocol

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

4. Transfer protocol

Units:

Temperatures in degrees Celsius

Air humidity in %

Absolute air humidity in g/kg and/or g/m3

CO2content in ppm

Variables in %

4.1. List of all communications objects

Abbreviation flags:

C Communication

R Read

WWrite

T Transfer

UUpdate

No. Name Function DPT Flags

0 Software version readable 217,001 C R T

1 Temperature/humidity malfunction

sensor

Output 1,001 C R T

2 CO2 sensor malfunction Output 1,001 C R T

3 Outside temperature reading Input 9,001 C W

4 Inside temperature reading Output 9,001 C R T

5 Overall temperature reading Output 9,001 C R T

6 Min./max. temperature value request Input 1,017 C W

7 Minimum temperature reading Output 9,001 C R T

8 Maximum temperature reading Output 9,001 C R T

9 Reset min./max. temperature value Input 1,017 C W

10 Temp. threshold value 1: Absolute

value

Input/Output 9,001 C R W T

U

11 Temp. threshold value 1: (1:+ | 0:-) Input 1,002 C W

12 Temp. threshold value 1:

Switching delay from 0 to 1

Input 7,005 C W

13 Temp. threshold value 1:

Switching delay from 1 to 0

Input 7,005 C W

14 Temp. threshold value 1: Switching

output

Output 1,001 C R T

15 Temp. threshold value 1:

Switching output block

Input 1,002 C W

15 Transfer protocol

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

16 Temp. threshold value 2: Absolute

value

Input/Output 9,001 C R W T

U

17 Temp. threshold value 2: (1:+ | 0:-) Input 1,002 C W

18 Temp. threshold value 2:

Switching delay from 0 to 1

Input 7,005 C W

19 Temp. threshold value 2:

Switching delay from 1 to 0

Input 7,005 C W

20 Temp. threshold value 2: Switching

output

Output 1,001 C R T

21 Temp. threshold value 2:

Switching output block

Input 1,002 C W

22 Temp. threshold value 3: Absolute

value

Input/Output 9,001 C R W T

U

23 Temp. threshold value 3: (1:+ | 0:-) Input 1,002 C W

24 Temp. threshold value 3:

Switching delay from 0 to 1

Input 7,005 C W

25 Temp. threshold value 3:

Switching delay from 1 to 0

Input 7,005 C W

26 Temp. threshold value 3: Switching

output

Output 1,001 C R T

27 Temp. threshold value 3:

Switching output block

Input 1,002 C W

28 Reserve

29 TR_1_ Eco-Standby HVAC 1 Input 1,003 C W

30 TR_1_ Comfort Activation HVAC 2 Input 1,003 C W

31 TR_1_ Frost/Heat activation Input 1,003 C R W T

32 TR_1_ Blocking object Input 1,003 C W

33 TR_1_ Target value, current Output 9,001 C R T

34 TR_1_ Switching object (0:Heat |

1:Cool)

Input 1,002 C W

35 TR_1_ Target value, comfort heating Input/Output 9,001 C R W T

36 TR_1_ Target value, comfort heating

(1:+ | 0:-)

Input 1,002 C W

37 TR_1_ Target value, comfort cooling Input/Output 9,001 C R W T

38 TR_1_ Target value, comfort cooling

(1:+ | 0:-)

Input 1,002 C W

39 TR_1_ Target value_Basic offset Input/Output 9,001 C R W T

40 TR_1_ Target value, Standby heating Input/Output 9,001 C R W T

41 TR_1_ Target value, Standby heating

(1:+ | 0:-)

Input 1,002 C W

42 TR_1_ Target value, Standby cooling Input/Output 9,001 C R W T

No. Name Function DPT Flags

16 Transfer protocol

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

43 TR_1_ Target value, Standby cooling

(1:+ | 0:-)

Input 1,002 C W

44 TR_1_ Target value, Eco heating Input/Output 9,001 C R W T

45 TR_1_ Target value, Eco heating (1:+ |

0:-)

Input 1,002 C W

46 TR_1_ Target value, Eco cooling Input/Output 9,001 C R W T

47 TR_1_ Target value, Eco cooling (1:+ |

0:-)

Input 1,002 C W

48 TR_1_ Control variable heating (stage

1)

Output 5,001 C R T

49 TR_1_ Control variable heating stage

2

Output 5,001 C R T

50 TR_1_ Control variable cooling (stage

1)

Output 5,001 C R T

51 TR_1_ Control variable cooling stage

2

Output 5,001 C R T

52 TR_1_ Status heating 1 (1=ON |

0=OFF)

Output 1,002 C R T

53 TR_1_ Status heating 2 (1=ON |

0=OFF)

Output 1,002 C R T

54 TR_1_ Cooling status 1 (1=ON |

0=OFF)

Output 1,002 C R T

55 TR_1_ Cooling status 2 (1=ON |

0=OFF)

Output 1,002 C R T

56 TR_1_ Comfort Delay Status Input/Output 1,002 C R W T

57 TR_1_Comfort extension time (in sec) Input/Output 7,005 C R W T

58 TR_1_Belimo_Control variable Output 5,001 C R T

59 Outside humidity reading Input 9,007 C W

60 Inside humidity reading Output 9,007 C R T

61 Overall humidity reading Output 9,007 C R T

62 Min./max. humidity value request Input 1,017 C W

63 Minimum humidity reading Output 9,007 C R T

64 Maximum humidity reading Output 9,007 C R T

65 Reset min./max. humidity value Input 1,017 C W

66 Humidity threshold value 1: Absolute

value

Input/Output 9,007 C R W T

U

67 Humidity threshold value 1: (1:+ | 0:-) Input 1,002 C W

68 Humidity threshold value 1: Switch-

ing delay from 0 to 1

Input 7,005 C W

69 Humidity threshold value 1: Switch-

ing delay from 1 to 0

Input 7,005 C W

No. Name Function DPT Flags

17 Transfer protocol

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

70 Humidity threshold value 1: Switch-

ing output

Output 1,001 C R T

71 Humidity threshold value 1: Switch-

ing output block

Input 1,002 C W

72 Humidity threshold value 2: Absolute

value

Input/Output 9,007 C R W T

U

73 Humidity threshold value 2: (1:+ | 0:-) Input 1,002 C W

74 Humidity threshold value 2: Switch-

ing delay from 0 to 1

Input 7,005 C W

75 Humidity threshold value 2: Switch-

ing delay from 1 to 0

Input 7,005 C W

76 Humidity threshold value 2: Switch-

ing output

Output 1,001 C R T

77 Humidity threshold value 2: Switch-

ing output block

Input 1,002 C W

78 Humidity controller: Blocking object Input 1,002 C W

79 Humidity controller: Target value Input/Output 9,007 C R W T

80 Humidity controller: Target value (1:+

| 0:-)

Input 1,002 C W

81 Humidity controller: Control variable

dehumidification (stage 1)

Output 5,001 C R T

82 Humidity controller: Control variable

dehumidification stage 2

Output 5,001 C R T

83 Humidity controller: Control variable

humidification

Output 5,001 C R T

84 Humidity controller: Dehumidification

1 status (1=ON | 0=OFF)

Output 1,001 C R T

85 Humidity controller: Dehumidification

2 status (1=ON | 0=OFF)

Output 1,001 C R T

86 Humidity controller: Humidification

status (1=ON | 0=OFF)

Output 1,001 C R T

87 Dewpoint temperature Output 9,001 C R T

88 Coolant temp.: Threshold value Output 9,001 C R T

89 Coolant temp.: Actual value Input 9,001 C W

90 Coolant temp.: Offset change (1:+ | 0:-

)

Input 1,002 C W

91 Coolant temp.: Switching delay from

0 to 1

Input 7,005 C W

92 Coolant temp.: Switching delay from

1 to 0

Input 7,005 C W

93 Coolant temp.: Switching output Output 1,001 C R T

No. Name Function DPT Flags

18 Transfer protocol

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

94 Coolant temp.: Switching output

block

Input 1,002 C W

95 Absolute humidity [g/kg] Output 14,005 C R T

96 Absolute humidity [g/m³] Output 14,017 C R T

97 Ambient climate status: 1 = comforta-

ble | 0 = uncomfortable

Output 1,002 C R T

98 Outside CO2 reading Input 9,008 C W

99 Inside CO2 Internal reading Output 9,008 C R T

100 Total CO2 reading Output 9,008 C R T

101 CO2 maximum value request Input 1,017 C W

102 Maximum CO2 reading Output 9,008 C R T

103 Reset CO2 maximum value Input 1,017 C W

104 CO2 threshold value 1: Absolute

value

Input/Output 9,008 C R W T

U

105 CO2 threshold value 1: (1:+ | 0:-) Input 1,002 C W

106 CO2 threshold value 1: Switching

delay from 0 to 1

Input 7,005 C W

107 CO2 threshold value 1: Switching

delay from 1 to 0

Input 7,005 C W

108 CO2 threshold value 1: Switching out-

put

Output 1,001 C R T

109 CO2 threshold value 1: Switching out-

put block

Input 1,002 C W

110 CO2 threshold value 2: Absolute

value

Input/Output 9,008 C R W T

U

111 CO2 threshold value 2: (1:+ | 0:-) Input 1,002 C W

112 CO2 threshold value 2: Switching

delay from 0 to 1

Input 7,005 C W

113 CO2 threshold value 2: Switching

delay from 1 to 0

Input 7,005 C W

114 CO2 threshold value 2: Switching out-

put

Output 1,001 C R T

115 CO2 threshold value 2: Switching out-

put block

Input 1,002 C W

116 CO2 threshold value 3: Absolute

value

Input/Output 9,008 C R W T

U

117 CO2 threshold value 3: (1:+ | 0:-) Input 1,002 C W

118 CO2 threshold value 3: Switching

delay from 0 to 1

Input 7,005 C W

119 CO2 threshold value 3: Switching

delay from 1 to 0

Input 7,005 C W

No. Name Function DPT Flags

19 Transfer protocol

Sensor KNX AQS/TH-B-UP • as of software 3.1 • Status: 24.09.2014 • Technical changes reserved. Errors reserved.

120 CO2 threshold value 3: Switching out-

put

Output 1,001 C R T

121 CO2 threshold value 3: Switching out-

put block

Input 1,002 C W

122 CO2 threshold value 4: Absolute

value

Input/Output 9,008 C R W T

U

123 CO2 threshold value 4: (1:+ | 0:-) Input 1,002 C W

124 CO2 threshold value 4: Switching

delay from 0 to 1

Input 7,005 C W

125 CO2 threshold value 4: Switching

delay from 1 to 0

Input 7,005 C W

126 CO2 threshold value 4: Switching out-

put

Output 1,001 C R T

127 CO2 threshold value 4: Switching out-

put block

Input 1,002 C W

128 CO2 controller: Blocking object Input 1,002 C W

129 CO2 controller: Target value Input/Output 9,008 C R W T

130 CO2 controller: Target value (1:+ | 0:-) Input 1,002 C W

131 CO2 controller: Control variable venti-

lation (stage 1)

Output 5,001 C R T

132 CO2 controller: Control variable venti-

lation (stage 2)

Output 5,001 C R T

133 CO2 controller: Ventilation 1 status

(1=ON | 0=OFF)

Output 1,001 C R T

134 CO2 controller: Ventilation 2 status

(1=ON | 0=OFF)

Output 1,001 C R T

135 Comparator 1 actuating variable:

Input 1

Input 5,010 C W

136 Comparator 1 actuating variable:

Input 2

Input 5,010 C W

137 Comparator 1 actuating variable:

Input 3

Input 5,010 C W

138 Comparator 1 actuating variable:

Input 4

Input 5,010 C W

139 Comparator 1 actuating variable:

Input 5

Input 5,010 C W

140 Comparator 1 actuating variable: Out-

put

Output 1,001 C R T

141 Comparator 1 actuating variable:

Block

Input 1,002 C W

142 Comparator 2 actuating variable:

Input 1

Input 5,010 C W

No. Name Function DPT Flags

This manual suits for next models

4

Table of contents

Other Elsner Accessories manuals

Elsner

Elsner KNX T-UP gl Guide

Elsner

Elsner KNX AQS/TH Guide

Elsner

Elsner 71300 Guide

Elsner

Elsner Sewi KNX TH-L-Pr Guide

Elsner

Elsner Vari KNX 3L-TH-D Guide

Elsner

Elsner KNX RW Guide

Elsner

Elsner Vari KNX 3L Guide

Elsner

Elsner KNX L User manual

Elsner

Elsner Cala KNX AQS/TH Guide

Elsner

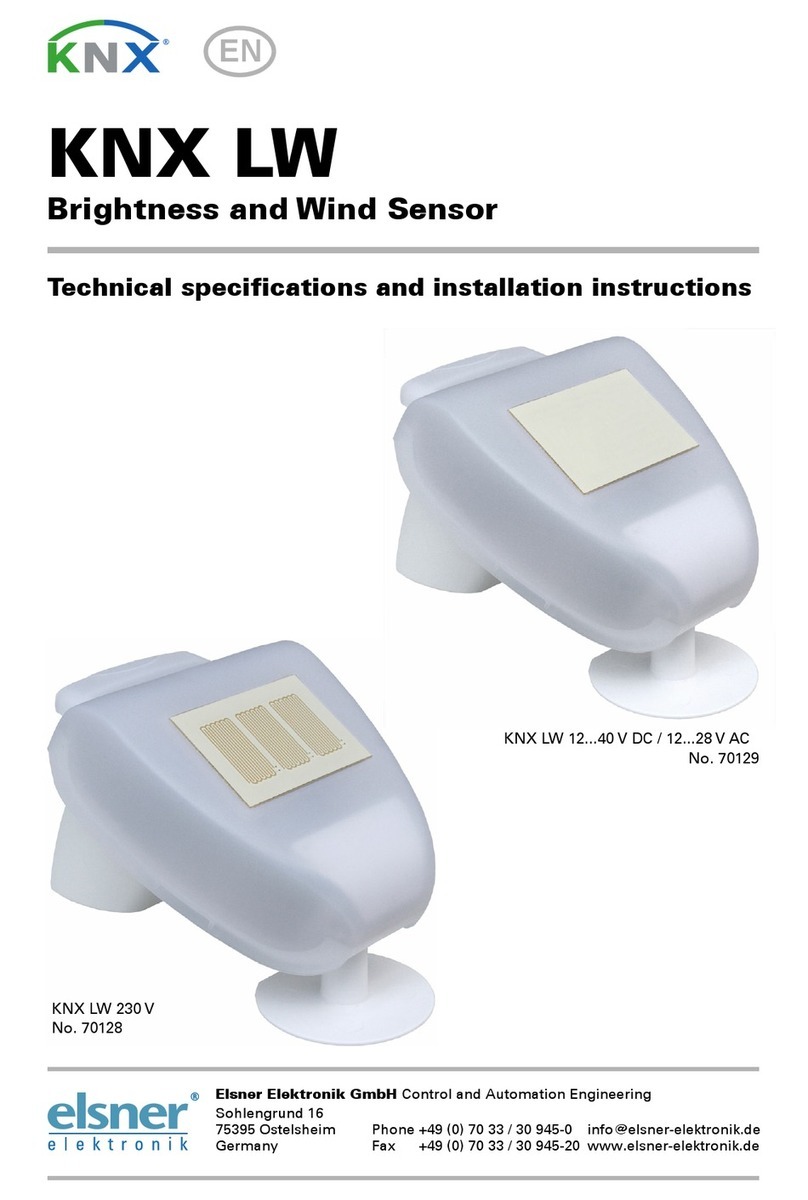

Elsner KNX LW Series User manual

Popular Accessories manuals by other brands

Wirebus

Wirebus WCS-300 user manual

Honeywell

Honeywell Notifier NFSTI-SMT2 Installation and maintenance instructions

XDream

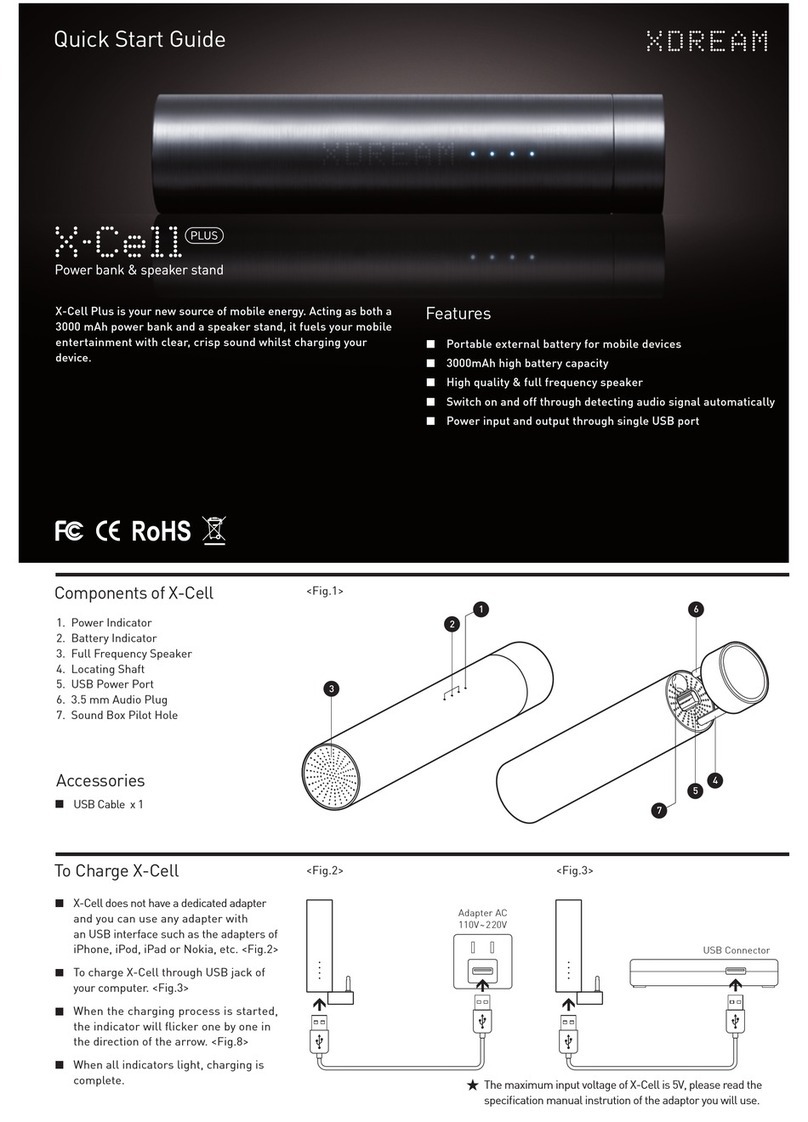

XDream X-Cell Plus quick start guide

LEGRAND

LEGRAND Wattstopper FSP-301 installation instructions

Panasonic

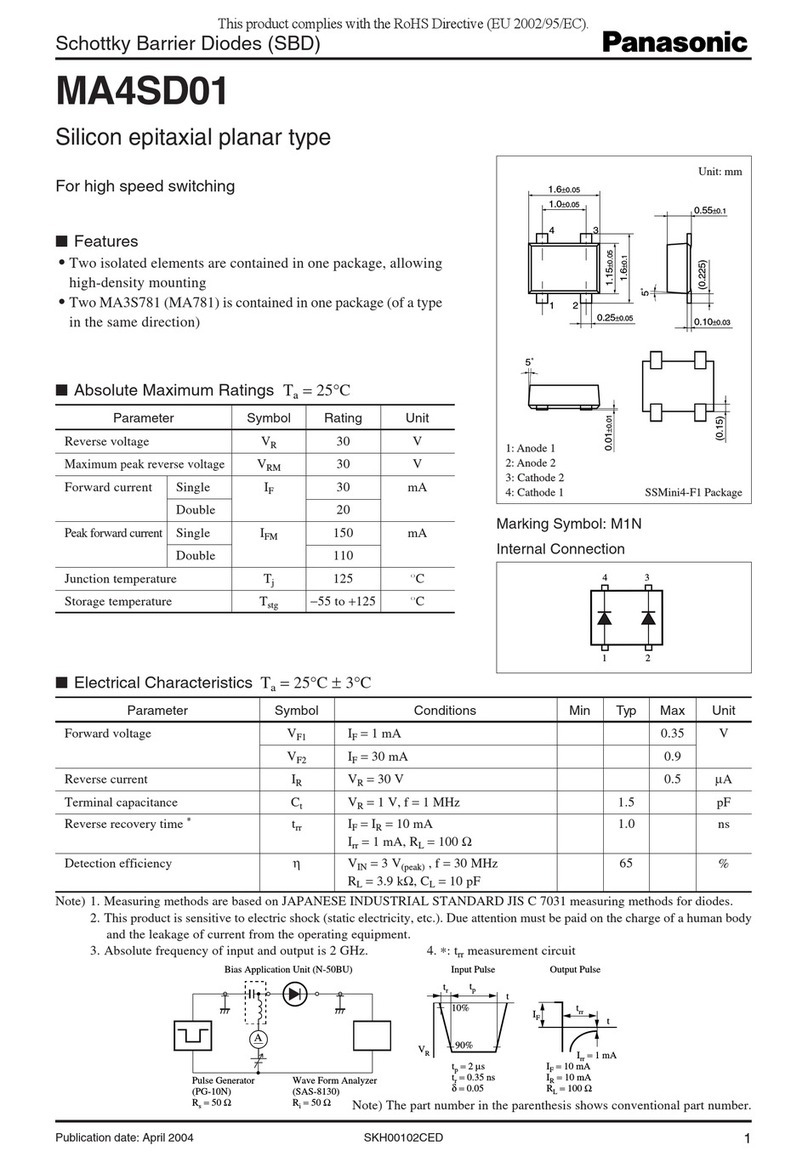

Panasonic MA4SD01 Specification sheet

Wavetronix

Wavetronix Click 510 quick start guide