4 Parkell.com | Questions? Contact Parkell Technical Support at (800) 243-7446

manufacturer. Otherwise, degradation of the performance of

this equipment could result.

•This equipment is not suitable for use in the presence of a

flammable anesthetic gas mixture (when used along with air

or oxygen).

Clinical Precautions

• Although the following precautions may be common sense to the

experienced user of ultrasonic scalers, they bear repeating in the

interest of safety, and the management of unnecessary risk.

•Ultrasonic scalers should only be used by trained, dental

professionals.

• Use of appropriate personal protection equipment and high-

volume intraoral suction is strongly recommended when operating

this device, to avoid exposure to contaminated aerosols.

•DO NOT OPERATE UNIT WITHOUT WATER FLOWING. Water

flow through tip during use must always be enough to cool

handpiece and insert.

• Do not allow prolonged contact of insert tip with lips, cheek,

tongue, or other soft tissues. Insert tips are sharp and should be

used carefully.

•Handpiece and inserts supplied along with the unit are not

sterile and needs to cleaned and sterilized in autoclave by the

user prior to the first use and before each use, as specified on

the insert package instructions and in Infection Control

procedure specified in this instruction manual.

• To keep heat generation to minimum, use the lowest scaling

power that is eective.

•Before using the insert in the oral cavity, adjust water mist by

varying the POWER & WATER settings.

• For patient comfort, use a generous flow of water as a coolant,

lubricant, and debris flush.

•If patient is new to ultrasonic scaling, explain to them what to

expect. When done properly, the patient should not experience

any uncomfortable heat. If patient experiences excessive heat,

adjust POWER and WATER controls accordingly, or examine

inserts for wear or damage.

• Do not test a scaler tip on your fingers while operating, as this is

not a valid test of how scaling feels to the patient. If you touch

the tip, it will feel uncomfortably hot to your fingers.

•Hold the handpiece in a comfortable pen-grasp. Elevated heat

may be felt if the lighted handpiece is gripped where the insert

meets the handpiece.

• Keep the long axis of the insert tip parallel to the long axis of the

tooth to wipe deposits from the tooth with a light, brushing

stroke with the side of the insert. Do not gouge the tooth with

the point of the tip.

•Excess pressure will not improve scaling eciency and may

cause overheating of the tooth and pain to the patient. Keep the

scaler insert in motion always, using repeated gentle strokes to

remove all tenacious deposits.

• Occasionally pause during scaling by removing foot from pedal

to evaluate deposit removal. Exercise caution near ceramic or

resin restorations, as they can fracture if stressed.

Inserts

Magnetostrictive Inserts for the TurboSensor+ scaler are available

separately and are not included with the basic scaler unit. The unit

is designed to work with all Parkell and other market-leading 30KHz

inserts. Brand new inserts may fit very tightly in the handpiece

initially and may be inserted and removed more easily by using a

slight twisting motion, and by lubricating the insert “O” ring with

water. Old, worn, or blunt inserts will perform poorly, generate

excess heat, and should be replaced when necessary.

Installing Your Scaler

• Parkell TurboSensor+ System is designed to rest on a level

surface. Be sure the unit is stable. This will assure that an

accidental pull on the handpiece or corded foot pedal does not

cause the unit to fall onto the floor.

•The scaler requires access to a source of drinking-quality water

and a grounded electrical outlet.

• Locate the control unit such that it can be easily disconnected

form the mains power line in case it needs to be disconnected

for any reasons. Disconnection form the mains power line can

be accomplished by removing the power cord from the wall

plug, removing the power cord from the in-line “power supply

adapter” or by removing the 2.5 mm metal plug connector from

the back of the scaler.

•Install the scaler where control panel and foot pedal will be easy

to reach during scaling procedures.

• The rear of the unit requires access so the water filter may be

changed periodically without diculty.

•The device and its separate power adapter generate a minimal

amount of heat. Avoid covering them to allow normal cooling.

Water Connection

Before plugging in the device, connect the scaler’s water line to a

drinking-quality water supply (15-35 psi optimal), free of sediment.

An external, oce-wide water filter is recommended to minimize

frequent changes of the device’s in-line water filter.

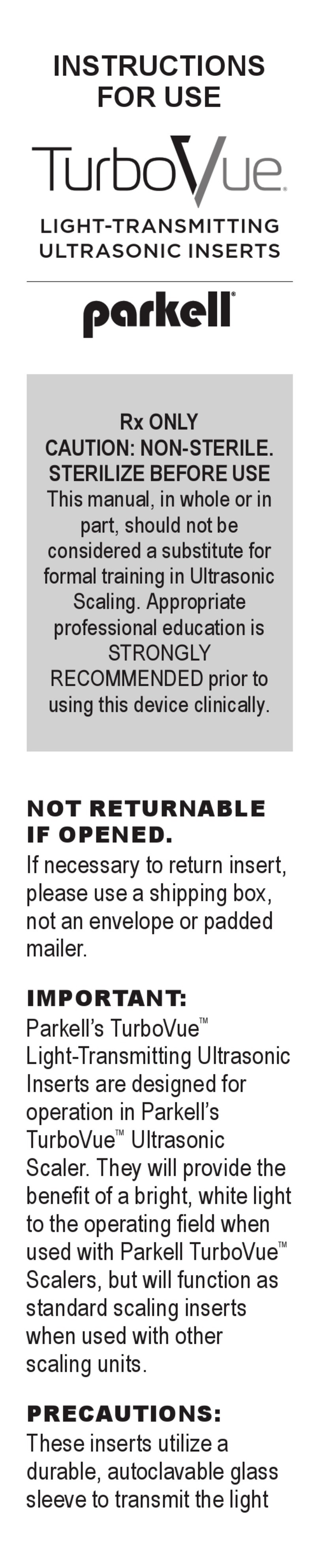

The male quick-connect that comes on the

end of the water hose is the standard fitting

presently used in the dental industry. If you

are replacing a scaler that uses an Adec-

type or other type of connection, remove

the old fitting from the unit hose and attach

it to the new water line. Check for leaks at all

hose and filter connections before use, and

tighten if necessary.

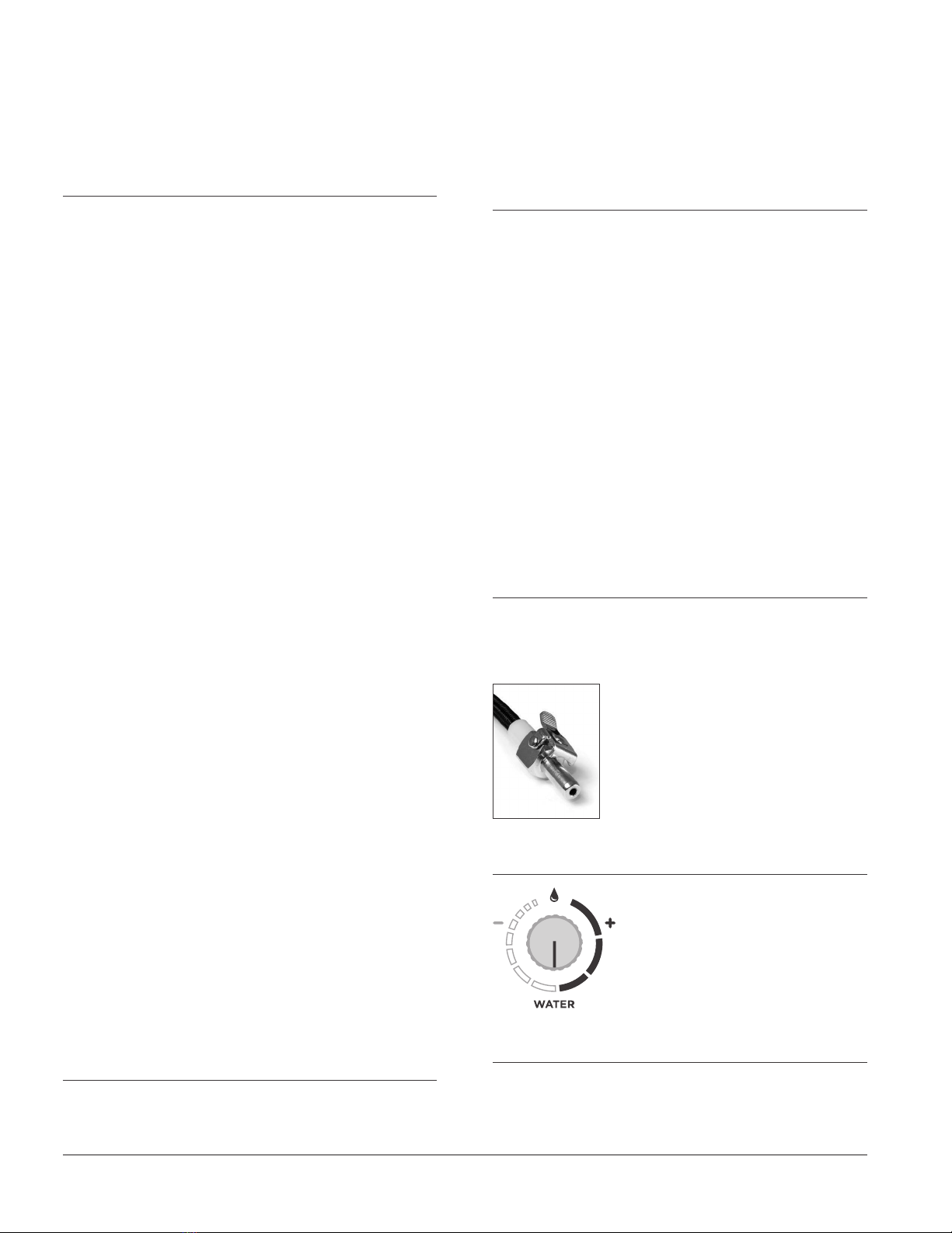

Controlling the Water Flow

Observing the arrow printed on the

control panel, turn the water control

counter- clockwise to increase the flow,

or clockwise to decrease water flow. If

water does not flow through the insert

when the foot pedal is depressed, the

water passage in the scaling insert may

be clogged.

Electrical Connection

The scaler must only be powered via the power supply assembly

that is supplied with the device by Parkell. Power supply provided

by Parkell is a Medical-Grade, IEC 60601 compliant, TUV approved