Bulletin TI-75A20C Installation, Operation and Maintenance Manual

Technical Information Parker Balston 75-A20 Compressed Air Dryer

Parker Hannin Corporation

Industrial Gas Filtration and

Generation Division

Lancaster, NY • 1-716-686-6400

1

Parker Balston 75-A20 Compressed Air Dryer

Bulletin TI-75A20C

Installation, Operation, and Maintenance Manual

CELL: DRY

®

Introduction

Installation

Balston compressed Air Dryers provide clean, dry air from

an existing compressed air supply. The 75-A20 Air Dryer

delivers -100°F (-73°C) dewpoint air.

The 75-A20 Compressed Air Dryer is powered by a 12 VDC

power supply. Each dryer is equipped with a plug-in trans-

former for connection to the local power supply.

These instructions must be thoroughly read and under-

stood before installing and operating this product. If you

have any questions or concerns, please call the Technical

Services Department at 800-343-4048, 8AM to 5PM Eastern

Standard Time (North America only) or email at balston-

techsupport@parker.com. For other locations, please

contact your local representative.

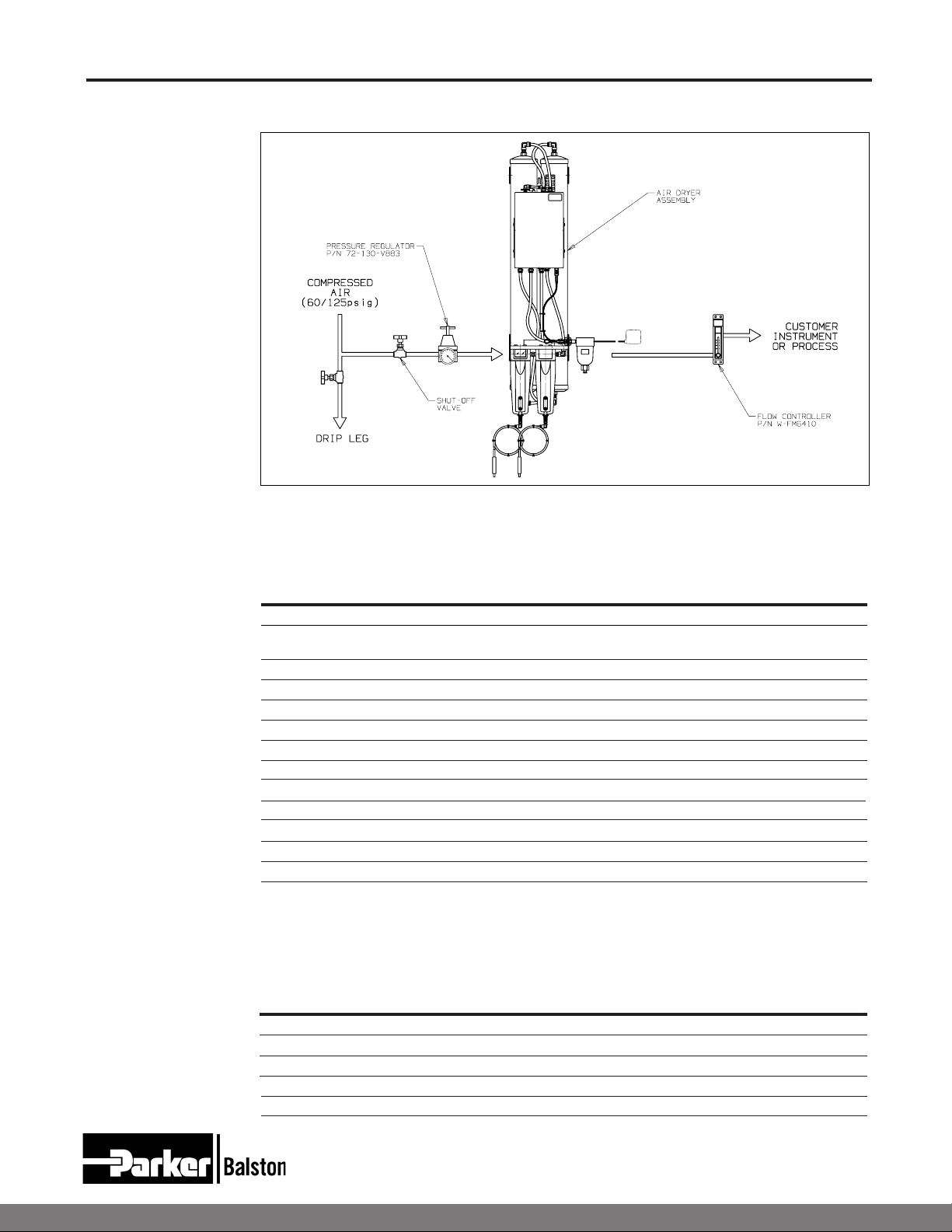

The dryer should be fastened securely, in a vertical position,

to a wall or similar mounting surface according to National

Electrical Code (NEC) and local building code guidelines. All

mounting hardware supplied by the customer should be ad-

equately sized to support the weight of the unit in its mounted

position.

To facilitate routine maintenance, install a shut-off valve on the

supply air line, upstream from the dryer. Pipe the supply air

(60 psig-125 psig, 4.1 barg-8.6 barg) to the inlet port of

the dryer. (Note: Pipe size must match inlet and outlet port

sizes or adequate lengths of pipe must be used to reduce/

increase pipe size to match ports. Please consult factory for

additional assistance.) The air dryer should be installed on a

compressed air system which contains a properly sized

aftercooler. The temperature of the supply air entering the

Balston Air Dryer should not exceed 78°F(25°C). If the

temperature of the inlet compressed air exceeds 78°F(25°C),

the dewpoint of the air generated by the dryer may exceed

the rated dewpoint. If the compressed air supply has excess

water and/or oil or is supplied to the dryer from an elevated air

line, a drip leg must be installed directly upstream from the dryer to reduce the amount of water and oil

which could get into the dryer and associated valves and cause non-warranty damage to the unit (see Fig-

ure 2). A minimum supply air pressure to the air dryer of 60 psig (4.1 barg) is required to maintain proper

operation of the drying towers and associated valves. The maximum supply pressure should not exceed

125 psig (8.6 barg) or damage to the unit may occur.

It is important to control output pressure and ow from the dryer to avoid exceeding the rated capacity of

the dryer. If the maximum ow rate of the dryer is exceeded, the process air may not meet the published

dewpoint specications. The installation of a pressure regulator and ow control valve downstream from

the Balston Air Dryer is recommended to control output ow characteristics.

Figure 1 - 75-A20 Compressed Air Dryer