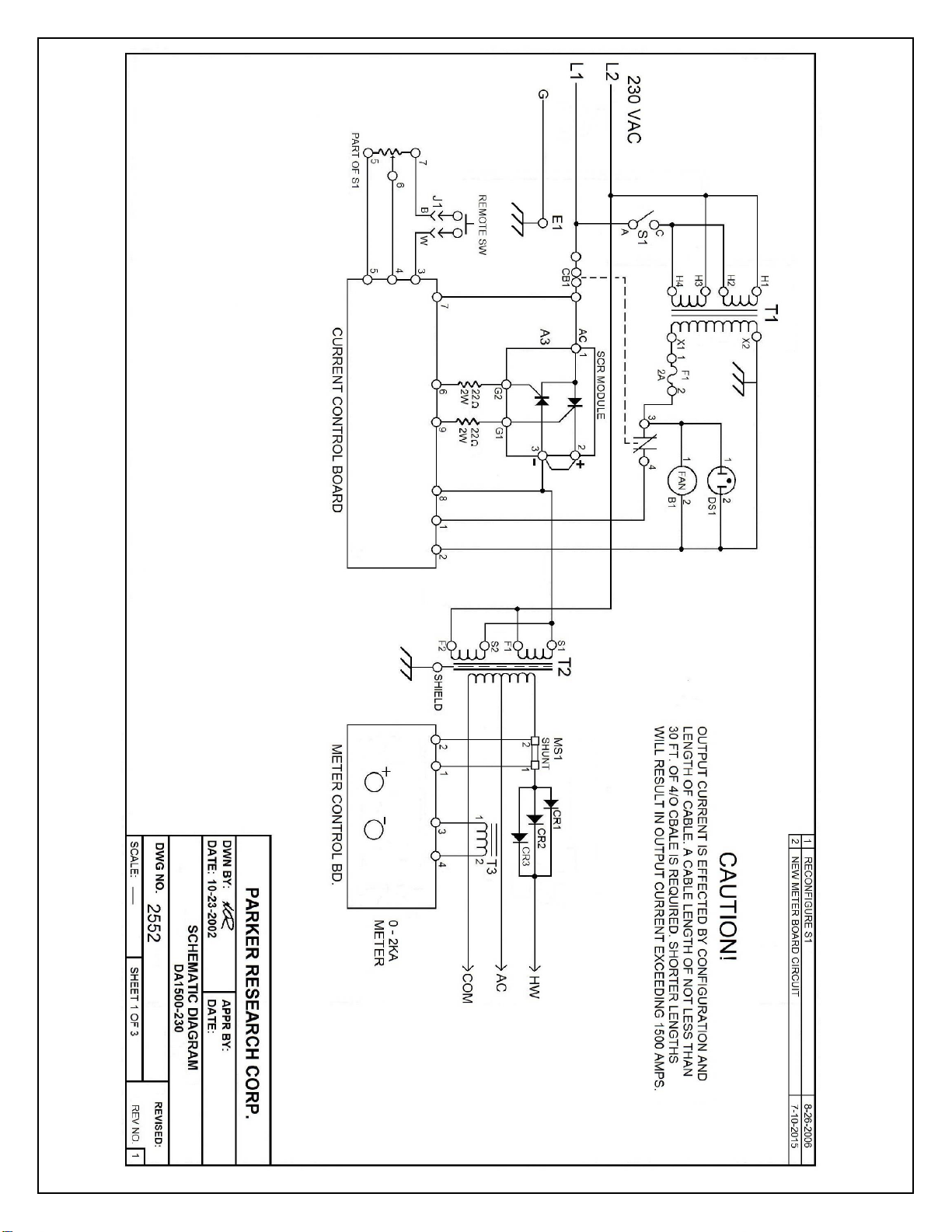

ELECTRICAL FEATURES

The DA1500 unit is built to operate from either 230VAC or 460VAC (not interchangeably),

50/60 Hz., Single phase current. Line current at rated output is approximately 45 amperes at

230 volts and 23 amperes at 460 volts. Check "Data Nameplate" on the unit for correct

operating voltage.

The DA1500 is sold without a power cord plug. Only locally approved plugs with the proper

rating should be used and installed by certified personnel.

The DA1500 is wired at the factory for either 230VAC or 460VAC operating voltage. Change

over from one voltage to another can not be done in the field. Unit must be returned to the

factory for modification.

An automatic thermal reset circuitbreaker is provided to prevent overheating and damage to

electrical components.

The current control potentiometer in conjunction with internal electrical circuit, provide infinitely

variable magnetizing and demagnetizing current control.

The power transformer operating in conjunction with an SCR module, transforms the high

voltage line input to low voltage, high amperage AC or Half-Wave DC output. While these

components are fan cooled, they are designed for intermittent service at 1500 amperes output.

To avoid overheating and possible damage, a minimum duty cycle of 50% must be adhered to.

CAUTION: Attaching less than 30' of 4/O cable (two 15' cables) may cause excessive line

current draw and possible overheating of parts.

CONNECTION

1. With current control in the "Off" position, connect the line cord to the properly fused and

grounded disconnect switch of proper rating. Consult "Data Nameplate" on the back of the unit

for correct operating voltage.

2. Turn the current control so that the unit powers "On". A red pilot light will glow indicating

that there is power to the unit and that it is "On".

3. Plug in and twist clockwise two 15' 4/O magnetizing cables into the output connectors at the

front of the unit. Note: One cable must be connected to the "Common" connector. The other

cable must be connected to either the A.C. or HWDC cable connector. Connect the two

eitherend connectors or two lug connectors at the opposite end of the cables to form a "loop".

Plug in the control cable and activate to check operation for both AC and DC output.

For maximum output on either AC or half-wave DC, it is necessary to reduce the inductive loop

of the external cables as much as possible\; that is, the spacing

between the external 4/O cables must be kept at a minimum. If possible, the first ten feet of

cable may be bound of taped together for optimum current output.

NOTE: When cables are used as a coil with AC current, ammeter readings will be lower due

to coil/part inductance.