General safety rules. Please read all instructions. Failure to follow all instructions listed

below may result in injury. If the equipment is used in a manner other than as specified in

these operating instructions, the protection provided by the equipment may be impaired.

Always wear eye protection

DO NOT O ERATE unit from a DC power source.

Warning: Do not change AC/DC selector switch with probe on.

Do not abuse the power cords. Never carry the instrument by the cord or attempt to unplug

the instrument using the cord. Always operate the instrument with the standard installed

cord. Changing or using a damaged cord can increase the risk of electrical shock. The cord

should be checked periodically for any damage.

Do not position the instrument such that it would be difficult to operate the disconnect device

(plug) on the end of the power cord.

The outside housing should remain intact and solid. Any damage, chipping, or separating

exposing internal wires is a hazard. Instruments should not be used in this condition. The

outside housing should be periodically checked for damage.

Duty Cycle: The 200 series are designed for a 50% duty

cycle, or approximately two minutes on and two minutes off.

Continuous operation may cause overheating and damage

the Contour Probe.

Operating Environment: Temperature: 32° to 104°F (0° to

40°C). Relative humidity: 10% to 95%, non-condensing.

Shipping and Storage Environment: Temperature: 40° to

140°F (4.44° to 60°C). Relative humidity: 5% to 95%.

Vibration and shock: As encountered in normal shipping

and handling with no degradation.

General Cleaning

The outside surface of the instrument can be periodically

wiped with a clean cloth and a mild general purpose

cleaner. Avoid using cleaners such as lacquer thinner, or

mineral spirits that could damage the outside housing.

Never attempt field service. All 200 series contour probes should be returned to the factory

for repairs.

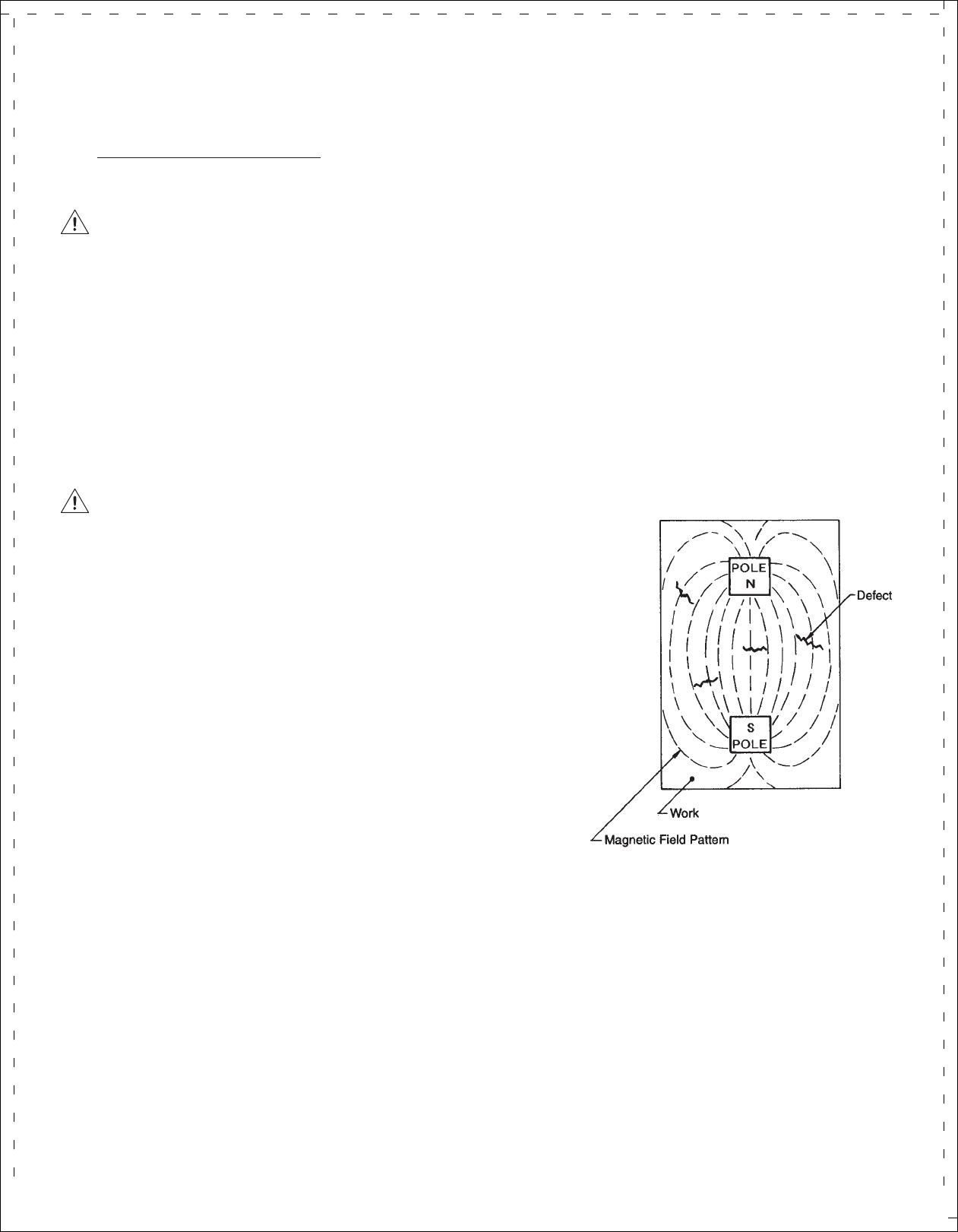

O ERATION: Connect the instrument plug into a Grounded power outlet of proper voltage.

Place the Contour Probe legs upon the work surface with the suspected defect at right angles

to the legs (Good contact will produce the best results). Push the test switch to energize the

instrument. Lightly dust or float dry magnetic inspection powder over the area being

inspected. Defect indications will be revealed in a direction shown on figure 2. Turn the

Probe 90 degrees from the first test and repeat the process. This method may also be utilized

when applying a wet medium. Check all procedures and standards for further details involving

inspection specifics.

FIG. 2

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com