EN | User Manual

BSP-MT 10-95/D3 1

Index

Machine passport 3

General information 4

Manufacturer’s details .............................................................................................................. 4

Details on the dryer................................................................................................................... 4

About these operating instructions........................................................................................... 5

For your own safety 6

General safety notes................................................................................................................. 6

Intended use of the dryer.......................................................................................................... 7

Signs, instruction plates and danger zones at the dryer........................................................... 8

Transportation, installation and storage 10

Information on transportation packaging................................................................................ 10

What to do in the case of transport damage occurring? ........................................................ 10

Transporting and installing the dryer....................................................................................... 11

Storing the dryer ..................................................................................................................... 13

Technical product description 14

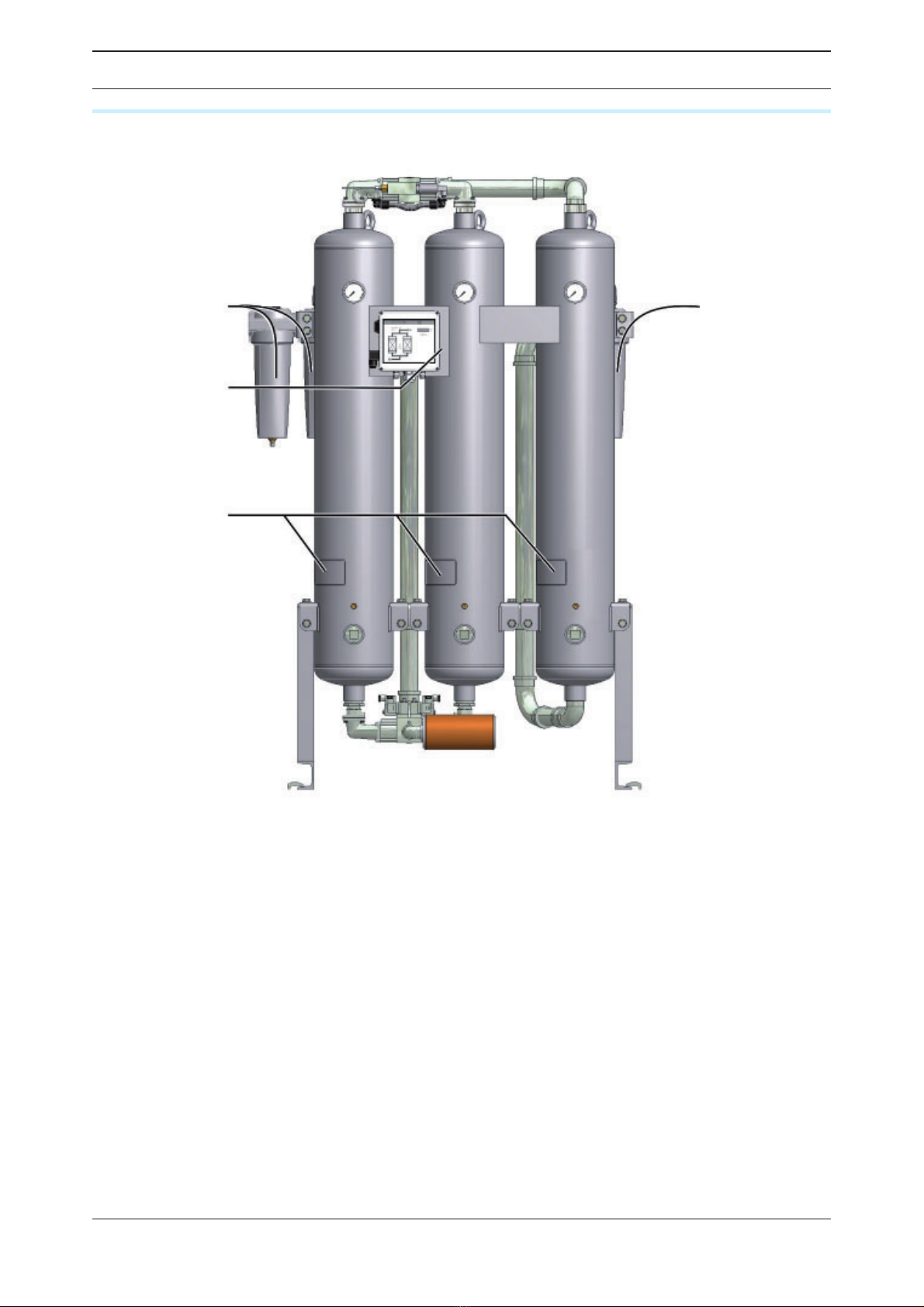

Summary Drawing Standard Dryer*........................................................................................ 14

Function description ............................................................................................................... 14

Available options..................................................................................................................... 17

Installation 18

Preconditions for installation .................................................................................................. 18

Connect piping ....................................................................................................................... 19

Installing the electrical connection.......................................................................................... 20

Start-up 22

Requirements for initial start-up ............................................................................................. 22

Setting times of the operating phases .................................................................................... 23

Overview of operating and control elements .......................................................................... 23

Start up dryer.......................................................................................................................... 26

Changing cycle mode (optional) ............................................................................................. 28

Monitoring dryer operation 29

With dewpoint-sensing control (optional) ............................................................................... 29

Shutdown and restart dryer 30

Emergency shutdown ............................................................................................................30

Depressurising and shutting down the dryer .......................................................................... 30

If work is to be carried out on the electrical system ............................................................... 31

Restart .................................................................................................................................... 31

Maintenance and repair of the dryer 33

Notes on maintenance............................................................................................................ 33

Regular maintenance intervals................................................................................................ 34

Instructions for use of the dongle ........................................................................................... 35

Daily maintenance tasks ......................................................................................................... 36

Maintenance work to be completed every 12 months............................................................ 37

Notes on further maintenance work........................................................................................ 39

Identify and eliminate faults 40

Summary of faults................................................................................................................... 40

Annex with technical documentation 44