Paul Wegener PWBlogg N6/40 User manual

Operating manual

Data acquisition system

PWBlogg

Type: N6/40

Paul Wegener GmbH

Paul Wegener GmbH

Marienstraße 24

D-06493 Ballenstedt

3. Edition 2013, Editing Date 08/13

© Paul Wegener GmbH, Ballenstedt

All rights reserved. No section of the operating manual may be replicated or processed, duplica-

ted or distributed using electronic systems in any way (print, photocopy, microlm or other me-

thods) without prior written permission of the Paul Wegener GmbH.

Design and specications are subject to change without notice.

2

Operating manual of data acquisition system PWBlogg

The data logger PWBlogg N6740 is in accordance with the directive 94/9EG (ATEX) as operatio-

nal supplements falling in category II 3 G for safe use within gas explosion hazard area of zone 2

deliverable.

The data logger with ignition protection type nA is a non-sparking operating resource with low pow-

er input according to DIN EN 60 079-15.

Please, pay attention to the following note on safety:

• The online-outlet must only be used when there is no existence of an explosive atmosphere.

When the system is not used, the online-outlet has to be closed using the protective cap.

• Check whether there is a necessity of embedding into the potential equalization of the equipment

or the metering point. This potential equalization can happen via process (pressure) connection.

• Charging the accumulator must only be done outside of the ex-area (provided that there is no

explosive atmosphere.

• Damaged devices must not be operated anymore. Please contact manufacturer for purpose of

repair.

• Allsubsequentmodicationstothedeviceresultintheconsequencethatasecureuse

isnomoreguaranteedwithinex-zone2andtheEC-declarationofconformitylosesist

validity.

3

Safetyprecautions

Power supply of the data measurement and storage device is provided by a built-in lithium ion ac-

cumulator. Please consider the following notes on safety during operation of the devices:

• Charging must only be done by the provided charger

• Charging must be done away from easily inammable items

• Do not short circuit lithium ion accumulator

• Burning accumulators must never be extinguished by water! EXPLOSION HAZARD!

• Do not throw into re! EXPLOSION HAZARD!

• Do not charge unattended

• Do never open battery cell! EXPLOSION HAZARD!

• Do not use damaged accumulators!

• If electrolyte touches skin, immediately rinse skin with plenty of water and soap and consult a

doctor.

• If electrolyte touches eyes, immediately rinse the eyes with plenty of water and consult an oph-

thalmologist.

• Recycle completely discharged accumulators only.

Attention: The device consists of electrostatically sensitive components. Opening

thedevicemustonlybedonebymanufacturerorbyauthorizedpersons.

Safetyinstructionsforuseinex-zone2

Paul Wegener GmbH

4

Contents

1 Start-up instruction 5

2 Data logger PWBlogg N6/40 5

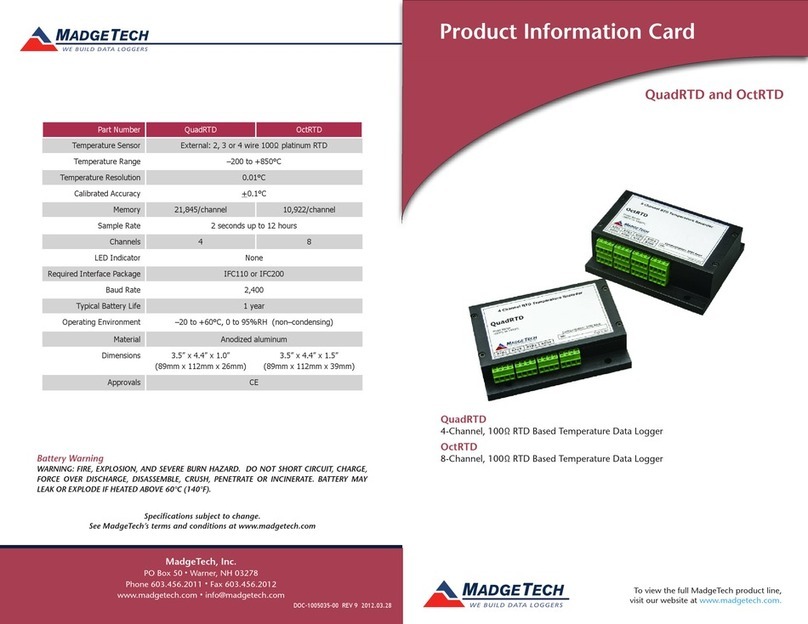

2.1 Data logger parameters 6

2.2 Error sources 7

2.3 Data communication 7

3 Charging the built-in accumulator 9

4 Technical specications 9

4.1 Data logger 9

4.2 Explosion protection (optional) 10

4.3 Data memory 10

4.4 Estimation of accumulator service life 10

5 Recycling of batteries and old appliances 10

6 Troubleshooting 12

Operating manual of data acquisition system PWBlogg

5

1 Start-upinstruction

Please note the following references during the rst initiation of the data logger:

• Install the software PWB-Soft including driver for the USB cable on your PC/laptop.

• Thereafter, connect the data logger to the PC/laptop using the provided PC data cable. For that,

take an unused interface of your PC.

• Start the software.

• Set up the serial interface in the dialog box „Settings“ of menu item „File“. You will recognize the

interface by the indication (USB).

• Establish connection between PC and data logger via „Connection“.

• Make all necessary settings in dialog eld „Conguration“. In particular, note that a 1 minute

sample rate is adjusted and start measurement is dated ahead by one year when delivering the

device in order to take care of the accumulator.

• After conrming by „OK“, the data logger will be congured again and the memory will be clea-

red. Measurement can start now.

• Note that measurement starts only when exceeding the preset time of measurement start.

2 DataloggerPWBloggN6/40

The data logger has been particularly developed for logging pressure and temperature readings.

Because of its solid stainless steel case, the data logger is particularly suitable for net analysis in

the eld of gas and water. The measurement range begins at 50 mbar.

Data logger

The data logger has an integrated analog digital converter with high resolution which is responsible

for logging and digitizing pressure and temperature readings. A microprocessor stores the readings

in the integrated memory. At its highest expansion stage, it can log 3,8 million readings. Data logger

parameterizing as well as reading and evaluating performance data is done on any PC, laptop or

netbook with Windows operating system by using PWB-Soft 2.1. Just a USB interface for connec-

ting the reading cable is necessary.

Pressure measurement

Pressure can be recorded both relatively and absolutely. Relative pressure mesurement is done ze-

ro-referenced against ambient air pressure on site. A waterproofed pressure equalization element

provides pressure equalization inside the housing. To protect the pressure equalization element

optimally from permanent moisture penetration by submergence of the metering point, this element

is connected to the data logger by a tube. The pressure equalization element can be optimally po-

sitioned by a exible fastener.

When taking absolute measurement, no pressure equalization is necessary as pressure is measu-

red against vacuum or a xed pressure. To calculate relative pressure, the absolute reading can be

offset against the air pressure metered on-site and, hence, the relative pressure can be determined.

But this methode is predominantly qualied for pressure reading in the bar range!

6

Paul Wegener GmbH

2.1 Dataloggerparameters

Following, relevant settings for recording and saving performance data can be adapted to measu-

rement requirements by means of the conguration dialog of the PWB-Soft on PC/laptop/netbook/

pocket PC:

• Identication (eg company address)

• Short text (location, project number)

• Start measurement (date/time)

• Intervall 1 and interval 2

• Threshold defaults for analog channels

• Way to store performance data (ring memory / linear memory)

Start measurement

The start measurement determines date and time of measurement commencement. Hence, this

eld undertakes two important tasks. On the one hand, a synchronous measurement start for land

measuring can be set (all loggers commence measurement at the same time). On the other hand,

this eld is used for permanent deactivating measurement. As long as start measurement is not

reached, the logger is in energy saver mode. When the logger is not used, that way it can be simply

deactivated.

Identication/Short text

The elds Identication and Short text can be used for saving any descriptive information eg loca-

tion or project. The Short text can additionally be useful as default for saving performance data on

PC, laptop or netbook.

Interval 1 und interval 2

Two increments (sample rate) for logging and saving performance date can be set. Interval 1 is

adjustable from 1s up to 1h and is used for logging performance data during normal operation. In-

terval 2 can be set from 1s (optional 10ms) up to 1min. It will be activated once a threshold violation

is recognized.

Threshold monitoring

The data logger provides specifying thresholds and records threshold violations by means of a se-

cond sample rate. Additional to the threshold, a hysteresis can be specied

Important parameters to monitor thresholds are described as follows:

Storage mode

The storage mode species whether performance data are supposed to be always recorded or in

case of an alarm only. That way it provides event-driven data recording.

Sample mode

The sample mode can be set to „limit value monitoring“ or „standard“. At „standard“ mode, interval

1 values are measured and recorded (depending on memory saving mode). In case of a threshold

violation a redirection to interval 2 is done where measuring is carried out as long as the threshold

violation is cancelled (in consideration of adjusted hysteresis values).

The setting „permanent limit value monitoring“ means permanent sampling in interval 2. This leads

to an immediate identication of threshold violations. Thereafter, the memory interval 1 will be redi-

rected to interval 2. Please note that frequent sampling of transducers increases power consump-

tion of data logger and decreases economic life-time of the battery!

Shorted alarm storage

In case of a threshold violation normally data recording will be continued with interval period 2. The

period of data recording can be much shorter than expected. To avoid it, the option „shorted alarm

storage“ can lower that period of time where interval 2 for storage is used. The storage is limited to

a maximum of 2 x interval 1 (eg 2 x 5 min). Subsequently, it is continued to measure in interval 2

but recorded just with the cycle of interval 1.

Password protection

The conguration can be protected via password against unauthorized access. Without knowledge

of password, it is not possible to clear stored data or to change conguration of the data acquisition

system.

Operating manual of data acquisition system PWBlogg

7

The analog signals of transducers are converted into a digital value with resolution of 8 bit, 12 bit,

14 bit or 16 bit. The following table demonstrates the difference between resolutions by means of

a 16 bar transducer. The values, represented in PWB-Soft program or on LCD must be rounded to

the defaulted number of decimal places so that the increment between two neighbouring values is

not always identical.

ADU digital steps reading resolution

8 bit 256 62,5 mbar

12 bit 4096 4 mbar

14 bit 16384 1 mbar

16 bit 65535 0,25 mbar

Table: AD conversion, resolution

Potential error sources are non-linearities of AD converter which are irrelevant on resolution of 8

bit or 12 bit. However, another important one is the digital step at small resolutions. At the limit of

two sequent digital values, the tolerance between the measured (in digital steps presentable) and

the real value (other sources of error excluded) already amounts ½ resolution step. As in the table

8 bit is equivalent to 31,25 mbar. Additionally, there are device-dependent sources of error such

as temperature drop or deterioration of components. At resolutions as 14 bit and 16 bit, they have

much importance.

2.2 Errorsources

2.3 Datacommunication

The specially developed software PWB-Soft provides data communucation with the data logger

N6/40. Any necessary parameters on measurement are set here. Fot that purpose this software

provides different dialog windows.

8

Paul Wegener GmbH

Performance data evaluation can be done in tabular form or as chart.

Individual periods can be enlarged by the integrated zoom function.

Operating manual of data acquisition system PWBlogg

9

• For charging the accumulator, use the provided original charger exclusively

• Make sure that the charger‘s specied input voltage corrensponds to your local supply voltage.

• The used power socket must be accessible throughout entire charging process.

• While charging, temperature must be between +10°C and +45°C.

• The status LED‘s of the charger indicate charge state during process (red = charging, green =

charging nished)

• Charging an empty accumulator takes about 3 hours.

• You can inform yourself on accumulator‘s residual capacity by means of the PC software PWB-

Soft.

• To preserve the accumulator, you should deactivate measurement when not needed for some

time by setting measurement start ahead. The ideal storage residual capacity is about 20%,

never store with an empty accumulator.

Note:Depthdischargedamagestheaccumulatorpermanently.

When falling below minimum voltage, data logging will be stopped. The data logger will be operated

in power-saving mode. If the accumulator‘s residual capacity falls below 20%, then, at the latest, it

should be recharged. We recommend 100% charging prior to any operation.

The accumulator must not be replaced by user. If for your N6/40 a new accumulator is needed,

forward the device to the manufacturer for replacement.

3 Chargingthebuilt-inaccumulator

4 Technicalspecications

4.1 Datalogger

Case stainless steel, approx. 140 x Ø40 mm

Degree of protection IP67

Transducers pressure transducer DS1/40 0...50 bar up to 0...70 bar

optional: temperature transducer, in controller integrated -20...60°C

Data memory 256kB, up to 3,8 MB

Threshold adjustable upper and lower limit value and hysteresis

Sample rate freely adjustable 1s up to 1h

AD converter 8 bit (256 digital levels, ±½ LSB)

12 bit (4096 digital levels, ±1LSB)

14 bit (16384 digital levels, ±1LSB)

16 bit (65536 digital levels, ±1LSB)

Real time clock deviation 5 ± 23 ppm (∆f/f0) at 25°C

Storage mode ring memory mode(overwrites oldest data at full memory or linear memory

mode (stops at full memory)

Interface serial interface, 9600 Bd, max. 115200 Bd

when reading data

Power supply 3,7V lithium ion accumulator (2600 mAh)

Operating/storage

Temperature -20..60°C

Paul Wegener GmbH

10

Used electric appliances, batteries and rechargeable batteries are subject to particular statutory

provisions. Batteries, rechargeable batteries and electric appliances must not be disposed with the

household waste. The end user is obligated to return them by the law. Used electric appliances,

batteries and rechargeable batteries can be disposed at collecting points, municipal disposal areas

or by manufacturer / supplier.

The Paul Wegener GmbH as seller of batteries and electric appliances fullls its take-back obliga-

tion and disposes used batteries and old electric appliances free of charge.

This take-back obligation, however, limits itself to used electric appliances, batteries and recharge-

able batteries which belong or belonged to the product range of the Paul Wegener GmbH and the

amount which was delivered by the Paul Wegener GmbH.

The end user bears the forwarding charges.

Storage times of the internal memory result from the number of channels occupied, from preset

sample intervals 1 and 2 as well as from storage and sample mode. If the reading resolution is > 8

bit (12, 14 or 16 bit), possible storage times will halve themselves.

Non sparking II3G Ex nA IIB T4 according to EN 60079-0 and EN 60079-15 for safe use within

the explosion-hazard area of zone 2.

4.2 Explosionprotection(optional)

4.3 Datamemory

5 Recyclingofbatteriesandoldappliances

4.4 Estimationofaccumulatorservicelife

Following table contains accumulator durations depending on preset sample rate and based on

following assumptions:

• constant ambient temperature of 20°C

• constant power consumption of built-in components

• no capacity loss by aging of the accumulator

• no fault current due to defective components

As the above-mentioned exceptions are unrealistic, to be on the safe side, we assume 60% of the

real accumulator capacity is provided only. For calculation, the underlying standby current of the

system will be increased by factor 2. Though deviations (positive, negative) can not be excluded

from mentioned duration!

Sample rate in s Batteryservicelifein

days

1 131

2 202

5 297

10 352

15 376

30 402

60 417

Operating manual of data acquisition system PWBlogg

11

EG-DECLARATIONOFCONFORMITY

Herewith we declare that the data acquisition systems of type range

PWBlogg N6/40

complies with the directive 2004/108/EG in reference to electromagnetic compatibility and 94/9/EG

for use according to regulations in consideration of explosion-hazard areas. The data acquisition

system was developed according to following harmonizing of standards:

EN 61000-6-3 subject basic standard for emitted interference – emitted interference for living

quarters, business- and trade as well as small rms

EN61000-6-2 subject standard for interference resistance– industrial sector

EN 60079-0 electrical equipment for explosion-hazard areas, section 0: general requirements

EN 60079-15 electrical equipment for explosion-hazard areas, section 15: construction, test and

marking of electrical equipment of ignition protection type „n“

Marking for safe use in explosion-hazard areas with category 3G (zone 2):

II3GExnAIIBT4

Manufacturer: Paul Wegener GmbH

Marienstraße 24

D-06493 Ballenstedt

Tel.: +49(0)39483 96 300

Fax.: +49(0)39483 96 400

Internet: www.paul-wegener.de

e-mail: info@paul-wegener.de

Thesafetyadviceoftheproductdocumentationmustbefollowed!

Ballenstedt, 01.08.2013

Wegener

Managing Director

12

6 Troubleshooting

Problem Measure

Software reports:

„No modules found!“

Check the following:

• whether the correct interface has been chosen

• whether the cable to data logger and PC is connected properly

• A defective accumulator can not be charged, not even by mains adapter. The data

logger can not be connected without power supply! In this case, have the accumula-

ter replaced by manufacturer.

No data stored in controller Check, whether:

• a preset start time has been reached

• all transducers and cables are functional

Have checked by manufacturer, whether:

• accumulator is functional

• moisture has been intruded into the data logger

Accumulator is low Have it replaced by manufacturer

Password forgotten Read out performance data, send reading le to manufacturer

Software does not read

per-formance data comple-

tely or reports errors when

reading out the data

Check, whether:

• the PC data cable is properly connected

Have checked by manufacturer, whether:

• moisture is intruded in the data logger

• accumulator of the data logger is functional

Connect it directly again (menu item „module/connect“) and start reading performance

data again.

Modern computers have power management functions. During shutdown of hard disk

or change into standby mode the CPU can be busy temporarily, so that it „oversleeps“

the sent characters. This leads to abort of reading out. If necessary, extend periods for

activating standby functions or switch off the power management.

Paul Wegener GmbH

Operating manual of data acquisition system PWBlogg

13

14

Paul Wegener GmbH

Operating manual of data acquisition system PWBlogg

15

16

Paul Wegener GmbH

Tel.:

Fax:

Internet:

e-mail:

+49 (0) 39483 96 300

+49 (0) 39483 96 400

www.paul-wegener.de

info@paul-wegener.de

Most recent emendment: 01.08.2013

PWB FORM 2085-EN13

Paul Wegener GmbH

Marienstraße 24

D-06493 Ballenstedt

Table of contents

Other Paul Wegener Data Logger manuals

Popular Data Logger manuals by other brands

WIS International

WIS International WISARD-550 Operator's guide

American Thermal Instruments

American Thermal Instruments LOG-IC 360 user guide

Aanderaa

Aanderaa SMARTGUARD 5100 operating manual

ORSIS

ORSIS COAMCT installation manual

Teracom

Teracom TCW220 user manual

Sirius Technologies

Sirius Technologies ST301U operating manual