pauly CPV1038 01 Series User manual

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 1/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

pauly

Operating instructions

Optical Anti-Collision Device

TypeCPV1038

E_52692.pdf

Features

Functionalities

Cat. 2, PL=c, SIL 1

in acc. with EN ISO 13849 and

EN 62061

Two optical systems in one

enclosure

Two adjustable independent

clearance distances

Clearance distance up to 50 m

High performance in terms of

detection

Pollution warning/ Anti Sabotage

system

Integrated test system –a highly

dynamic process reproduces the

light reflected by the reflector

Safe mounting of reflectors

oCollision protection

oDistance monitoring

Only for cranes that run on a common crane

track or rail.

Revision Index: 2019-29

Revision date: 12.04.2019

Processed by: tb

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 2/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

Table of Contents

1. Identification / General Remarks 3

1.1 Product versions / Plates representations 3

1.2 Name and address of the manufacturer 3

1.3 Applied standards and technical specifications: 4

1.4 Definition of symbols: 4

2. Product description 4

2.1 Product mark 4

2.2 Intended use, general function and area of application 5

2.3 Incorrect use and foreseeable misuse 5

2.4 Safety information 6

3. Definitions –technical data 7

4. Operating instructions 9

4.1 Information on this technical description 9

4.2 Device description 9

4.3 Description of function 10

4.3.1 Triangulation triangle 10

4.3.2 Approach movement 11

4.3.3 Continually self-testing 12

4.3.4 Possible movement of the crane 12

4.3.5 Movement of the crane is stopped 12

4.4 Pollution control function 13

4.4.1 Principle 13

4.4.2 Pollution example 13

4.4.3 Pollution Indicator –meaning of the different circuit states 14

4.5 Assembly 15

4.5.1 Horizontal arrangement of the triangulation triangle 15

4.5.2 Distance monitoring accuracy 16

4.5.3 Taking the tolerances into consideration with respect to clearance distance 17

4.6 Information on assembly 18

4.7 Adjustment using the “light beam method” 19

4.8 Electrical connection 20

4.9 Applicable documents 22

5. Maintenance and cleaning 22

6. Contents of the EU Declaration of Conformity 23

7. Decommissioning 24

8. Spare parts 24

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 3/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

1. Identification / General Remarks

1.1 Product versions / Plates representations

CPV1038

CPV1038*01

Bezeichnung

General description

Optical Anti-Collision Device

Typ

Type

CPV1038

CPV1038 /R/2M20/i/… 5269x…

0393

Seriennummer

Serial number

Baujahr

Year of manufacture

Reichweite

Range

0,5…25/50m

Versorgung

Supply

Schutzart

Protection mode

IP65

Reaktionszeit

Response time

80ms

Fotoelektrik Pauly

59368 Werne / Germany

www.fotoelektrik-pauly.de

Bescheinigungsnummer

Certificate number

HSM 09 079

Sicherheits-Integritätslevel

Safety Integrity Level

1

gemäß DIN EN 62061

according to DIN EN 62061

Sicherheitskategorie

Safety category

2

Performance

Level

c

MTTFd[a]

86

gemäß DIN EN ISO 13849-1

according to DIN EN ISO 13849 -1

Bezeichnung

General description

Optical Anti-Collision Device

Typ

Type

CPV1038*01

CPV1038*01 /R/2M20/i/… 5269M01x…

0393

Seriennummer

Serial number

Baujahr

Year of manufacture

Reichweite

Range

1…25m

Versorgung

Supply

Schutzart

Protection mode

IP65

Reaktionszeit

Response time

80ms

Fotoelektrik Pauly

59368 Werne / Germany

www.fotoelektrik-pauly.de

Bescheinigungsnummer

Certificate number

HSM 09 079

Sicherheits-Integritätslevel

Safety Integrity Level

1

gemäß DIN EN 62061

according to DIN EN 62061

Sicherheitskategorie

Safety category

2

Performance

Level

c

MTTFd[a]

86

gemäß DIN EN ISO 13849-1

according to DIN EN ISO 13849 -1

1.2 Name and address of the manufacturer

Fotoelektrik Pauly GmbH

Wahrbrink 6

59368 Werne, Germany

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 4/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

1.3 Applied standards and technical specifications:

EN ISO 13849

Safety of machinery –Safety-Related Parts of Control

Systems

EN 62061

Safety of machinery - Functional safety of safety-related

electrical, electronic and programmable electronic control

systems

1.4 Definition of symbols:

Must follow –Critical information

This symbol describes safety warning of dangerous situations and indicates

necessary measures and / or appropriate precautionary measures.

Failure to comply can result in death or property damage.

Must know –Important information

This symbol describes e.g. situations that could damage the product or

devices in its vicinity, and accordingly provide appropriate action.

The sign identifies particularly important passages.

2. Product description

2.1 Product mark

CPV1038 und CPV1038*01: high performance reflex light barriers for distance monitoring tasks

using the triangulation method.

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 5/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

2.2 Intended use, general function and area of application

Acknowledgement of the contents of these operating instructions forms part of the intended use.

Notes and safety information must be observed in particular.

The Model CPV1038 System is

a mechanism for collision protection or distance monitoring exclusively for stationary power

driven cranes that run on a common crane track. The reflector centre on the other crane must

be situated at the optical device (lens) level.

intended for use in weatherproof applications where the direct influence of the weather is

prevented

exclusively intended for use in machinery within the meaning of the scope of EN 60204-32

(Electrical Equipment of Cranes), EN 15011 (Bridge and gantry cranes) and EN 12077-2

(Limiting devices).

When used as collision protection device, the moving crane is prevented from colliding e.g. brought

to a standstill in reference to the other crane (opposite crane).

When used as a distance monitoring device, a risk triggering approach of cranes is detected.

At least one device is required for each crane and the corresponding reflector is positioned at the

opposite wall/crane.

2.3 Incorrect use and foreseeable misuse

It is not permissible to use the device in any manner that deviates from the contents of the

operating instructions or operate it outside the prescribed areas of application.

The CPV1038 is not suitable for operation in

areas with significant challenging environmental requirements (e. g. potentially explosive

areas).

areas of excessive pollution influence where a proper function may not be ensured, despite

regular cleaning of the optical elements.

applications where normal operation due to excessive fog, excessive steam or excessive

smoke cannot be guaranteed.

systems where disconnecting the current does not lead to a safe mode.

collision protection and distance monitoring for cranes which run on a curved crane/rail track.

collision protection and distance monitoring for cranes which do not run on a common

crane/rail track.

collision protection of e.g. Industrial trucks or similar transport equipment.

use without reflector (please refer section 3)

Any technical alteration will result in cancellation of the product warranty!

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 6/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

2.4 Safety information

System-related movement tolerances of crane system components and the possible

associated effects on the switching behaviour of the distance monitoring system

must be taken into consideration when planning crane systems.

A correct assembly and alignment of the system are essential for the correct

operation of the system’s safety function.

The set clearance distance could be reduced, e.g. by fog, steam or smoke.

During limited vision, e.g. caused by fog, steam or smoke, the function of the

distance monitoring system must be checked by moving the cranes together.

The light beam on the system must not be interrupted, for example by obstructions

or suspended objects. It is essential that proper attention is paid to this during

assembly and operation of the system.

Before commencement of work, the system’s safety function must be checked by

moving the cranes together (daily functional check).

The installation of the light barriers may only be performed by authorized technical

personnel who have the requisite professional expertise to install electrical devices on

crane systems.

The device must be immediately taken out of operation in the event of damage or leaks in

the housing, cable or line entries.

Requirements resulting from provisions relating to cranes must be applied under all

circumstances.

All different components with safety functions must be taken into account of the safety

parameters (PL, PFHd, MTTFd), e.g. an optionally required additional external power supply

or output side follow-up circuit.

Further or supplementary protective measures may be required on the basis of risk

assessments for special areas of application, e.g. restart inhibit. According to

EN ISO 13849, an automatic restart may only take place, if no hazardous situation exists.

The distancing system may not be bridged.

The crane operator and/or the crane manufacturer must be aware and comply to the

information that applies to his area of deployment; this also applies to the product, cables

and lines installation

If condensation on the reflector surface cannot be excluded for an application with high air

humidity or/and abrupt change in temperature then an anti-fogging coated reflector version

must be used. A suitable reflector type will be model 4R100BLAF or model 18R100BLAF

(see catalog of applicable documents in section 4.9).

If the device is operated in conjunction with other components such as control systems or

sensors, the corresponding user instructions must be heeded.

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 7/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

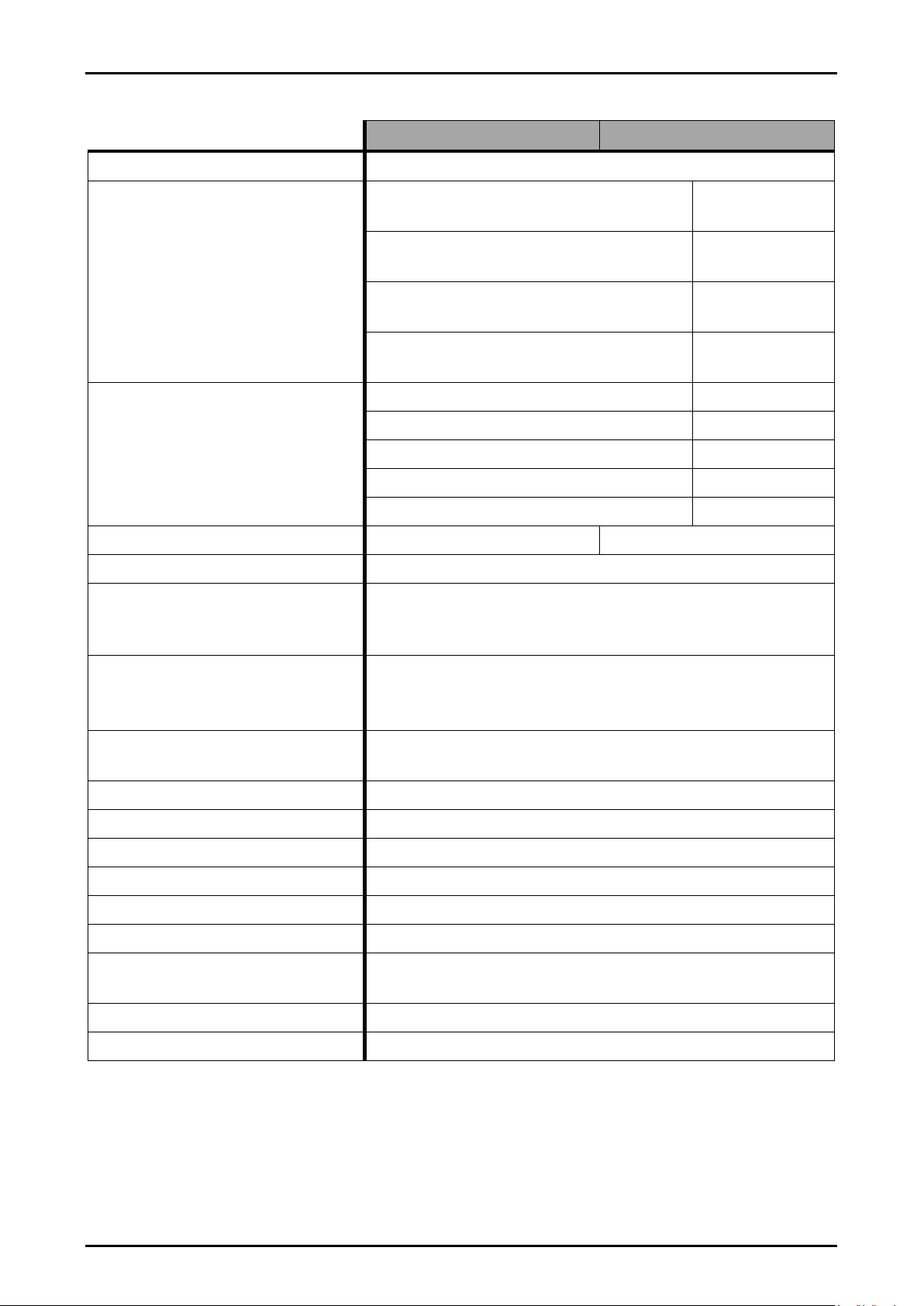

3. Definitions –technical data

CPV1038

CPV1038*01

Certificate no.

HSM 09 079

Safety ratings of complete system

in acc. with EN 62061 respectively

EN ISO 13849-1

Safety Integrity Level (SIL)

SIL 1 in acc. with

EN 62061

Performance Level (PL)

PL c in acc. with

EN ISO 13849-1

Category

Cat. 2 in acc. with

EN ISO 13849-1

DC [%]:

60 in acc. With

EN ISO 13849-1

Safety ratings of the electronic

device

in acc. with EN ISO 13849-1

PFHd[h-1]:

6,61 x 10-7

MTTFd[a]:

86

nop [n/a]

8760

CCF

95

Mission time TM[a]

20

Maximum clearance distance

50 m

25 m

Optical systems

2

Safety-related tolerance of the

systematically distancing

accuracy

Maximum 9%

(in accordance with diagram fig. 4.4.3)

Safety-related tolerance of the

distancing accuracy due to

environmental influences

Additional 8%

(by reason of environmental influences,

e.g. fog, steam, smoke)

Power supply / output or current

consumption

(: Option)

230VAC ± 10 %

/ 16VA

115VAC ± 10 %

/ 16VA

42…48VAC ± 10 %

/ 16VA

24VDC + 20 % / - 10 %

/ ~ 700mA

Connection

2 x cable glands; terminal strip

Switching outputs

Main contact (to switch off the

crane movement)

for each optical system: 2 x relay NO contacts;

supervised and force guided

Status message

for each optical system: 1 x relay NC contact

Pollution warning

1 x relay change-over contact

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 8/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

CPV1038

CPV1038*01

Switching capacity

Min. switching current

10 mA @ > 5 V

Main contact (to switch off the

travel movement)

AC1: 5 A @ 230 VAC DC1: 6 A @ 24 VDC

AC15: 2 A @ 230 VAC DC13: 1 A @ 24 VDC

Status message

AC1: 5 A @ 230 VAC DC1: 6 A @ 24 VDC

AC15: 1 A @ 230 VAC DC13: 1 A @ 24 VDC

Pollution warning

AC1: 6 A @ 250 VAC DC1: 6 A @ 24 VDC

AC15: 2 A @ 250 VAC DC131: 1 A @ 24 VDC

Electrcal life

DC1: > 1 x 106@ max. switching capacity

AC1, AC15, DC13:> 2 x 105@ max. switching capacity

Switching rate

3 / s

Access time

≤80 ms

Switching displays

Switch indicator

for each optical system: 2 x LED green

Level indicator (for sighting

reflector)

for each optical system: 4 x LED red (DIANA)

Transmitted light

850 … 880 nm, invisible

Steady light resistance

> 80 k lux

Operating mode

Alternating light, dynamic, continually self-testing

Signal mode

Dark switching

Housing

Cast aluminum

Protection mode

IP65 –protection against dust and jets of water

Weight

~ 5000 g (without adjustment flange)

Operating temperature

- 25 °C … + 60 °C, non-condensing

Climatic conditions

in acc. with EN 60721-3-3:1995, table 1

max. relative humidity (d): 95%;

max. solar radiation (j): 700W/m²;

Condensation (m): none;

Wind-driven precipitation (n): none;

Formation of ice and frost (including freeze-thaw) (p): none

Special functions

Exterior test system

The safety-related switching outputs will be switched off and

the movement of the crane will be halted if there is

insufficient detection capacity

Sabotage protection

Covering of light barriers is detected and will lead to the

switching off of the safety-related switching outputs and the

crane movement will be halted

Pollution warning

The light signal level is evaluated continuously

Accessories

Reflectors

(intended use as per the clearance distance)

4R100BL

0.5 … 25 m

1 … 25 m

4R100BLAF

0.5 … 25 m

1 … 25 m

18R100BL

0.5 … 50 m

1 … 25 m

18R100BLAF

0.5 … 50 m

1 … 25 m

Adjustment flange

JF57S

Regarding CPV1038*01: Device without optical sensing behaviour in range 1 to 6 m.

1

With spark suppressor only, see Section Fehler! Verweisquelle konnte nicht gefunden werden.

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 9/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4. Operating instructions

4.1 Information on this technical description

These operating instructions contain information on the correct use of the CPV1038 distance

monitoring system. They constitute an integral part in the scope of supply.

4.2 Device description

A distance monitoring system or collision protection system consists of a reflex light barrier and a

reflector. The CPV1038 distancing system sets two definite clearance distances separately from

each other. Each individual clearance distance is set in accordance with the triangulation principle.

The electronics for the reflex light barrier system are housed in an enclosure with IP 65 protection.

A protection roof protects the lens system of the reflex light barrier against external conditions, for

example rain, snow or dust. The protection roof is fixed on the enclosure lid. For opening the lid,

the protection roof can be folded up.

An adjustment flange is available for mounting the reflex light barrier. This enables fast and

accurate assembly and alignment.

There are two optical systems in the enclosure. The two optical systems can be set to different

clearance distances independently of each other. Each individual clearance is set by means of a

system-specific spindle axle.

Each system is assigned its own external test unit. The external test units generate continually

defined light signals (infra-red light), which impact on the internal receiving unit through the

receiving lens. The external test units continuously simulate the light reflected by a reflector.

A highly dynamic signal processing procedure evaluates the rays of light pulses received. This

evaluation means that the distance monitoring system is fail-safe, shock resistant, resistant to

external light and stable.

When the set clearance distance is reached, the reflector on the opposite crane can be viewed.

The view of the reflector and any internal component faults decisively alter the dynamic signal

processing and accordingly slow down or stop the crane’s movement. When farther clearance

distance is reached, the crane’s speed is slowed down. Once the nearer clearance distance is

reached, the crane completely stops (safe state).

Each system of the reflex light barrier continuously performs tests on its function using the highly

dynamic signal processing procedure –“continually self-testing”. Any worsening in visibility

conditions or direct pollution of the lenses leads to weakening of the signal. Significantly weakened

signals that could substantially impair the function are detected at an early stage and directly lead

to the stopping of the crane (safe state).

The high optical performance of the system means the distance monitoring system can be used for

distances up to 50 m and still have very considerable reserves in terms of function.

Travel movement can be halted if the light barrier is made “blind” due to the lens being covered

over at close range –“sabotage protection”.

The integrated signal-emitting pollution evaluation is effective for the current reflector view and

evaluates the current signal level. If the signal level on the active reflector view is too low the

pollution is displayed via a signalling contact.

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 10/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

The requisite reflector plates on the reverse are available in different sizes. The format to be used

for the reflector is determined by the clearance distance and the resultant triangulation angle.

For clearance distance

reflector area (width x height)

Model

up to 25 m

400 mm x 100 mm

4R100BL(AF)

up to 50 m

900 mm x 200 mm

18R100BL(AF)

The reflector comprises a carrier plate with individually mounted reflector elements on it. The

reflector elements are fastened with screw connections that cannot be loosened with conventional

tools. Moreover, due to their design, the reflector elements cannot get be misplaced. The special

design of the reflector plate means that the reflector elements are protected against strong

pollution deposits and overflowing water. It is not possible to dismantle the reflector using

conventional tools without damaging it.

4.3 Description of function

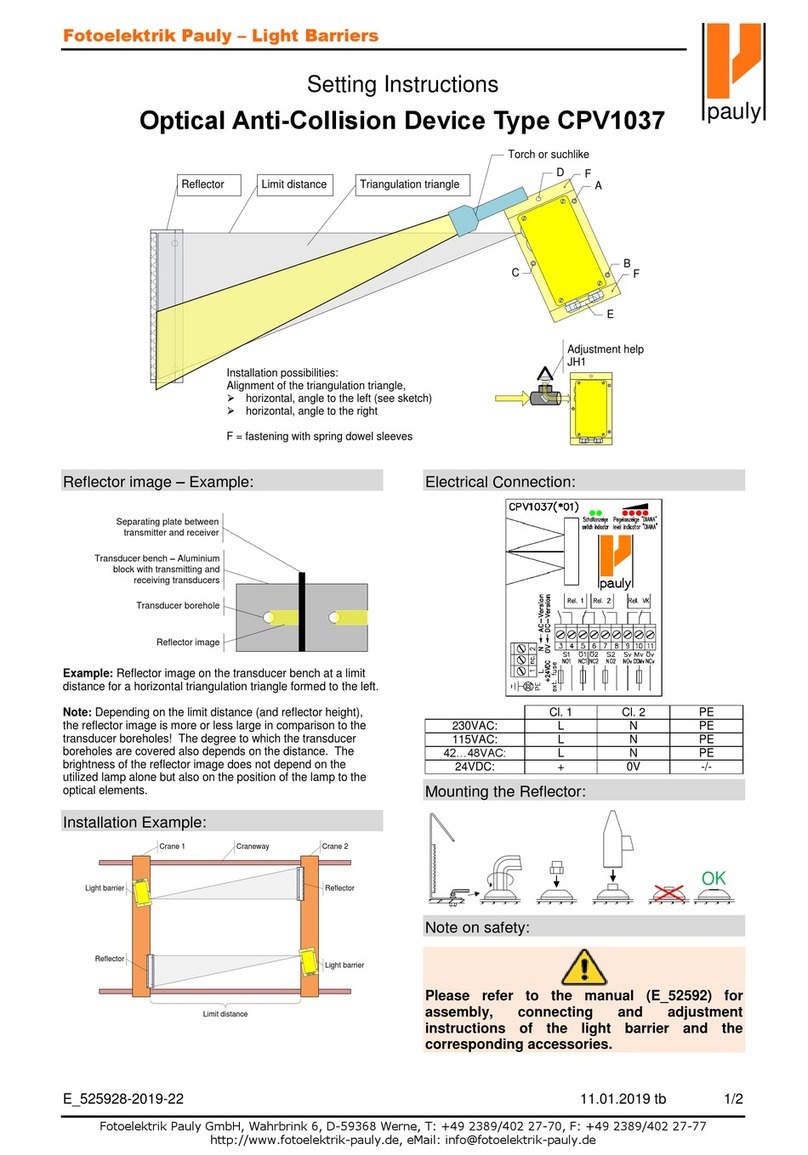

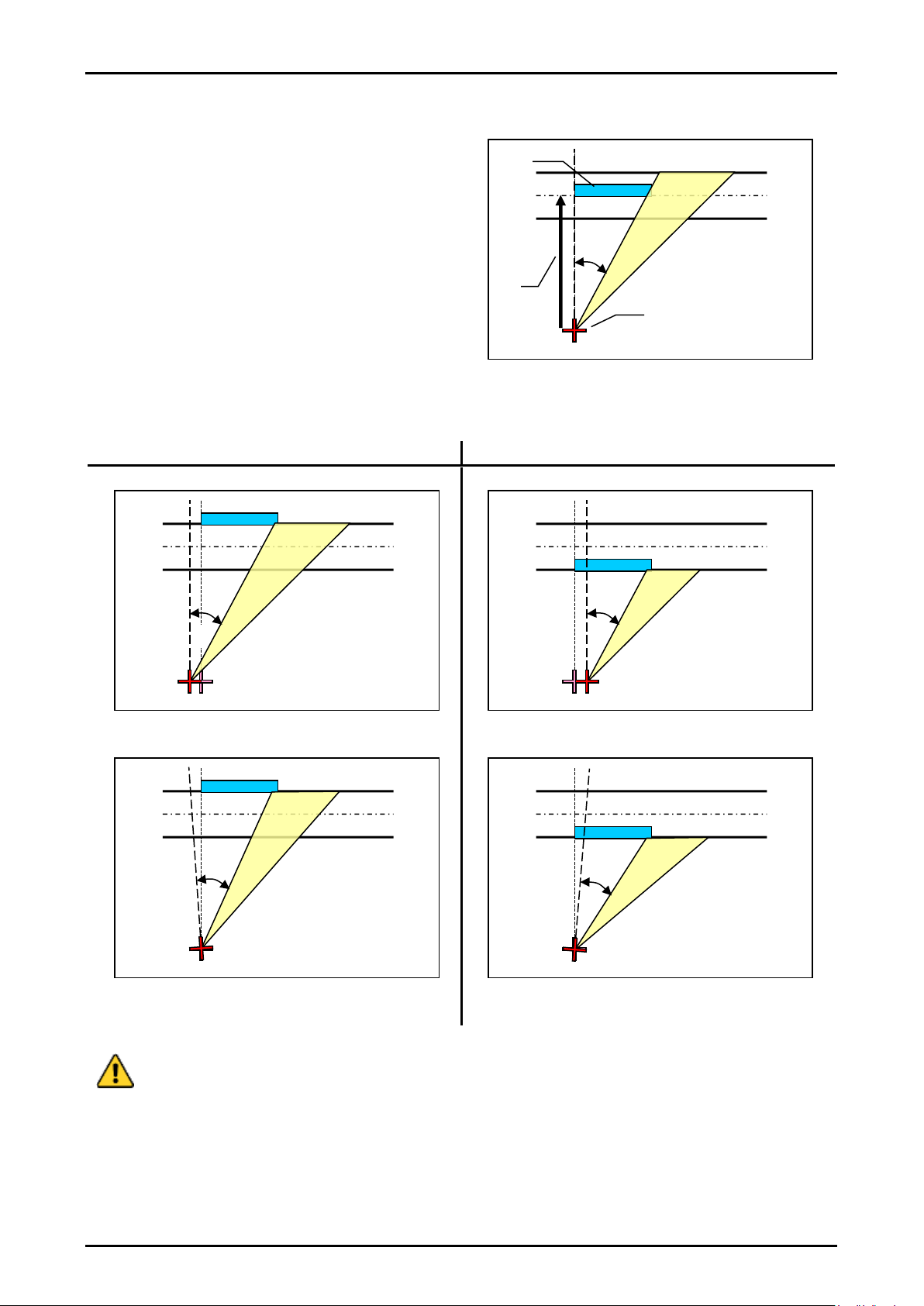

4.3.1 Triangulation triangle

The clearance distance is determined using the

triangulation method. For this purpose, the high

performance reflex light barrier must be aligned at an

angle to the direction of movement of the crane

towards the reflector affixed to the other crane. The

right-angled triangulation triangle is formed as

follows: (when sighted from the light barrier)

from the distance between the two cranes –

connecting line between the installation location

of the light barrier and the left reflector

edge = adjacent side to angle >< and

from the width of the reflector = opposite leg to

the angle >< and

from the outer light cone form the reflex light

barrier = hypotenuse of the right-angled triangle.

Fig.: 4.3.1

Triangulation triangle

Reflex-light barrier

Crane 2

Crane 1

Reflector

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 11/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.3.2 Approach movement

The reflex light barrier illuminates the edge of the

reflector during the approach movement, when the

set clearance distance is reached. The first system in

the reflex light barrier sights the reflector. The

switching outputs of the first system of the reflex light

barrier are switched off –pre-disconnection.

If the approach is continued and the second set

clearance distance is reached, the second reflex light

barrier illuminates the edge of the reflector. The

switching outputs of the second system in the reflex

light barrier are switched off.

The safety-related switching outputs

switched off and crane travel is

brought to a halt! The cranes stops

with a safe distance from each other.

Fig.: 4.3.2-1

Fig.: 4.3.2-2

The level of the light signal depends on the degree of coverage by the light spot of the reflex light

barrier on the reflector. Even very small amounts of cover lead to very high signal levels. This

results in a signal level with extremely steep edges.

Crane 2

Crane 1

Attention

Crane 2

Crane 1

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 12/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.3.3 Continually self-testing

During the entire operation the light reflected by the reflector is reproduced by each external test

unit. Each external test unit generates a modulated light signal and shines through the receiver

lens and onto the own receiver. The modulated test signal received is evaluated by the highly

dynamic signal processing procedure. In this manner, a functional check of all optical and

electronic construction elements is conducted simultaneously. The light barriers performs self-tests

continuously.

If the reflector is not sighted and if no optical or electronic faults are present, the NO contact of two

separate and mutually monitored switching relays for releasing the travel movement are switched

on. The design has resulted in relays that are specially qualified. Positively driven contacts here

ensure a high degree of reliability. The power via the contacts has to be limited by an overcurrent

protection device.

4.3.4 Possible movement of the crane

Prerequisite: The reflector is undetected. The actual distance between the cranes is greater than

the set clearance distances. The beams of the reflex light barriers goes past the reflector. There

are no optical or electronic faults.

Effect: The crane is cleared for movement. For each system, two safety-related relays are switched

on and these signal the clearance for crane movement through the closed NO contacts. 2 green

status LEDs are switched on directly with the relays and visualize the clearance for crane travel.

4.3.5 Movement of the crane is stopped

Prerequisite: The set clearance distance is reached during the approach travel. The reflector edge

of the other crane moves into the beam of the first or second system of the reflex light barrier.

Effect: The reflex light barrier detects its emitted light signal and switches the system associated

two safety-related relays off. The green status LEDs darken. The travel movement is stopped.

REMARK:

Switching off the safety-related relays, depending on the task, can be used either to reduce the

speed or stop the travel movement.

In accordance with its purpose, the two systems serves to influence the cranes movement by

means of a pre-disconnection and a main disconnection.

Once the first distance has been reached, the pre-disconnection typically slows down the crane

movement while the crane movement is stopped once the main disconnection is reached.

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 13/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.4 Pollution control function

4.4.1 Principle

Primarily, the photoelectric barrier monitors itself continuously, independent of the travel

movements. The light signal level, which is sent from the external test unit through the receiver

lens, is evaluated at all times. The weakening of a specific signal level due to contamination of this

test device (see also example in section 4.4.2) leads initially to a pollution warning signal. If the

pollution is not eliminated, and with the increasing pollution, the specific function signal is further

weakened then this leads to the stopping of the travel movement and the safety-related switching

relays is switched off.

In a secondary effect, the reflector signal level is evaluated with active reflector detection. The

weakening of a specific signal level here also leads to a pollution warning signal.

The pollution on the external test unit of the light barrier will be much more sensitively evaluated

than the pollution on the reflector.

The pollution warning signal is displayed with the “VK-relay”. The triggered relay means that there

is a pollution which must be eliminated as soon as possible, where the location of the pollution

should be derived from the circuit states of the VK-relay and the states of the safety-related relays

(see also section 4.4.3).

4.4.2 Pollution example

Dust precipitation on an external test unit which can

lead to a Pollution warning signal and/or blocking of

the system.

In case of cleaning of the reflex light barrier system,

the pollution of lenses, external test unit and the

reflector are to be particularly eliminated

For the cleaning procedure, please note in addition

the chapter 5 on “Maintenance and cleaning” of the

respective operating instructions.

Fig.: 4.4.2

An appropriate warning system should be triggered by the pollution warning relay to

provide timely detection and removal of pollution to maintain system availability.

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 14/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

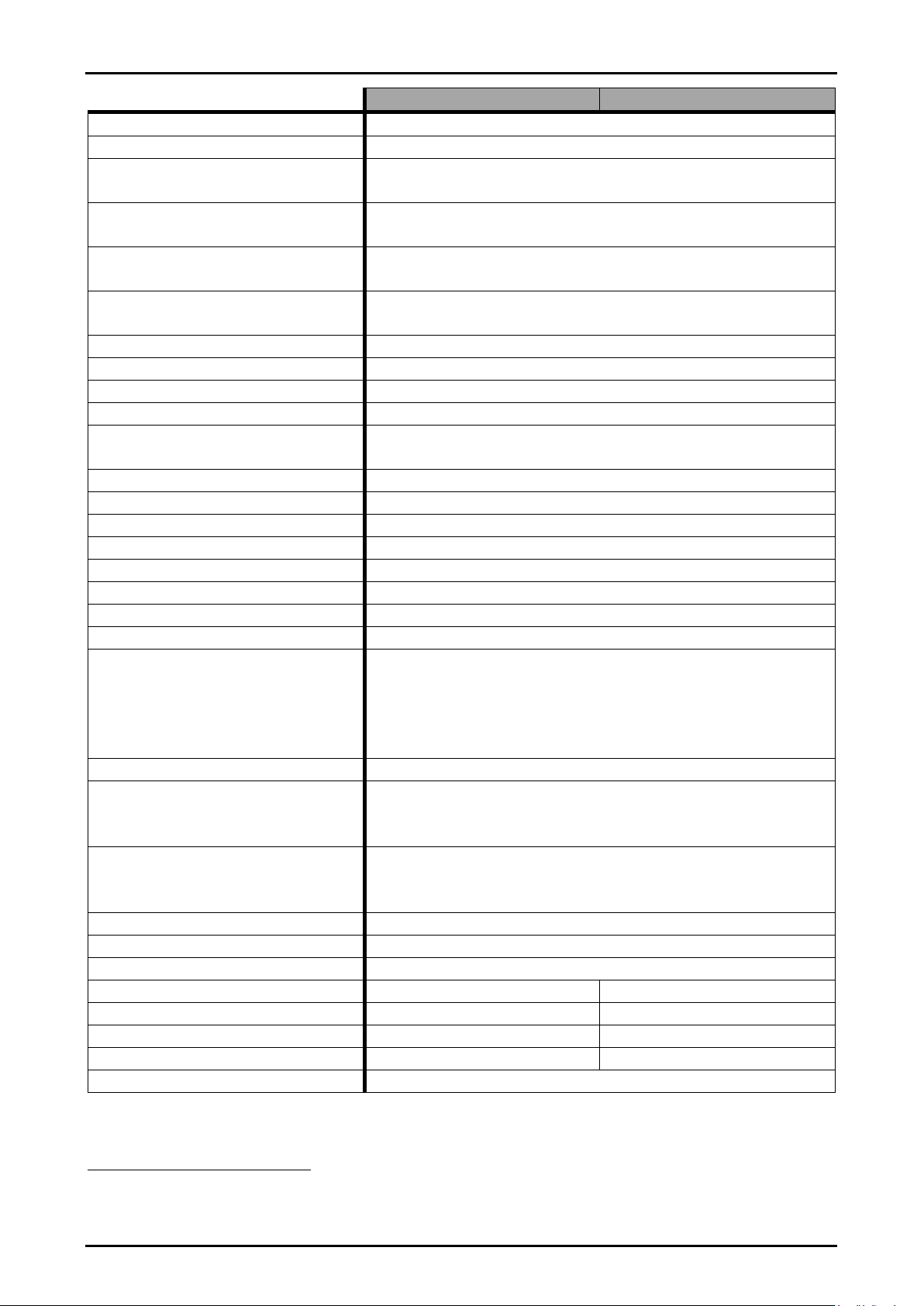

4.4.3 Pollution Indicator –meaning of the different circuit states

Table: 4.4.3

Drive action

Specific signal

level external test

unit

Specific signal

level reflector

view

Pre-switching

safety-related

relay, circuit state

Main-switching

safety-related

relay, circuit state

VK-relay circuit

state

Meaning

Distance travel without

reflector view

Higher than

V-level

-

on

on

off

No pollution on LB

Less than

V-level, but

higher than

switch-off level

-

on

on

on

Pollution on LB –Prompt

cleaning of light barrier and

reflector required!

Less than

switch-off level

-

off

off

on

Severe pollution on LB with

transition into the secure status

(stopping of the travel movement)

–Immediate cleaning of light

barrier and reflector required!

Approach travel with

reflector view

-

Higher

than

V-level

off

on

off

No pollution on the reflector

-

Less

than

V-level

off

on

on

Pollution on the reflector OR

incomplete reflector view in the

pre-switching mode

-

off

off

on

Pollution on the reflector OR

incomplete reflector view in the

main switch-off mode

Legend / Explanations

V-level

Pollution warning level (default setting by manufacturer)

LB

Light barrier

Pollution on the

reflector

The Pollutants on the reflector has to be assumed if the limit distance has

been reached and the corresponding safety-related relays switched off, AND

after switching off the safety-related relays a sufficiently large distance has

been driven which should generates a larger reflector signal level than the

specific V-level itself.

Incomplete

reflector view

A permanently very small reflector view with signal level less than V-level

BUT signal level high enough to stop the travel movement.

Pollution Control

signal

The pollution warning signal is displayed with a relay (VK). The relay is

switched on with a delay of approx. 3s up to 5s if the current signal level

does not exceed the specific V-level during this period.

The pollution warning signal is reset immediately if the current signal level

exceeds the V-level again.

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 15/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.5 Assembly

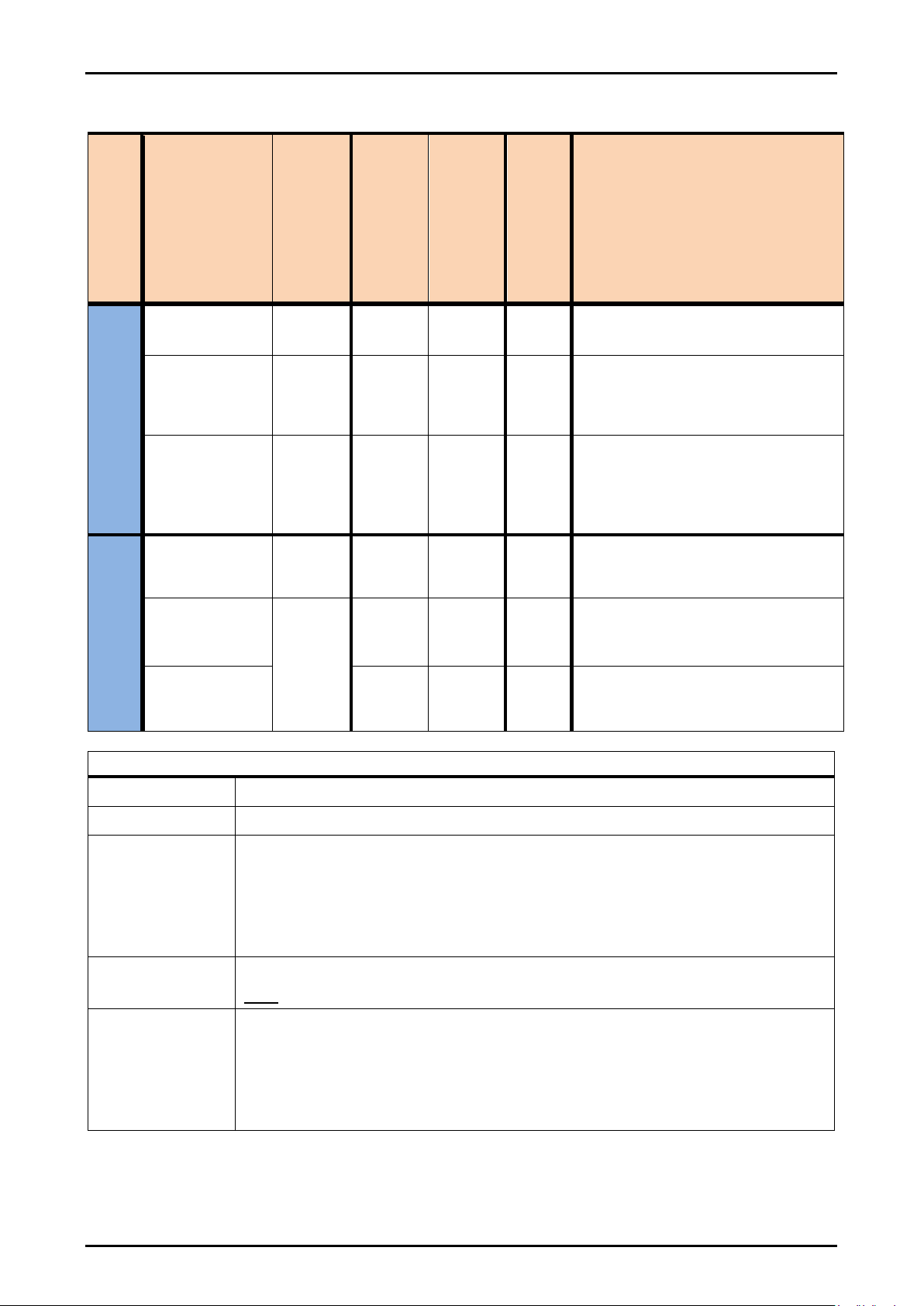

4.5.1 Horizontal arrangement of the triangulation triangle

Reflector () and light barrier-CPV1038 ()

are mounted horizontally. The triangulation

triangle () then lies in the space horizontally.

is mounted onto the crane using the JF57S

adjustment flange. An imaginary line () that

runs parallel to the crane track () connects

on the right edge of the reflector (). The

angle () of the triangulation triangle should

be selected such that the is pointing

towards the left reflector edge when the limit

distance is reached () (see also chapter on

“adjustment”).

The triangulation triangles must be designed in such a way that the light barrier optics do not

look into each other, directly or via reflections. Examples:

Fig.: 4.5.1-2:

Proper arrangement

Fig.: 4.5.1-3:

Proper arrangement

Fig.: 4.5.1-4:

Wrong arrangement

Fig.: 4.5.1-5:

Wrong arrangement

Note to fig. 4.5 1-3: The distance between the applied outer edge of the device and the reflector

must be at least 200mm.

The Reflector and CPV1038 must be mounted

at the same height. This means that the

middle of the reflector () must be positioned

at the same height () as the middle of the

lens system of CPV1038 (). The height of

both parts should be taken from a common

reference point ().

It is essential to ensure that both optical systems can still view the reflector when both

cranes have been moved together up to buffer distance!

Mount the reflector close to the edge of the crane bridge. Avoid blocking the visible area

of the reflector.

Fig.: 4.5.1-1: Example of a triangulation triangle

clamped to the left

Fig.: 4.5.1-6

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 16/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.5.2 Distance monitoring accuracy

The clearance distance () is determined by

the fixed beam angle set (). The accuracy

and the reproducibility of the clearance

distance depend on the movement tolerances

of the individual crane components. Horizontal

lateral shifts or rotations of the crane bridges

have a direct impact on the installation position

of the reflex light barrier () or the reflector ()

and accordingly shorten or lengthen the

clearance distance set.

Lengthening the clearance distance

Shortening the clearance distance

System-related movement tolerances in crane systems, crane/rail track and the

associated impact on the switching behaviour of the distance monitoring system should

be taken into consideration at the planning stage for the crane system and crane/rail

track.

Fig.: 4.5.2-1: Set clearance distance

Fig.: 4.5.2-2: Shifting to the left

Fig.: 4.5.2-3: Shifting to the right

Fig.: 4.5.2-4: Rotation to the left

Fig.: 4.5.2-5: Rotation to the right

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 17/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.5.3 Taking the tolerances into consideration with respect to clearance distance

The very high performance of the system facilitates “tolerant” functional behaviour. However a

certain tolerance in terms of distance behaviour must be taken into account for the very reason of

this high performance in order for perfect, planned functional behaviour of the system to be

guaranteed at all times in the long term (e.g. aging). For this reason the following possible

tolerances must be taken into consideration from the start.

Fig.: 4.5.3: Tolerance in relation to the triangulation angle

The safety-related tolerances in the distances accuracy must be taken into account by

adding them to the planned clearance distance.

In case of applications with environmental influences, e.g. excessive fog, excessive

steam or excessive smoke, additionally 8% of the planned clearance distance must be

considered

Case example with and without environmental influences:

Planned distancing = 15 m

Reflector width = 400 mm (crane reflector 4R100BL)

Calculated triangulation angle 1.5°

Tolerance in accordance with diagram fig. 4.5.3: 7% ≙1,1 m

Additional tolerance because of environmental influences: 8% ≙1,2 m

Minimum distancing to be set

without environmental influences = 16.1 m + movement tolerance.

with environmental influences = 17,3 m + movement tolerance.

Deviation in % from the

clearance distance

Triangulation angle in degrees

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 18/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.6 Information on assembly

The mounting has to be done in such a way that a misalignment caused by

mechanical vibration or bumps can be excluded. After finishing the fine alignment,

the transducer benches have to be tightened with the fixing screws.

The adjustment flange has to be locked with the mounting surface. Drill a hole of

6mm diameter and 20mm length close to each fastening hole and pin the

adjustment flange with the enclosed spring dowel sleeves.

The reflector must be installed in non-accessible areas or must be concealed.

The reflector should be protected from pollution by suitable measures e.g. a

protective housing.

The light beams of the systems must not be interrupted e.g. obstructions or

suspended objects. This must be taken into account at all events during assembly

and operation of the system.

It is to be absolutely ensured that the optics of the distancing assembly still has a

reflector view if both cranes have driven together to buffer separation distance!

When calculating the clearance distance the reaction time of the system must be

taken into consideration as decisive parameter for the stopping path of the crane.

The set clearance distance must be tested and recorded.

The reflector centre on the other crane must be situated at the optical device (lens) level

(see Fig. 4.5.1.6).

The devices on a crane and the adjacent crane must be mounted in such a way that their

optical system do not look into each other (directly or via reflections), Any mutual

influence must be excluded (see Fig.: 4.5.1-2…-5).

In contrast to the assembly location of the reflector, assembly of the light barrier

(optoelectronics) must take place at the site where more pollution is to be expected.

The fixture of the CPV on the associated adjustment flange must be done by means of

the provided fasteners.

The fastening of the reflector must take place using rivets, adhesive or welded

connectors or using the screws supplied (safety screws with locking wedge),so that

dismantling can only take place by destroying the fastening element.

During and after the adjustment, it must be ensured that the plastic (safety) inserted part

of the lock nut engages on the thread and the springs are pretensioned.

Assembly may only be performed by a trained professional.

Triangulation angle Δ≥1° to be set, see graph Fig.: 4.5.3: Tolerance in relation to the

triangulation angle

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 19/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.7 Adjustment using the “light beam method”

Both cranes are moved together to the limit

distance (). For the adjustment the end of

the reflector () is illuminated with a portable

spotlight () placed close to the optical unit.

With the lid of the device open, it is possible to

detect the reflection of the brightly illuminated

reflector () on the transducer bench of the

reflex light barrier ().

With the lid of the device closed, the reflector

image can be observed from outside through

the lens of the reflex light barrier using a

special adjustment help ().

The vertical adjustment of the light barrier is

set by means of the adjusting screw (). The

center of the reflector image should be

adjusted to the height of the transmitter and

receiver diode converter holes.

The slotted mounting (and ) can be used

to rotate the device at the horizontal level.

Separately accessible spindle drives –behind

the dummy screw () –can be used to set

each individual optical system separately to a

definite distancing range.

Graphical representation of the reflector image

() on the transducer bench () during the

adjustment procedure using the “light beam

method”.

The light barrier is able to sight the reflector

when the edge of the light image falls into the

transmitter hole () or receiver hole ().

If the light images of the reflector move in a

straight line and horizontally across the

transducer bench during the further approach

travel, then the triangulation triangle is

clamped absolutely horizontally. The dividing

wall () prevents an optical short-circuit

between transmitter and receiver.

See also the separate document „Setting Instructions CPV1038“

Fig.: 4.7-3

Fig.: 4.7-1

Fig.: 4.7-2

Fig.: 4.7-4: Representation of the reflector image

for a triangulation angle clamped to the right.

Fotoelektrik Pauly –Light barriers

E_52692 Ref. 2019-29 20/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.8 Electrical connection

Fig.: 4.8: Connection diagram CPV1038

Table 4.8

Terminal block

Naming

Function

1

L1 / +24V DC

Supply voltage Version ‘AC’: L1

Version ‘DC’: + 24 V

2

N / 0V

Supply voltage Version ‘AC’: N

Version ‘DC’: 0 V

PE

PE

Protective earth conductor

3 & 4

NO11

Make contact 1 (normally open contact) of system 1,

safety-related

5 & 6

NC11||NC12

Break contact of system 1

7 & 8

NO12

Make contact 2 (normally open contact) of system 1,

safety-related

9 … 11

NOv/COMv/NCv

Pollution warning changeover contact

12 & 13

NO21

Make contact 1 (normally open contact) of system 2,

safety-related

14 & 15

NC21||NC22

Break contact of system 2

16 & 17

NO22

Make contact 2 (normally open contact) of system 2,

safety-related

This manual suits for next models

1

Table of contents

Other pauly Lighting Equipment manuals