Pavone Sistemi UWT6008 User manual

Pavone Sistemi

pesatura elettronica industriale

TECHNICAL MANUAL

UWT6008 / JBX8 LCD Electronic weighing instrument

Program P32001 Rel.0.0

Rel ID 18280501

TABLE OF CONTENTS

TECHNICAL FEATURES.......................................................................................................... 3

CONNECTIONS, POWER SUPPLY, SERIAL ITEMS, USB, FIELD BUS ............................................ 4

CONNECTIONS, LOAD CELLS, OUTPUTS............................................................................... 5

INTRODUCTION .................................................................................................................. 6

FRONT PANEL OF THE DEVICE .............................................................................................. 7

KEYBOARD USE ................................................................................................................... 7

PROGRAMMING MENU ....................................................................................................... 10

CALIBRATION SETTINGS....................................................................................................... 13

LOAD CELLS BALANCING..................................................................................................... 14

WEIGHT CALIBRATION......................................................................................................... 15

ANALOG OUTPUT SETTINGS ................................................................................................ 16

SERIAL PORTS – RS232 SETTINGS.......................................................................................... 17

SERIAL PORTS – RS485 SETTINGS.......................................................................................... 17

SERIAL PORTS SETTINGS - ETHERCAT CONFIGURATION.......................................................... 18

SERIAL PORTS SETTINGS - PROFIBUS CONFIGURATION .......................................................... 19

SERIAL PORTS SETTINGS - PROFINET CONFIGURATION .......................................................... 19

SERIAL PORTS SETTINGS - ETHERNET/IP CONFIGURATION ..................................................... 20

SERIAL PORTS SETTINGS - CANOPEN CONFIGURATION ........................................................ 21

SERIAL PORTS SETTINGS - ETHERNET CONFIGURATION.......................................................... 21

I/O SETTINGS...................................................................................................................... 22

SETTING THE WEIGHTING PARAMETERS ............................................................................... 23

FILTER SETTINGS................................................................................................................... 24

FUNCTIONAL FEATURES SETTINGS........................................................................................ 25

DATE CLOCK ADJUSTMENT ................................................................................................. 27

ACCESS DISPLAY.................................................................................................................. 27

CONSULTATION OF FISCAL MEMORY ................................................................................... 28

OPERATING FUNCTIONS - CELL SIMULATION......................................................................... 28

OPERATING FUNCTIONS - SINGLE CELLS DISPLAY .................................................................. 28

LOAD CELLS EMULATION...................................................................................................... 29

OPERATING FUNCTIONS - THRESHOLD PROGRAMMING ....................................................... 30

OPERATING FUNCTIONS - STORING THE MEASURE............................................................... 30

SERIAL COMMUNICATION PROTOCOLS ............................................................................... 31

MODBUS COMMUNICATION PROTOCOLS ........................................................................... 36

FIELDBUS COMMUNICATION PROTOCOLS............................................................................ 39

CANOPEN COMMUNICATION PROTOCOLS......................................................................... 43

TECHNICAL FEATURES

Transducers power supply: 5 VCC (max. 16 cells of overall 350 Ohm)

Measuring range: -3.9 ÷ +3.9 mV/V

Input sensitivity: Min. 0.02 μV

Linearity: < 0.01% FS

Thermal drift: < 0.001% FS/ °C

Display: 128 x 64-pixel graphic LCD

A/D converter: 24 bits

Internal resolution: > of 16,000,000 points

Signal capture frequency: 12 ÷ 1000 Hz

Displayable resolution: 999,999 divisions viewable on the net weight

Divisions value (selectable): x1, x2, x5, x10, x20, x50

Settable decimals: 0.0; 0.00; 0.000; 0.0000

Filter: selectable 0.1 to 250 Hz

Keyboard: 4-button membrane

Device power supply: 12÷24 Vdc ± 15% - power consumption 4 W

Operating temperature: -10/+ 50°C (max. humidity: 85% without conden-

sation)

Storage temperature: -20/+70°C

Logical outputs: 2 relays, Max. 48 VAC/VCC, 2A each

Logical inputs: 2 opto-isolated at 12/24 VDC PNP (external power

supply)

Serial ports: 1 USB device + 1 RS232C + 1 RS485

Field bus: ETHERNET 10/100 with TCP, MODUBUS/TCP, UDP,

IP, ICMP, ARP; PROFIBUS DP; DEVICENET; PROFINET;

ETHERNET/IP; CANOPEN; ETHERCAT protocols

Optional analog output: 16-bit opto-isolated Voltage: 0 ÷ 5/10 V (min. R: 10

K Ohm), Current: 0/4 ÷ 20 mA (max. R: 300 Ohm).

Analog output calibration: From the keyboard

Analog output linearity: < 0.02% FS

Analog output thermal drift: 0,001% FS/°C

Microcontroller: ARM Cortex M0+ at 32 bits, 256KB Flash repro-

grammable on-board from USB

Data memory: 64 Kbytes expandable up to 1024 Kbytes.

Compliance with regulations: EN61000-6-2, EN61000-6-3 for EMC; EN61010-1

for Electrical Safety, EN45501 for metrology

Electric connections: Removable screw terminal boards, 3.81 mm pitch

Dimensions: 100 x 75 x 110 mm (L x H x P)

Mounting type: On DIN rail

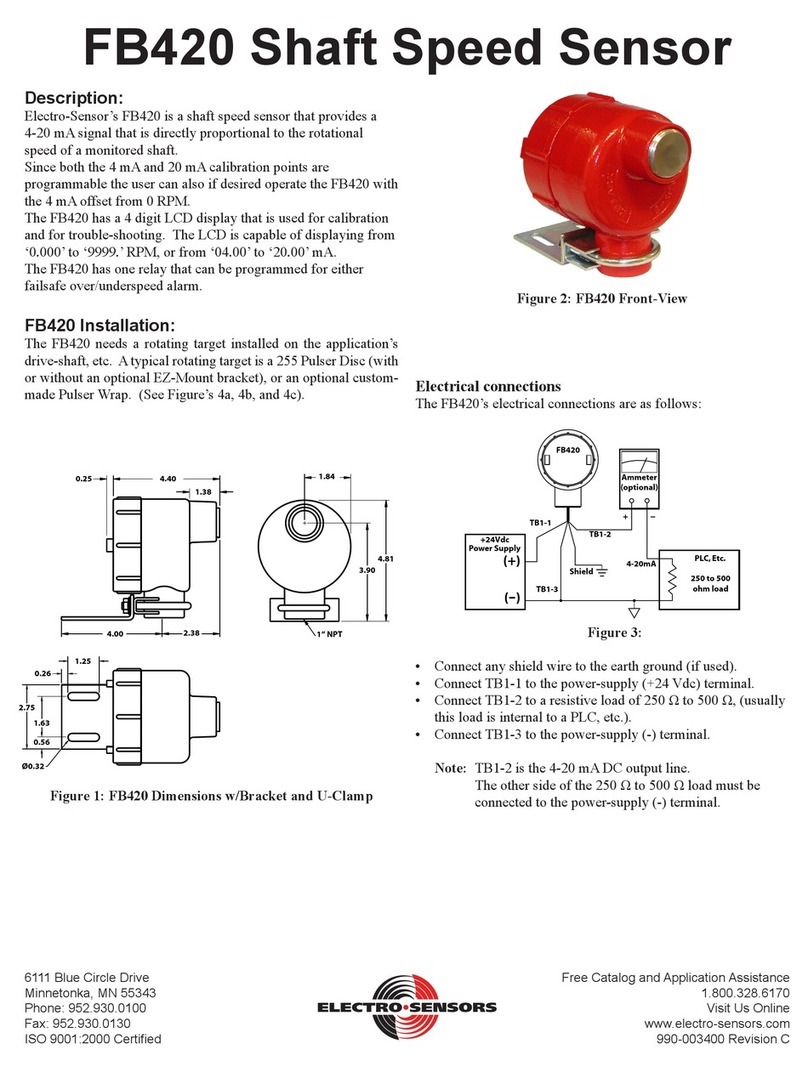

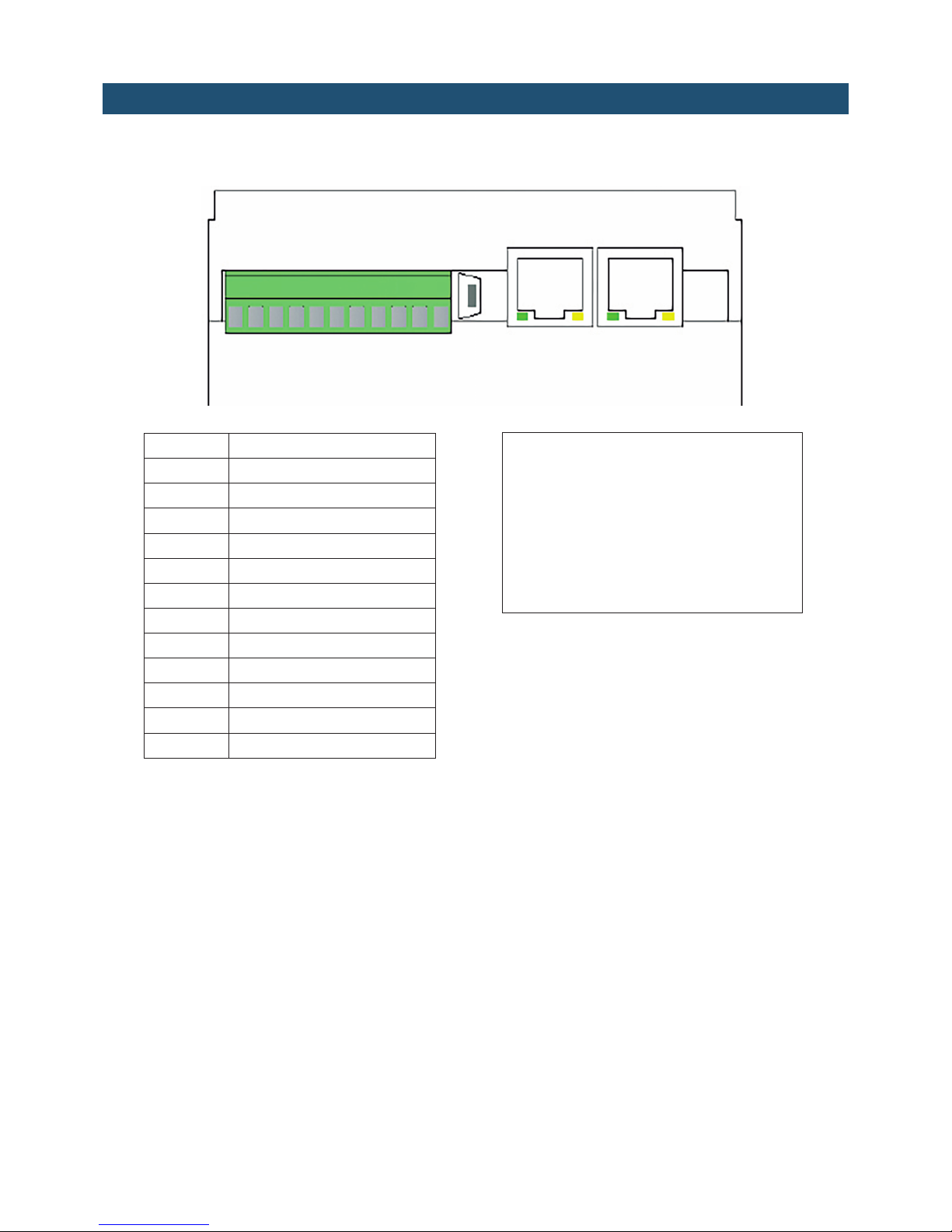

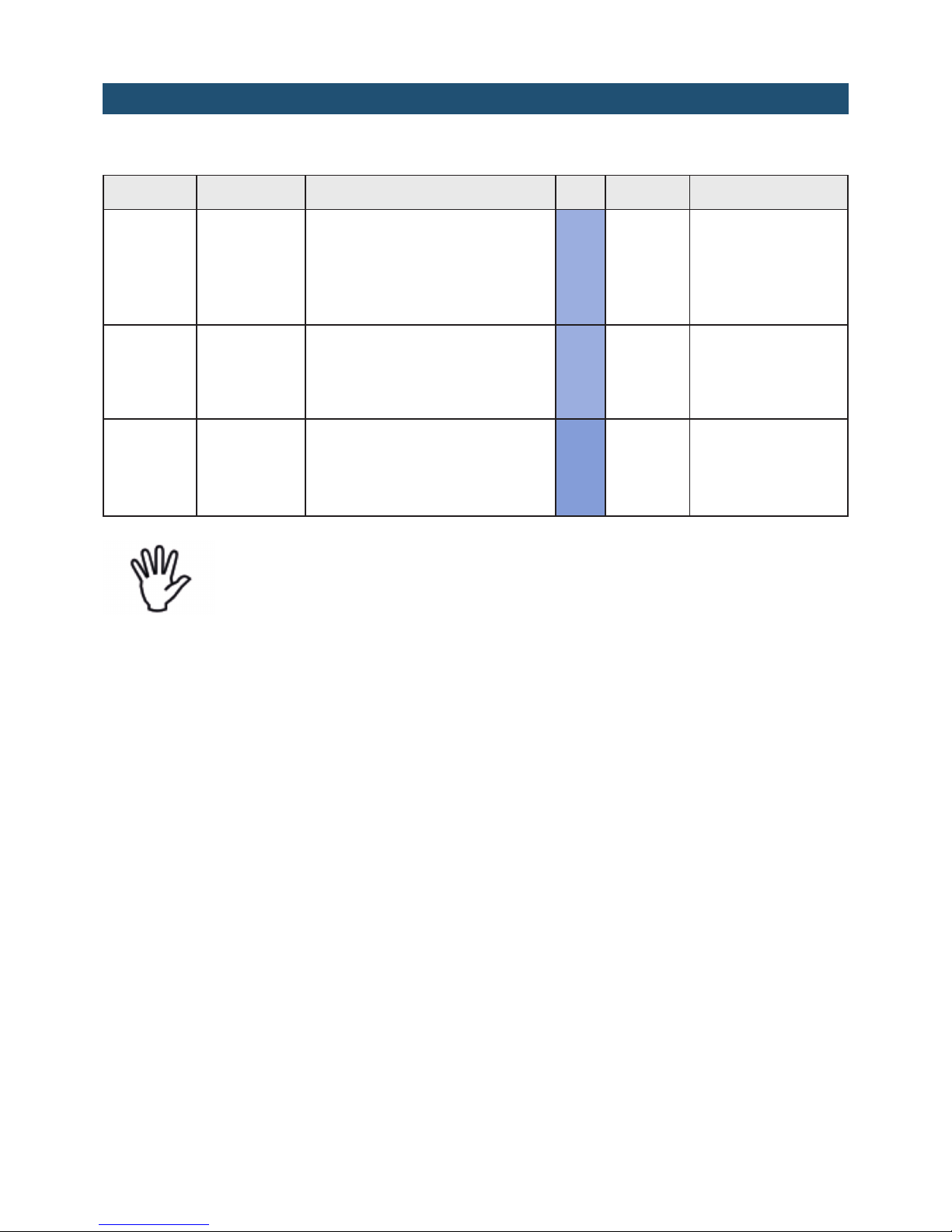

CONNECTIONS, POWER SUPPLY, SERIAL ITEMS, USB, FIELD

BUS

NUM Terminal board 3.81 mm

1 + Input 1

2+ Inlet 2

3 - Common items to inputs

4 Rs485 +

5 Rs485 -

1 TX RS232

2 RX RS232

3 GND + Serial screens

9 + 24 VDC power supply

10 - GND power supply

USB

Field bus

ETHERNET 10/100 with TCP,

MODUBUS/TCP, UDP, IP, ICMP, ARP;

PROFIBUS DP; DEVICENET;

PROFINET; ETHERNET/IP;

CANOPEN; ETHERCAT protocols

1 11

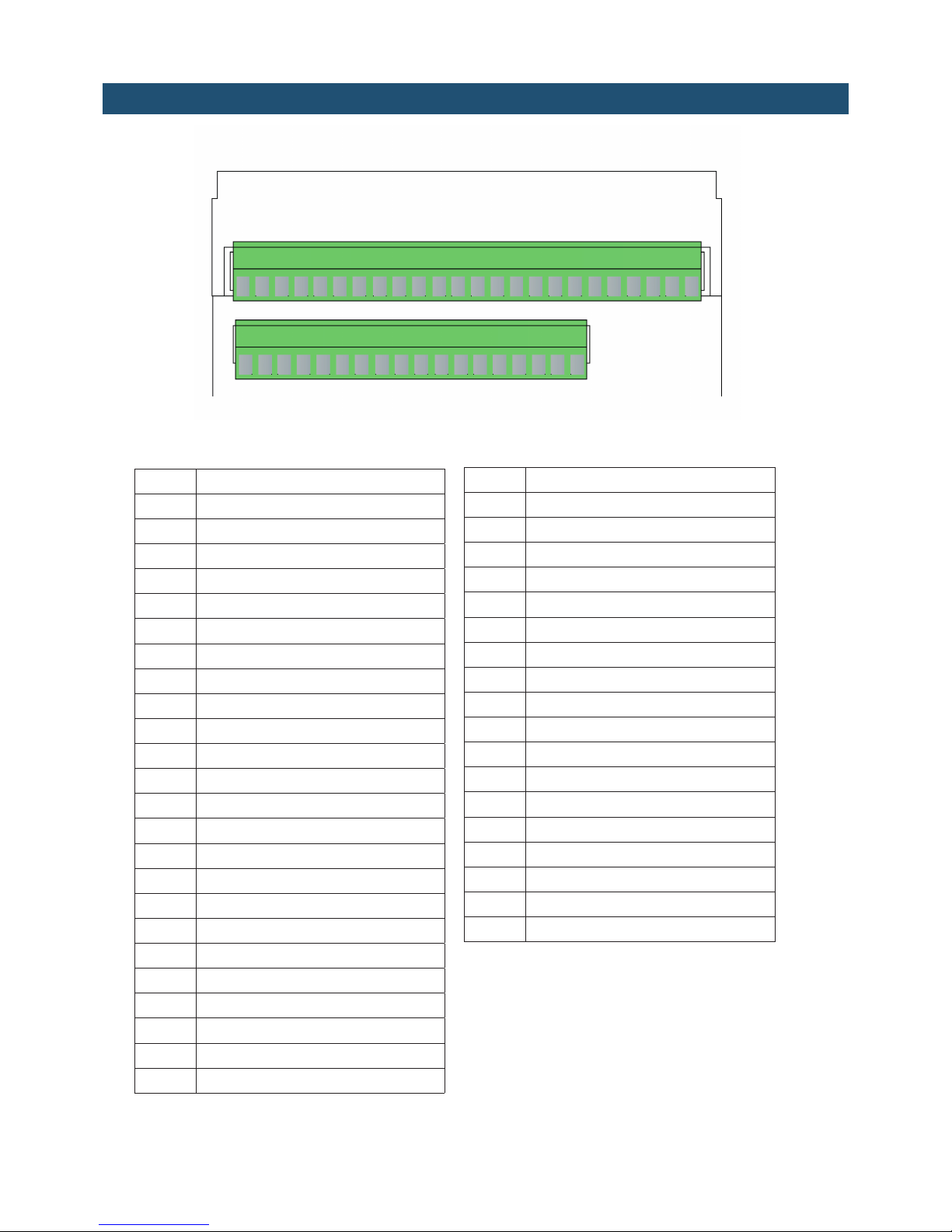

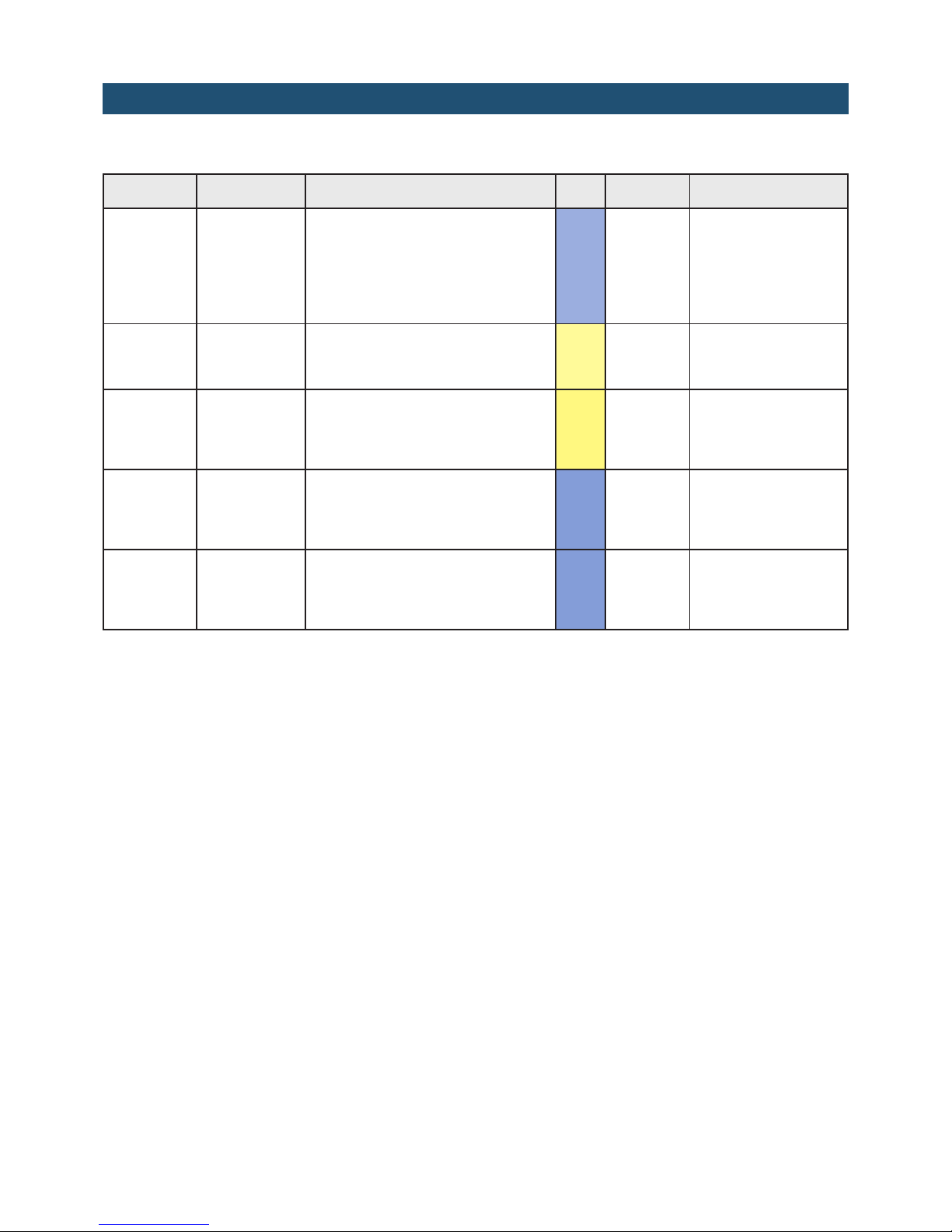

CONNECTIONS, LOAD CELLS, OUTPUTS

NUM Upper 3.81 mm terminal board

1 Cell 1 Power supply +

2 Cell 1 Signal +

3 Cell 1 Signal -

4 Cell 1 Power supply -

5 Cell 2 Power supply +

6 Cell 2 Signal +

7 Cell 2 Signal -

8 Cell 2 Power supply -

9 Reference +

10 Reference -

11 Cell 3 Power supply +

12 Cell 3 Signal +

13 Cell 3 Signal -

14 Cell 3 Power supply -

15 Cell 4 Power supply +

16 Cell 4 Signal +

17 Cell 4 Signal -

18 Cell 4 Power supply -

19 TX RS232

20 RX RS232

21 Serial GND

22 + Analog output mA

23 + Analog output V

24 - Analog output

If the cells used are 4-wire, make a jumper between Power supply + and Reference +, and between

Power supply - and Reference -.

NUM Lower 3.81 mm terminal board

25 Cell 5 Power supply +

26 Cell 5 Signal +

27 Cell 5 Signal -

28 Cell 5 Power supply -

29 Cell 6 Power supply +

30 Cell 6 Signal +

31 Cell 6 Signal -

32 Cell 6 Power supply -

33 Reference +

34 Reference -

35 Cell 7 Power supply +

36 Cell 7 Signal +

37 Cell 7 Signal -

38 Cell 7 Power supply -

39 Cell 8 Power supply +

40 Cell 8 Signal +

41 Cell 8 Signal -

42 Cell 8 Power supply -

124

25 42

INTRODUCTION

The device is a precision transmitter, the result of the most recent and advanced technology

for weighing and measuring systems of load cells. The device allows to display analog cells

separately (up to a maximum of 8 cells).

The device converts the mV signal of the load cells into a high resolution digital signal (24 bits)

for each individual cell; the sum of the points will therefore give more precise information on

the weight value captured.

The transmitter can be integrated as a slave in different network types, through various Serial

or Fieldbus communication protocols.

The common analog load cells are connected to the transmitter, instead of the expensive digital

cells. The combination provides the following advantages:

1.Independent display of the output in mV/V and of the weight value of each individual

cell.

2.Monitoring of all load cells and alarm generation for excessive cell signal drifts,

missing connections, failure of one of the cells, unbalanced weight distribution.

3.The emulative control allows the continuity of work of the weighing system even in case

of failure on one of the load cells, up to repair or replacement.

4.The equalization function automatically compensates for the differences between the

weight values detected by the load cells during the start of the scale.

5.A particular algorithm allows to equalize the corners of the scale with only 1 passage

of the sample weight (instead of the numerous steps required by the traditional

procedure with multi-turn trimmer).

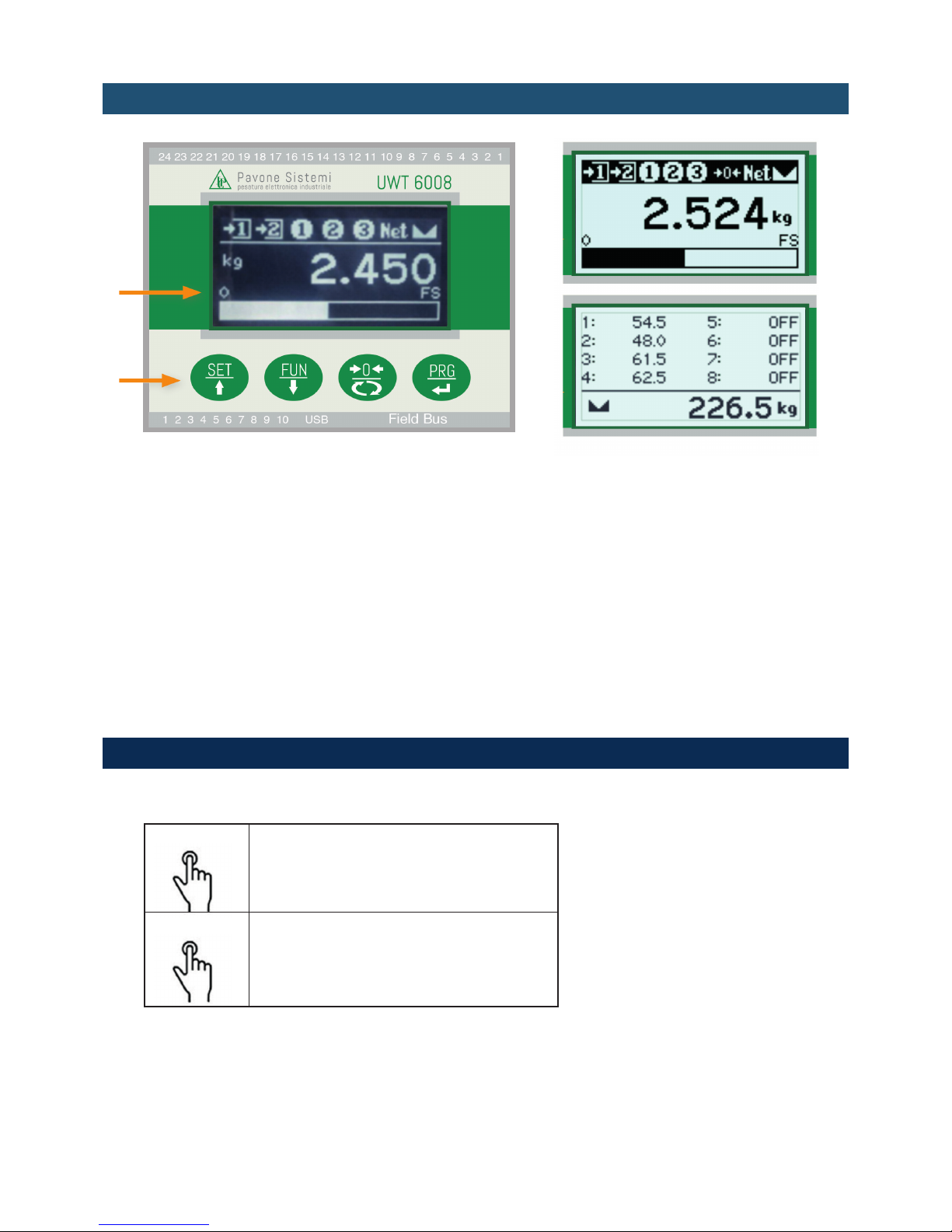

FRONT PANEL OF THE DEVICE

LCD DISPLAY

Normally the measured net weight is shown on the display. According to the various

programming procedures, the display is used for programming the parameters to be entered

in the memory, i.e. messages indicating the type of operation being carried out and therefore

helping the operator in the management and programming of the device.

STANDBY FUNCTION

The display can assume standby status, during which the brightness of the display is reduced

and the keypad is locked. All other functions of the device are ON and working.

See the paragraph concerning the activation/deactivation of the standby status.

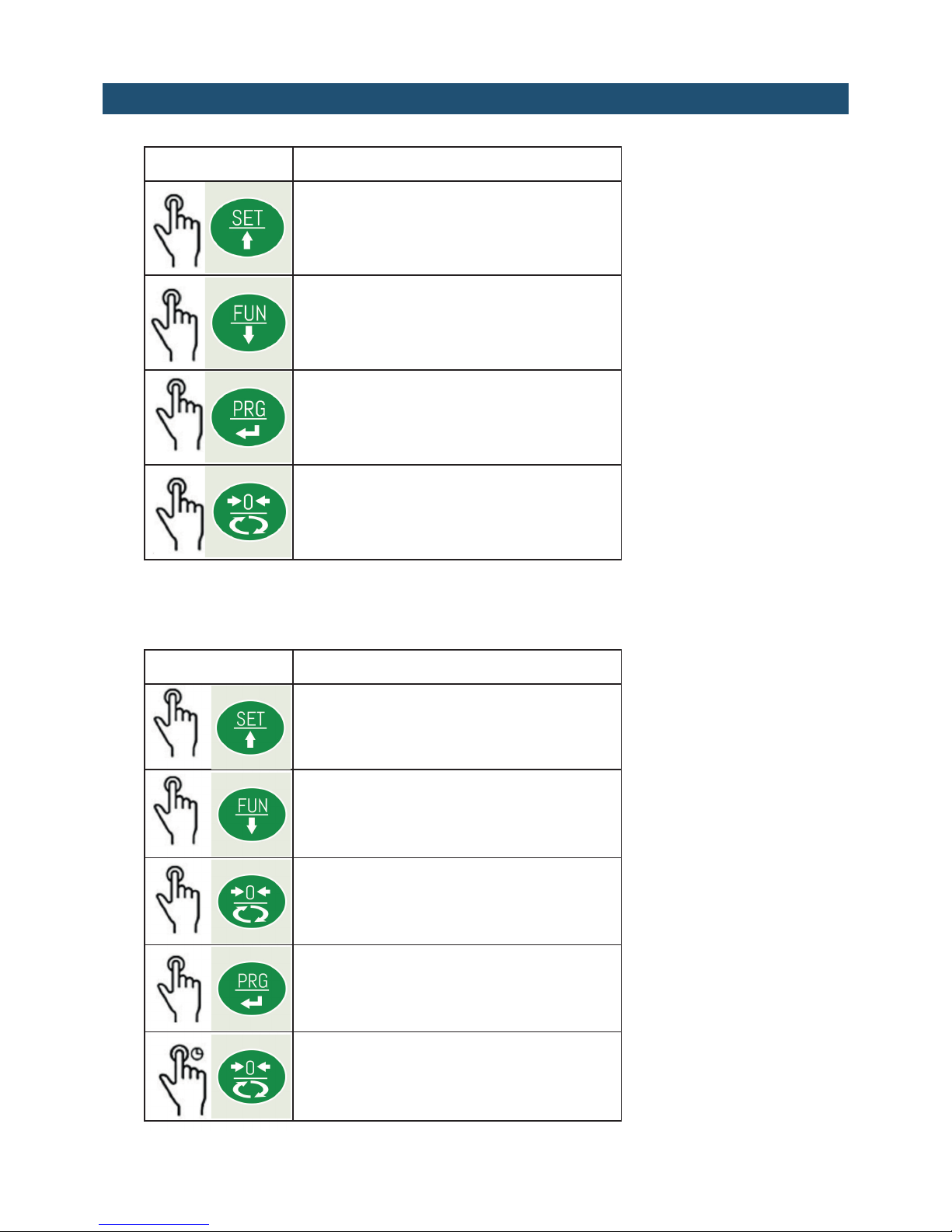

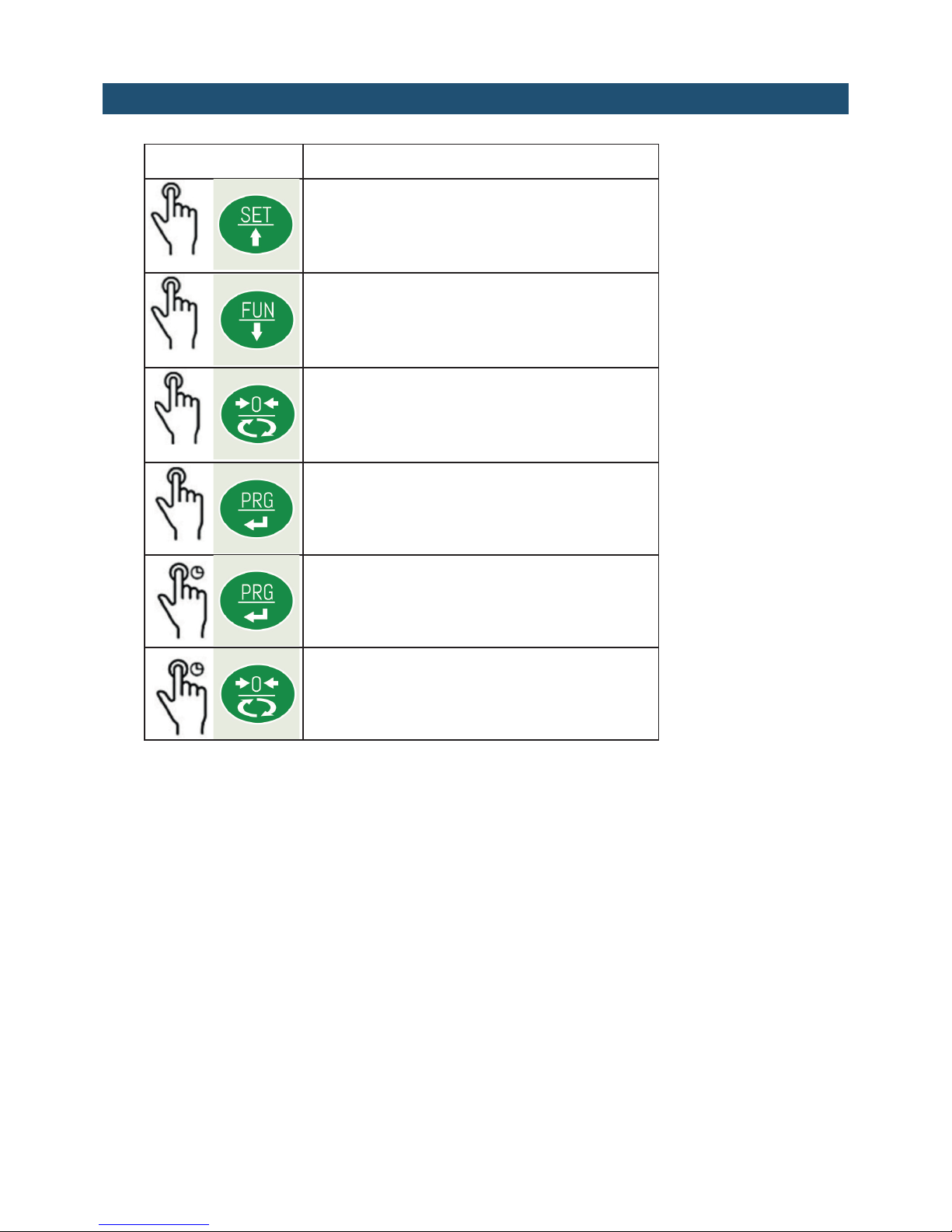

KEYBOARD USE

The device is programmed and controlled through the mechanical keyboard consisting of 4 keys,

having the following functions:

Short press on the single button. The buzzer

will release a short sound.

Long press on the single button. The buzzer

will release a short sound when pressed and

a long sound after 2 seconds.

The use of the keyboard in the different standard procedures is described below.

BROWSERING THE PROGRAMMING MENU

Operation Description

Go to the previous menu item.

Go to the next menu item.

Access the function for the displayed item.

Exit menu or return to the top level.

PROGRAMMABLE VALUE COMPOSITION

Operation Description

Increases the selected digit.

Decreases the selected digit.

Selects the next digit.

Ends composition and stores the value.

Resets all digits.

MAIN FUNCTIONS

Operaton Description

Enters the setpoint setting

Switches display (Gross/Net/Cells)

Sends string onto the serial item

Enters the Programming menu

Performs semi-automatic zeroing

PROGRAMMING MENU

To access the programming menu, press and hold the long PRG key in the weight display

screen.

ACCESS TO THE MENU WITH METRIC OPERATION (Jumper enabled)

The programming of the weighing parameters and the weight calibration settings are allowed

only to personnel authorized by current legislation, through password protected access or by

activating the calibration DIP switch (CAL). In the case of a calibration DIP switch set to ON,

the access password is not required (procedure described below).

This procedure requires the password table.

To access the menu, the operator identification code is required. The timed

message “ID” is displayed and then the code is entered, so enter the

identification code of the authorized access operator, corresponding with the

password table number and confirm with ENTER. If the value 0000 is confirmed,

access to the menu parameters will be limited (it will not be possible to access

the programming of the weighing parameters and the weight calibration

settings).

A randomly determined 3-digit number appears on the display. Find the

corresponding password (4-digit) on the table

Enter the password obtained from the table and confirm with the ENTER key. If

the value 0000 is confirmed, access to the menu parameters will be limited (it

will not be possible to access the programming of the weighing parameters and

the weight calibration settings).

Each access of authorized personnel is recorded in the searchable memory of

the last 5 accesses.

In case of non-metric use, the jumper must be set in CALIBRATION position; in

this way, the access to the menu is free (without password request).

ID: 001

Cod: 123

Pw: 1234

MENU NAME DESCRIPTION

INFO Information: Parameter menus that can be displayed for identification of the

device and its configuration.

TEST Test Menu of the instrument's hardware test operation procedures.

SETUP Setup Menu of the programmable parameters that determine the start-

up of the instrument.

Menu Message Name Description Type

INFO FIRMWARE Firmware code Indication of the installed Firmware code Screen

FULL SCALE Full scale of the device Indication of the set full scale value Screen

N.OF CELLS Number of cells enabled Indication of the number of enabled cells Screen

FIELDBUS Fieldbus present Indication of the type of fieldbus configured Screen

ADDRESS Fieldbus address Indication of the set fieldbus address. This menu

item is only displayed in the RS485 and PROFIBUS

configurations.

Screen

IP ADDRESS Fieldbus IP address Indication of the set fieldbus IP address. Item di-

splayed only in the PROFINET and ETHERNET/

IP configurations.

Screen

SUBNET Fieldbus Subnet Mask Indication of the set fieldbus subnet mask. Item

displayed only in the PROFINET and ETHERNET/

IP configurations.

Screen

ANALOG

OUT

Analog output configu-

ration

Indication of presence and type of analogue

output (Not present - Unipolar - Bipolar)

Screen

MEMORY Optional Memory Con-

figuration

Indication of presence and type of memory

(None - Alibi memory)

Screen

In the case of PROFINET field bus: the IP address and Subnet Mask parameters are programmable by PLC and are

updated in this menu only when the device is switched on; after a change in these parameters from the PLC, it is

necessary to switch the device off and on again to display the correct value. It is important to remember that even

if you set the IP address and subnet mask parameters in Temporary mode, these parameters are not automatically

updated in the device. Moreover, when the device is turned off and on again, these parameters will be all set to

0.0.0.0.

Menu Message Name Description Type

TEST

SIGNAL Cell signal Display of the mV/V signal input to the device Screen

HI-RES Resolution x10 Display of the weight with a resolution 10 times

greater than the one set

Screen

PWR

SUPPLY

Supply voltage Display of the supply voltage measured by the

device

Screen

MEMORY Memory test

(Only with configured

memory)

Automatic test of operation of the additional

memory

Test

IN / OUT I/O test I/O test with simultaneous display of inputs and

outputs

(See specific description)

Test

RS 232 RS232 test Sending and reception test

(See specific description)

Test

RS 485 RS485 test Sending and reception test Test

ANALOG

OUT

Analog output test Test procedure with manual activation of the ou-

tput value (See specific description)

Test

Menu Sub Menu Name

SETUP

CALIBRATION Calibration Settings (*)

ANALOG Analog output settings (Only with configured analogue output)

CONNECTIONS Serial and fieldbus port settings

IN OUT Logical Input and Output Settings

PARAMETERS Measurement metrological parameters settings (*)

FILTER Filter settings

FUNCTIONS Functional characteristics settings

CLOCK Date clock settings (***)

ACCESSES Display of the last 5 authorized personal accesses (**)

ALIBI MEM. Consultation of fiscal memory (**)

(*) These menu items are only displayed in the case of FREE operation or in case of authorized personnel access via

password (in case of METRIC operation).

(**) These menu items are only displayed in the case of METRIC operation.

At the exit of the setup menu, if changes have been made to the parameters, the message SAVING IN PROGRESS is

displayed

(***) This menu item is only displayed in case of hardware with a date clock.

CALIBRATION SETTINGS

Access to this menu is only permitted in the case of FREE operation or in case of authorized personnel

access via password (in case of METRIC operation).

CALIBRATION SUBMENU:

Menu Name Description Type Default Range Fieldbus

Addr.

UNITS

Unit of

measure

Selecting the measurement

unit used, the desired unit of

measurement can be set.

kg

RESOLUTION Division

value

Value of a single division. The

ratio between the maximum

system capacity and the division

value constitutes the system

resolution (number of divisions).

Sel. 1

0,0001 ÷ 50

In steps of

1,2,5

(*)

CAPACITY Load cell

capacity

Value of the nominal capacity of

each cell, in the selected unit of

measure. Following the change

in these values, the theoretical

calibration is performed.

Com. 0 0 ÷ 999999 1103 (MSB)

1104 (LSB)

SENSITIVITY

Sensitivity

of load

cells

Sensitivity of every single

cell. Following the change,

the theoretical calibration is

performed.

Com. 2

mV/V

0,1 ÷ 4

mV/V 1105

FULL-SCALE Full-scale

Maximum system capacity limit.

Following the change, the

analogue scale full scale value is

set.

Com. 0 0 ÷ Cells

capacity

1301 (MSB)

1302 (LSB)

DEAD

WEIGHT Fixed tare

Programming of the fixed tare

value (in kg). Following the

change, a theoretical zero

calibration is performed.

Com. 0 0 ÷

Capacity

1106 (MSB)

1107 (LSB)

CAL.TYP

Selection of the type of

calibration. Upon confirmation,

one of the following procedures is

started.

Sel. Dead Weight

o Table, EQ

BALANCING Balancing

It performs a compensation of the

load cells so that they all have the

same weight response

Spc

DEAD W.

Dead

Weight

calibrat.

Calibration of Zero and Weight

Sample and linearization with

sample weights (***)

Spc 501÷503

TABLE Table calibration (****) Spc 1151÷1172

G-CAL Severity Gravity acceleration at the

calibration site. (**) Com. 0 977000÷

984000

1108 (MSB)

1109 (LSB)

G-USE Use

gravity

Acceleration of gravity in the

place of use. (**) Com. 0 977000÷

984000

1110 (MSB)

1111 (LSB)

LOAD CELLS BALANCING

The procedure can be performed if at least 2 load cells are used, otherwise, the menu will not be

active.

AUTOMATIC PROCEDURE

To carry out the automatic balancing procedure, a weight must be provided to be moved over the various cells to

perform the calculation.

Once you have entered the menu and set the scale zero, you must set the value of the weight used for the procedure,

so that the automatic weighing calibration is also carried out at the end.

• At this point, the device will indicate to load the cell number 1.

• Load the sample weight and press the ENTER button

• Then proceed with the subsequent cells until the last one

If the loaded cell is not correct or if the procedure is not successful, the device will give an error; in

this case, correct the problem and try the procedure again.

BALANCING FACTOR

It is possible to manually modify the balancing factor, by accessing the appropriate menu and modifying the value

present in the selected cell.

The value can be set from 0.1000 to 9.9999 (the default value is 1.0000).

WEIGHT CALIBRATION

(*) The setting of the division values via fieldbus takes place differently from that made by the device. Refer to the

1101 and 1102 addresses of the MODBUS register table.

(**) These parameters only available in the case of METRIC operation.

(***) SAMPLE WEIGHT CALIBRATION AND LINEARIZATION

Once the DEAD W. function has been selected, it is possible to perform the zero calibration or the sample weight

procedure.

Zero calibration: (ZERO key pressed for a long time): Perform the operation with the empty scale but complete with

the tare weight stabilized. The displayed weight must be reset. This operation can be repeated several times. Exit the

CAL. function by pressing the PRG key for a long time.

Sample weight calibration: (short press SET key) Before carrying out the operation, load the sample weight on the

scale and wait for it to stabilize; the display shows the measured value to be calibrated, through the composition of

a programmable value. If the set value is higher than the resolution offered by the device, it is not accepted and the

display shows an error message for a few seconds. Confirm the weight value by pressing the PRG key for a long

time.

Exit the CAL. function by pressing the PRG key for a long time.

Linearization with sample weights: (long press SET key) Up to 5 linearization points on a positive scale are possible.

The progressive linearization points are displayed alternately with the current weight. Press the SET button to set the

value of the sample weight loaded and stabilized. Upon confirmation, proceed to the next step. If 0 is set, the value

is not stored. To end the procedure, press the PRG key for a long time. It is possible to store a number of points lower

than 5.

It is always possible to repeat the calibration operations.

(****) TABLE CALIBRATION

It allows you to manually program up to five calibration points, in addition to the zero value. The values correspond

to those determined by the linearization procedure with sample weights. In this way, it is possible to display the

values determined automatically with this procedure or modify and program them according to preset values.

Message Name Description Type

0 SIGNAL

Zero signal Signal value in mV/V corresponding to the scale zero. Com.

P1 VALUE Weight of point 1 Weight value corresponding to the 1st calibration point Com.

P1 S1GNAL Signal of point 1 Signal value corresponding to the 1st calibration point. Com.

P2 VALUE Weight of point 2 Weight value corresponding to the 2nd calibration point. Com.

P2 S1GNAL Signal of point 2 Signal value in mV/V corresponding to the 2nd calibration point. Com.

P3 VALUE Weight of point 3 Weight value corresponding to the 3rd calibration point. Com.

P3 S1GNAL Signal of point 3 Signal value in mV/V corresponding to the 3rd calibration point. Com.

P4 VALUE Weight of point 4 Weight value corresponding to the 4th calibration point. Com.

P4 S1GNAL Signal of point 4 Signal value in mV/V corresponding to the 4th calibration point. Com.

P5 VALUE Weight of point 5 Weight value corresponding to the 5th calibration point. Com.

P5 S1GNAL Signal of point 5 Signal value in mV/V corresponding to the 5th calibration point. Com.

GET 0 Zero capture Capturing the signal in mV/V corresponding to the scale zero. Spc

ANALOG OUTPUT SETTINGS

ANALOG SUBMENU:

Message Name Description Type Default Range Ind.Fieldbus

RANGE

Analog

output

range

Selection of the analogue output

type Sel. 0÷10V

0-10V [0]

0-5V [1]

4-20mA [2]

0-20mA [3]

1506

MODE

Analog

output

mode

Selection of the value sent by

analog output. Sel. NET

NET [0]

GROSS [1]

PEAK [2]

1505

ANA 0 Fixed tare Analog output offset Com. 0 1501 (MSB)

1502 (LSB)

ANA FS Full-scale

It is the weight corresponding to

the full scale of the analog output,

which may be different from the

weighing system's capacity.

Com. Maximum

capacity 0÷Capacity 1503 (MSB)

1504 (LSB)

0 ADJ. Adjusting

zero

User procedure for zero adjustment

(*) Spc 0

FS.ADJ. Full scale

adjustment

User procedure for full scale

adjustment (*) Spc 0

(*) The analog output is calibrated at the factory for each selectable range. This further procedure is

available to the user for adjustment, for each selectable range. In case of complete reset of the setup

memory, the factory calibration is re-established.

SERIAL PORTS – RS232 SETTINGS

CONNECTIONS SUBMENU:

Message Name Description Type Default Range

C1 MODE

RS232 output

mode Selection of the value sent by

RS232 output.

Sel. NET NET

GROSS

PEAK

C1 PROT. RS232 com-

munication

protocol

Selection of the communication

type for the RS232 ports

Sel. None None

Continuous tx

On demand

Automatic

Slave

Printer

C1 BAUD RS232 Bau-

drate

Selection of the Baudrate for the

RS232 port

Sel. 9600 1200 ÷ 115200

C1 FORM RS232 Frame Frame type.

In the case of a SLAVE protocol, it

is not possible to select 7-bit data

format (E-7-1 and O-7-1):

Sel. N-8-1 N-8-1, N-8-2, E-7-2

E-8-1, O-7-2, O-8-1

SERIAL PORTS – RS485 SETTINGS

CONNECTIONS SUBMENU:

Message Name Description Type Default Range

C2 MODE

RS485 output

mode Selection of the value sent by

RS485 output.

Sel. NET

As for C1 Mod.

C2 PROT. RS485 com-

munication

protocol

Selection of the communication

type for the RS485 ports

Sel. None None

Continuous tx

On demand

Automatica

Slave

ModBus

C2 BAUD RS485 Bau-

drate

Selection of the Baudrate for the

RS485 port

Sel. 9600 1200 ÷ 115200

C2 FORM RS485 Frame Frame type.

In the case of a SLAVE or MODBUS

protocol, it is not possible to select

7-bit data format (E-7-1 and O-7-1):

Sel. N-8-1 N-8-1, N-8-2, E-7-2

E-8-1, O-7-2, O-8-1

C2 ADDR. RS485 ad-

dress

Communication address of the

device

Com. 1 1 ÷ 32

SERIAL PORTS SETTINGS - ETHERCAT CONFIGURATION

CONNECTIONS SUBMENU:

Message Name Description Type Default Range

EN.FBUS.

Abilitazione-

Fieldbus

Enabling EtherCAT Fieldbus; if

OFF, no error message regarding

the EtherCAT communication is

displayed

Sel. OFF OFF

ON

INP.REG. Dimension

Input Area

Dimension of the input area

for EtherCAT fieldbus (values

expressed in bytes).

Sel. 128 32, 64, 96, 128

OUT.REG. Dimension

Output Area

Dimension of the output area

for EtherCAT fieldbus (values

expressed in bytes).

Sel. 128 132, 64, 96, 128

In case of ETHERCAT fieldbus: the devices must be connected with a ring type (as specified by

EtherCAT), so refer to the installation manual for the use of INPUT and OUTPUT ports

4 different XML setting files are provided:

“Hilscher NIC 50-RE ECS V2.2 32 Byte.xml” (input area: 32-byte, output area: 32 byte).

“Hilscher NIC 50-RE ECS V2.2 64 Byte.xml” (input area: 64-byte, output area: 64 byte).

“Hilscher NIC 50-RE ECS V2.2 96 Byte.xml” (input area: 96-byte, output area: 96 byte).

“Hilscher NIC 50-RE ECS V2.2 128 Byte.xml” (input area: 128-byte, output area: 128 byte).

The file that corresponds to the size of the input and output areas selected in the device must be imported into the PLC

(for example, if the device is set to IMP.REG.=128 and OUT.REG.=128.=128, the file “Hilscher NIC 50-RE ECS V2.2

128 Byte.xml” must be imported into the PLC). Multiple files with different sizes can be imported, but, in this case, it

will not be possible to perform the automatic search and setup of devices on the network

SERIAL PORTS SETTINGS - PROFIBUS CONFIGURATION

CONNECTION SUBMENU

Message Name Description Type Default Range

EN.FBUS.

Enabling

Fieldbus

Enabling Profibus fieldbus;if OFF,

no error message regarding

the Profibus communication is

displayed

Sel.

OFF OFF

ON

ADDR.PR. Profibus Ad-

dress

Communication address of Profibus

protocol

Sel. 1

1 ÷ 126

INP.REG. Dimension

Input area

Dimension of the input area for

Profibus fieldbus (values expressed

in bytes)

Sel.

128 32, 64, 96, 128

OUT.REG. Dimension

Output area

Dimension of the output area for

Profibus fieldbus (values expressed

in bytes). 128 32, 64, 96, 128

SERIAL PORTS SETTINGS - PROFINET CONFIGURATION

CONNECTION SUBMENU

Message Name Description Type Default Range

EN.FBUS.

Enabling

Fieldbus

Enabling Profinet fieldbus;if OFF,

no error message regarding

the Profinet communication is

displayed

Sel.

OFF OFF

ON

INP.REG. Dimension

Input area

Dimension of the input area for

Profinet field (values expressed in

bytes).

Sel. 128

32, 64, 96, 128

OUT.REG. Dimension

Output area

Dimension of the input area for

Profinet field (values expressed in

bytes).

Sel.

128 32, 64, 96, 128

The XML “GSDML-V2.3-HILSCHER-NIC 50-RE PNS 32-20160122.xml” configuration file is

provided. The size of the input and output areas set in the PLC (possible selections: 32, 64,

96 or 128 bytes) must correspond to the size of the input and output areas selected in the

instrument (“INP.ADJ.” And “OUT.ADJ.” Parameters).

The instruments are supplied with the parameter “Profinet Name” not setup and with an IP

address of 0.0.0.0.

SERIAL PORTS SETTINGS - ETHERNET/IP CONFIGURATION

CONNECTION SUBMENU

Message Name Description Type Default Range

EN.FBUS.

Enabling

Fieldbus

Enabling Profibus fieldbus; if OFF,

no error message regarding the

Ethernet/IP communication is

displayed

Sel.

OFF OFF

ON

IP IP Address Protocol IP address Ethernet/IP Com.

0.0.0.0

0.0.0.0

÷

255.255.255.255

SUBNET. Subnet Mask Subnet Mask Ethernet/IP protocol Com.

0.0.0.0

0.0.0.0

÷

255.255.255.255

INP.REG. Dimension

Input area

Dimension of the input area

for Ethernet/IP fieldbus (values

expressed in bytes)

Sel.

128 32, 64, 96, 128

OUT.REG. Dimension

Output area

Dimension of the input area

for Ethernet/IP fieldbus (values

expressed in bytes).

Sel.

128 32, 64, 96, 128

The EDS configuration file “HILSCHER NIC 50-RE EIS V1.1.EDS” is provided. The size of the input and output areas

set in the PLC (default input area of 128 bytes, default output area of 128 bytes) must match the size of the input and

output areas selected in the instrument (“INP.ADJ.” Parameters and “OUT.ADJ.”).

This manual suits for next models

1

Table of contents

Other Pavone Sistemi Accessories manuals

Popular Accessories manuals by other brands

Mesalabs

Mesalabs Smart-Well 1710 Operation manual

Waterpik

Waterpik WF-20 Series user manual

Philips

Philips HF3505 user manual

Heathkit

Heathkit Heathkit HP-1144 Guide manual

Barbarian Basketball Systems

Barbarian Basketball Systems Titanium Series Assembly instructions and owner's manual

Omni Ultraviolet

Omni Ultraviolet UV WAND SANITIZER manual