PAXXO PACTOSAFE 4.0 User manual

2

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

3

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

S.4271.01

English (original instructions) ............................................................................................................... 5

Português.......................................................................................................................................... 19

4

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

DECLARATION OF CONFORMITY

Manufacturer:

PAXXO AB Tel: +46 (0)40 18 60 25

Bjurögatan 35 E-mail: order@paxxo.se

211 24 MALMÖ Web: www.paxxo.com

Sweden www.pactosafe.com

We, PAXXO AB, declare under our sole responsibility that the product(s) to which this declaration

relates is/are in conformity with the technical requirements of the standard(s) and directive(s) declared

on this declaration of conformity.

Brand: Pactosafe

Models nos: 540WS and 540WSWM

to which this declaration relates are manufactured in conformity with DIRECTIVE 2006/42/EC of the

European Parliament and of the Council on the approximation of the laws of the Member States

relating to machinery with special reference to Annex 1 on essential health and safety requirements

in relation to construction and manufacturing of machines, and are in conformity with the following

standard(s) or other normative document(s):

following the provisions of the Directives:

•

Low Voltage Directive (2014/35/EU)

•

Electromagnetic Compatibility Directive (2014/30/EU)

•

Machinery Directive (2006/42/EC)

•

WEEE Directive – Waste Electrical and Electronic Equipment (2012/19/EU)

•

RoHS Directive – restriction of the use of certain hazardous substances in

electrical and electronic equipment (2011/65/EU)

following the provisions of harmonised Standards:

•

SS-EN ISO 12100:2010 “Safety of machinery – Basic concepts, general principles for

design. Basic terminology, methodology (ISO 12100–1:2003)”

•

SS-EN 60204–1:2018 “Safety of machinery – Electrical equipment of machines”

•

IEC 61010–1:2010 “Safety requirements for electrical equipment for measurement,

control and laboratory use – Part 1: General requirements”

•

IEC 61326-2-3:2013 Electrical equipment for measurement, control and laboratory use –

EMC requirements. Emission Class A and B. Immunity: Basic and Industrial.

The machine is approved by TÜV NORD in accordance with DIN EN 61010–1:2011 and EN 61010-

1:2010. TÜV NORD GS-Mark Certificate no. 44 786 130714-001, valid until 08.02.2028.

CB test certificate IEC 61010–1 by NEMKO, test report 187875.

Henrik Peters

Managing Director, Paxxo AB

Malmö 2023-09-01

5

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

Table of Contents – English

1. Introduction .................................................................................................6

2. Storage, transport and operation .................................................................7

3. Safety instructions .......................................................................................7

4. Functional description..................................................................................9

5. Technical specification............................................................................... 10

6. Unpacking/Putting into operation............................................................... 11

7. Replacement of foil cassette ...................................................................... 12

8. Waste disposal .......................................................................................... 13

9. Adjustment of bag length........................................................................... 13

10. Battery operation and charging (optional)................................................. 13

11. Checking the sealing result ...................................................................... 14

12. Checking the safety device ...................................................................... 14

13. Troubleshooting....................................................................................... 14

14. Cleaning and decontamination................................................................. 16

15. Replacing the plug-in unit ........................................................................ 17

16. Disposal .................................................................................................. 17

6

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

1. Introduction

This manual contains information about the Pactosafe® (hereinafter “the machine”).

Manufacturer:

PAXXO AB

Bjurögatan 35

SE-211 24 MALMÖ

Sweden

Tel: +46 (0)40 18 60 25

E-mail: [email protected]

www.paxxo.com

Important!

All personnel working with this product are obligated to read and make sure they understand

this manual. Special attention should be paid to the section regarding safety.

No changes may be made to the product without the written consent of the manufacturer.

Always state the serial number when contacting the distributor/manufacture. It is found on the

back of the machine.

The company’s management system is certified in accordance with ISO 9001 and 14 001.

Application:

The Pactosafe waste sealing unit is designed to be used for the safe packaging of hazardous

waste. No sharp objects or syringes.

Placing:

The Pactosafe waste sealing unit is always supplied together with a stand on wheels which is

designed to stably stand on the floor.

PAXXO AB

Henrik Péters

Managing Director

7

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

2. Storage, transport and operation

Storage, transportation and operational guidelines:

The machines may only be stacked 2 (two) on top of each other.

Note! For indoor use only.

Rel. humidity range 10–90%.

Ambient temperature 0–40ºC (32–100ºF).

Altitude: Maximum 2000 m (6000 ft) above sea level.

3. Safety instructions

For safe use of the machine, the following instructions must be followed:

Before using the machine, the operator must have undergone training and have read and

understood the manual and its instructions. The training is important to avoid danger and injury. If

the equipment is used in a manner not specified by the manufacturer, as indicated in this manual,

protection provided by the equipment and accessories may be impaired.

The Pactosafe 540WS (stationary version) must be connected to a grounded electrical outlet and

a maximum length of power cord of 10 feet/3 metres.

The power cord may only be connected to an easy-to-reach electrical outlet. Make sure that

nothing is blocking the outlet from the machine.

When plugging and unplugging the unit from the electrical outlet, it is important to only pull on the

plug and not the cable.

Explanation of symbols:

Symbol A Symbol B Symbol C Symbol D Symbol E

Symbol A:

Attention! Read the operator’s manual explanation of signs.

Symbol B:

Keep fingers and hands clear of the funnel when the sealing bars are closing. Entanglement

hazard. Do NOT operate with exposed long hair, jewellery or loose clothing as this may cause

injuries.

Symbol C:

Caution, hot surface can occur during, or after, sealing of material.

Symbol D:

Warning, biohazard.

Symbol E:

It is prohibited to put metal parts or medical instruments in the machine.

The machines must not be used with any sharps or syringes.

8

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

Continued from previous page.

The machine is classified as laboratory equipment and should be managed as such. The machine

may not be used in medical operating rooms (OP) of hospitals. The machine can be used in

patient rooms (sick rooms) of hospitals, but only if the machine is placed at least 1.5 m away from

the patients and away from the patient area.

The machine may not be left unattended during operations in sick rooms.

The operator must show due regard to the environment when handling residual products by

avoiding the release of hazardous substances and/or must adhere to local, national or international

regulations.

To ensure complete sealing, the waste must have passed the sealing bars before they close.

The machine is to be used according to working environmental policies and requirements of

European, national or international regulations and directives.

The control systems or electrical installation not covered by our delivery must be installed by

authorised personnel and the installation must conform to the relevant EU directive, standards

and/or local regulations.

The operator is not allowed to perform any modifications, repairs or maintenance on the machine!

Modifications, repairs, servicing and maintenance have to be performed by authorised personnel

from PAXXO only. The operator may only undertake routine cleaning of the machine as described

in this manual.

The machine may not be used until any fault or shortcoming has been rectified.

If the machine cannot be used, replacement plug-in units are available.

Do not work with the machine if the power cord or the housing of the power supply or battery

charger has been damaged.

This may cause electric shock!

Any damaged power cord or housing of the power supply or battery charger must be replaced by

a component of the same exact type before using the machine again.

The operator is not under any circumstances allowed to replace the batteries by himself/herself.

The rechargeable battery pack must only be replaced by authorised personnel from PAXXO.

Safety devices and warning stickers must be checked regularly. If applied stickers have been

damaged or are unreadable, they must be replaced immediately.

Attention: To avoid the risk of explosion and burning, do never replace the batteries by non-

rechargeable batteries. Only use rechargeable batteries of the same type and manufacturer

specified in the manual and on the valid list (BOM) of the machine.

Only cassettes designed for the machine may be used. The warranty is only valid when Pactosafe

cassettes are used. Other types of foil might ignite and start a fire.

This machine has a noise level below 70 dB.

For any cleaning operations, the machine must be switched off and unplugged. More instructions

regarding cleaning can be found in chapter 14.

It is prohibited to put any kind of flammable liquids into the waste.

9

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

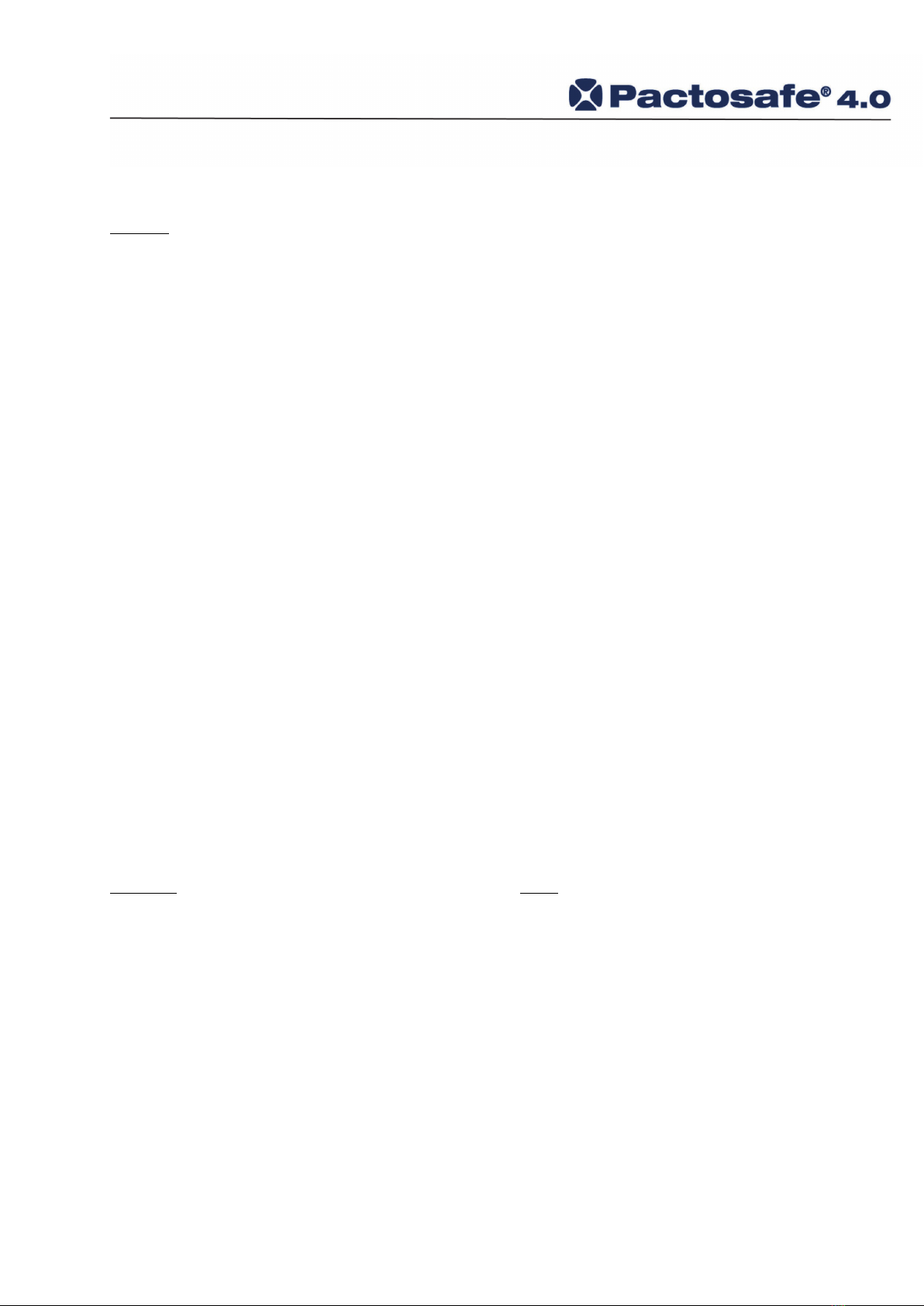

4. Functional description

The machine is designed for the handling of hazardous waste.

The waste is placed in a funnel (a), which is covered by a seemingly endless, tubular

polyethylene (PE) foil (b).

When the foot pedal is pressed, the open end of the PE foil (c), with the waste inside, is

sealed together.

The sealed bag is then fed down (d) into the hazardous waste container below the unit (e),

while at the same time a new foil from the bag cassette is fed in so that further waste can be

packaged.

Should a longer bag than the pre-set length be required, press the foot pedal until the waste

has passed the sealing bars.

The machine does not release any hazardous substances, gases or other emissions during

sealing. Complete incineration of the foil will only yield water, carbon dioxide (CO2) and energy.

10

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

5. Technical specification

Device Pactosafe 4.0 Wide

Type 540WS, 540WM

IP Class IP20

Protection class III, SELV (safety extra-low voltage)

Rated Voltage 12 V DC

Rated current 9 A ±10%

Warranty on unit 2 years

Electrical specification for switching power adapter:

Main voltage input 100-240 V AC

Main frequency 50/60 Hz

Main voltage output 12 V DC

Rated current 0.7 A input Max 10 A output

Protection class I

Power consumption 130 W

Power consumption in standby 1 W

Connection input EU, UK or JP plug

Approvals TUV GS, MET US/C

Manufacturer Power-Win Technology Corp.

Model PW-100A-1Y12GPB

Electrical specification for battery charger:

Main voltage input 100-240 V AC

Main frequency 50/60 Hz

Rated current input 0.6 A

Protection class II

Output 5,0-15V DC 1A, 2,1 mm pin

Connection input EU, UK or JP plug

Approvals TUV GS, MET US/C

Manufacturer Mascot

Model Pactosafe, Type 2216

The machine may only be used with Pactosafe charger Type 2216 made by Mascot

Battery specification:

Battery pack 12V Ni-MH, 8000mAh

Model 10 cells D size

Battery charging Max. 1.8 A 12 V DC

Manufacturer Shenzhen SupPower

Warranty on battery 1 year

Manufacturer’s declaration:

Manufacturer Paxxo AB verifies that 100% of incoming power adaptors and battery chargers are tested

by suppliers according to the requirements for the product.

11

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

6. Unpacking/Putting into operation

The machine is delivered mounted, in a box. The stand has to be set to the desired height; the

foot pedal and cable have to be connected. The packing must then be recycled.

•Remove all components from their packaging.

•Check that all components are present; see pictures 1–6.

The power adaptor (3) is only included in the stationary model and the battery charger

(4) is only included in the mobile model.

•Set the stand (1) to the desired height using the four screws and nuts (2). Connect the

power adaptor (3) or battery charger (4) to an electrical outlet with the same

specification as indicated on the label of the power adaptor or battery charger.

N.B.:

The picture is only an example. The sign may vary depending on the country

where the machine is used.

•Fit the foot pedal (6) to the front panel, cut the air hose to the desired length.

•Turn on the switch.

N.B.:

The machine takes approx. 5 seconds to start up.

•Press the foot pedal and check that the foil is feeding down on both sides and it is

being sealed.

•Check the sealing result against the pictures in Section 11.

•The machine is now ready to use.

1

12

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

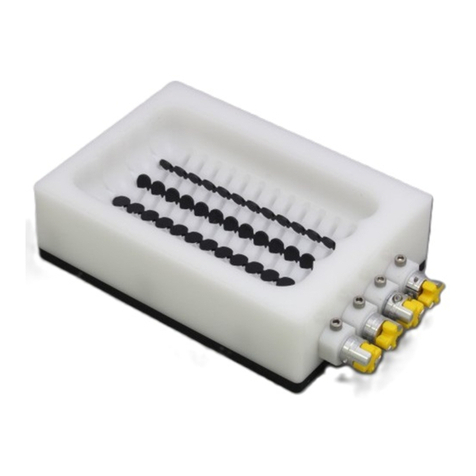

7. Replacement of foil cassette

To signal the end of the foil cassette and that it is time to replace it, a red

STOP

is printed on the

last 2 metres of the foil.

Only the original foil cassette from PAXXO, item number

10880

, is to be used.

Any other types of foil might ignite and start a fire. It is

important to use the right type of foil cassette as

functionality cannot otherwise be guaranteed.

•Turn off the switch.

•Open the cover and place the foil cassette around the funnel and cut the ribbons (1).

Pull the foil from the outside (2).

•Pull the foil down and make sure that the feeding wheels grip the foil (3).

•Turn on the switch and wait approx. 5 seconds.

•Press the foot pedal and check that the foil is fed down on both sides and is being sealed.

•Close the cover.

•Check the sealing result against the pictures in Section 11.

•The machine is now ready to use.

2

1

3

13

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

8. Waste disposal

The packaged waste should be collected in a container for hazardous waste and handled

according to local instructions. The system is tested for safe disposal of cytotoxic waste for 7

(seven) days.

For more information go to: www.pactosafe.com

9. Adjustment of bag length

If required, the bag length can be adjusted.

The adjustment range is from approx. 140–400 mm.

The length of the bag is pre-set using a knob to the right on the front panel of the unit.

The pre-set value is the length of the next bag after sealing.

The bag length can be increased by keeping the foot pedal depressed before sealing.

Tip!

Avoid unnecessarily long bags to conserve foil usage. Minimise the volume. Avoid long bags,

as air fills up the bags and the waste container fills up sooner.

10. Battery operation and charging (optional)

A battery is available as an optional extra when ordering.

Red LED light on front panel is constantly

lit. Do not use the machine – it needs to be charged.

Red LED light lights up during sealing. This does not mean that something is wrong; wait.

Orange LED light on the charger. The battery is being rapidly charged.

Yellow LED light is lit. The battery is not connected or the charger is starting up.

Orange/green LED light flashes. Something is wrong with the charging or connection.

Green/yellow LED light on charger. The charger has reached its peak.

Green LED light on the charger. The battery is fully charged – disconnect the charger.

•If the machine is not to be used for a long time, switch it off to save the battery. Keep in mind that

the machine takes about 5 seconds to start after the switch has been switched on again.

•For the battery not to lose its ability to charge, it must be charged at least once a month.

•Never use the machine while it is charging.

•After about 6 hours of charging, the charger switches to maintenance charging/pulsing.

•Always unplug the charger from the wall outlet before disconnecting it from the machine.

•When charging, always connect the charger to the machine before connecting it to the wall outlet.

•The battery has a longer life if it is fully charged before use and should always be fully charged.

•The machine may only be charged with the Pactosafe charger Type 2216 manufactured by

Mascot.

14

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

11. Checking the sealing result

It is important to check the result of the sealing regularly to ensure that the bags are hermetically

sealed. Severe wear and tear on the sealing bars or damage to them can adversely affect the

result.

The foil has not melted together.

Correct sealing joint.

Flat and even sealing joint.

Holes in the foil, uneven sealing

joint.

12. Checking the safety device

It is important to check the crush guard on a weekly basis.

Press on the foot pedal and hold an object of 10–20 mm thickness between the sealing bars. The

sealing bars should stop and return to their starting position when they encounter resistance more than

8 mm in thickness.

Check annually whether the stickers on the funnel are damaged. Contact the manufacturer if they need

to be replaced.

13. Troubleshooting

Always state the serial number when contacting the distributor/manufacturer.

It is found on the back of the machine.

When ordering, a newly repaired plug-in unit is sent with

replacement instructions, and the defective plug-in unit should

be returned in the same box. The plug-in units are repaired and

delivered in tailor-made boxes.

Spare part list:

543WS

Plug-in unit

5424

Power adaptor

5428

Battery pack

543WM

Plug-in unit with battery

5910

Power cable

5524

Knobs

5410

Funnel, wide

5426

Batttery charger

5602

Foot pedal

5557

Wingnuts for legs (4 pcs)

15

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

Continued from previous page, 13. Troubleshooting

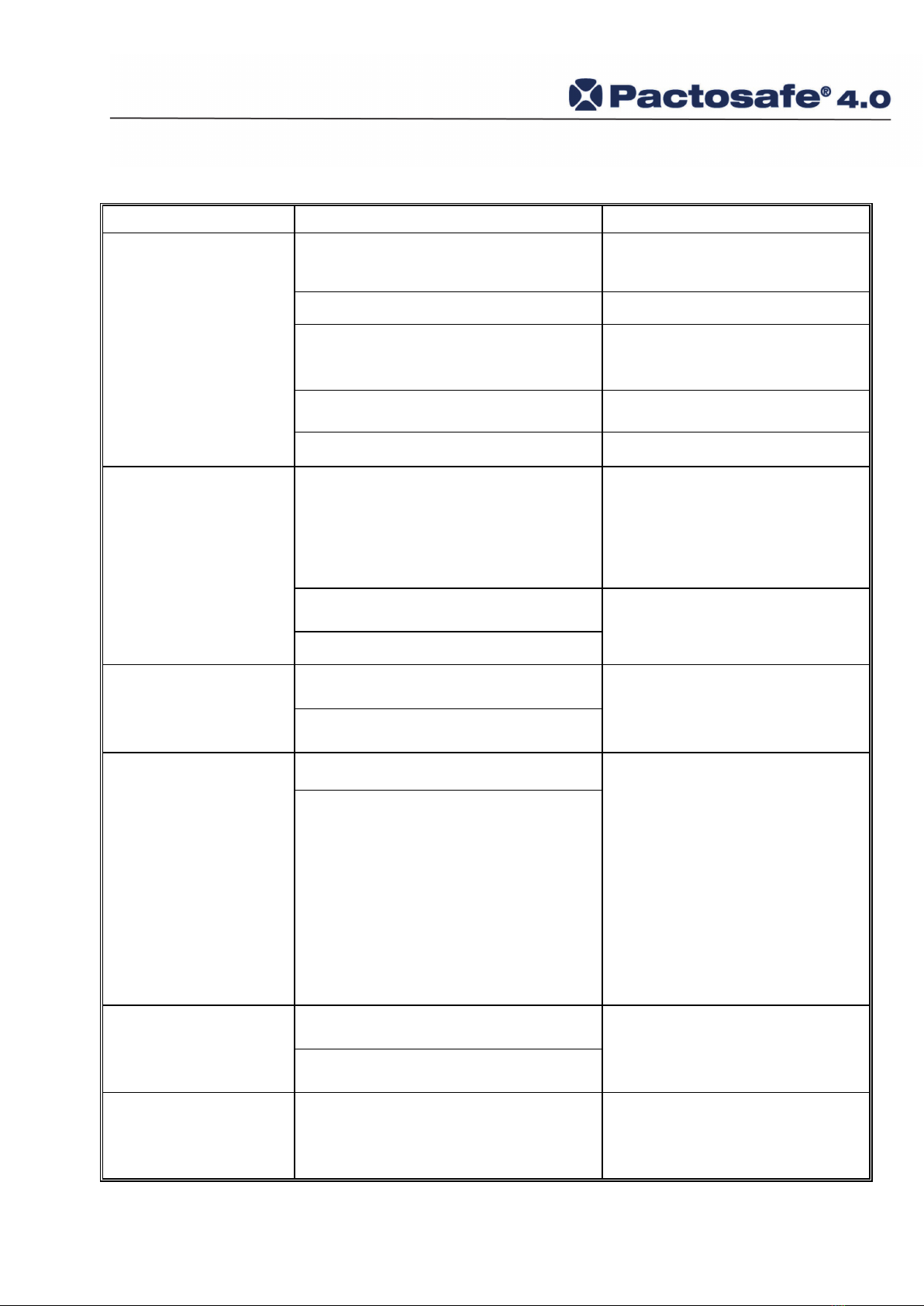

Issue

Possible cause

Action

Nothing happens when

pressing the foot pedal.

The machine is not connected to an

electrical outlet.

Connect the machi

ne to an electrical

outlet.

Switch is not on. Turn on the switch.

No signal from foot pedal.

Check its connection and whether it

is damaged. Shorten or replace if

necessary.

The machine is starting up. The system takes 5

seconds to

become operational.

Battery discharged. Charge the battery.

The feeding of the foil

works but not the sealing.

Something is jamming the cog wheels and

is blocking the sealing bars.

Check the sealing bars to make sure

nothing is stuck. Turn the unit upside

down to che

ck that nothing is stuck

unde

r the unit. Shake gently if

necessary. See section

15

“Replacing the plug-in unit”

.

The sealing bars are damaged. Contact the distributor/manufacturer.

Something is wrong inside the unit.

Incomplete sealing of the

foil.

See picture in Section 11.

The sealing bars are damaged.

Contact the distributor/manufacturer.

Something is wrong inside the unit.

The sealing of the foil is

too powerful.

See picture in Section 11.

Something is wrong inside the unit.

Contact the distributor/manufacturer.

With frequent use, the sealing bars can

build up heat and the plastic melts in the

seal joint. To avoid

this, wait at least

15 seconds between each seal, so that the

sealing jaws have time to cool. It can also

be an indicati

on that the funnel is

incorrectly fitted or that the plastic is pulled

down unevenl

y. Apply the cassette again

and make sure that the funnel is seated

correctly.

The foil is adhering to the

sealing bars.

Waste is stuck between the sealing bars.

Clean the sealing bars with alcohol.

The sealing bars are damaged.

The sealing bars will not

return to the start

position.

Switch the uni

t OFF and then ON

again. The machine will return to its

start mode.

16

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

14. Cleaning and decontamination

The machine must be decontaminated by cleaning according to the instructions below.

Always use suitable gloves.

It is important to decontaminate the machine to avoid transmission of drugs and infection.

•Turn off the switch.

•Unplug the power cord from the electrical outlet.

•Use a clean cloth to wipe the chassis and the stand with

alkaline detergent (pH> 7) and then use water to wash

away any drug residues.

•For platinum-containing chemotherapy drugs, a cleaning

agent with acidic properties (pH <3) and water must

then be used.

After this, an alcohol-based disinfectant can be used to

eliminate microorganisms.

Alternatively, disinfectants containing surfactants can be

used, eliminating both drug residues and

microorganisms.

•If the nature of the contamination is such that Chlorine

or Virkon is better suited, this can certainly be used.

•Dry the sealing jaws (1) and the feeder wheels (2) with

an alcohol-based cleaner, once a week, for extended

functionality.

•Plug in the power cord to the electrical outlet.

•Turn on the switch.

•The machine is now ready to use.

1

2

17

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

15. Replacing the plug-in unit

Removing the plug-in unit

•Turn off the switch on the front panel.

•Pull out the air hose that leads to the foot pedal from the front panel

(see picture).

•Disconnect the cable at the back.

•Unscrew the two knobs on the upper edge of the back.

•Carefully remove the plug-in unit from the frame, like a drawer.

1. Clean the plug-in unit according to the instructions above

before returning it.

2. Turn the unit (upside down) and clean the rectangular area

where all waste passes.

Fitting a new plug-in unit

•Fit the supplied replacement plug-in unit into position.

•Screw the two black knobs at the back securely into place.

•Connect the cable at the back.

•Push the hose for the foot pedal into place on the front panel.

•Switch the unit on.

Returning a unit

Put the used and replaced plug-in unit in the box.

Instructions for replacing and cleaning the unit are included

in the box.

Fill in the attached status report and specify the error.

Return the box immediately to the distributor/Paxxo.

16. Disposal

The power adaptor/battery charger and plug-in unit for the Pactosafe can be sent back to the

manufacturer for recycling. Recycle the stand and chassis as metal. When replacing the battery,

the battery should be taken to a battery disposal/recycling station.

Knobs

18

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

19

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

Índice – Português

1. Introdução.............................................................................. 20

2. Armazenamento, transporte e funcionamento......................... 21

3. Instruções de segurança......................................................... 21

4. Descrição funcional ................................................................ 23

5. Especificações técnicas.......................................................... 24

6. Desembalagem/Colocação em funcionamento....................... 25

7. Substituição do rolo de película .............................................. 26

8. Eliminação de resíduos........................................................... 27

9. Ajuste do comprimento do saco............................................. 27

10. Funcionamento e carregamento da bateria (opcional) ........... 27

11. Verificação do resultado da selagem..................................... 28

12. Verificação do dispositivo de segurança................................ 28

13. Resolução de problemas ...................................................... 28

14. Limpeza e descontaminação ................................................ 30

15. Substituição da unidade intercambiável ................................ 31

16. Eliminação............................................................................ 31

20

Paxxo AB, Bjurögatan 35, 211 24 Malmö, Sweden • Tel : +46 (0) 40 18 60 25 • www.paxxo.com

1. Introdução

Este manual contém informação sobre o Pactosafe® (doravante designado por "a máquina").

Fabricante:

PAXXO AB

Bjurögatan 35

SE-211 24 MALMÖ

Suécia

Tel.: +46 (0)40 186025

E-mail: [email protected]

www.paxxo.com

Importante!

Todas as pessoas que trabalham com este produto são obrigadas a ler e certificar-se de que

compreendem este manual. Deve ser prestada especial atenção à secção relativa à segurança.

Não podem ser efetuadas alterações ao produto sem a autorização por escrito do fabricante.

Indicar sempre o número de série ao contactar o distribuidor/fabricante. Encontra-se na parte de trás

da máquina.

O sistema de gestão da empresa é certificado de acordo com as normas ISO 9001 e 14 001.

Aplicação:

A unidade de selagem de resíduos Pactosafe foi concebida para ser utilizada para o

acondicionamento seguro de resíduos perigosos. Sem objetos afiados ou seringas.

Colocação:

A unidade de selagem de resíduos Pactosafe é sempre fornecida com um suporte de rodas que é

concebido para ser colocado no chão forma estável.

PAXXO AB

Henrik Péters

Diretor-geral

Other manuals for PACTOSAFE 4.0

3

Table of contents

Languages:

Other PAXXO Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Promega

Promega Maxwell 16 operating manual

REITEL

REITEL SONIRET operating instructions

Zeiss

Zeiss Lightsheet 7 Installation requirements

DH Lifelabs

DH Lifelabs AQUASOLVO AAE-30 06 Series quick start guide

Sartorius Stedim Biotech

Sartorius Stedim Biotech Flexel Series user manual

Hach

Hach sensION MM340 user manual