PCB Load & Torque, Inc. Toll-Free in USA 866-684-7107 716-684-0001 www.pcbloadtorque.com

S-TYPE LOAD CELL OPERATION MANUAL

4

6.1.2 Hysteresis

The difference between the ascending and descending

measured readings at 40% of full scale is used to calculate the

hysteresis value.

6.1.3 Best Fit Output

The best fit calibration second-order equation has been

calculated from the calibration data by the method of least

squares. Deviation between measured output and best-fit

output is calculated and displayed in the column next to the

best-fit output for each measurement increment. The

deviations (% Full Scale) of measured outputs from the

calculated best fit are tabulated for each measured reading.

6.1.4 Strain Gage Measurements

6.1.5 Shunt Calibration Standard Resistor

All S-type load cell calibrations use a 60K Ohm (0.1%)

precision resistor shunt calibration value that is supplied into

the calibration report.

6.1.6 Static Error Band (SEB)

The static error band (SEB) is determined by the maximum

deviations of the ascending and descending calibration points

from the best fit straight line through zero output. The SEB

includes the effects of nonlinearity, hysteresis, and non-return

to minimum load.

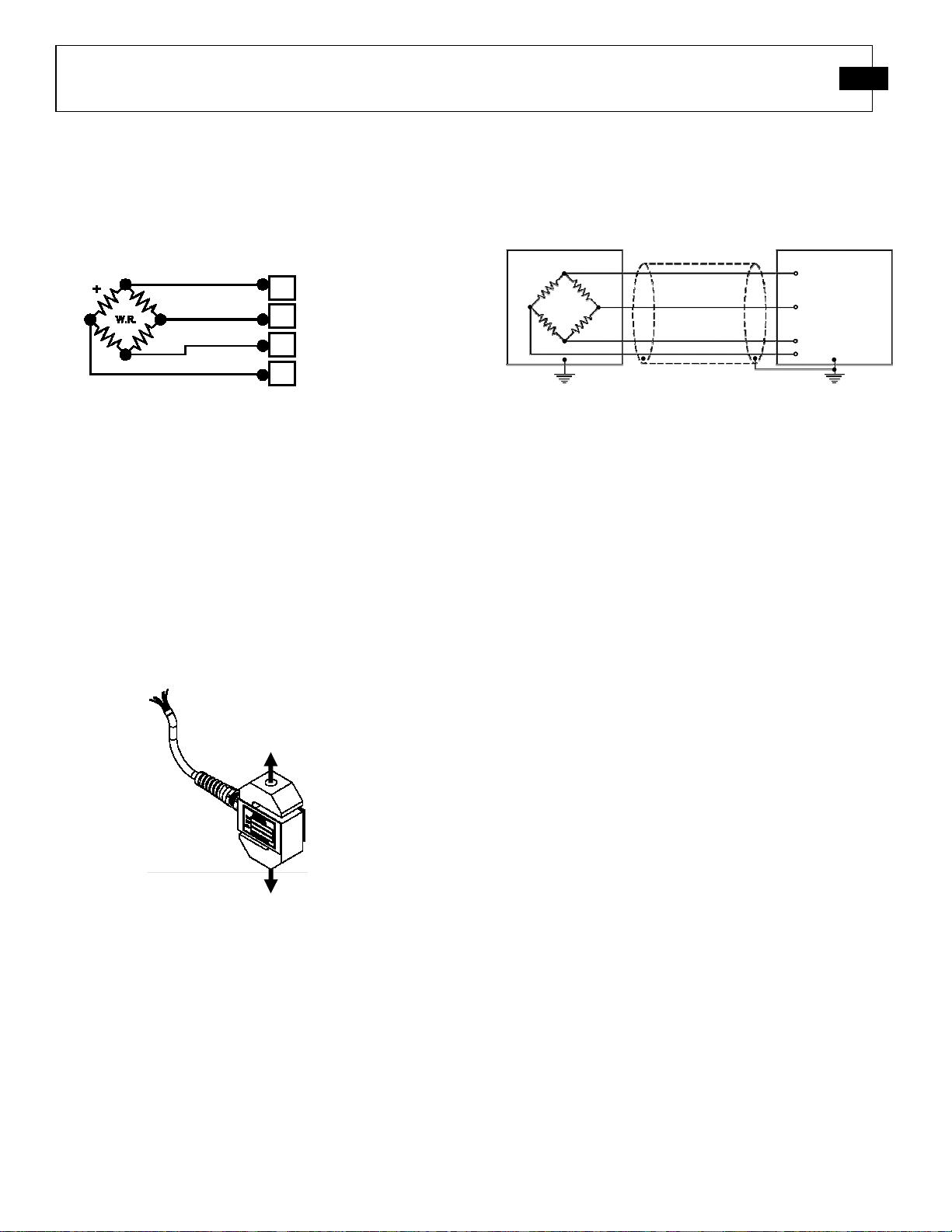

7.0 SHUNT CALIBRATION DESCRIPTION

Shunt calibration is used to simulate a known tension or

compression load on a load cell. The calibration certificate

will indicate which leg of the bridge to apply the shunt resistor

to for both tension and compression load simulation. Typically

tension is simulated by inserting the shunt resistor between the

+P and +S connector leads. Compression loading is simulated

by inserting the shunt resistor between the +S and –P

connector leads.

7.1 Resistor Value

S-type load cells have a nominal 2.0 mV/V full scale output.

For a 350 ohm strain gage bridge the precision shunt resistor

is, 60,000 ohms ±0.1%, simulates an output of approximately

73% of the full scale output for the load cell. The calibration

values for each bridge are found on the calibration certificates

supplied with each load cell.

7.2 Shunt Calibration Process

To perform the shunt calibration, use the following procedure:

1. Stabilize all forces on the load cell. If possible,

remove all loads.

2. Allow the powered sensor and signal conditioner to

warm up for a minimum of 30 minutes

3. Set the load indicator display to read exactly 00.000.

4. Connect the shunt resistor to the terminals specified

in the calibration certificate, and adjust the span or

gain until the display reads the force value stated on

the certificate.

5. Repeat steps 1-3 to verify that a valid calibration

setting has been obtained.

6. If possible, apply a known load to the measurement

system to further verify that the calibration has been

accurately set up.

7.3 Estimating Shunt Resistor for a Given Load

The following formula can be used to estimate the

approximate value of shunt resistor required to simulate a

mechanical load.

R

cal

= (250* R

b

) / (Output

FS

* L

cal

)

Where: R

cal

= Shunt Resistor (K ohms)

R

b

= Bridge Resistance (ohms)

Output

FS

= Full Scale output of the load cell (mV/V)

L

cal

= Load to be simulated, % of Load Cell Capacity

8.0 MAINTENANCE

Routine maintenance of the S-type load cell should include

cleaning the electrical connectors, housings, and mounting

surfaces with solutions and techniques that will not harm the

physical material of construction. Make sure liquids are not

allowed to migrate into devices that are not hermetically

sealed. Such devices should only be wiped with a damp cloth,

and never be submerged or have liquids poured on them.

Never use a pressure washer on the load cells.

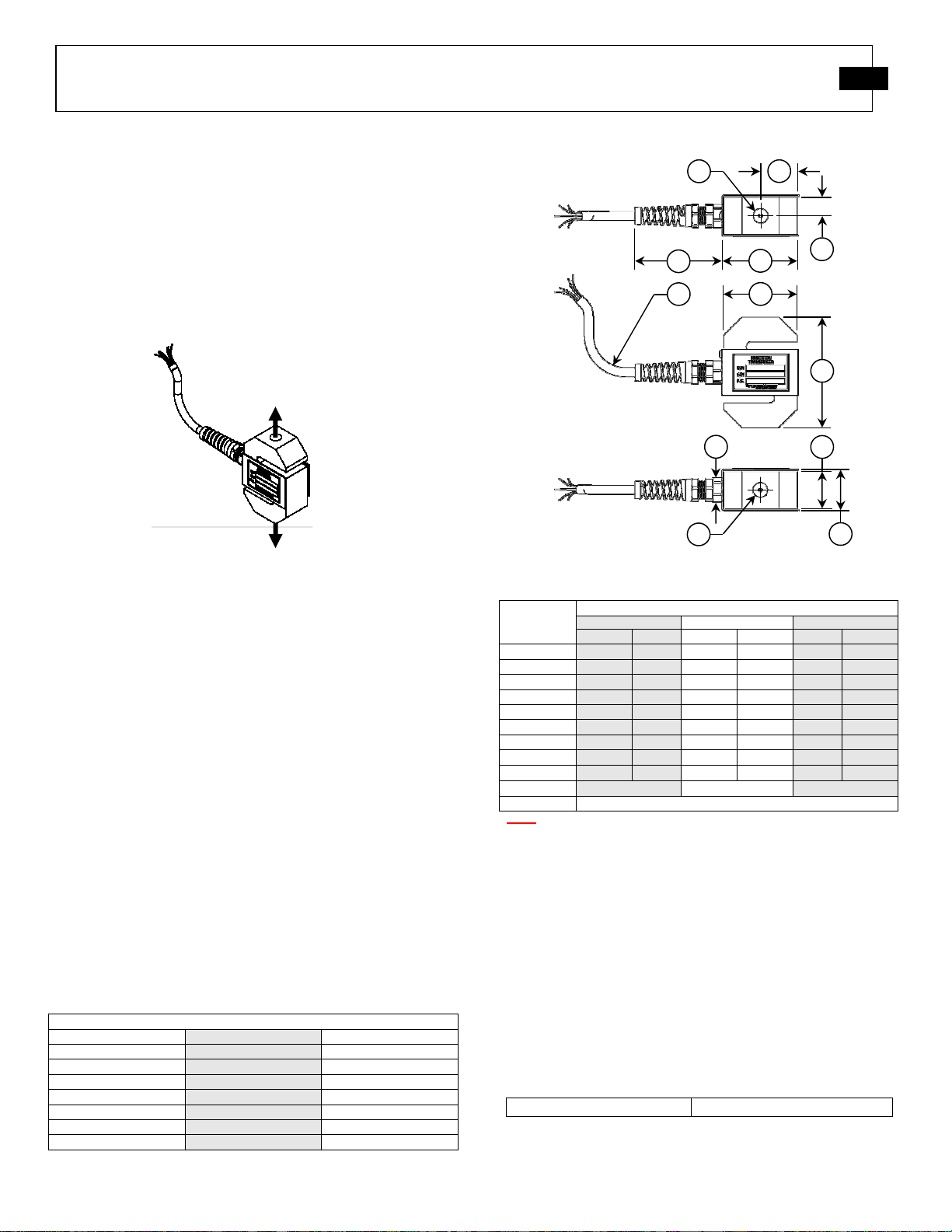

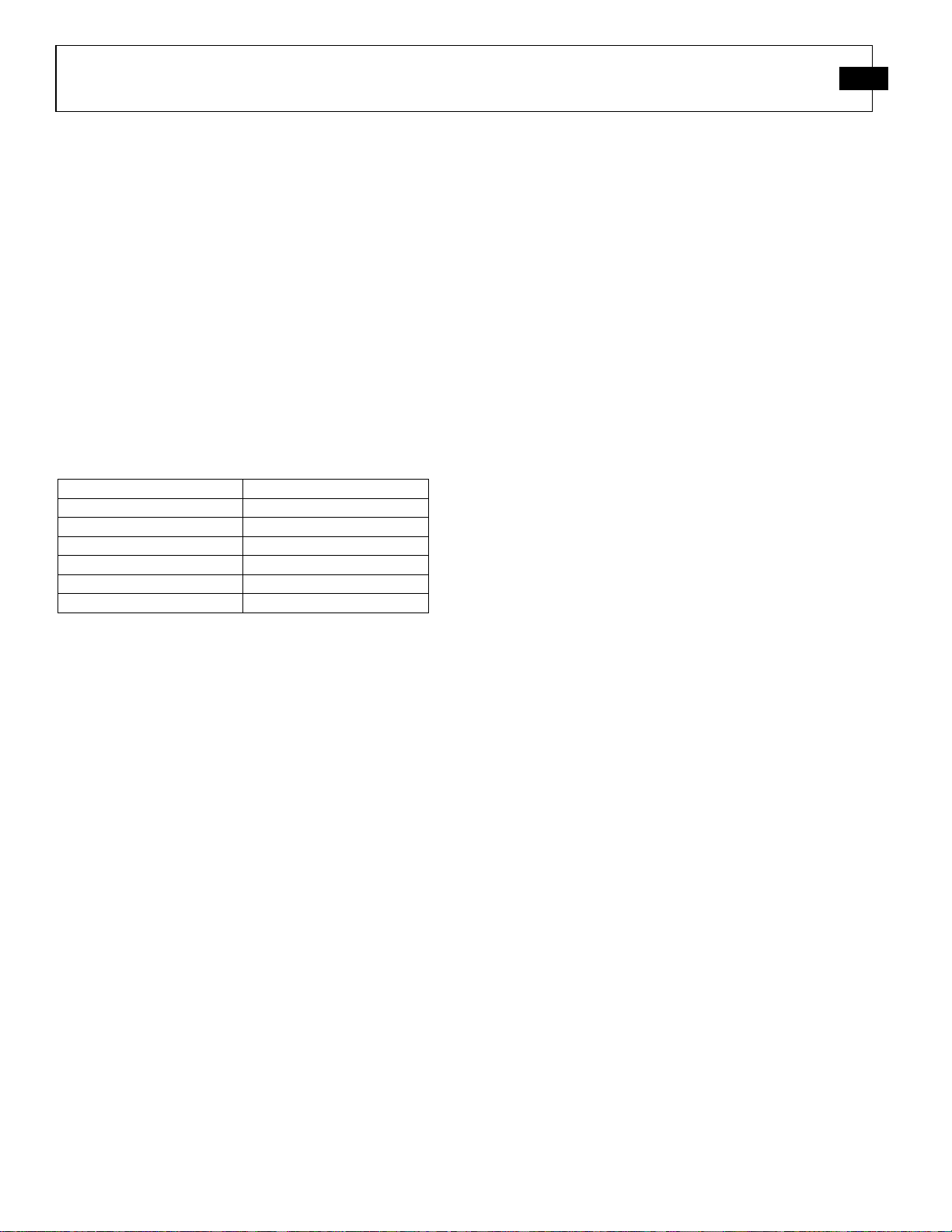

Bridge Resistance: 350 Ohm Nominal

Excitation: +P(A) to –P(D) Ohms

Signals: +S(B) to –S(C) Ohms

Leakage to Ground: > 5k GOhm

Bridge Unbalance: ±1.0% Full Scale

Output: 2.0 mV/V Nominal

Maximum Voltage: 20 VDC

Table 5 – Strain Gage Measurements