Kidde EG4 Series Assembly instructions

© 2020 Carrier 1 / 4 P/N 3102554-EN • REV 002 • ISS 31AUG20

Genesis LED EG4 Series Wall

Notification Appliance Installation

Sheet

Description

Genesis LED EG4A horns, EG4V strobes, and EG4VA horn-strobes

are wall-mounted plug-in fire alarm notification appliances designed for

indoor dry applications. See Table 1 to Table 3 for a list of models.

Table 1: EG4A horn models

Catalog number

Description

EG4

ARF Wall horn, red, FIRE

EG4

ARN Wall horn, red, no marking

EG4

AWF Wall horn, white, FIRE

EG4

AWN Wall horn, white, no marking

Table 2: EG4V strobe models

Catalog number

Description

E

G4VRF Wall strobe, red, FIRE

E

G4VRN Wall strobe, red, no marking

E

G4VWF Wall strobe, white, FIRE

E

G4VWN Wall strobe, white, no marking

Table 3: EG4AV horn-strobe models

Catalog number

Description

E

G4AVRF Wall horn-strobe, red, FIRE

E

G4AVRN Wall horn-strobe, red, no marking

E

G4AVWF Wall horn-strobe, white, FIRE

E

G4AVWN Wall horn-strobe, white, no marking

Genesis LED EG4 Series notification appliances feature:

• Field-configurable horn and strobe outputs. See Figure 2.

• Enhanced synchronization circuitry to comply with the latest

requirements of UL 1638 and CAN/ULC-S526.

• Input wiring test points on the front of the appliance when the

cover is removed.

Note: Synchronized operation requires a separately installed

synchronization device. See the control unit or power supply

compatibility list for compatible synchronization devices.

Configuration

Caution: Equipment damage hazard. Using excessive force when

removing the appliance cover may damage the cover and prevent it

from latching in place.

To configure the notification appliance:

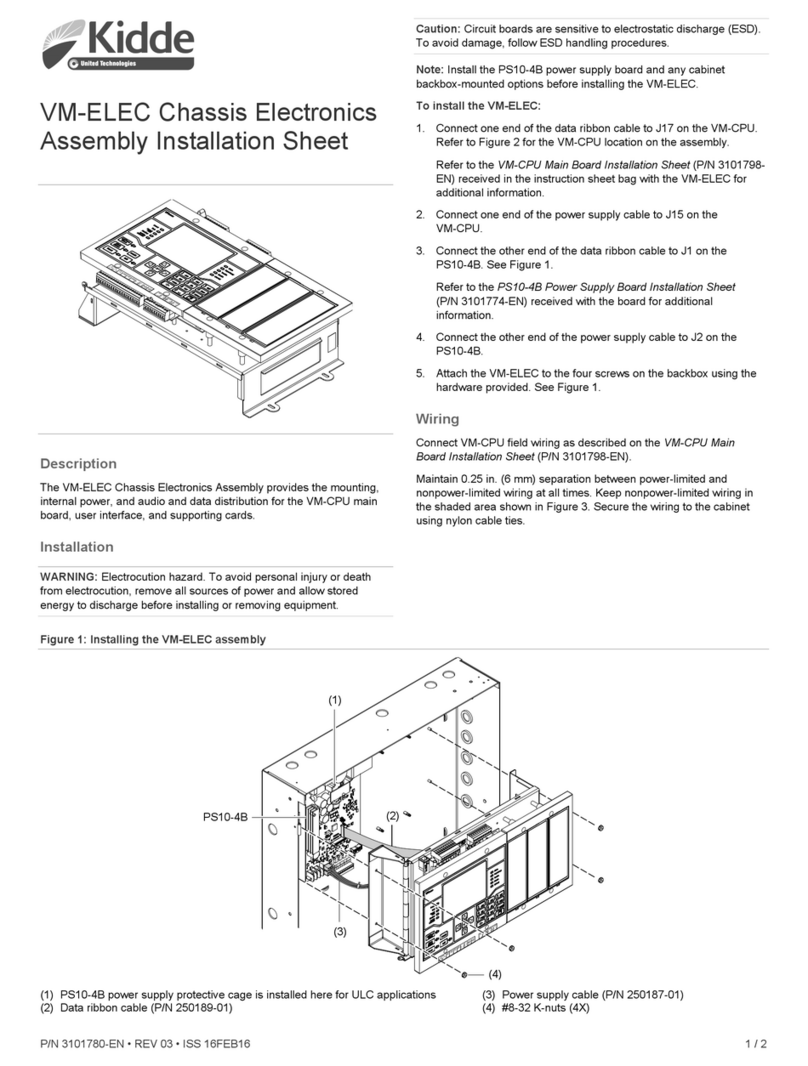

1. Remove the appliance cover. See Figure 1.

Insert a small, flat-bladed screwdriver into the slot at the bottom of

the appliance.

Gently pull up on the screwdriver to pry the bottom of the

appliance cover down and away from the appliance.

Lift the bottom of the cover out and over the top of the appliance.

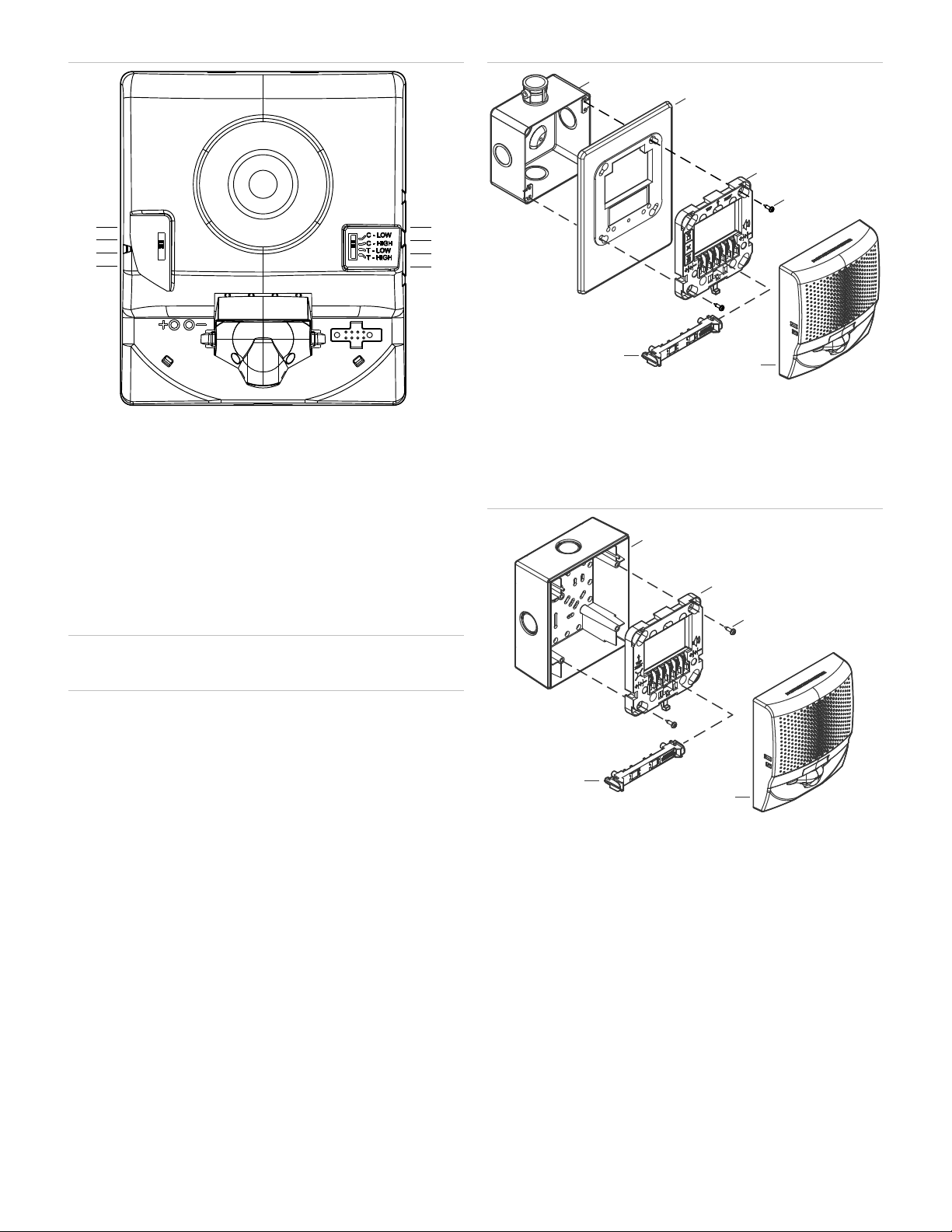

2. On horns and horn-strobes, set the sound output switch for the

required value. See Figure 2.

3. On strobes and horn-strobes, set the light output for the required

value. See Figure 2.

4. Replace the appliance cover.

Figure 1: Removing and replacing the cover

2 / 4 P/N 3102554-EN • REV 002 • ISS 31AUG20

Figure 2: Light and sound output settings

(1) Constant, low dB

(

2) Constant, high dB

(

3) T3 temporal, low dB

(4) T3 temporal, high dB

(5) 110 candela

(

6) 75 candela

(

7) 30 candela

(8) 15 candela

Note: Temporal 3 coding is the required output for fire notification

devices per NFPA 72. Any device coding other than Temporal 3 is at

the discretion and approval of the local authority having jurisdiction

(AHJ).

Installation

Install and wire this device in accordance with applicable national and

local codes, ordinances, and regulations.

Caution: Electrical supervision requires that you break the wire run at

each terminal. Do not loop the notification circuit field wires around the

terminals.

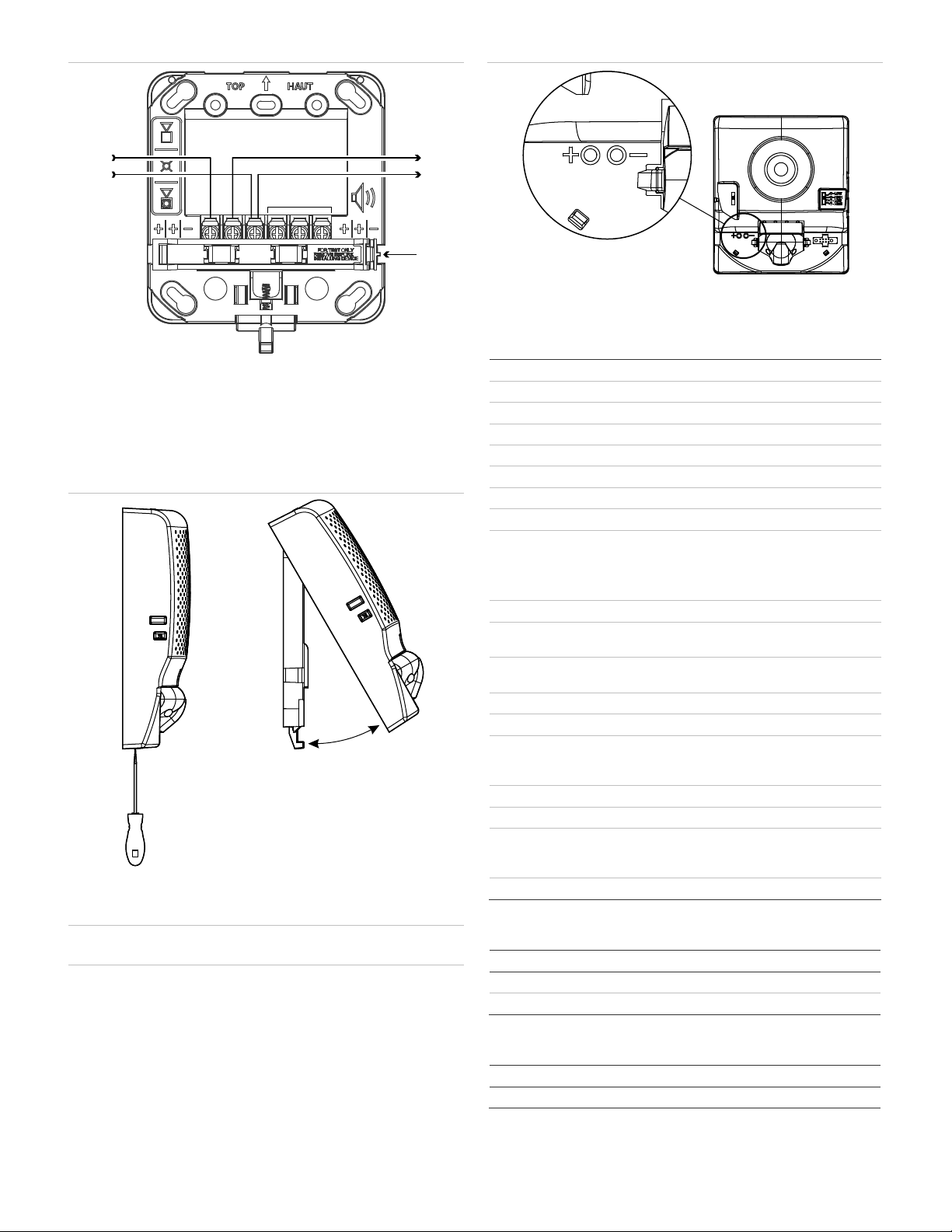

To install the appliance:

1. Using the screws supplied with the wiring plate, attach the wiring

plate and, if used, the trim plate to the electrical box. See Figure 3

and Figure 4. Do not overtighten the screws.

The trim plate is ordered separately.

2. Connect the field wiring. Observe signal polarity for the appliance

to operate properly. See Figure 4.

3. Remove the shorting clip (Figure 3, item 6). Retain for future use.

4. Plug the appliance into the wiring plate by setting the appliance on

the top of the wiring plate, and then snapping the bottom into

place. See Figure 5.

To unplug the appliance, press the spring clip on the bottom, and

then lift the appliance away from the wiring plate.

5. Test the unit for proper operation.

Figure 3: Typical electrical box mounting

(1) Electrical box

(2) Trim plate (optional)

(3) Wiring plate (required)

(4) Machine screw (2X, supplied with wiring plate)

(5) Notification appliance

(6) Shorting clip

Figure 4: Typical surface box mounting

(1) Surface box

(2) Wiring plate (required)

(3) Plastite screw (2X, supplied with surface mount box)

(4) Notification appliance

(5) Shorting clip

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(3)

(4)

(2)

(1)

(5)

(6)

(1)

(2)

(3)

(5)

(4)

P/N 3102554-EN • REV 002 • ISS 31AUG20 3 / 4

Figure 5: Wiring

(1) Horn/strobe circuit in (signal polarity shown in the active condition)

(2) Horn/strobe circuit out

(3) Shorting clip

Note: To maintain circuit continuity, do not remove the shorting clip

(Figure 4, item 3) until you are ready to install the notification

appliance.

Figure 6: Removing and replacing the appliance

Maintenance and testing

Caution: Equipment damage hazard. To maintain the required agency

listings, do not change factory-applied finishes.

This unit is not serviceable or repairable. If the unit fails to operate,

contact the supplier for a replacement.

Perform a visual and operational inspection in accordance with

applicable codes and standards or as directed by the local authority

having jurisdiction.

Input wiring test points are available on the front of the appliance when

the cover is removed. The test points let you easily spot check the field

circuit wiring without the need to remove the appliance from the wall.

See Figure 6.

Figure 7: Test points

Note: Marking indicates signal polarity when the circuit is active.

Specifications

Operating voltage

16 to 33 VDC, 16 to 33 VFWR

Operating current

See Table 4 to Table 6

Horn signal type

Constant or temporal (TC3)

Sound output

See Table 7

Sound pattern

See Table 8

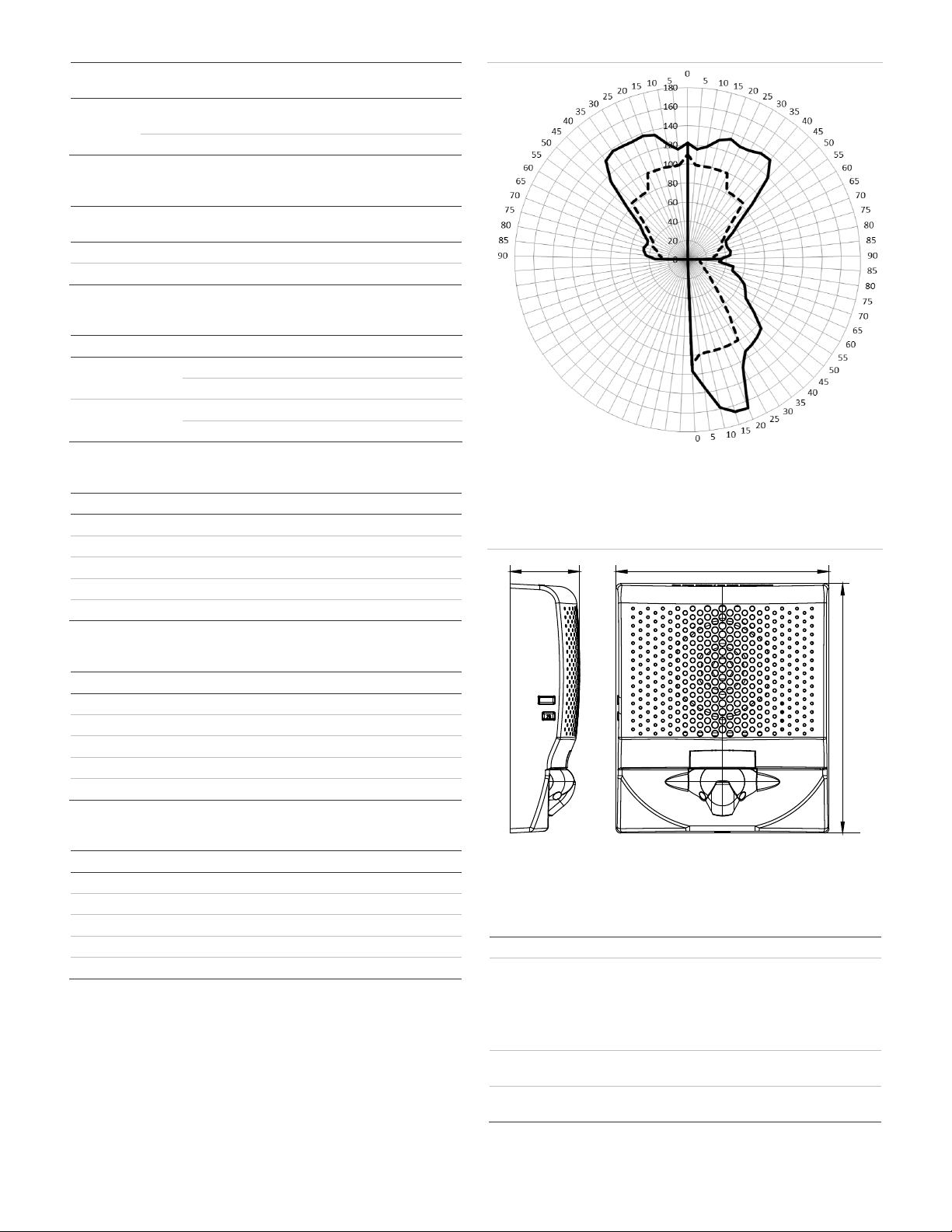

Light output

15, 30, 75, or 110 cd

Strobe flash rate

1 fps (flash per second) approx.

Light distribution

See Figure 7

Synchronization

20 Ω max. between any two devices.

To determine allowed wire resistance, refer to

these specifications, and the specifications

for the synchronized signal source.

Dimensions

See Figure 8

Strobe

-to-box center

offset

−1.70 in (−4.32 cm)

Compatible electrical

boxes

1-gang, 2-gang, 4-inch square, G4RSB,

G4WSB

Wiring plate

GRSW

Wire size

12 to 18 AWG (0.75 to 2.50 mm²)

Screw torque

Mounting screws

Terminal screws

10 lbf-in (1.2 N-m) max.

12 lbf-in (1.4 N-m) max.

Trim plate

s EG4TR, EG4TW

Replacement covers

See Table 9 to Table 11

Operating

environment

Temperature

Relative humidity

32 to 122°F (0 to 50°C)

0 to 93% noncondensing

Storage temperature

-40 to 158°F (-40 to 70°C)

Table 4: Operating current (horn models)

Sound setting

16 to 33 VDC

16 to 33 VFWR

C

-LOW, T-LOW 18 mA 22 mA

C

-HIGH, T-HIGH 28 mA 38 mA

Table 5: Operating current (strobe models)

Strobe setting

16 to 33 VDC

16 to 33 VFWR

15, 30, 75

, 110 28 mA 36 mA

(1) –

+(2)

(3)

–

+

N.C.

4 / 4 P/N 3102554-EN • REV 002 • ISS 31AUG20

Table 6: Operating current (horn-strobe models)

Strobe

setting

Sound setting

16 to 33 VDC

16 to 33 VFWR

15, 30, 75

,

110

C-LOW, T-LOW 40 mA 48 mA

C-HIGH, T-HIGH 50 mA 60 mA

Table 7: Sound output (horn and horn-strobe models)

Sound

setting Reverberant

(UL 464)

Anechoic

(CAN/ULC-S525)

C

-LOW, T-LOW 80 dBA 86 dBA

C

-HIGH, T-HIGH 86 dBA 92 dBA

Table 8: Sound pattern (ULC)

Axis

Angle Change in output

Horizontal

135° and 45°

–3 dBA

150° and 30° –6 dBA

Vertical

135° and 40° –3 dBA

150° and 30° –6 dBA

Table 9: EG4A horn replacement covers

Catalog number

Description

EG4

ARF-CVR Cover, wall horn, red, FIRE

EG4

ARN-CVR Cover, wall horn, red, no marking

EG4

AWA-CVR Cover, wall horn, white, ALERT

EG4

AWF-CVR Cover, wall horn, white, FIRE

EG4

AWN-CVR Cover, wall horn, white, no marking

Table 10: EG4V strobe replacement covers

Catalog number

Description

EG4

VRF-CVR Cover, wall strobe, red, FIRE

EG4

VRN-CVR Cover, wall strobe, red, no marking

EG4

VWA-CVR Cover, wall strobe, white, ALERT

EG4

VWF-CVR Cover, wall strobe, white, FIRE

EG4

VWN-CVR Cover, wall strobe, white, no marking

Table 11: EG4AV horn-strobe replacement covers

Catalog number

Description

EG4

AVRF-CVR Cover, wall horn-strobe, red, FIRE

EG4

AVRN-CVR Cover, wall horn-strobe, red, no marking

EG4

AVWA-CVR Cover, wall horn-strobe, white, ALERT

EG4

AVWF-CVR Cover, wall horn-strobe, white, FIRE

EG4

AVWN-CVR Cover, wall horn-strobe, white, no marking

Contact information

For contact information, see www.kidde-esfire.com.

Figure 8: 110 cd light distribution

(1) Horizontal left

(

2) Horizontal right

(3) Vertical bottom

──────── Measured

─

────UL minimum

Figure 9: Dimensions

(1) 1.62 in. (4.11 cm)

(2) 4.95 in. (12.57 cm)

(3) 5.78 in. (14.68 cm)

Regulatory information

UL rating

Regulated 24 DC and 24 FWR

FCC compliance

This device complies with part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) This device may not

cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

Industry Canada

compliance

This Class A digital apparatus complies with

Canadian ICES-003.

Environmental

class

Indoor, dry

(1) (2)

(3)

(3)

(1) (2)

This manual suits for next models

4

Other Kidde Industrial Equipment manuals