3

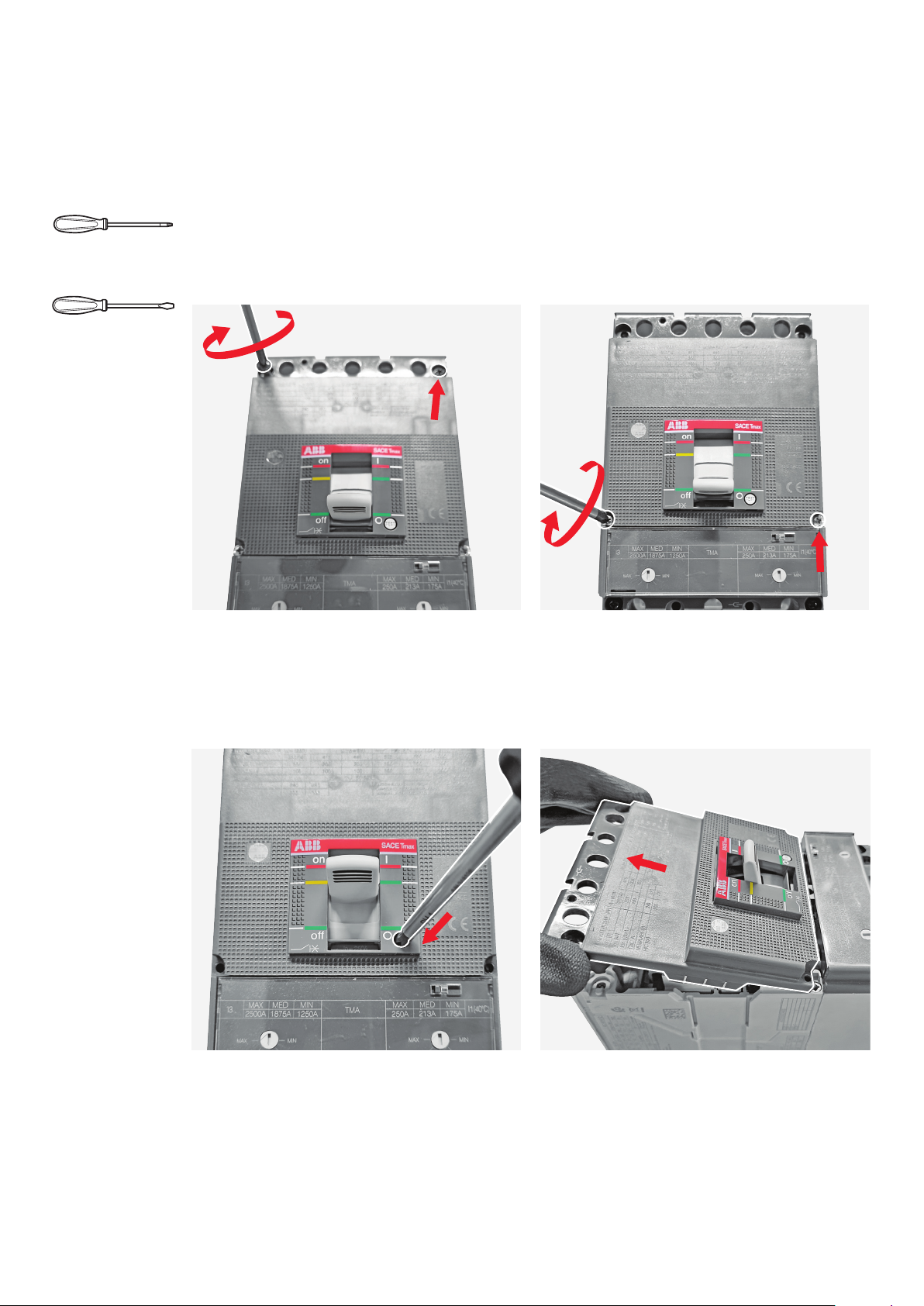

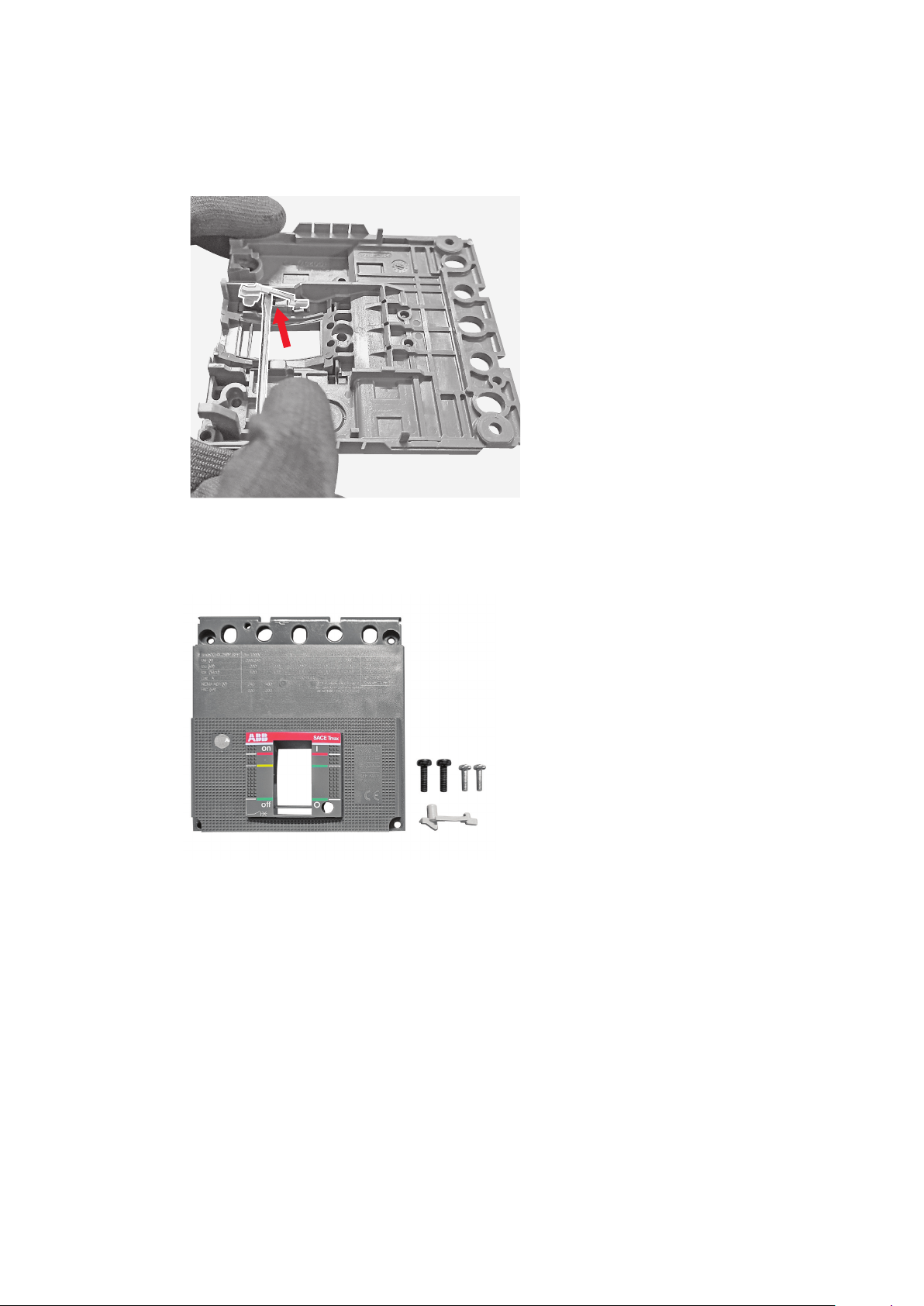

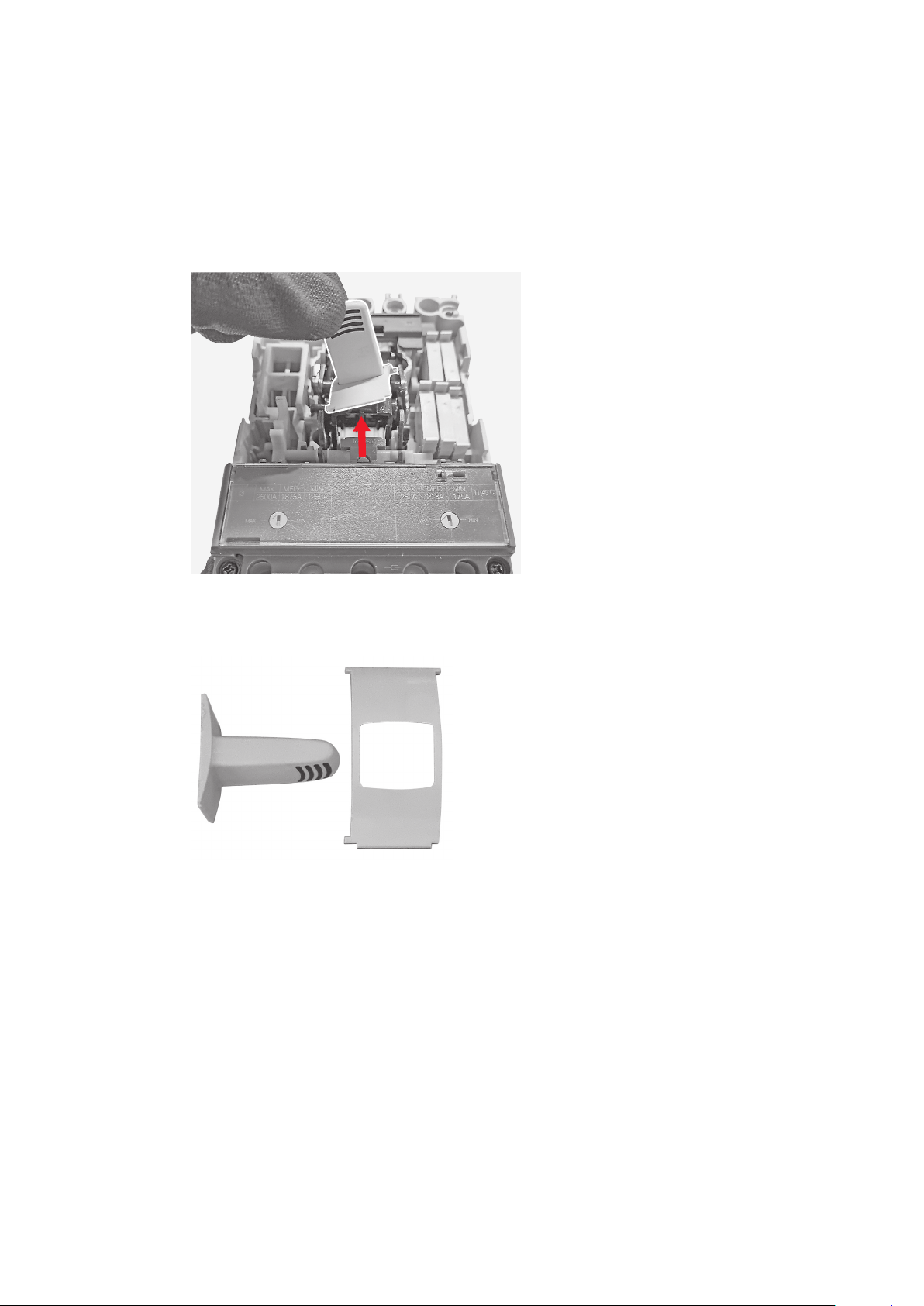

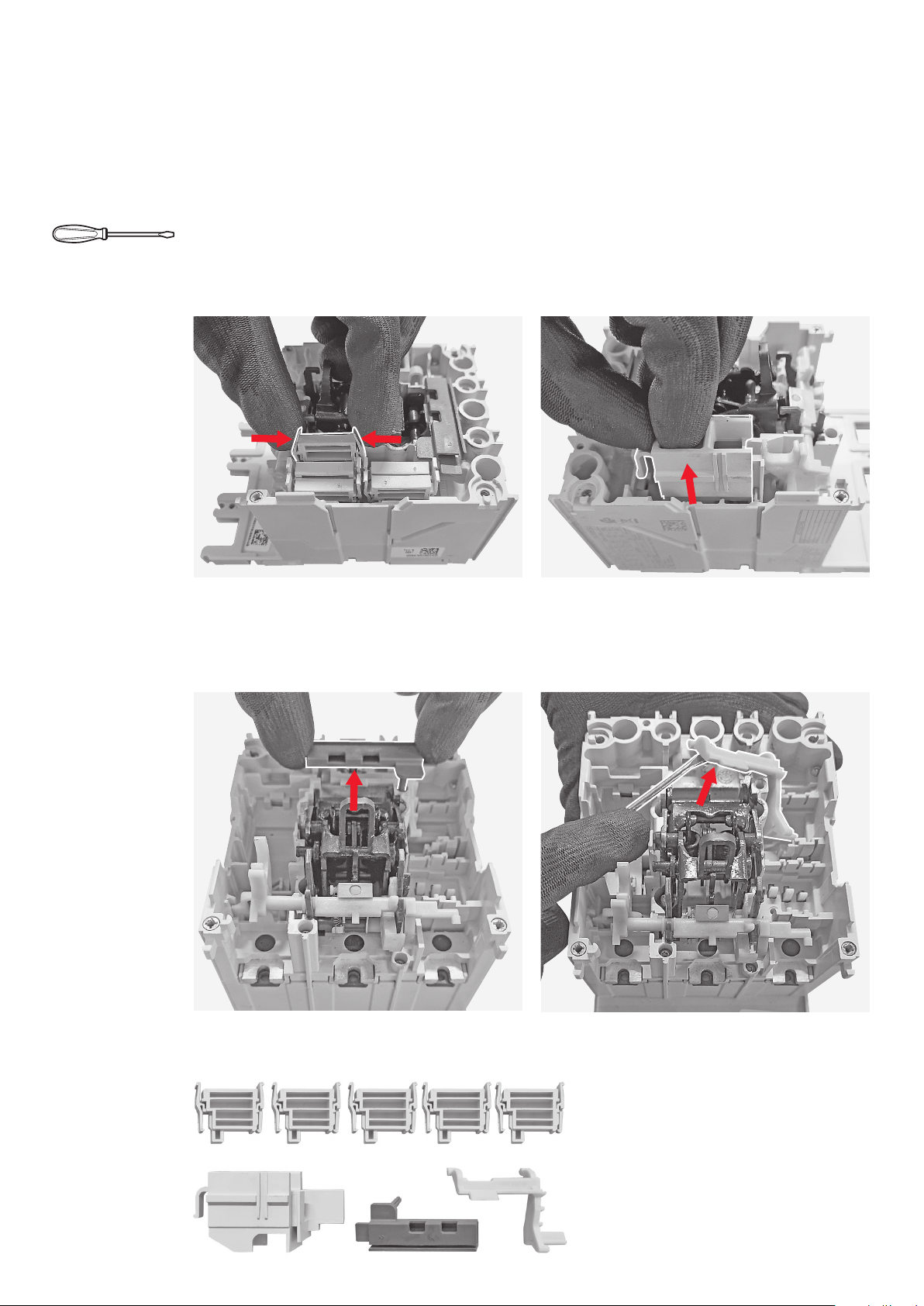

Disassembly instruction tmaX Xt Xt4 tHermomaGnetic

1. SCOPE

Scope of this document is to illustrate the step-by-step disassembly process of ABB SACE Tmax XT XT4

moulded case circuit breaker equipped with a thermomagnetic trip unit.

Document is focused on Tmax XT XT4 3p IEC version, anyway it allows to cover other versions of Tmax

XT XT4 circuit breaker equipped with a thermomagnetic trip unit with just few slight differences to be

taken into account.

Gloves Glasses Safety shoes Protective clothes

4. TOOLS

Disassembly operations require the use of tools (e.g. screwdriver, torx key, pliers, …); tools to be used

are specified inside each phase of the disassembly process (see Chapter 6).

3. PERSONAL PROTECTIVE EQUIMENT (PPE)

When performing disassembly, following safety Personal Protective Equipment (PPE) must be worn:

2. SAFETY NOTES

Before proceeding with any disassembly operation, it’s mandatory to put the circuit breaker in open

position.

Disassembly operations of circuit breakers must be performed by qualified and skilled personnel in

the electrical field (IEV 195-04-01: person with relevant education and experience to enable him or her

to perceive risks and to avoid hazards which electricity can create) and having a detailed knowledge of

circuit breakers.

Disassembly activites must be performed in an ergonomic workspace able to ensure protection of per-

sons demanded to perform disassembly activities.

Applicable national legislation and international standards in force at the time of disassembly of circuit

breakers must be taken into account in addition to prescriptions illustrated in this document.

ABB declines any responsibility for injury to people or damage to property resulting from a failure to

comply with the instructions set out in this document and with any applicable safety standard.