14

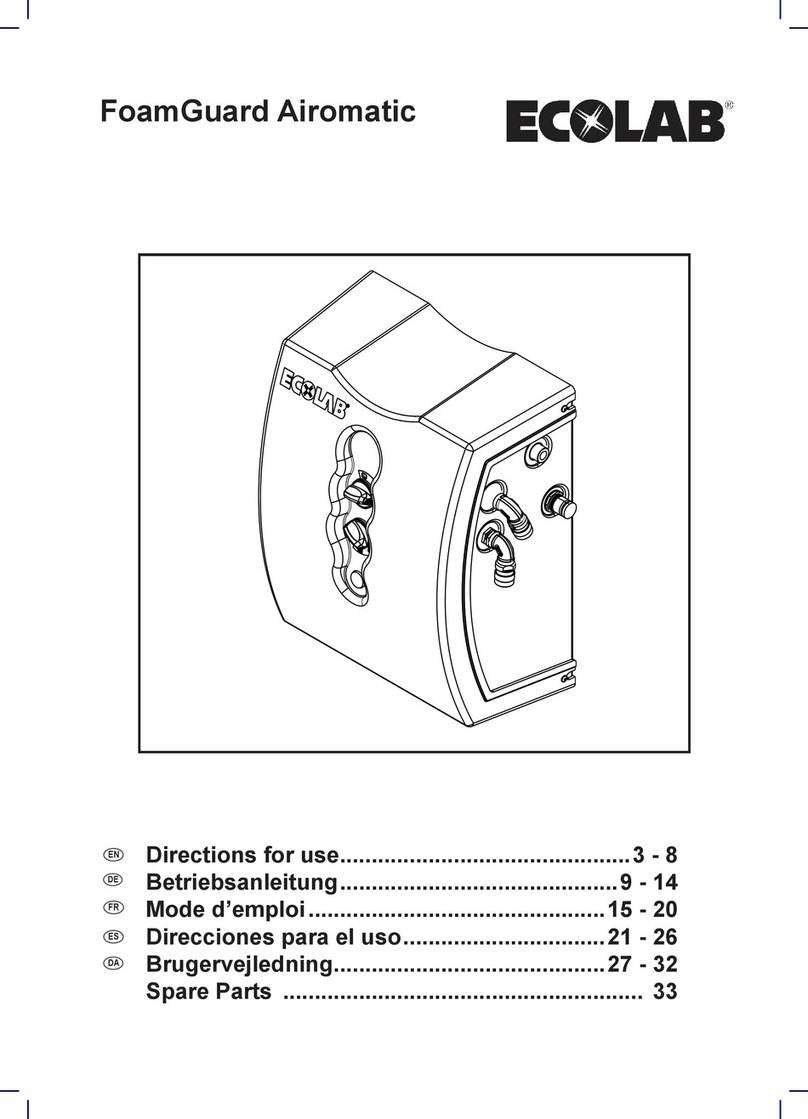

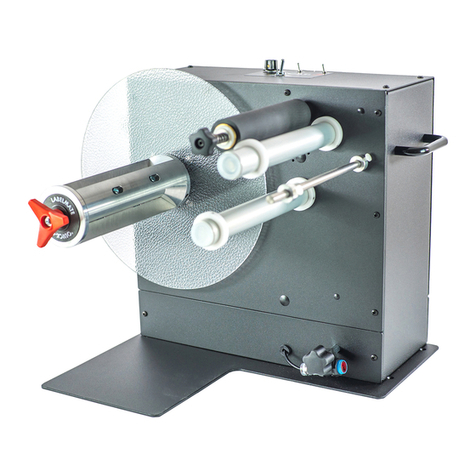

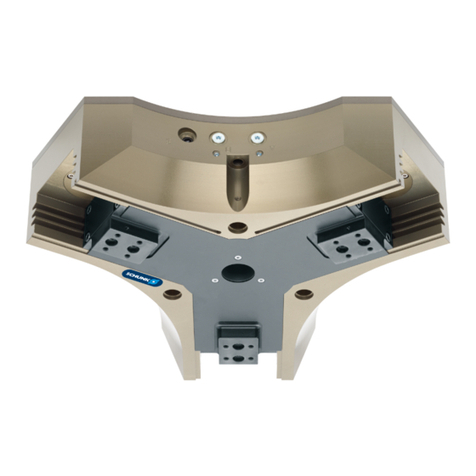

Fig. 7 17465

⇓

Fig. 8 17467

Fig. 9 17469

2. Maintenance

The boosters do not require main-

tenance.

The filter must, however, be clea-

ned with regular intervals (approx.

1-3 month) dependent on the

water’s lime contents.

2.1 Filter (Fig. 7)

Booster 6 and 12

1. Press ‘O’ on the control box to

stop the Booster.

2. Close the ball valve for the inlet

water.

3. Open a tap to make the system

pressure free.

4. Check that the system is pres-

sure free. Manometer must drop

to 0.

5. De-assemble the filter and put it

in a lime dissolving fluid until the

lime has dissolved.

Remark. On Booster 6 the pres-

sure switch must be de-assemb-

led first.

6. Rinse the cleaned filter

thoroughly and assemble it

again.

Booster 24

The separate filter which is as-

sembled on the inlet pipe must be

cleaned in accordance with the

producer’s directions.

It is recommended to clean the

Booster regularly.

2.2 Before a Long Break

If a long production break is plan-

ned (more than 6 month) where

the pump is emptied of water, it is

recommended to safeguard the

pump in the following way:

1. De-assemble the connection’s

protection screen.

2. Spray a couple of drops of silico-

ne oil on the shaft between the

cylinder head and connection.

The manual from the pump sup-

plier must furthermore be followed

closely.

3. Start

Remark: The pump must be aired

out and filled with water before

start.

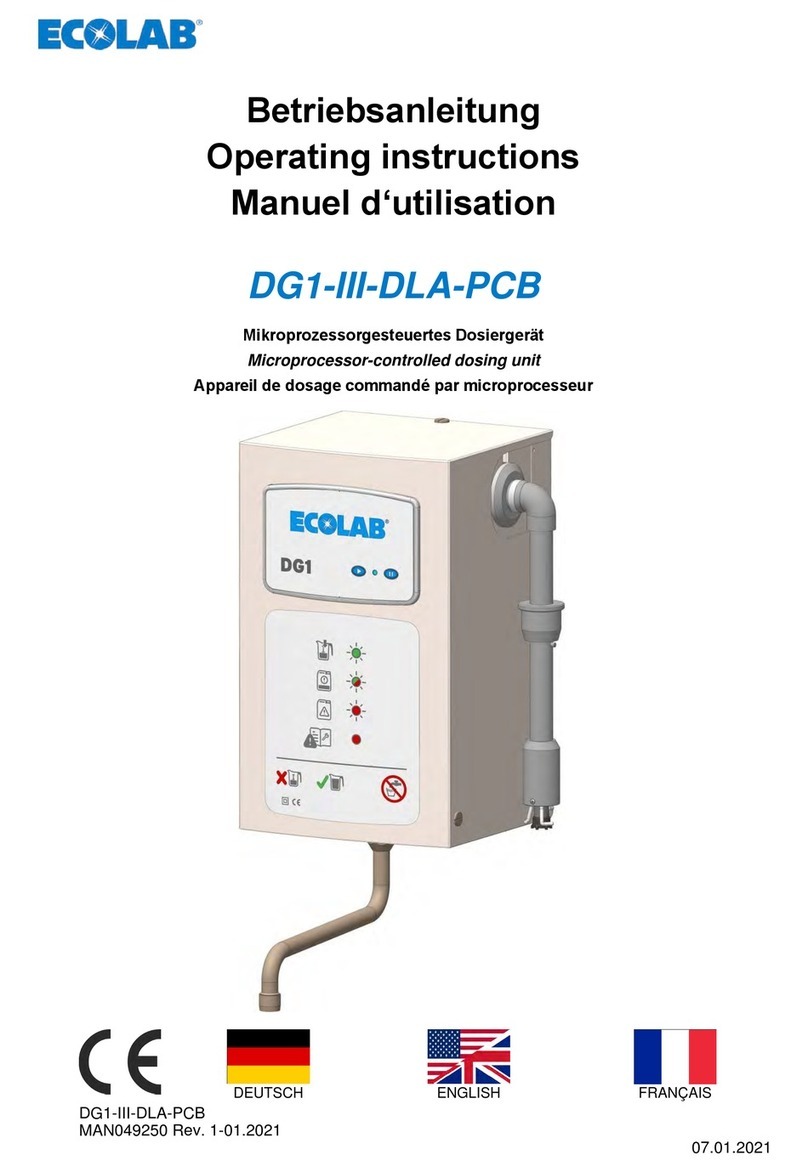

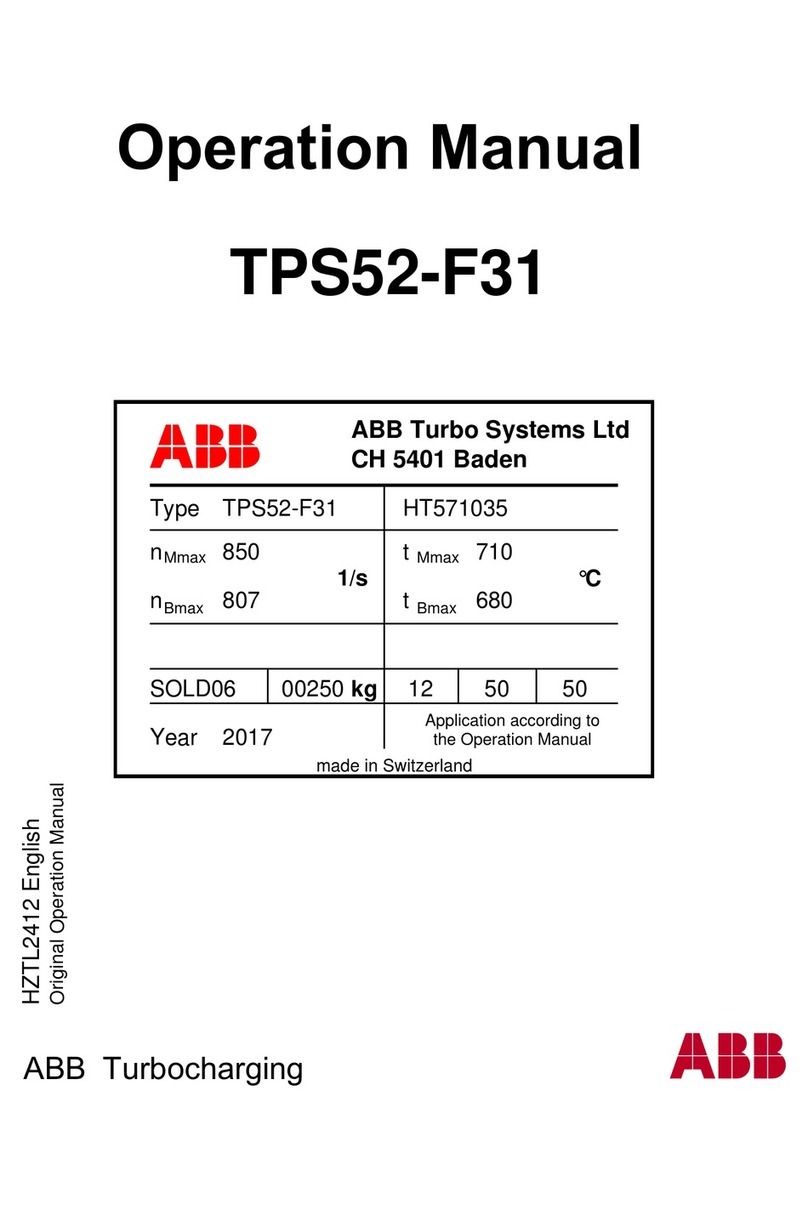

Remark: Check that the flow switch

is placed correctly, see Fig. 8. The

flow switch must be placed paral-

lel with the pipe so that the line

comes out in the flow direction.

3.1 New System

To ensure a problem free start of a

new system, the system must be

flushed through and aired out:

Airing out of pipe system

1. Open the water supply to flush

through and air out the system.

Open the tap farthest away until

no air or dirt come out. Then

flush and air out the second

farthest tap and continue until

the closest tap has been flushed

and aired out.

2. Assemble all Terminals/

Satellites.

Airing out of pump(s)

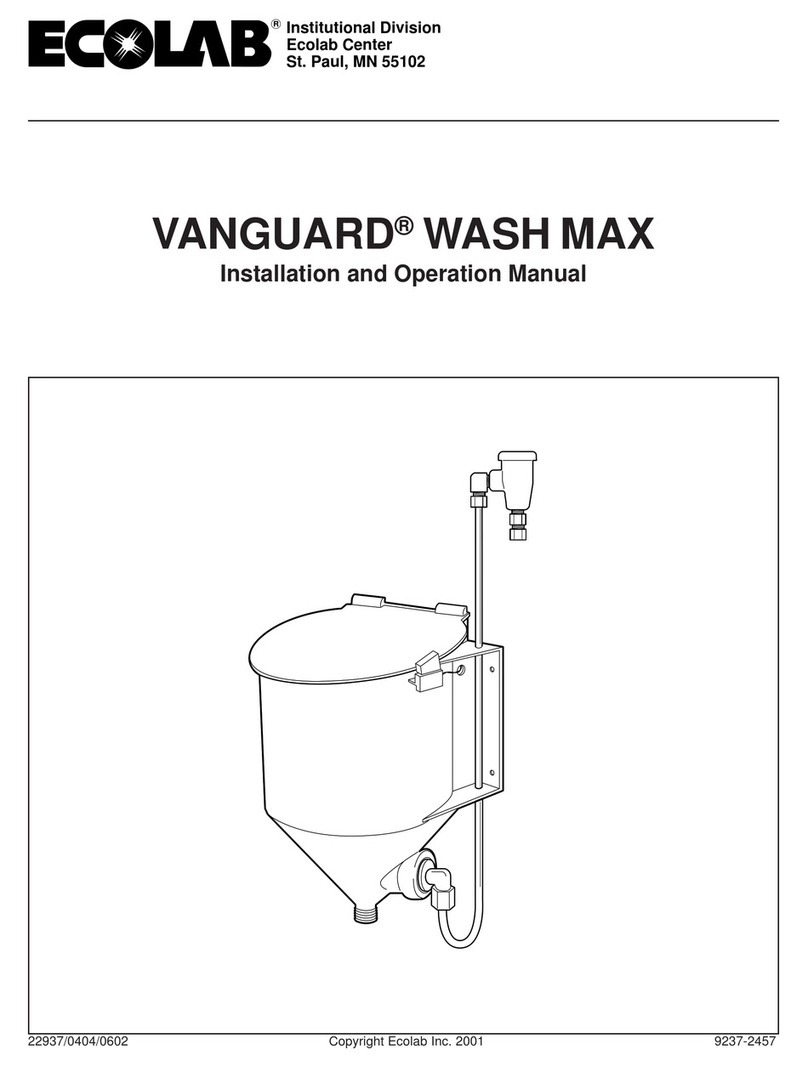

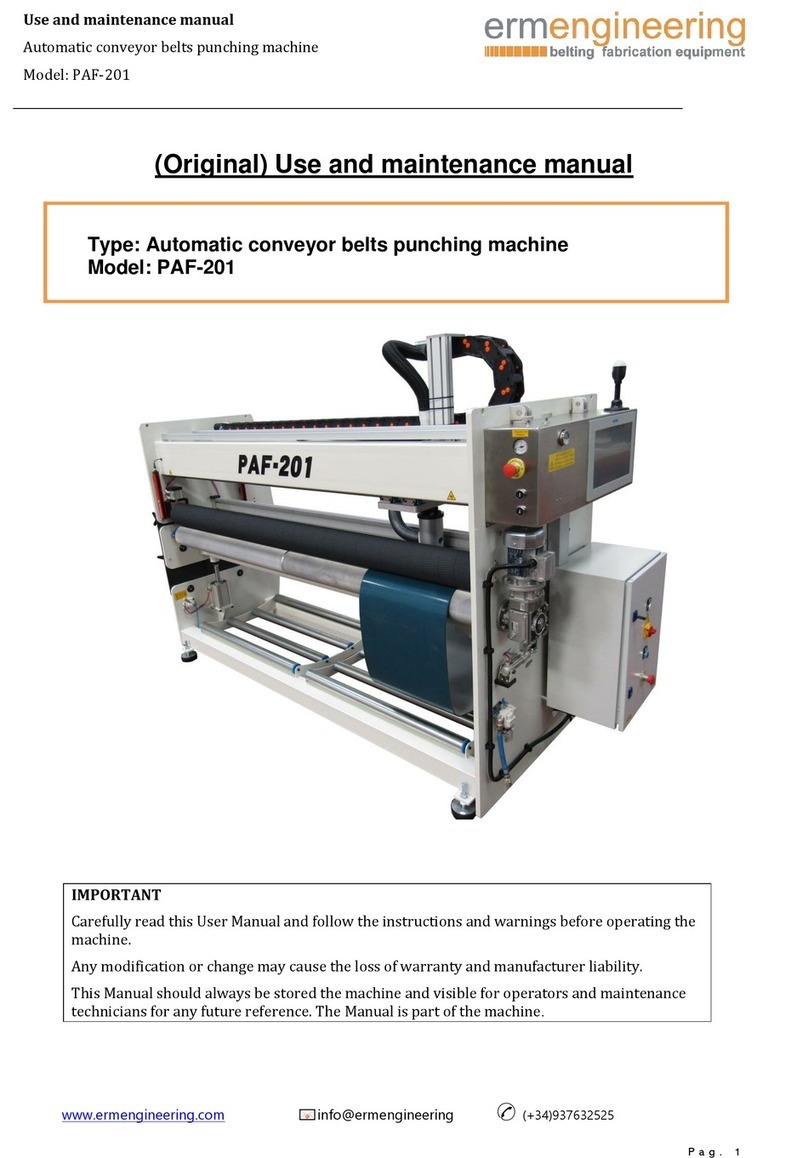

3. Loosenthe thermostat (A, fig. 9)

1-2 rounds until water and air

come out.

Remark: Never loosen the

thermostat when the pump is

running. The gasket may be

damaged.

Take care not to damage the

thermostat’s line connection.

4. Tighten the thermostat device

again.

5. Start the Booster so that the re-

maining air pockets can be pres-

sed up to the top of the pump.

Check at the same time that

the pump’s outflow direction

is correct. See the arrows on

top of the motor.

6. Stop the Booster.

7. Loosen the thermostat 1-2

rounds again and air out until

only water comes out.

8. Tighten the thermostat again.

9. Start the Booster again.