Novexx Solutions EIDOS XTO Series User manual

User Manual XTO intermittent series

Edition C - 01/2024

Original Instructions - keep for future reference

RT805

USER MANUAL

XTO2i.20 / XTO2i.40 / XTO2i.60

XTO22i.40 / XTO22i.60 / XTO22i.90

Intermittent Thermal Transfer Overprinter

(TTO)

This manual contains the EC Declaration of Conformity

User Manual XTO intermittent series

Edition C - 01/2024

1

Contents

Contents

Information ................................................................................................................................ 2

NOTES ON THE CORRECT USE OF THE PRINTER ..............................................................................2

GENERAL NOTES...............................................................................................................................2

SAFETY NOTICES...............................................................................................................................3

GENERAL PRECAUTIONS ..................................................................................................................3

DANGEROUS AREAS ON THE PRINTING UNIT..................................................................................4

PROTECTION ELEMENTS PROVIDED ON THE PRINTER ....................................................................8

Product Description ................................................................................................................. 13

FUNCTIONALITY .............................................................................................................................13

PECULIARITY ...................................................................................................................................13

CARRIAGE STROKE LENGTHS AND MACHINE TYPE........................................................................14

SYSTEM MODELS............................................................................................................................15

REAR CONNECTION PANEL ............................................................................................................19

OPERATING PANEL.........................................................................................................................20

BASIC SETTINGS..............................................................................................................................23

Operation ................................................................................................................................ 30

INSERTING CONSUMABLES ............................................................................................................30

THE THERMAL RIBBONS .................................................................................................................31

PRINTING........................................................................................................................................32

CREATION AND SENDING OF THE LABEL WITH EASYCODE ...........................................................33

HOW TO STORE LABEL FILES (.LM1)...............................................................................................35

HOW TO BACK UP ..........................................................................................................................35

SETTING AND MONITORING ..........................................................................................................36

STATUS MESSAGES.........................................................................................................................58

Multipitch motorized positioner ............................................................................................... 60

DEVICE MANAGEMENT..................................................................................................................61

Preventive Maintenance .......................................................................................................... 64

CLEANING INSTRUCTIONS..............................................................................................................64

CLEANING THE PRINT HEAD...........................................................................................................65

CLEANING THE PRINTING PLATE....................................................................................................65

CLEANING ROLLS AND RIBBON PASSAGES ....................................................................................66

CLEANING THE CARRIAGE SLIDING GUIDE.....................................................................................67

Appendix 1 ............................................................................................................................... 68

EC DECLARATION OF CONFORMITY...............................................................................................68

Appendix 2 ............................................................................................................................... 69

CE LABEL.........................................................................................................................................69

Appendix 3 ............................................................................................................................... 70

ZEBRA and EIDOS NICELABEL EMULATION FILE MANAGEMENT (.prn, .zpl) .................................70

User Manual XTO intermittent series

Edition C - 01/2024

2

Information

Information

NOTES ON THE CORRECT USE OF THE PRINTER

Read these notes together with Chapter “Safety notices" to ensure that the printer is used correctly.

Switching on the printer.

•If the printer has been left in a cold or excessively hot environment for a considerable time, wait

at least 1 hour before switching it on to prevent humidity collecting on the internal circuits.

•After switching off, wait for a few seconds before switching on the printer again.

Use in particularly places

If the printer is going to be used in particularly humid conditions (for example cheese factories) the

protection kits are necessary. Do not use it where there is a lot of oil, iron particles, or dust.

Disposal

The device may not be disposed of with household rubbish. This appliance is labelled in

accordance with European Directive 2012/19/UE concerning used electrical and

electronic appliances (waste electrical and electronic equipment - WEEE).

The guideline determines the framework for the return and recycling of used appliances

as applicable throughout the EU. To return your used device, please use the return and

collection systems available to you.

GENERAL NOTES

Validity of this manual and required compliance

This user manual refers exclusively to the electronic printer for thermal transfer to film named XTO.

It is used for proper operation and adjustment of the printer.

The printer must be properly installed and configured to allow for operation and settings.

For information about installation and maintenance, see the Installation manual.

For technical questions not covered in this operating manual request a service technician.

Technical release

Software version XTO: 2.9

Hardware version XTO: 68XTO2I20E, 68XTO2I40E, 68XTO2I60E

68XTO22I40B, 68XTO22I60B, 68XTO22I90C

These instructions have to be kept for future reference and must be

available throughout the expected life of the product.

Liability and Copyright

All rights to this manual are reserved. This manual may not be reproduced in any form, either wholly

or partially, without the express written authorisation of Eidos Srl. The contents of this manual are

subject to modifications and improvements without prior warning. Every effort has been made to

ensure the accuracy of the contents. If errors and/or inaccuracies are detected, inform Eidos Srl in

order to make the manual as exhaustive as possible. Eidos Srl accepts no responsibility for any

accidental errors or for any damage arising from the supply, scope or use of this manual.

User Manual XTO intermittent series

Edition C - 01/2024

3

Information

How information is represented

Explanation of symbols

WARNING!

A warning symbol refers to risks that can result in severe or fatal injuries! The text

within this area contains instructions for preventing damage.

➔

Instructions must be followed without exception.

WARNING! The text within this area contains important recommendations as well as additional

information or information to use the product correctly and efficiently.

SAFETY NOTICES

The printer is provided with a “EC Declaration of conformity” according to the "Machinery Directive

2006/42/EC" which includes the reference standards for "Electromagnetic Compatibility" and

"Electrical Safety":

1.

Do not start up the machine without first reading and implementing the prescriptions of the

“USER MANUAL” and the present “SAFETY NOTICES”.

2.

The printing unit is equipped with two covers: the first [RM1] is removable while the second

[RM2] can be opened by rotating it on two hinges. The removable cover [RM1] is monitored

by two sensors [SENS_C1] and [SENS4] which switch off the power supply to the motors when

the cover is open. The presence of a mechanical interlock [IB1] does not allow you to open

the cover [RM2] without first removing the cover [RM1] and it does not allow you to insert

and close the cover [RM1] before closing the cover [RM2]. To prevent finger access in the

carriage [C1/C2] movement area [A/B], the XTO print unit and the print plate must always be

aligned with each other.

3.

The printer must not be used in an explosive environment or be used to treat explosive

materials.

4.

The printer must not be used in irregular situations such as working without guards being

correctly fitted to the machine; working with products other than those prescribed.

5.

After 7 years of operation on an 8-hour daily shift, a complete overhaul of the product is

recommended.

GENERAL PRECAUTIONS

1.

Be careful when moving or carrying the printer. Wear safety shoes when installing or removing

the printer from the packaging machine: dropping the printer may cause injury or property

damage. The machine must NOT be used by the lid or the handle. (See the "LIFTING AND

TRANSPORT" Chapter of the Technical Manual RT806).

2.

Do not open the printer during printing.

3.

When cleaning the surface of the printer case, do not use the cloth that is soaked in thinner,

trichloroethylene, benzine, ketone or similar chemicals.

4.

Do not spill liquids or spray insecticide on the printer.

5.

When printer trouble occurs, do not try to dissemble it. Instead, consult our service personnel.

User Manual XTO intermittent series

Edition C - 01/2024

4

Information

DANGEROUS AREAS ON THE PRINTING UNIT

Dangerous areas on XTO2i.nn - front and bottom view

Note:

During the installation it is necessary to fix the printing plate and the

printing unit so that the plate prevents finger access to the areas [A] and [B]

where the carriage with the print head moves.

Figure 1: dangerous areas on XTO2i.nn - front viewl

Figure 2: dangerous areas on XTO2i.nn – bottom viewl

s2

s1

S

H

T

t

X

Y

A

B

[RM1]

[RM2]

[C1]

User Manual XTO intermittent series

Edition C - 01/2024

5

Information

Dangerous areas on XTO22i.nn (model with double carriage) - front and bottom view

Note:

During the installation it is necessary to fix the printing plate and the

printing unit so that the plate prevents finger access to the areas [A] and [B]

where the carriage with the print head moves.

Figure 3: dangerous areas on XTO22i.nn - front view

Figure 4: dangerous areas on XTO22i.nn – bottom view

s2

s1

S

H

T

t

S

H

T

t

A

B

[RM1]

[RM2]

[C1]

[C2]

B

[C2]

[C1]

A

User Manual XTO intermittent series

Edition C - 01/2024

6

Information

Dangerous areas - rear view

Dangerous areas on - side views

Dangerous areas - carriage.

Figure 5: Dangerous areas - rear view

W

P

Figure 6: Dangerous areas - side views

Figure 7: Dangerous areas - carriage

M2

M3

M1

Y

U

P

X

Ct

Sm

t

User Manual XTO intermittent series

Edition C - 01/2024

7

Information

Passive (non-motorized) rotating rollers

Definitions

H

Movement of the carriage during printing or positioning in the "Service" area.

Danger of crushing the fingers

S

Movement of the carriage when returning to Home after printing or during a return from

"Service". Danger of crushing the fingers.

A

Access from the lower right side: carriage moving to the right (home position return)

B

Access from the lower left side: carriage moving to the left (print)

T

Movement of the print head

s1

Rotation of the mandrel holding the ribbon release coil

s2

Rotation of the mandrel holding the ribbon rewinding coil

X

Movement of the carriage during printing or positioning in the "Service" area.

Danger of crushing the fingers.

Y

Movement of the carriage when returning to Home after printing or during a return from

"Service". Danger of crushing the fingers.

P

Rotation movement of the pulley and the belt for transmitting motion to the carriage

W

Rotation movement of the pulley and the belt for transmitting motion to the carriage

Ct

Print head movement servomotor cam

R1

Rubberized ribbon encoder roller

R2…7

Free rollers for ribbon guide

Hot parts highlight on XTO:

Part temperatures were measured at ambient temperatures of 20 ° C and after the XTO ran at

full cadence for 7 hours.

M1

Ribbon unwinding motor body

T max. 45°C

M2

Ribbon rewinding motor body

T max. 50°C

M3

Carriage movement motor body

T max. 60°C

U

CPU Heatsink

T max. 50°C

t

Print head

T max. 60°C

sm

Print head motion servo motor body

T max. 55°C

Figure 8: free rollers

R1

R2

R3

R4

R6

R7

R5

R3

R4

for

XTO22

i.nn only

User Manual XTO intermittent series

Edition C - 01/2024

8

Information

PROTECTION ELEMENTS PROVIDED ON THE PRINTER

Covers fixed with screws

WARNING!

Disconnect the 48Vdc power supply to the printer before removing the fixed guards

[RF1], [RF2], [RF3a], [RF3b]. The fixed guards must be removed only for extraordinary

maintenance or repairs.

Movable interlocked guard [RM1] and openable guard [RM2]

Figure 9: fixed cover

Figure 10: movable interlocked guard and openable guard

RM1

RM2

RF3a

RF2

RF1

RF3b

User Manual XTO intermittent series

Edition C - 01/2024

9

Information

Fixed guard but not solidly screwed to the Printing Unit:

The Printing Plate [PP] cannot be strongly screwed to the Printing Unit [PU] because it is necessary

to leave the passage to the packaging film [PF] to be printed.

Note:

During the installation it is necessary to fix the printing plate [PP] and the

printing unit [PU] so that the plate prevents finger access to the areas [A]

and [B] (Figure 2-Figure 4) where the carriage with the print head moves.

On supports where there is an independent adjustment of the Printing Unit [PU] and the Printing

Plate [PP], it is always necessary to maintain a relative position between the two parts that prevents

access to dangerous areas. Also to obtain a good print quality, the print head must be positioned at

a distance from the edge of the rubber layer, not less than 5 mm and that the Printing Plate [PP] is

always centred with respect to the Printing Unit [PU].

[PU]

[PF]

[PP]

Figure 11: Printing plate

Figure 12: Printing plate and Print Unit position

User Manual XTO intermittent series

Edition C - 01/2024

10

Information

Monitoring sensors movable guard [RM1] inserted

Figure 14: monitoring sensors

Figure 13: printing plate alignment

SENS4

SENS_C1

Magnetic sensor

IB1*

Mechanical interlock

*ATTENTION: in case of

breakage of the IB1 block, it

will be necessary to replace

the opening cover, otherwise

the printer will be NOT safe.

User Manual XTO intermittent series

Edition C - 01/2024

11

Information

External safety contacts: SAFETY_A and SAFETY_B (SAF_EXT)

NOTE: If not used, they must be jumpered.

Not interlocked movable guard [RM3]

The guard is accessible only after removing the interlocked mobile guard [RM1].

Magnets and magnets ring

To ensure good fastening of the movable guard [RM1] to the printing unit, magnets [mg1], [mg2]

have been provided on the printer body and magnetic rings [am1], [am2] on the ribbon inserter.

Figure 15: safety contacts

[SAF_EXT]

SAFETY_A

SAFETY_B

SAFETY_SAF

Figure 16: guard - in figure the XTO22i.nn with double carriage

mg2

am2

mg1

am1

Figure 17: magnets

RM3

User Manual XTO intermittent series

Edition C - 01/2024

12

Information

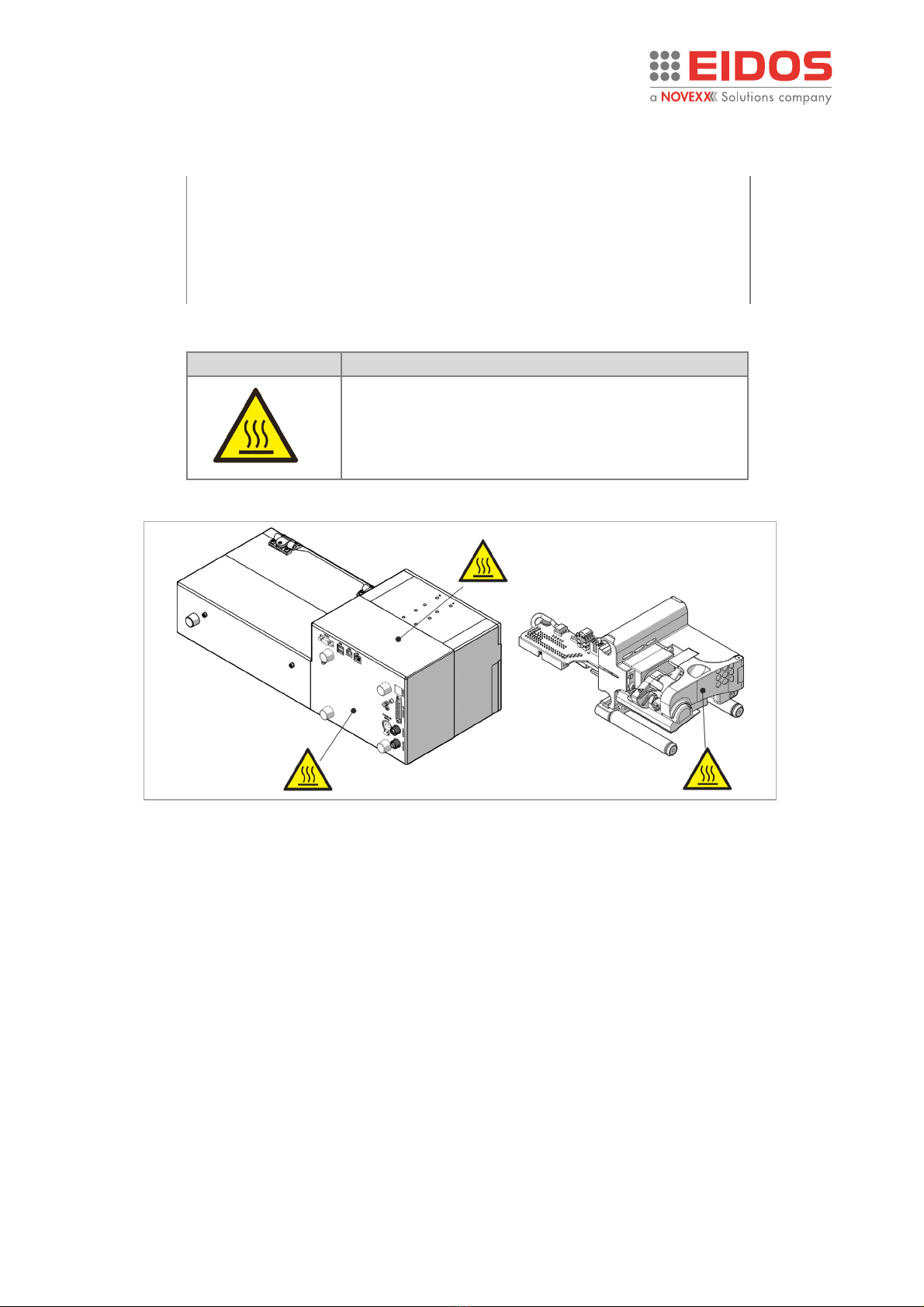

Warning symbols on the machine

CAUTION!

Warning symbols on the machine provide important information for the

operating personnel.

➔Do not remove warning symbols.

➔Replace missing or illegible warning symbols.

Meaning of the warning symbols:

Warning symbol

Meaning

The "Hot surface" symbol informs the operator and

the staff assigned to the

maintenance of the

presence of potentially dangerous hot surfaces.

Allow the device to cool off before touching it.

Figure 18: warning symbols

User Manual XTO intermittent series

Edition C - 01/2024

13

Product DESCRIPTION

Product Description

FUNCTIONALITY

The XTO intermittent is an electronic printer for "thermal transfer to film" that is able to write

automatically and directly on the plastic or paper film used in packaging machines by means of an

inked thermal ribbon. The packaging film must be stationary during printing.

The XTO intermittent codes the different production batches with variable text, barcodes and logos

extremely flexibly, ensuring high quality and fast printing.

In stand-alone operation, the label files created with the EASYCODE program installed in a PC can

be loaded in the printer using the USB memory key.

With the XTO22i.nn model, with double carriage, it is possible to halve the printing time and

considerably increase the operating speed. It is also possible to manage and print different print

formats and texts for each of the two printheads.

PECULIARITY

•Print Unit very light and compact, easy to be installed.

•Easy to service and repair; easy system of ribbon passage for changing operation.

•Programmable printing steps and format printing parameters loadable by the touch screen

display (optional) or the P.C. through the use of a browser (Chrome, Edge ...).

•Improve unit uptime: not necessary to uninstall the print unit from the line.

•Modular assembly: mechanic + electronic.

•Easy and fast replacement of electronic components (no interference with mechanical parts).

•HMI (Human-Machine Interface) user friendly.

•Simply ribbon changing operation.

•Simply print head and print plate cleaning and replacing directly on board the printer.

•Printer management (parameters, labels, diagnostic etc..) with local EIDOS Touch panel or

remote PC with a Web Browser.

User Manual XTO intermittent series

Edition C - 01/2024

14

Product DESCRIPTION

CARRIAGE STROKE LENGTHS AND MACHINE TYPE

XTO model

Carriage stroke [C]

Print head type

The maximum print length (carriage stroke

length) is autodetected when the printer is

switched on.

XTO2i.20

200 mm

53 mm

XTO2i.40

400 mm

53 mm

XTO2i.60

600 mm

53 mm

Distance between the two print heads [C1]

XTO model

Carriages stroke [C1+C2]

Print head type

Minimum

Maximum

XTO22i.40

400 mm

2 x 53 mm

180 mm

350 mm

XTO22i.60

600 mm

2 x 53 mm

250 mm

550 mm

XTO22i.90

900 mm

2 x 53 mm

350 mm

850 mm

The “XTO model” is shown on the red bar of the Help page.

The Printer is available as right hand (RH) version, i.e. printing occurs when the carriage moves from

left (home position) to right.

Figure 20: printer model

Figure 19: film passage and carriage stroke length

S00074

User Manual XTO intermittent series

Edition C - 01/2024

15

Product DESCRIPTION

SYSTEM MODELS

WARNING!** the 45CV914/1 cable is supplied 7 meters long, but during installation

it must be cut as short as possible, to avoid the error signalling (E207) when closing

the front cover. The cable must pass far from the cables that supply motors or

electrovalves, to avoid noises and spikes.

Note: The I/O SIGNALS Junction Box 49KS0162 is not intended for Industrial use.

Figure 21: XTO2i.nn system models

(capacitor kit to be connected

on the 48Vdc power supply

V+/V- output pins)

2 m

2 m

*nn = Carriage length (in cm) identifier

XTO

49KS0162

+

XTO

49KS0162

+

XTO

49KS0162

+

XTO

49KS0162

+

7XTO2Inn-2

7XTO2Inn*-1

7XTO2Inn-3

7XTO2Inn-4

45CV910/1

(capacitor kit to be connected

on the 48Vdc power supply

V+/V- output pins)

45CV910/1

45CV914/1

+48Vdc 220W

L = 7 m**

45CV914/1

+48Vdc 220W

L = 7 m**

2 m

2 m

User Manual XTO intermittent series

Edition C - 01/2024

16

Product DESCRIPTION

WARNING! *** the 45CV914/1 cable is supplied 7 meters long, but during

installation it must be cut as short as possible, to avoid the error signalling (E207)

when closing the front cover. The cable must pass far from the cables that supply

motors or electrovalves, to avoid noises and spikes.

Note: The I/O SIGNALS Junction Box 49KS0162 is not intended for Industrial use.

45CV932/1 + CE300434

45CV914/1

XTO

49KS0162

+

XTO

49KS0162

+

XTO

49KS0162

+

+48Vdc 320W

L = 7 m**

XTO

49KS0162

+

7XTO22Inn-2

7XTO22Inn*-1

7XTO22Inn-3

7XTO22Inn-4

45CV910/1

(capacitor kit to be connected

on the 48Vdc power supply

V+/V- output pins)

45CV910/1

Figure 22: XTO22i.nn system models

45CV932/1 + CE300434

45CV914/1

+48Vdc 320W

L = 7 m**

(capacitor kit to be connected

on the 48Vdc power supply

V+/V- output pins)

*nn = Carriage length (in cm) identifier

2 m

2 m

User Manual XTO intermittent series

Edition C - 01/2024

17

Product DESCRIPTION

IP Version: 7XTO2Inn*-1TR, 7XTO22Inn*-1TR / 7XTO2Inn-1IP, 7XTO22Inn-1IP

The TR printer version offers an IP30 protection degree, having electronic boards and print head

tropicalized. An IP printer version is available, with IP33 protection degree. It is equipped with

tropicalized electronic boards and print head, as well as a rear cover with adequate protection for

the connectors.

The optional 53SDK20 touch panel offers IP55 protection. An IP version of the Touch Panel, code

53SDK21, is also available, to be installed on the electrical cabinet of the packaging machine (a hole

is required).

Figure 23: IP model

Figure 24: IP protected components

L = 7 m***

Touch panel

53SDK20

Touch panel

53SDK21

Rear cover

with IP

33

protection and

angled connectors

(for

-IP model only)

Tropicalized

interface board

Tropicalized

CPU board

Tropicalized

Power board

Tropicalized

Led board

Tropicalized

carriage board

Tropicalized

Cryptomemory

Tropicalized

encoder board

Tropicalized

print head

USB port

XTO

45CV914/1

45CV910/1

(capacitor kit to be connected

on the 48Vdc power supply

V+/V- output pins)

*nn = Carriage length (in cm) identifier

** = see note on previous page

***= 320W forr XTO22i.nn

48Vdc-220W

48Vdc

-320W***

User Manual XTO intermittent series

Edition C - 01/2024

18

Product DESCRIPTION

53SDK21 Touch panel

It is a 7 "TFT color graphic display with capacitive touch connected via ethernet to the printer, from

which it is also powered.

To fix the EIDOS Touch Panel to the packaging machine, a hole must be made, to be made as per

the drawing below. Fixing is ensured by means of an IP55 protection class sealing gasket. The EIDOS

Touch Panel is therefore also suitable for applications in humid or dusty environments.

Note: The maximum thickness of the plate on which the "EIDOS Touch Panel" can be applied is

4.5 mm

Figure 25: Touch Panel EIDOS 53SDK21

Drilling template

Place the panel, centring it within

the hole on the electrical cabinet of

the packaging machine, by

tightening the metal plate from the

inner side, by means of the screws

and the washers.

This manual suits for next models

6

Table of contents

Other Novexx Solutions Industrial Equipment manuals