1 Use 3

1.1 Intended use. . . . . . . . . . . . . . . . . 3

1.2 User group . . . . . . . . . . . . . . . . . 3

2 Safety 4

2.1 Symbols . . . . . . . . . . . . . . . . . . 4

2.2 Operational safety . . . . . . . . . . . . . . 4

3 Delivery 5

3.1 Scope of delivery . . . . . . . . . . . . . . . 5

3.2 Identification and test . . . . . . . . . . . . . 6

3.3 Storage. . . . . . . . . . . . . . . . . . . 6

4 Tools and aids 7

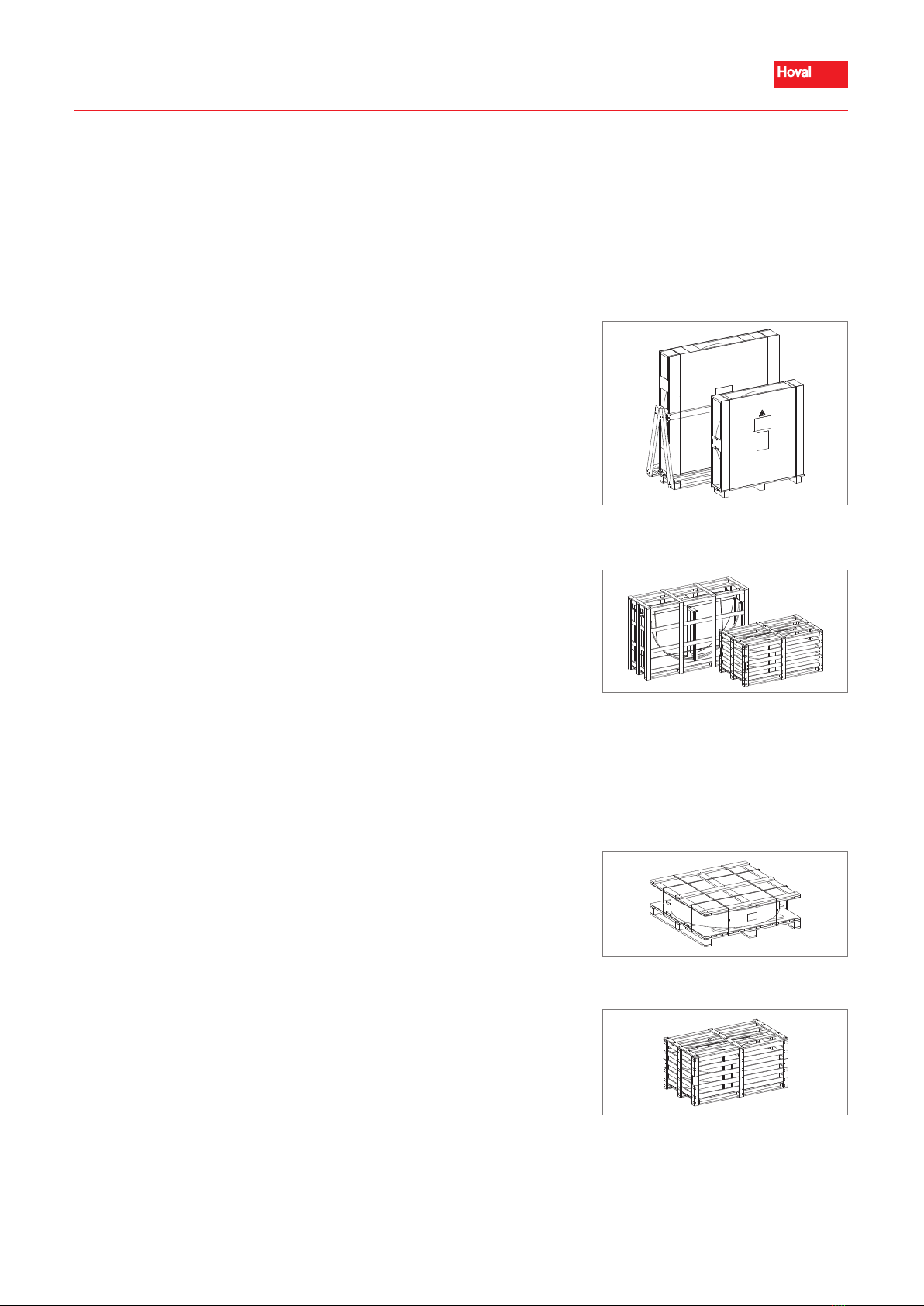

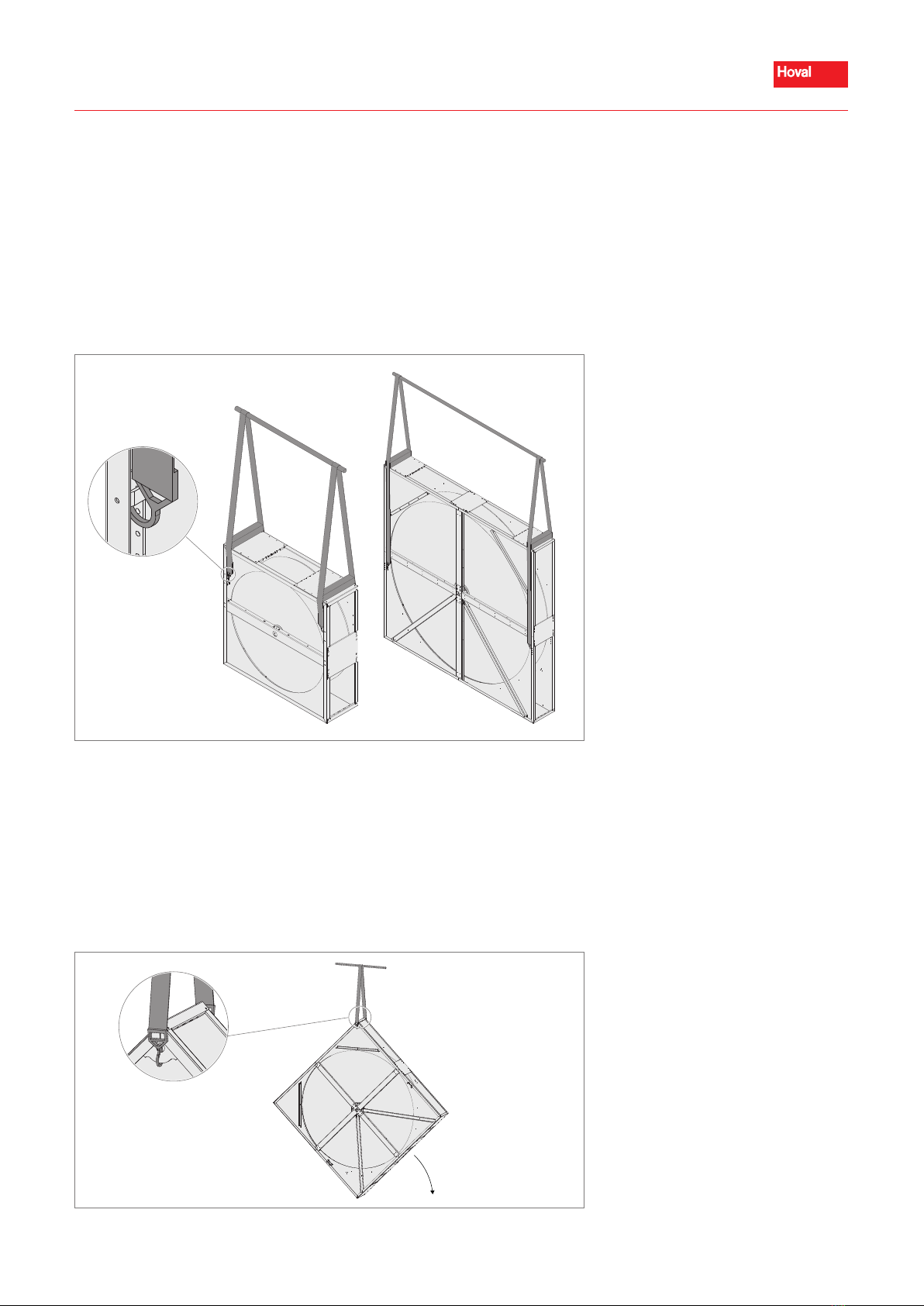

5 Lifting the exchanger 7

5.1 Lifting exchangers on pallets . . . . . . . . . . 7

5.2 Lifting exchangers with SM casing . . . . . . . . 8

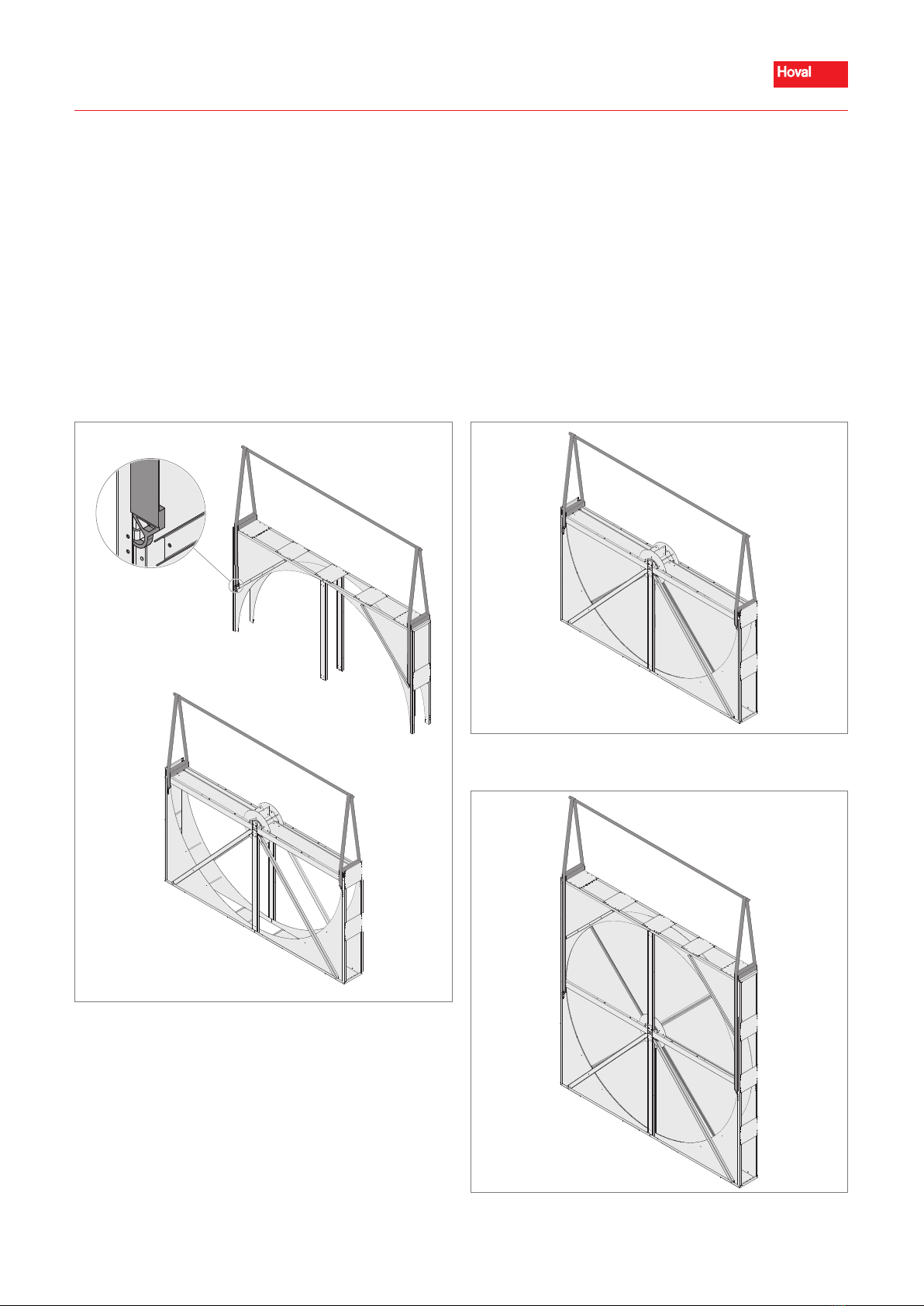

5.3 Lifting exchangers with SP casing . . . . . . . 10

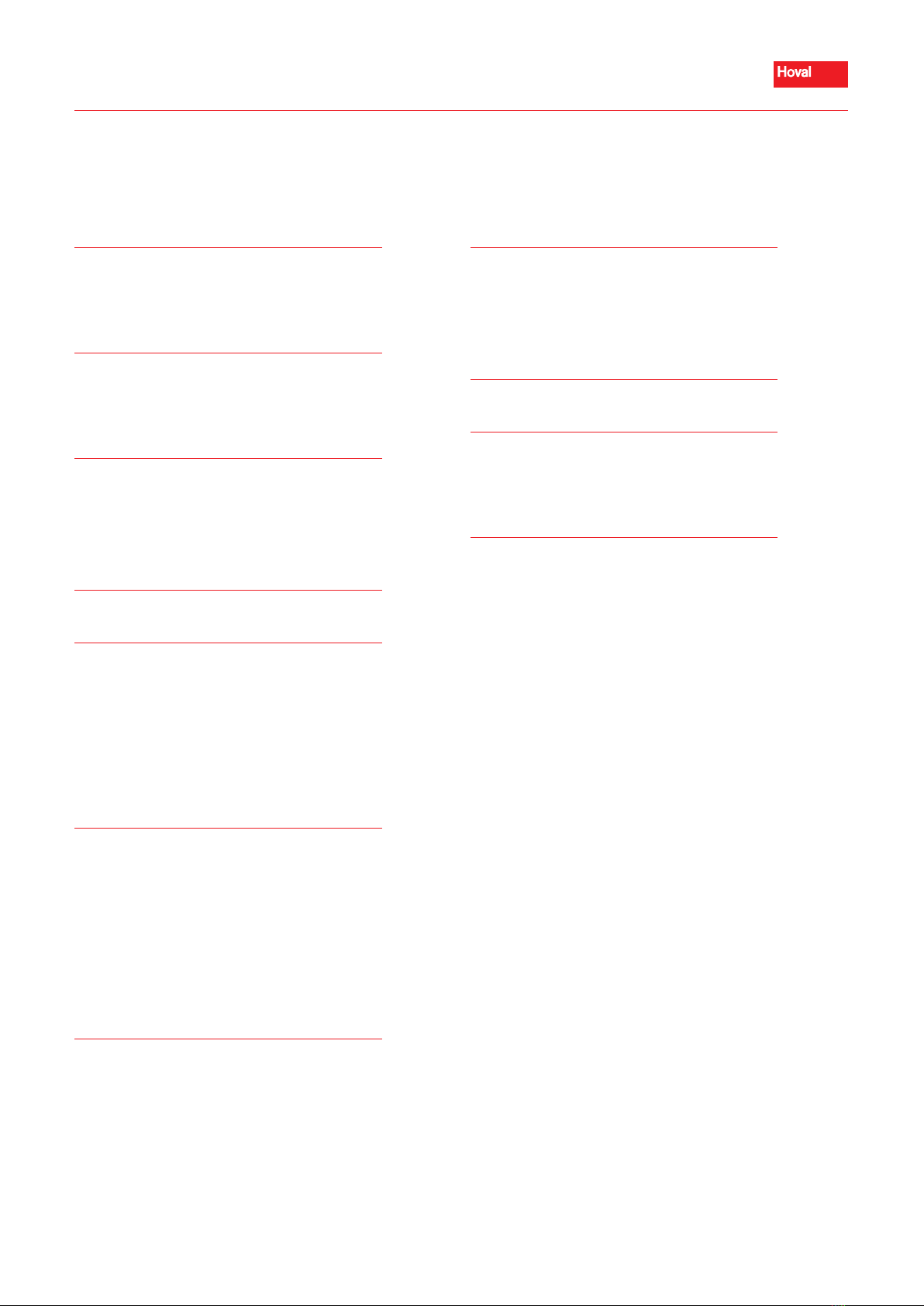

5.4 Lifting exchangers with PR casing . . . . . . . 11

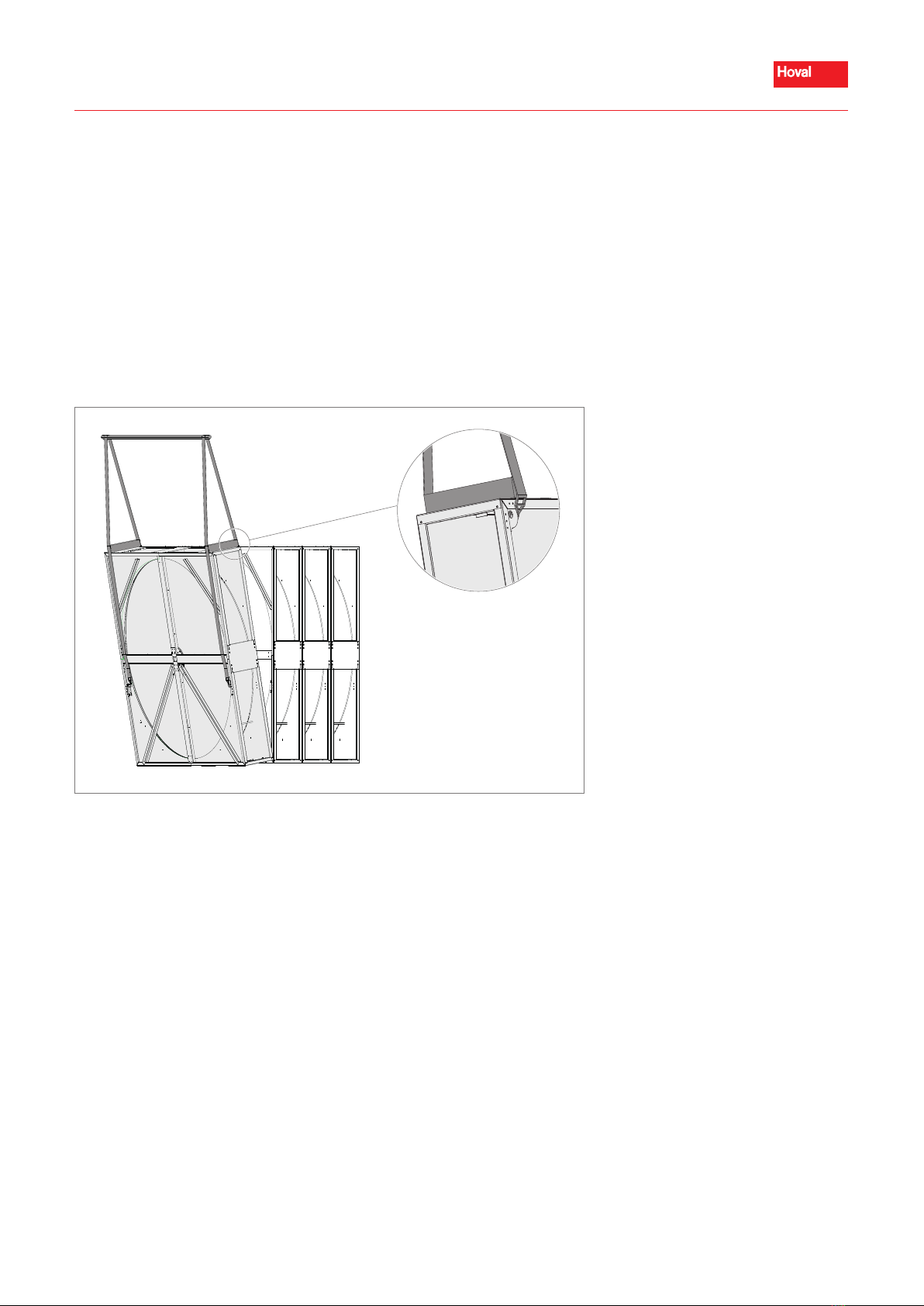

5.5 Lifting wheels without casing . . . . . . . . . 12

6 Assembly of segmented exchangers 13

6.1 Casing . . . . . . . . . . . . . . . . . . 13

6.2 Radial walls . . . . . . . . . . . . . . . . 16

6.3 Storage mass . . . . . . . . . . . . . . . 18

6.4 Purge sector. . . . . . . . . . . . . . . . 23

6.5 Seal . . . . . . . . . . . . . . . . . . . 25

6.6 Drive system. . . . . . . . . . . . . . . . 26

7 Assembly of half mounted exchangers 29

7.1 Casing . . . . . . . . . . . . . . . . . . 30

7.2 Radial walls . . . . . . . . . . . . . . . . 31

7.3 Storage mass . . . . . . . . . . . . . . . 32

7.4 Purge sector, seal, drive system . . . . . . . . 33

8 Installation in the air handling unit 34

8.1 Requirements for the installation site . . . . . . 34

8.2 Vertical installation . . . . . . . . . . . . . 34

8.3 Horizontal installation . . . . . . . . . . . . 35

9 Electrical connection 36

10 Commissioning 37

10.1 Checklist. . . . . . . . . . . . . . . . . 37

10.2 Monitoring work after 3 weeks . . . . . . . . 38

11 Maintenance and repair 38

11.1 Maintenance schedule . . . . . . . . . . . 38

11.2 Cleaning the storage mass. . . . . . . . . . 38

11.3 Spare parts. . . . . . . . . . . . . . . . 39

11.4 Replacement of the brush seal . . . . . . . . 40

11.5 Replacement of the V-belt . . . . . . . . . . 41

11.6 Servicing. . . . . . . . . . . . . . . . . 41

2

Rotary heat exchangers

4 219 613-en-03

Content