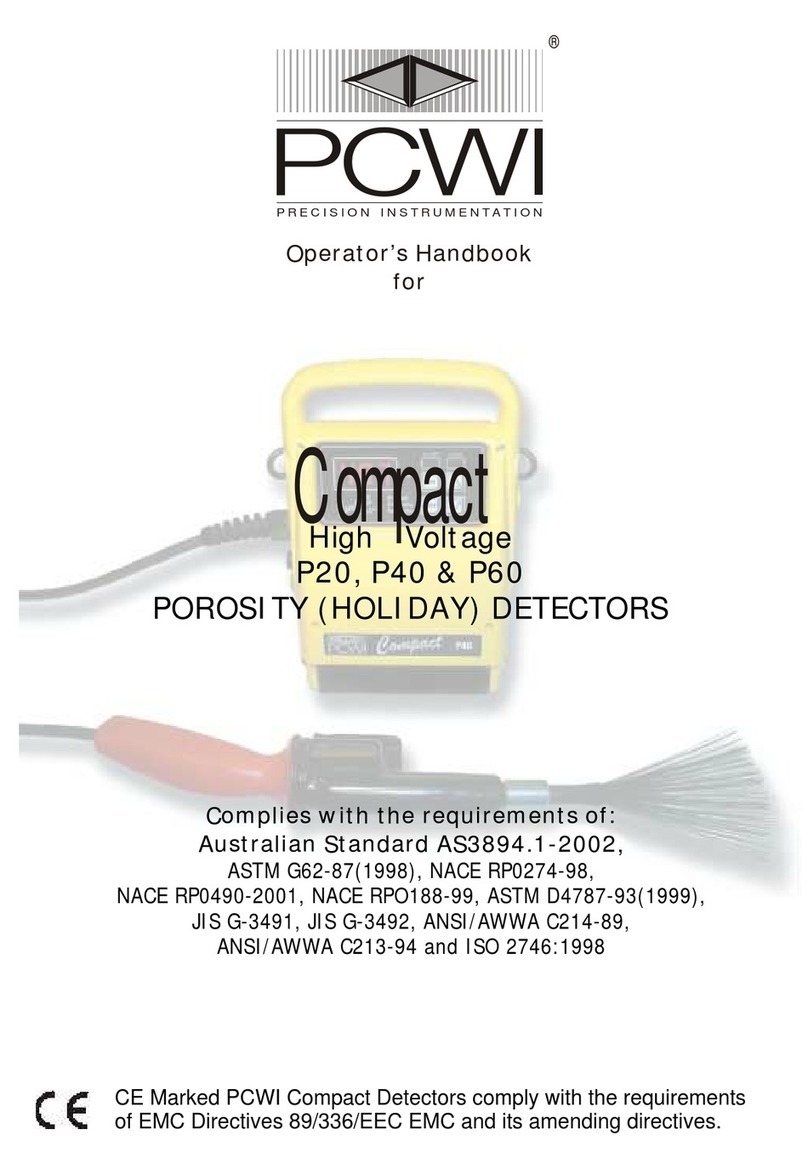

PCWI Compact DC12 Service manual

High Voltage

C15 & DC30

POROSITY (HOLIDAY) DETECTORS

D

®

PRECISION INSTRUMENTATION

Complies with the requirements of:

Australian Standard AS3894.1-2002,

ASTM G62-87(1998), NACE RP0274-98,

NACE RP0490-2001, NACE RPO188-99, ASTM D4787-93(1999),

JIS G-3491, JIS G-3492, ANSI/AWWA C214-89,

ANSI/AWWA C213-94 and ISO 2746:1998

Operator’s Handbook

for

Compact

CE Marked PCWI Compact Detectors comply with the requirements

of EMC Directives 89/336/EEC EMC and its amending directives.

PCWI Technology Pty Ltd ABN 96 078 337 354

Postal:

Office:

Phone: (02) 4954 3900

PO Box 900

HUNTER REGION MC

NSW 2310

Fax: (02) 4954 3999

Web:

Email:

www.pcwi.com.au

sales@pcwi.com.au

Intl: +61 2 4954 3900

13 Alhambra Avenue

CARDIFF NSW 2285

Newcastle - Australia

CONTENTS

1.0 Safety Precautions....................................................................2

2.0 Operation ................................................................................3

3.0 Specifications...........................................................................4

4.0 Control Panel Layout .................................................................5

5.0 Voltage Recommendations .....................................................6-7

6.0 Troubleshooting ....................................................................8-9

7.0 Optional Accessories ..........................................................10-11

8.0 Warranty ...............................................................................12

9.0 Service ..............................................................inside back page

Quality

Endorsed

Company

ISO9002

Lic 13066

Quality System

CERTIFICATE OF CALIBRATION

Model : Compact Detector

Manufacturer: PCWI Technology Pty Ltd

Serial No:. ………………..

Tolerance:. ±3%

Note: It is recommended that the unit be periodically checked

prior to use with a Certified PCWI Crestmeter.

SIGNED: ___________________

Laboratory Technician

Conformance: This detector has been tested at a series of voltages from

0 to 60,000 Volts against a PCWI Certified Meter and High

Voltage Probe, Report Number 205928 or Pulse Crest

Meter Report No VM-0085-00 and complies with PCWI

Standards of Manufacture.

PCWI’s Laboratory has also been assessed to AS ISO/IEC

17025-1999 General Requirements for the Competence of

Testing and Calibration Laboratories. All calibrations are

traceable to National and International Standards.

WARNING

This Equipment generates a high voltage and should be used

with care. Please consult these operating instructions before

use.

INTRODUCTION

Thank you for choosing the PCWI Compact for pre-installation and

post installation corrosion detection.

PCWI have designed this instrument with care, to provide ongoing

corrosion detection efficiency under a wide variety of coating

application conditions and to ascertain Porosity for the many protective

coatings currently in use. Under reasonable care in operation, the unit

will provide many years of trouble free detection.

To support the unit, PCWI maintain a comprehensive range of

Electrodes (probes) - extending the versatility of the Compact from

large to small and from accessible to inaccessible surfaces.

PCWI, in a continuing desire to achieve the maximum in corrosion

detection competence, welcomes user enquiries and

recommendations.

Yours sincerely

Paul Van Gaal

1

Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS - os

Aug 2002

1.0 SAFETY PRECAUTIONS:

All hand-held high voltage test equipment should be operated

by responsible, trained and authorised personnel.

The Detector output can be up to 35,000 volts. Should the

operator accidentally make contact with the test electrode, they

may experience a mild shock or zap, and in order to avoid this

possibility, the wearing of rubber gloves is recommended.

Furthermore, the operator should enjoy good health and not

suffer from a cardiac condition.

This equipment should only be used for the purpose for which it

was designed, ie: checking the porosity, or electrical

breakdown, of dielectric or insulating materials.

It is also recommended that testing should be carried out well

clear of personnel not involved in the testing procedure, or in

such a position whereby the surprise of receiving an electric

shock could cause a related accident, if for example, tests

being carried out close to moving or rotating machinery, or in

such an unstable position that the operator could fall and injure

themselves.

It is recommended that the operator should have an assistant,

to ensure that unauthorised personnel are kept well clear of the

testing area, and generally assist when necessary with the

testing procedure. It is also recommended that the Detector not

be operated within close proximity of sensitive electronic

apparatus, such as computer equipment.

Do not use the test equipment in any combustible or flammable

atmosphere, as a test voltage can cause an arc or spark to be

generated and an explosion could result.

Always consult the plant or safety officer before carrying out a

test procedure.

When testing tank internals, be certain the tank does not

contain solvents remaining from the painting procedure.

The unit must be earthed to both the item under test and to

ground.

If the operator has a

pacemaker, then they should not use this equipment.

CAUTION

DANGER

2os - Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS Aug 2002

Coating Thickness Range

Applied coats should be cured, thickness tested, visually inspected

and accepted – before high voltage porosity testing is carried out.

Coating thickness should be above 150µm; coatings below this

Connect the probe and earth leads to the unit. Connect the earth

clamp to the metallic substrate of the item to be tested –

substrate should be earthed to ground. Select the probe best

suited for the test and attach to the probe handle.

Fit the Fuse (if not already fitted).

Turn the unit on.

Test the batteries to ensure that they are charged.

Turn the voltage control clockwise to the required test voltage.

Place the probe near the metal substrate.

A spark should occur (if not re-check all leads and connections).

The unit should now be ready for use.

Re-check the output – adjust if necessary.

Place the probe on the coated surface and move at

approximately one metre per four seconds.

A spark at the probe – this can usually be seen and heard.

A light flashes on the front panel of the unit.

An audible sound – buzzer is mounted inside the unit.

Digital test voltage drops drastically.

The neon in the probe flashes.

Alarm sensitivity can be adjusted to suit after locating a flaw.

thickness should be tested with a wet sponge unit.

Note: If the neon is in place allow an additional 200v.

A fault is indicated by:

Note

2.0 OPERATION

:A definite flaw should be made in the coating and located with the

designated test voltage, therefore proving that the unit is locating

the type of fault you wish to find.

Probes must be kept in full contact with the surface, gaps in or

between the probe and the coating may result in flaws going

undetected.

Wire brushes, rubber and coil spring probes should all be kept in

good condition.

Probes other than fine wire brushes may require higher voltages.

(see also troubleshooting pages).

Wet and contaminated coatings should not be tested until dry

and clean

3

Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS - os

Aug 2002

Earthing

Leads

3.0 SPECIFICATIONS

STORAGE:

Where the item to be tested is not earthed to ground, a ground spike

be attached.

The unit should always be switched off before removing and

repositioning the earth lead. After the earth is repositioned, the

probe should always be flashed on the substrate to prove a good

contact has been made.

Carbon cored 22k High Voltage leads be used.

Use of copper cored leads will void warranty.

Weight: 2.2kg

Display: LCD 3¾ digits with battery indicator

Voltage 0 to: DC15:15kv DC30: 30kv

Resolution: 10v 100v

Short circuit: Test current less than 0.5mA

Power supply: 3Ah Slide-off

Recharge Time: 400mA for 10hrs.

Battery Test: When Porosity (Holiday) Detector is switched on, the

result is displayed on the LCD.

Dimensions: 260 x 160 x 70mm

Alarms: Audible – with sensitivity adjustment.

Visual – front panel light.

Neon in probe – 360° visibility

Probe lead: 2m carbon-cored high-voltage silicon-rubber.

Earth lead: 7m with a clamp fitted to one end.

Probes: 250mm Flat Brass Wire brush, trim length of 50mm

Carry Case: 130 x 355 x 465mm

Optional coils & brushes available: See accessories pages

The Detector should be stored in a dry place. Leads should not be

wound tightly. Battery should be fully charged.

must

mustW

4os - Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS Aug 2002

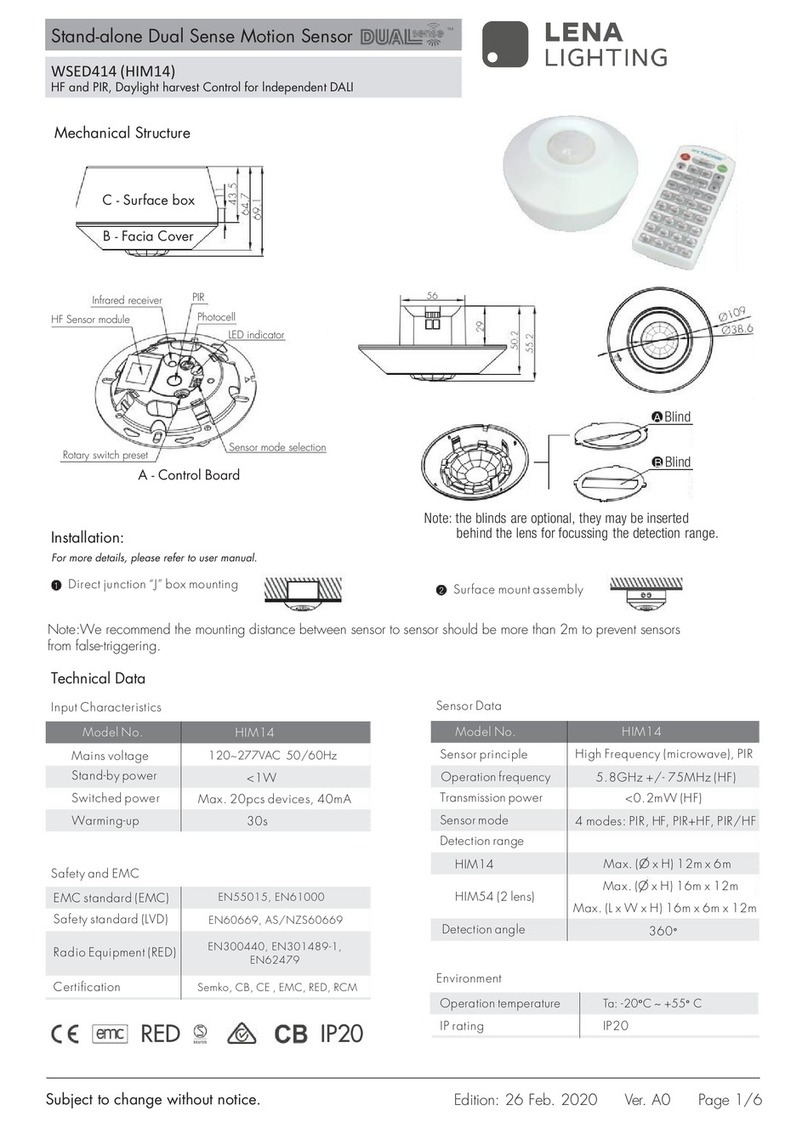

13

8

10

9

11 12

7

FUSE

T

1.6A

250V

High Voltage

Porosity Detector

ON

ALARM

Sensitivity

Voltage

OFF

Test

2

3

1

5

4

6

29.00

Batt

kV

E

F

29.00

Batt

kV

E

F

4.0 CONTROL PANEL LAYOUT

Probe Handle Diagram

Carbon Cored Lead “O” Rings

Screw Fitting

Neon

Lock Nut

End Cap

Neon Holder

Screw

Probe Handle Washer

Spring

1 LCD display (including battery condition

indicator)

2 Voltage control (10 turn)

3 Visual alarm indicates when fault is found

4 On switch

5 Off/test switch

6 Sensitivity control for the alarm

7 Audible alarm when fault is found

8 High Voltage probe connector

9 Fuse (1.6A slow blow) 5 x 20mm

10 Earth connection point

11 Charge connector – allows operation while

charging is in progress

12 Slide-off power pack

13 Earphone jack

5

Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS - os

Aug 2002

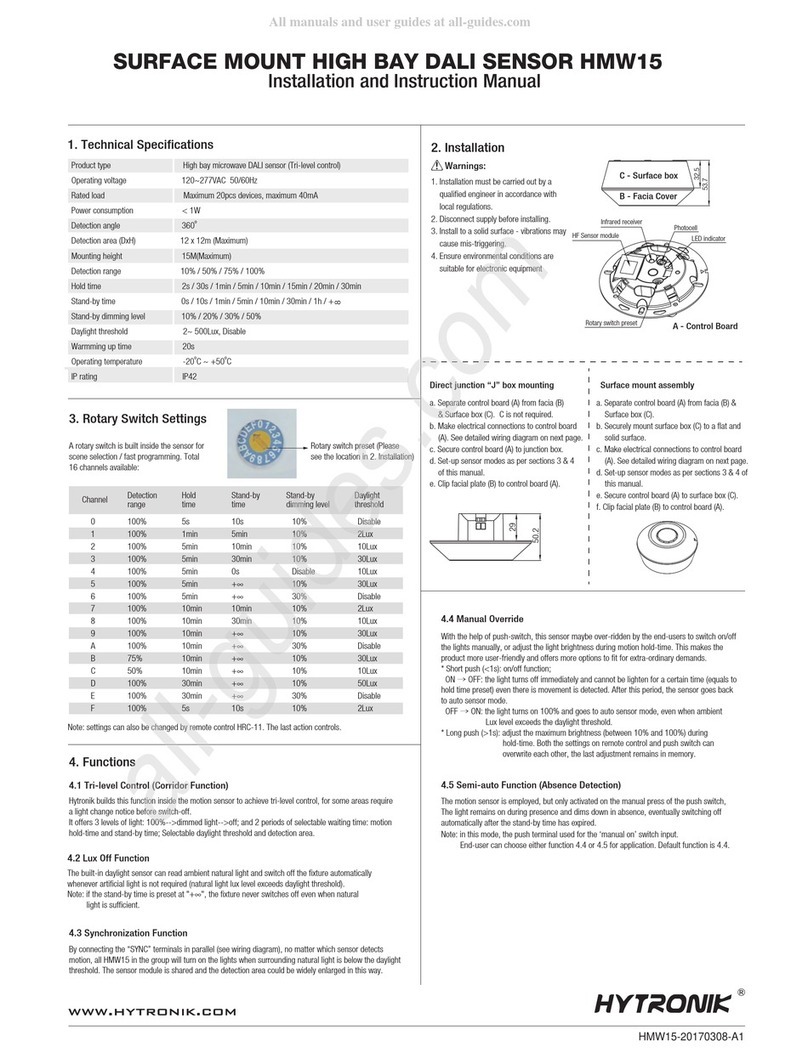

Table 1. Suggested for High Voltage Spark Testing

Total Dry Film Thickness Suggested

Inspection

(µm) (mils) (V)

200 to 280 8 to 11 1,500

300 to 380 12 to 15 2,000

400 to 500 16 to 20 2,500

530 to 1,000 21 to 40 3,000

1,010 to 1,390 41 to 55 4,000

1,420 to 2,000 56 to 80 6,000

2,060 to 3,180 81 to 125 10,000

3,200 to 4,700 126 to 185 15,000

The above table should be taken as a GUIDE only. It is

recommended that the whole of this standard be used.

Table 1 below is derived from NACE standards and should be

used as a guide only.

5.0 Voltage Recommendations

International Standards

NACE RP0188-99 derived table

New Protective Coatings

on Conductive Substrates

ALLOW AN ADDITIONAL 200 VOLTS IF THE NEON IN THE PROBE HANDLE IS IN USE.

6os - Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS Aug 2002

Table 2. kV Values from

NACE RP0490-2001

mm kiloVolts

0.250 1.650

0.280 1.750

0.300 1.800

0.330 1.900

0.360 1.950

0.380 2.050

0.410 2.100

0.510 2.350

0.640 2.650

0.760 2.900

Table 3. kV Values from

NACE RP0274-98

mm kiloVolts

0.51 6

0.79 7

1.6 10

2.4 12

3.2 14

4.0 16

4.8 17

13 28

16 31

19 34

The above tables should be taken as a GUIDE only. It is

recommended that the whole of this standard be used.

International Standards

NACE RP0490-2001 and RP0274-98 derived tables

Tables 2 & 3 below are derived from NACE standards and should

be used as a guide only.

Thin Film Pipeline

Coatings (FBE)

General Pipeline

Coatings

ALLOW AN ADDITIONAL 200 VOLTS IF THE NEON IN THE PROBE HANDLE IS IN USE.

7

Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS - os

Aug 2002

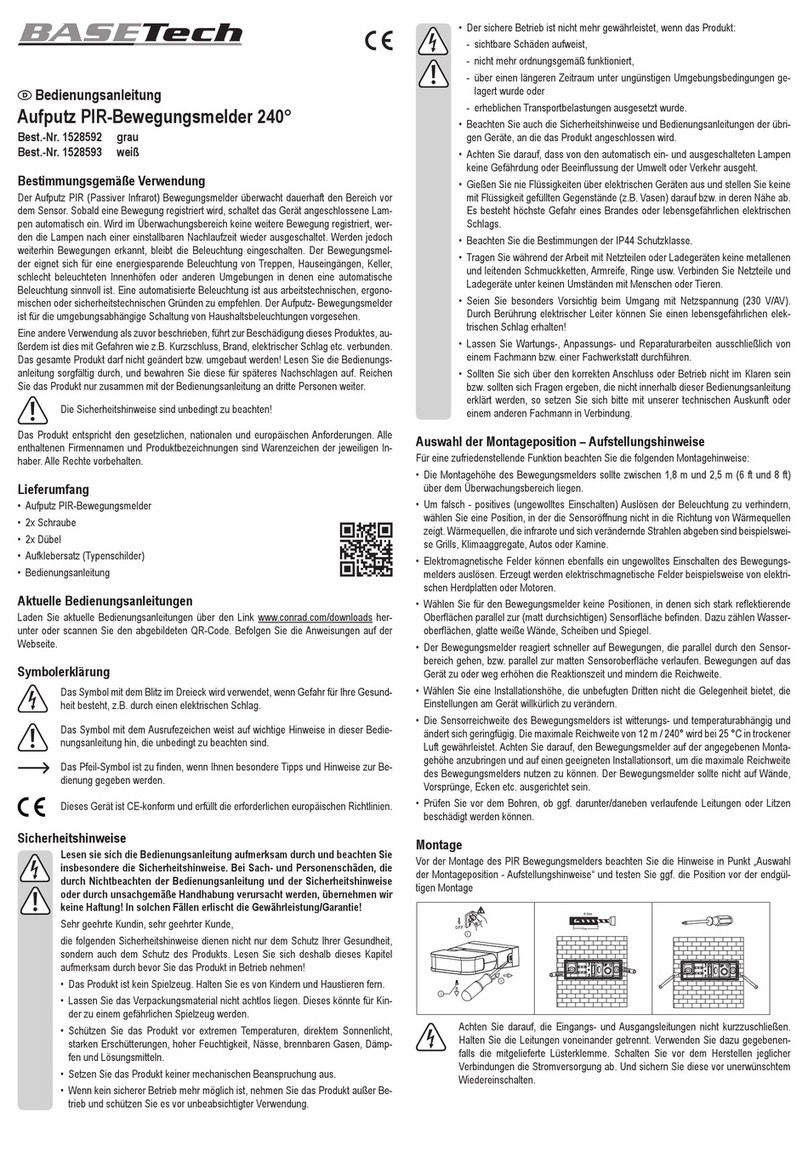

HV Lead

Neon

Holder

18to22kresistance

W

6.0 TROUBLESHOOTING

In order to ensure that your Compact Porosity Detector is operating to

specification, the Detector handle and lead should be checked prior to use.

Use the following procedure:

Unscrew the neon holder from the handle.

Using a multi-meter, complete the circuit and check the resistance at both the

handle and the high voltage plug .

If resistance is outside the 18,000 to 22,000 ohm range, or is open circuit:

(a) Check and for either poor connection or damage;

(b) Check for break or damage to the HV lead .

Replace/rectify connection and leads and then re-test.

ÊË

ÊË

Ì

8os - Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS Aug 2002

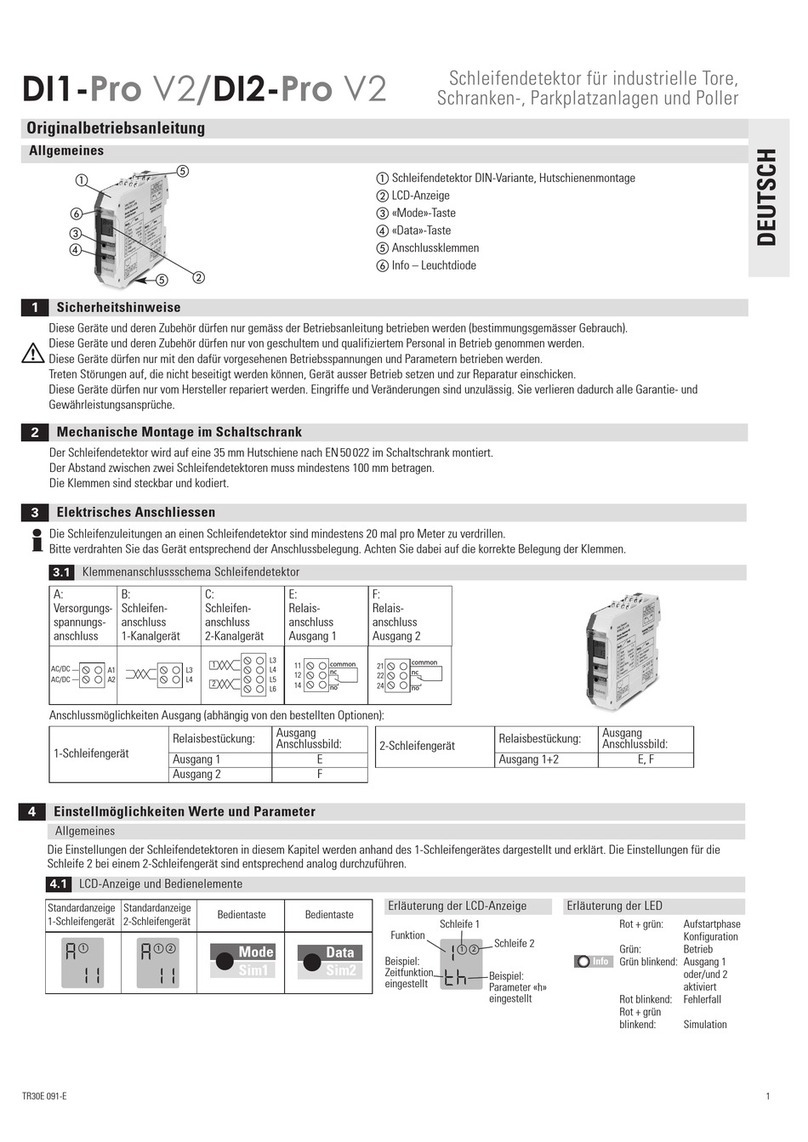

Symptom Cause Solution

No Display

Flat battery

No Power - fuse not fitted

Recharge battery

Fit fuse

Displayshows-1 Voltage higher than display capacity Decrease voltage

Display erratically

shows -1 Display drops to -1 when fault found Normal operation

Display voltage

drops during test

Slightly conductive, damp or salty

surface

Coating may not be fully cured

Probe surface area too large

Wash and clean the surface

Allow coating to cure

Use a smaller probe, or increase

voltage

Blackening

Display Poor Earthing Make positive earth connections

Alarm sounds

continuously

during test

Slightly conductive, damp or salty

surface

Coating may not be fully cured

Probe moved too fast

Probe surface area too great

Wash and clean the surface

Allow coating to cure.

Move probe 1 metre every 4 seconds

Use smaller probe

No alarm on fault

Sensitivity adjusted at too low a

setting

Voltage set too low

Increase sensitivity

Increase voltage

No spark at

probe tip

Neon in handle damaged

Damaged leads

Poor connections

Flat Battery

Replace neon (or use a metal

conductor piece)

Repair or replace leads

Clean and reconnect

Recharge battery

Probe voltage

lower than display

voltage

Neon in handle can use up to 200

volts

Damaged HV lead

Poor Earth connection

Turn up voltage control to

compensate for neon

Replace lead

Check all connections

9

Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS - os

Aug 2002

7.0 OPTIONAL DETECTOR ACCESSORIES

Crest Meters Certification&.

50mm (2in) to 600mm (24in) wide

25mm (1in) to 500mm (20in) Spiral wound and Disc

.

25mm (1in) to 500mm (20in) .

flat brushes.

Internal

circular pipeline brushes

External circular pipeline brushes

10 os - Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS Aug 2002

60mm, 125mm, 200mm, 450mm for flat or external

pipeline brushes.

connectors

Fan Brushes

450mm covered .probe extensions

Spare slip-out

7m with clamp.

8m trailing Earth lead (1m plastic encased).

Spare and neons.

power packs.

Earth lead

neon light holders

50mm (2in) to 1210mm (48in) complete with ball bearing

ends.

Coil Joiners.

Coils

11

Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS - os

Aug 2002

8.0 WARRANTY

Subject to the warranty conditions below this PCWI Instrument is warranted by PCWI

International Pty Ltd to be free from defects arising from faulty design, material, or

workmanship for a period of 12 months from the date of original purchase by the user or a

maximum period of 15 months from dispatch ex PCWI Australia.

Probes and leads are warranted for 3 months. They are consumable items, and subject to

wear and deterioration during use. The life of these parts can be much extended by

keeping them in a dry clean condition, and storing them in suitable protective containers.

During use, avoid “scrubbing” the probe along the surface of the work-piece.

During the warranty period listed above PCWI or it’s authorized service representative will

make good any defects covered by this warranty.

PCWI or it’s authorised service representative will decide if there are any defects in

design, material or workmanship.

This warranty only applies provided the instrument has been used in accordance with the

manufacturers operating handbook recommendations.

This warranty does not cover damage, malfunction or failure resulting from misuse,

neglect, abuse or used for a purpose for which it was not designed and no repairs,

alterations or modifications have been attempted by other than PCWI on an authorized

service.

This warranty applies only to the original user buyer.

This warranty does not cover any service that is needed after an accident, alterations,

misuse, fire or floods.

This warranty is the only one given by PCWI and no one has the authority to change, or

add to, the obligations and liabilities listed in it.

This warranty does not cover batteries, probe handle brushes (electrodes) and leads

which are subject to wear.

During the warranty period PCWI or its authorized service representative will bear the

transportation cost of the return of instrument/s repaired under warranty back to the

users premises within the country of purchase.

Defective goods must be returned to PCWI or an authorized service representative at the

Purchaser’s expense. The goods must be accompanied by the Purchaser’s written order

describing the defect and authorising PCWI or its authorized service representative to

invoice the Purchaser for any charges not covered by the warranty.

The purchasers order must also include the model and serial numbers of the instrument

and address of the distributor and date of purchase.

Upon receipt at the service point the instrument will be examined to determine the nature

and cause of the defect.

If the defect is covered by the warranty, a repair will be effected at PCWI’s or authorized

service representative expense. If the defect is not covered by the warranty, PCWI or

authorized service representative will quote the Purchaser for a replacement or repair,

and will not proceed until written acceptance of the quotation is received.

WARRANTY CONDITIONS

HOW TO MAKE A WARRANTY CLAIM

12 os - Compact DC15 and DC30 POROSITY (HOLIDAY) DETECTORS Aug 2002

9.0 SERVICE AND MAINTENANCE

AUTHORISED SERVICE REPRESENTATIVE

CARE AND MAINTENANCE

SERVICE REPAIRS AND MAINTENANCE

BEFORE YOU CALL FOR SERVICE

To enable speedy “return to service” whether under warranty or otherwise, PCWI have

appointed your distributor as a service centre and have provided all relevant information

and recommended parts to be carried to assist distributor’s technical staff carry out this

essential part of the PCWI customer service.

This equipment is protected against hostile environments and is designed for prolonged

use in the field without any special maintenance, other than routine battery recharging.

However, the equipment is not totally sealed and appropriate precautions should be

taken. Remember, it is a precision electronic instrument and should be treated as such.

There are no internal user controls.

The equipment should only be operated by qualified personnel.

Some organic materials may attack plastic parts and cause early degradation. Contact

with such materials should be avoided.

Do not operate damaged equipment.

Where the power supply is derived from internally mounted rechargeable cells and

disassembly of the unit is necessary to access those batteries,

.

Repairs not covered by the warranty or carried out after the warranty period, will be

charged at the current hourly or set service rate, plus the cost of materials.

Goods for repair must be sent at the Purchaser’s expense, and be accompanied by the

Purchaser’s written order describing the defect and authorising PCWI to invoice the

purchaser for labour, materials and return delivery cost.

Read the section on “troubleshooting” in this handbook and check the symptom, cause

and solution before you call for service.

this action would void

all warranty

No service or repair will be undertaken until a written order is received.

AUTHORISED SERVICE AGENT:

os - PCWI Compact DC15 and DC30 Porosity Detectors.cdr (Sep 2002)

©2002 PCWI Pty Ltd

PCWI

OFFERS

PCWI

Postal:

Office:

PO Box 900

HUNTER REGION MC NSW 2310

13 Alhambra Avenue

CARDIFF NSW 2285

Newcastle, Australia

Strong technical support

Market and product knowledge

NATA registered laboratory in metrology

Quality systems certified to ISO9002

Warranties and after sales service

Instrument Buyers Directory

In-house development and manufacturing enables us to provide strong

technical support and a quick response to enquiries and orders.

We understand technical specifications demanded by industry and

recognise customer requirements are specific in relation to testing and

measuring instruments.

PCWI’s in-house laboratory can support testing for a range of instruments

enabling Certification Traceable to National Standards.

PCWI’s Quality Management System is certified to ISO9002.

PCWI provides 12 months warranty for its Detectors with detailed operator

instruction handbooks and after sales service. An extension of this PCWI

service is provided by your local distributor.

For your free copy of our Annual Buyers Directory of Industrial Test &

Measuring Instruments please see contact details below.

Phone:

Fax: +61 2 4954 3999

www:

Email:

www.pcwi.com.au

sales pcwi.com.au

@

+61 2 4954 3900

This manual suits for next models

1

Table of contents

Other PCWI Security Sensor manuals

Popular Security Sensor manuals by other brands

Pittway

Pittway SYSTEM SENSOR 1151EIS Installation and maintenance instructions

FORTEZA

FORTEZA Forteza-50 Description Manual & Service Instruction

Consilium

Consilium Salwico Cargo user guide

Navim Group Company

Navim Group Company EsiWelma Sensigas URS20SS quick start guide

AQUALEAK

AQUALEAK WG1 Installation and operation instruction manual

Ametek

Ametek LAND MILLWATCH user guide