FRONT RIGGING

Attach hanger brackets to bracket receptacles on wheelchair.

1. Adjustment is made to desired length with individual sitting in wheelchair with feet on foot plates. Use

wrench and hex head driver to loosen or tighten bolt on slide tube of foot plates.

2. Remove hex head bolt and tube clamp and slide footrest tube up or down until desired length is

reached. Then reassemble hex head bolt into tube clamp and into threaded clamp insert. The lowest

point of the foot plates should be no less than 2-1/2” from the ground or floor.

NOTE: Check to ensure that desired front rigging adjustment does not cause pressure to legs at front of seat

upholstery. Such a condition could cause injury to the occupant.

WARNING:

DO NOT ATTEMPT TO STAND ON FOOT PLATES. Standing on the foot plates will cause the chair to tip forward

abruptly and may result in an injurious fall to the individual.

DO NOT ATTEMPT to lift chair by the footrests or leg rests. These components are designed to separate

and/or swing away from the wheelchair.

FOOT PLATES SHOULD BE in an upright position and swung out of the way when entering or exiting from the

wheelchair.

REAR WHEELS

Removing/Installing the Rear Wheels/Axles

1.Push in the tip of the quick-release axle and pull the wheel off of the axle.

2.Push in the tip of the quick-release axle again and pull the axle out of the wheel hub.

3.Repeat steps 1-2 for the other rear wheel.

4.To reinstall the rear wheel onto the wheelchair, reverse steps 1-3.

WARNING: Make sure the detent pin and locking pins of the quick-release axle are fully released BEFORE

operating the wheelchair. The locking pins MUST be protruding past the outside of the rear wheel axle

receiver for a positive lock. Keep locking pins clean.

Adjusting the Quick Release Axle

1.Install rear wheel and quick-release axle onto the wheelchair.

2.Depress detent pin in the quick-release axle and slide axle through the wheel hub.

3.Release detent pin ensuring that the locking pins are fully released.

4.Increase or decrease end play by adjusting the locknut on the end of the quick-release axle.

WARNING: Make sure the detent pin of the quick-release axle is fully released BEFORE operating the

wheelchair.

Keep locking pins clean.

Backrest Adjustment (Seat Depth / Back Recline)

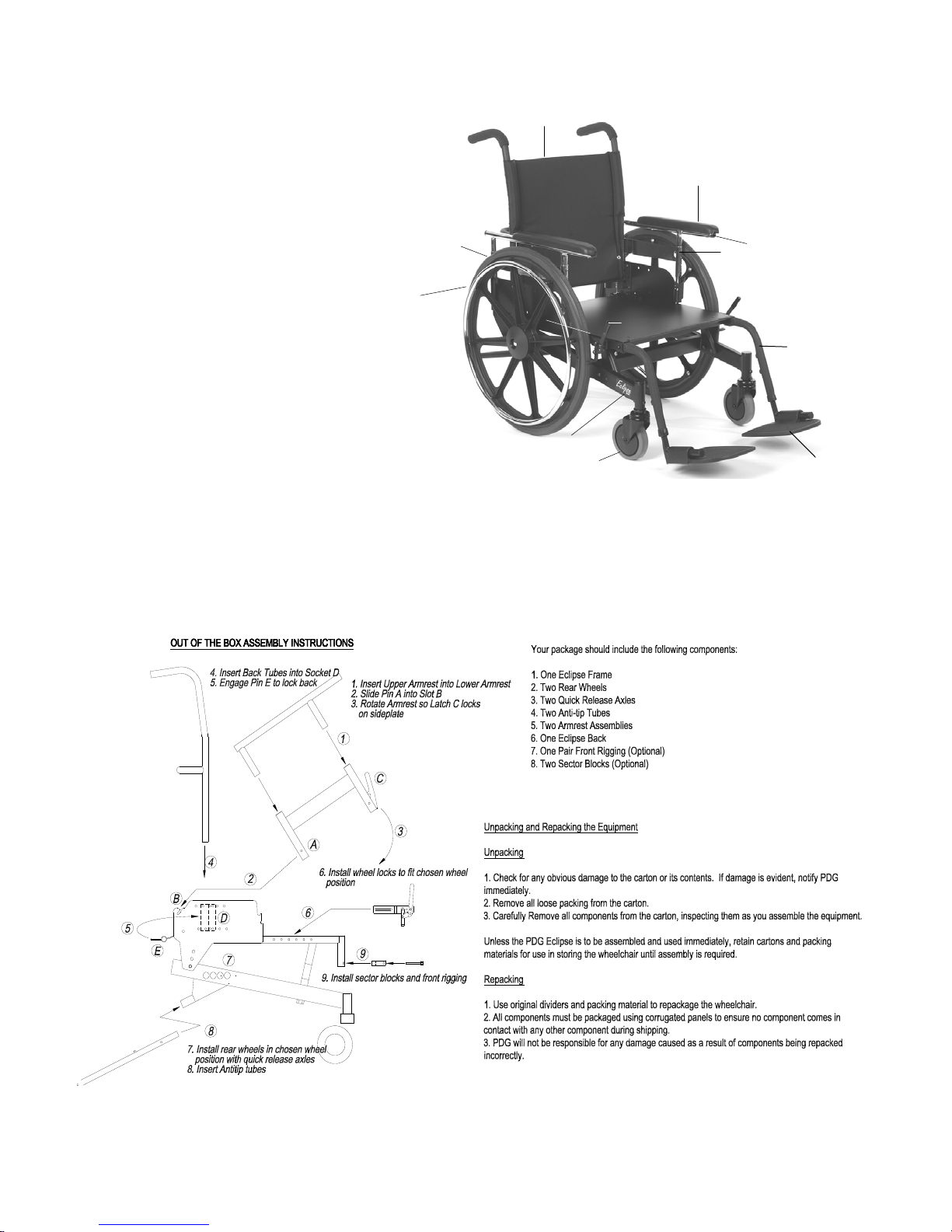

Install the Backrest Assembly onto the Frame Assembly by sliding the lower end of the Back tubes into the

Back Tube Receptacles located on the Frame. Note that the location of the back can be adjusted for

shorter or longer seat depths and the back recline angle can be adjusted by choosing various mounting

hole combinations when attaching the Back Tube Receptacle to the Frame Assembly.

Reclining Backrest Installation

A reclining backrest may be ordered with original equipment, or retrofitted onto an existing Eclipse

wheelchair. When installing a reclining backrest assembly, remove the original backrest support sleeves and

bolt the reclining backrest assembly in 6 locations along the skirt guard (3 bolts on each side). Note that the

location of the back can be adjusted for shorter or longer seat depths. Important! Move the rear wheels to

the most rearward axle mount position. This axle location is recommended to provide maximum stability

when the back is reclined. Install extra long anti-tip tubes (supplied with the reclining backrest kit). The extra

long antitip tubes provide additional protection against the wheelchair overturning when reclined. Be sure

to check the wheelchair stability in full recline with the user in the wheelchair to ensure acceptable

rearward stability prior to sending the user home.