pdlux 30N2 User manual

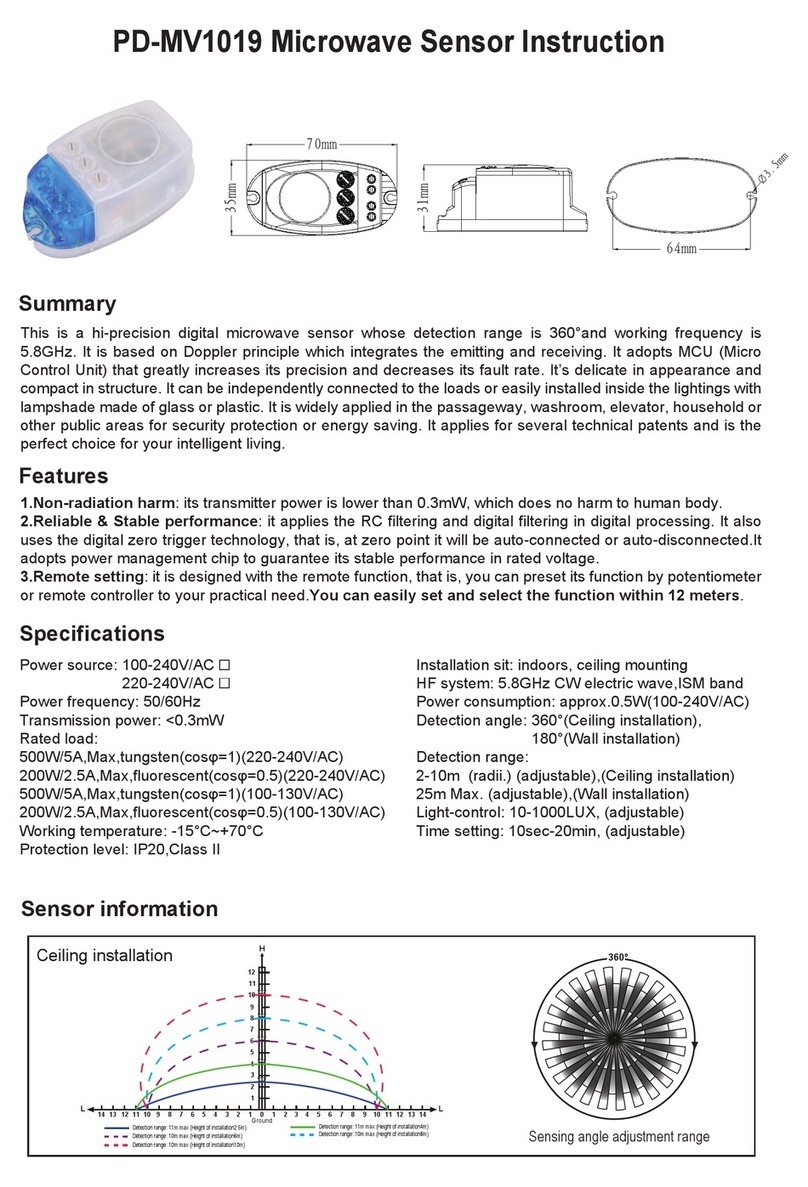

Summary

Specifications

Product size

Feature Settings description

30N2

Infrared Sensor

technology. The sensor section is completely separate

from the output control section and is extremely easy to

operate and easy to install. Fixed product only needs

two the screws make the installation of the sensor

simple. This is a completely revolutionary design. This

is our patented product.

The 30N2 uses a digital information processing

system. The easiest way to consider the 30N2 at the

start of the design is to remove the front frame of the

sensor and select the appropriate location for each

function to be replaced.

The 30N2 product can withstand a wide voltage of

100V-277V and can be used in any country in the

world. Standby power consumption <0.5W, powerful,

with dual control outputs, high power output can control

any load of 2300W, and the second output can control

any load of 1000W. There is also a 0-10V brightness

control port for controlling the brightness of the

dimming light. You can set the percentage of standby

brightness.

30N2 Considering the needs of different users, we

have reserved space for further expansion. Users are

welcome to ask about your needs. We are always

ready to add the features you need.

Please read the following sections of this manual

carefully for installation and operation.

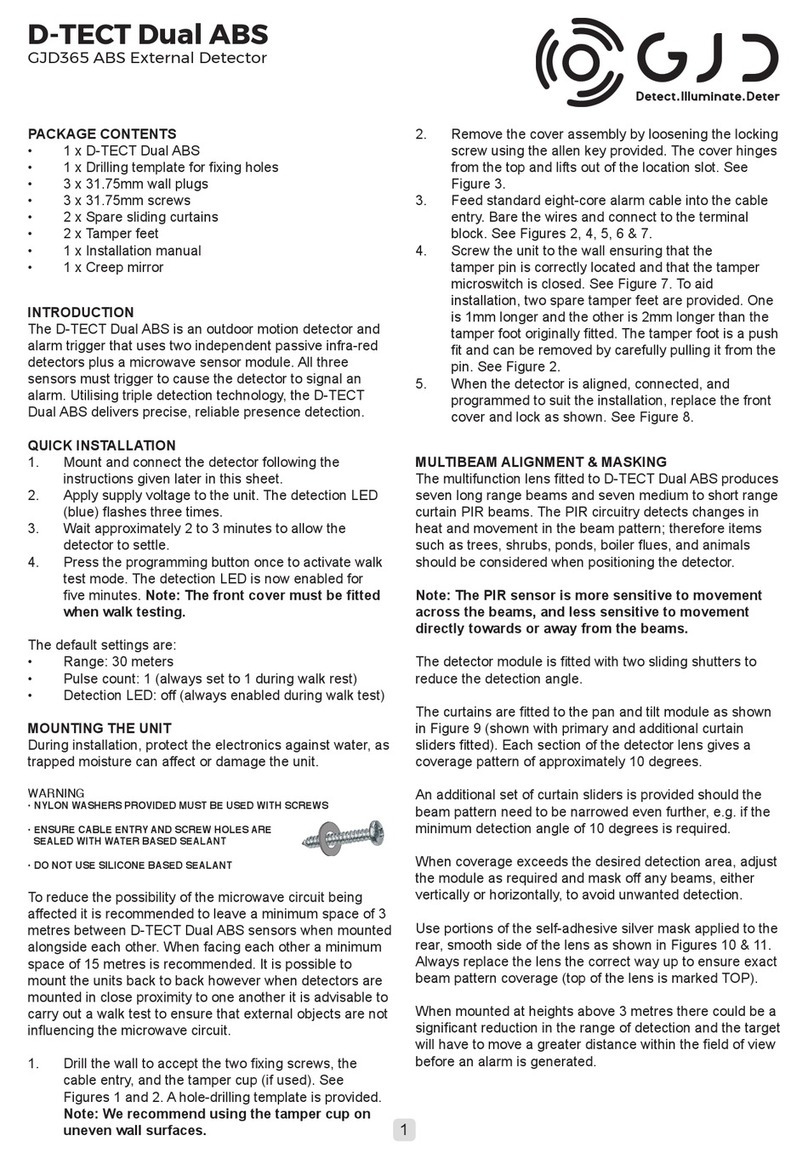

1. Sensitivity adjustment knob:

Sensitivity adjustment knob is responsible for

managing the detection sensitivity of the system. The

user can select the position of the knob as needed to

adjust to the detection range you want. In general, the

sensitivity is just enough to detect the sensor within the

detection range, not too high, because too high prone

to misoperation. Adjust sensitivity with due regard to

ambient temperature. The higher the ambient

temperature, the lower the detection sensitivity. The

manufacturer recommends that the ambient

temperature of 22°C to 24°C be used as a reference to

select the position of the sensitivity adjustment knob.

2. Delay adjustment knob:

The delay adjustment knob is responsible for

managing the load time after the sensor triggers the

work.

The knob can be set clockwise for a delay time of 10

seconds to 20 minutes. The user selects the

appropriate position of the knob according to needs.

3.LUX adjustment knob:

LUX setting knob is used by the system to detect the

ambient illumination, and it is the condition selection of

the sensor under the circumstance of which the user

chooses the ambient brightness that must be sensed.

When the knob goes counterclockwise to the bottom,

the sensor can only enter the induction when the

brightness of the installed position is lower than

10LUX, that is, the sensor can only work in the dark

hours at night. The higher the LUX value, the brighter

the ambient brightness. Users can set the appropriate

location according to their own needs.

4. D-TIME adjustment knob:

D-TIME knob is responsible for managing the

adjustment of the standby brightness of the sensor.

Knob clockwise direction can set 4 gears time. Users

The 30N2 product is a completely new concept design

with its output control section completely separated

from the sensor section. The bottom of the box can be

wired. It completely overcomes the problem of

traditional wiring connections. The sensor components

and control components use wireless connectivity

Operating Temperature: -10 - +40°C

Probe movement speed: 0.6-1.5m/s

relative Humidity: <93%RH

Static power consumption:<0.5W

Power supply Voltage: 100-277V,50/60Hz

Main control:

Power: 2300W/230V Max 3000W/230V

Auxiliary control:

Power: 1000W/230V Max 1200W/230V

Dimming control: 0-10V 50mA

Delay: 10 sec-20 minutes (adjustable)

Detection Distance: 2-16m (radii.)/22°C.(adjustable)

Standby time: off / 10min/ 20min/ constant light

Standby brightness: 5%, 10%, 20%, 30%

Optical control Illumination: <10LUX~2000LUX

(adjustable)

Detection angle: 360°

Mounting Height: 2.5m-4.5m

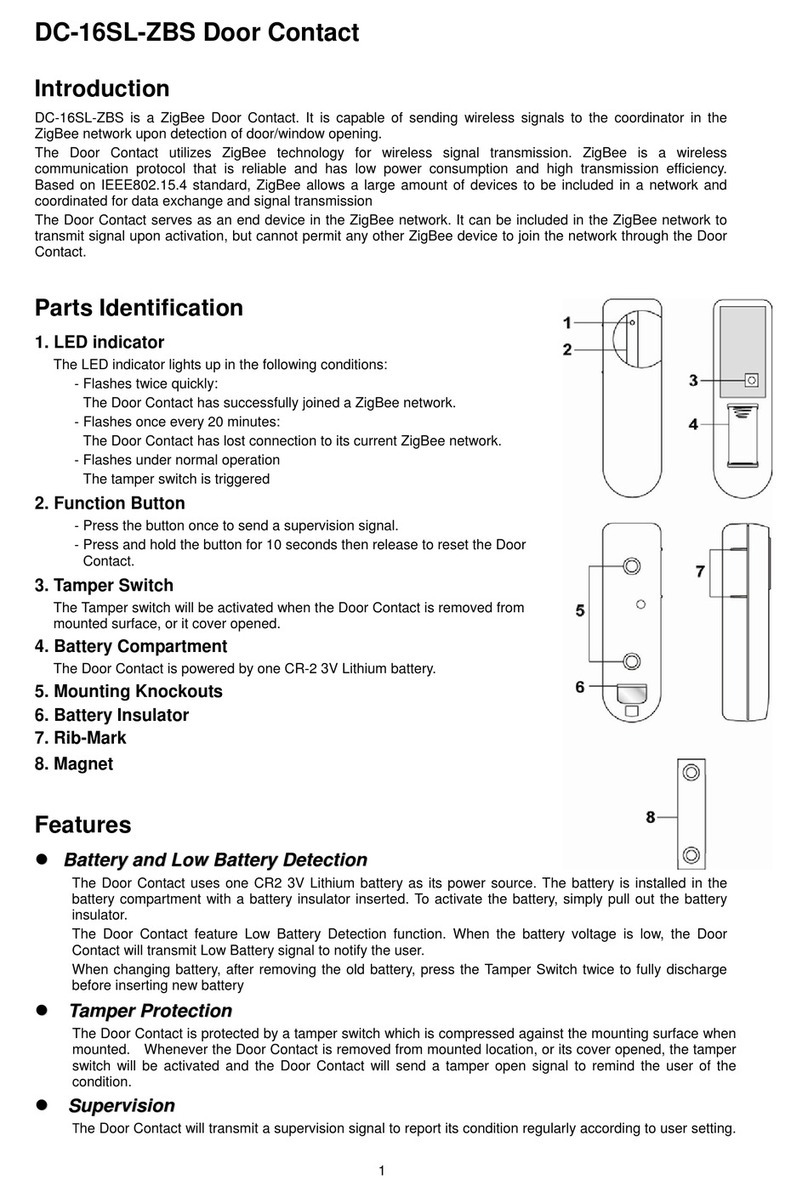

48mm

80.5mm

φ148mm

100mm

>200LUX, the product will exit the semi-bright mode.

counterclockwise rotation is in the end, with the

maximum detection distance (nearly 16 meters radius).

Attention:when using the product, please adjust the

product sensitivity to the appropriate position, do not

adjust the product sensitivity to the maximum, to avoid

improper operation caused by wind starting curtains,

leaves, small animals, power grid and electrical

equipment, which may cause the product not to work

properly. When it is found that the product does not work

properly, the user can try to lower the sensitivity

appropriately before carrying out the test. Before or

during the installation of the product, if the functional test

is carried out, the personnel must leave the product

sensor area and do not walk around to prevent

continuous work of the sensor due to human movement.

can set the appropriate location according to their own

needs.

5.DIM setting knob:

DIM knob is responsible for managing standby

brightness Settings. Knob clockwise direction can set 4

levels of brightness. Users can set the appropriate

location according to their own needs.

Induction information

Detection angleDetection range(22℃)Height of installation2.5~4.5m

360°

16m

2m 2m

16m

Product Testing

You can manually adjust work latency, sensitivity, ,light

control values,D-TIME and DIM (for more information:

knob settings);It is very convenient to use.Sensor

suction Top Mounting height 2.5~4.5 m (Installation

details: Installation instructions), and wiring according

to the wiring diagram.Switch on the power supply,

about 1 minutes after the sensor into a stable working

state.Here, adjust the delay time to a minimum and

adjust the light control value to the sun for testing.If you

finished all testing, you can make time delay, light

control value and sensitivity settings according to your

needs, and the installation is complete.

Parameter setup Method: potentiometer

The following settings may require multiple

adjustments to meet your requirements.

Four detection ranges are:

1:2m 2:8m 3:10m 4:16m

When adjusting the knob clockwise, the

detection distance increases and the

detection distance decreases when the

knob is adjusted counterclockwise.The

detection distance is minimal (a radius

of nearly 2 meters) when the

(3)Detection distance setting (sensitivity)

2-16m

The standby time of the four gears is:

1:off 2:10min 3:20min 4. Automatic

semi-bright at night

When adjusting the knob clockwise,

standby time increases; Adjust the knob

counterclockwise to reduce standby

time.

Note: when the light control value

(3)D-TIME setting

(1)Light-control setting

The work illumination value can be

adjusted <10-2000LUX range.

Optical control value of four grades is:

1:<10LUX 2:<200LUX 3:<400LUX

4:Daytime

The working illumination value is about

10 LUX when the counterclockwise

rotation is in the end, and the working

<10-2000LUX

the shortest time should be chosen when adjusting the

detection range or walking test.

Note: After the lights turn off, it takes nearly 4 seconds for

it to sense again.The light will only light up when the

signal is detected at the end of this time.

Correct use of delay adjustment: It is used to adjust the

delay time of the sensor to detect the light after the body

moves and lights up to the automatic extinguishing

lamp.Users can adjust according to actual

requirements.Because the infrared induction products

have continuous sensing function, in short, the sensor in

the delay time before the end of any induction, the

system will be re-timed, as long as the person in the

detection range of activities, the lamp will not be

extinguished.Therefore, it is recommended that users

try to adjust the delay time to achieve energy saving.

(2)Delay setting

10sec-20min

The delay time of the four gears is:

1:10s 2:1min 3:6min 4:20min

The clockwise rotation increases while

the counterclockwise rotation

decreases. When adjusted to the

maximum, the delay time is 20 minutes.

When adjusted to a minimum, the delay

time is 10 seconds. It is suggested that

illumination value is about the day when the clockwise

spin is in the end.

The brightness of standby gear four is:

1:5% Brightness 2:10% Brightness

3:20% Brightness 4:30% Brightness

When the knob is adjusted clockwise,

the standby brightness increases; when

the knob is adjusted counterclockwise,

the standby brightness decreases.

(3)DIM setting

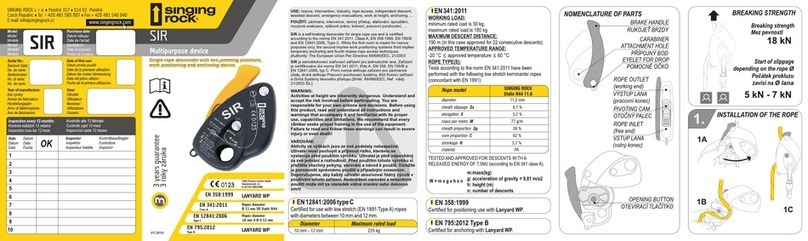

15-key remote controller PD-FS15

Functions:

ON- ON mode, in ON mode, the LED

indicator in sensor will flash once a

second, the load connected will keep

working for 6 hours and then

automatically turn to AUTO mode.

AUTO-auto-sensing mode: When signal detected,

the LED indicator in sensor will flash once.

UNLOCK – press UNLOCK and start setting. If

you do not make any setting, the system will be locked

in 2 minutes, that is you are not allowed to modify

settings. If you do make settings, the system will be

locked 5 seconds after the last setting, that is you are

not allowed to modify settings.

When choosing the 15-key remote

controller, please read through the

instruction below, you will find more

functions.

SENS-- set sensibility, MIN,6m,8m,MAX can be

chosen.

TIME--- set time delay, 10”,2’,6’,20’ can be chosen.

LUX---- set working light, 10,50,150,2000(LUX)can

be chosen.

After all above selected, press OK or SEND to start the

settings and the sensor works as the controller settings.

NOTE: the controller is inside with CMOS that

can memorize all the effective settings!

Connection

Installation is based on the wiring diagram provided.

TEST key

: when the line is

connected successfully and the

control panel is not installed,

press this key to TEST whether

the load is connected normally.

Note: press once to switch on the

load, and the indicator light is

always on; Press again to

disconnect the load and

extinguish the indicator.

R port control:

It can touch any point of L/N once to switch on the main

control relay and close it within the delay time.

(1)The power supply should be cut off before

installation;

(2)Rotate the upper cover counterclockwise and remove

it;

Install the probe toward the area that people often

pass when installing。

Move the probe in the direction of the ambient light

source for more accurate illumination settings。

Detect the signal again within the induction delay

time, and the delay time will be superimposed。

Light-controlled LUX Knob: refers to the working

environment illumination;When the knob is clockwise

to the end, the whole day in the inductive state;When

Installation Attention

Ask an electrician or a person with relevant

experience to install;

Do not use volatile objects as mounting substrates;

There should be no obstacles, non-stop moving

objects in front of the detection window that affect its

detection;

Do not install in areas where the airflow has changed

significantly;Such as: Air conditioning, heating fan;

If the sensor is found to be faulty after installation, For

your safety please do not open the sensor housing

without permission.

Installation

(3)Install the bottom

cover and screw

(such as ③) ;

(4) Connect the

power line and load

line to the power

supply terminal

according to the

wiring diagram;

(5) Align the bottom

cover, turn clockwise

to tighten the upper

cover (such as ④),

and the installation is

completed.

Bottom

Cover

③

④

Remark:

- + K1 K2 R/SL L L` L` N N

Dimmable

Sensor

0-10V DC

Pusg

button

(N.O.)

Other load

Supply

Voltage

N

L

Led Lighting

OUTPUT

INPUT

+ -

Dimmable

Ballast

Some problem and solved way

Load does not work:

a. Check that the power supply, load connection is

correct;

b. Load is intact;

c. Check that the working illumination set by the sensor

is consistent with the ambient illumination.

Low Sensitivity

a. Check if there are obstacles in front of the probe

window that affect the sensor receiving signal;

b. Check if the ambient temperature used by the sensor

is too high;

c. Check if the inductive signal source is in the sensor's

detection area.;

d. Check if the installation height is within the limits

specified in this manual.

Sensor does not automatically turn off load:

a. Is there a continuous sensing signal in the detection

area?

b. Whether to set the sensor's work delay to the Max;

c. Whether the power supply used corresponds to the

requirements in the instruction manual;

d. If there are significant changes in temperature near

the sensor, such as air conditioning, heater and other

equipment.

e. Whether the direction of movement is correct.

the knob is counterclockwise to the end, illumination

<10LUX to enter the inductive state.

Delay Time Knob: refers to the lamp to receive the

inductive signal after the light to no subsequent

induction signal, the lamp work stage value。

This manual for the content of this product programming

at time, We will not notice if there are any updates.

The contents of the instruction manual are strictly

prohibited for any reproduction by other purposes

without the permission of the company.

Other pdlux Security Sensor manuals

pdlux

pdlux PD-MV1019 User manual

pdlux

pdlux PD-MV1017B User manual

pdlux

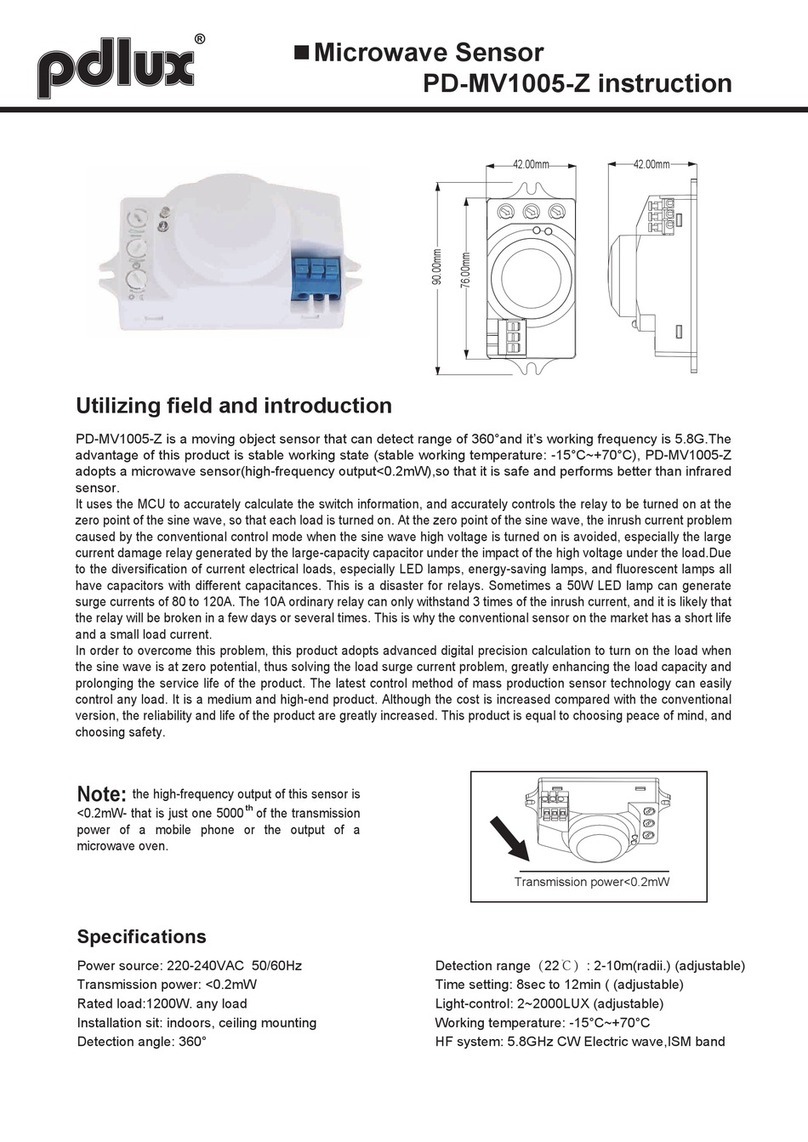

pdlux PD-MV1005-Z User manual

pdlux

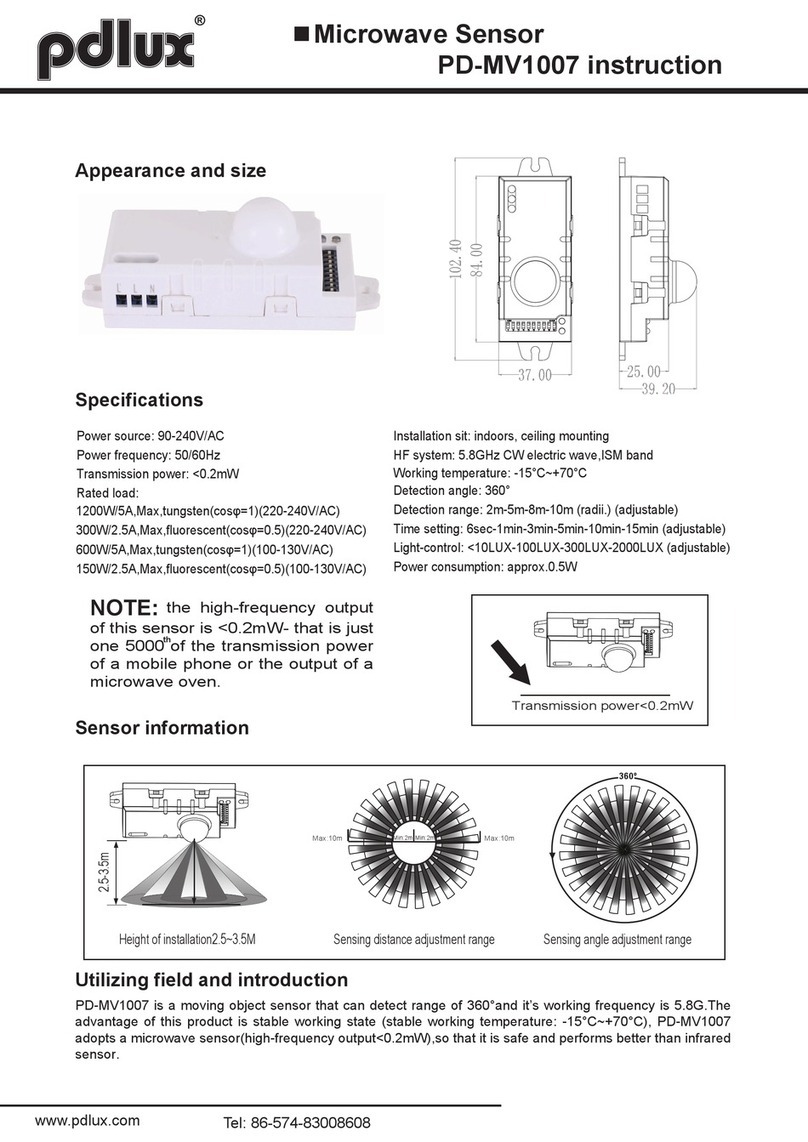

pdlux PD-MV1007 User manual

pdlux

pdlux PD-PIR101-Z User manual

pdlux

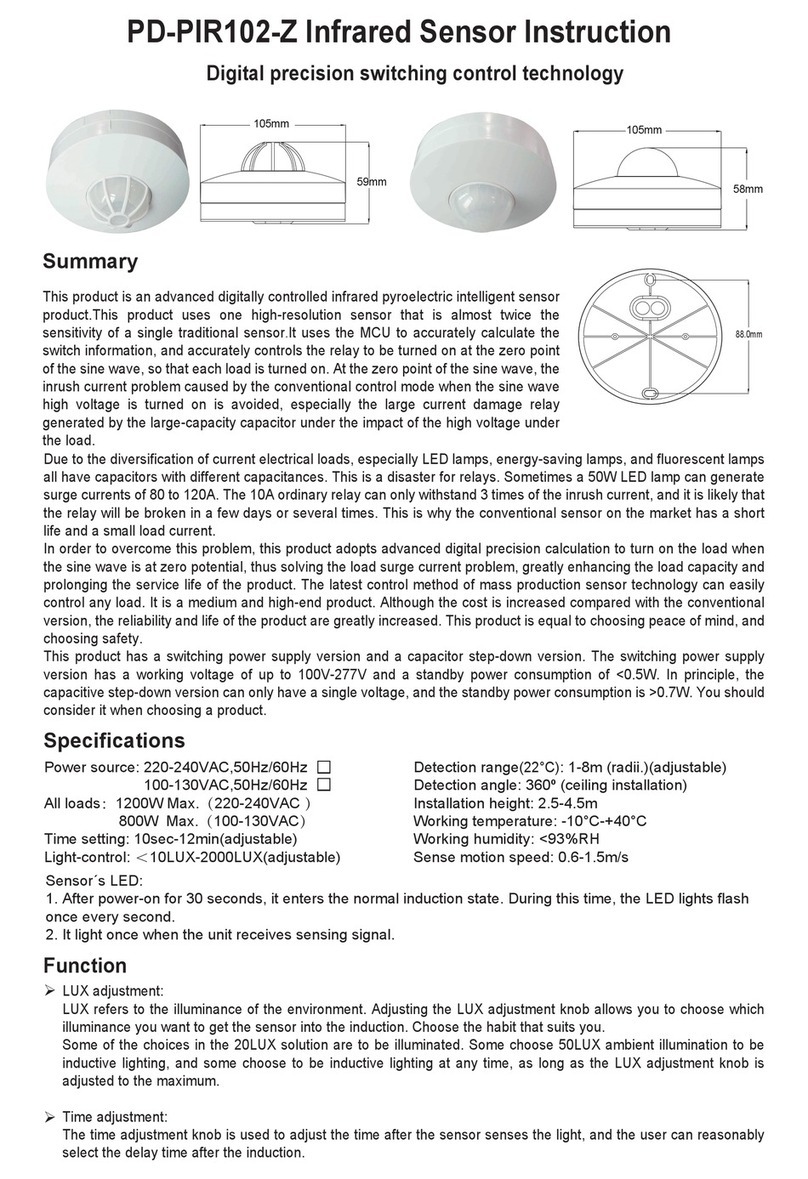

pdlux PD-PIR102-Z User manual

pdlux

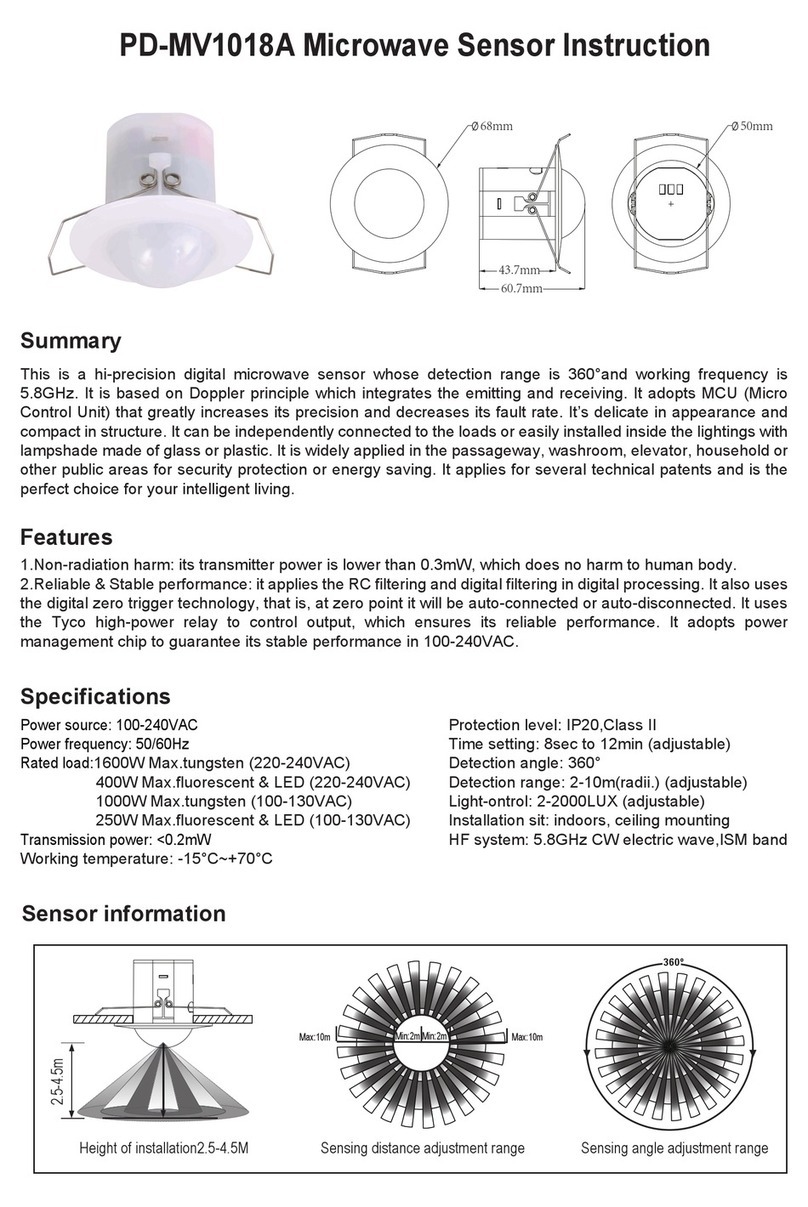

pdlux PD-MV1018A User manual

pdlux

pdlux PD-MV1007A User manual

pdlux

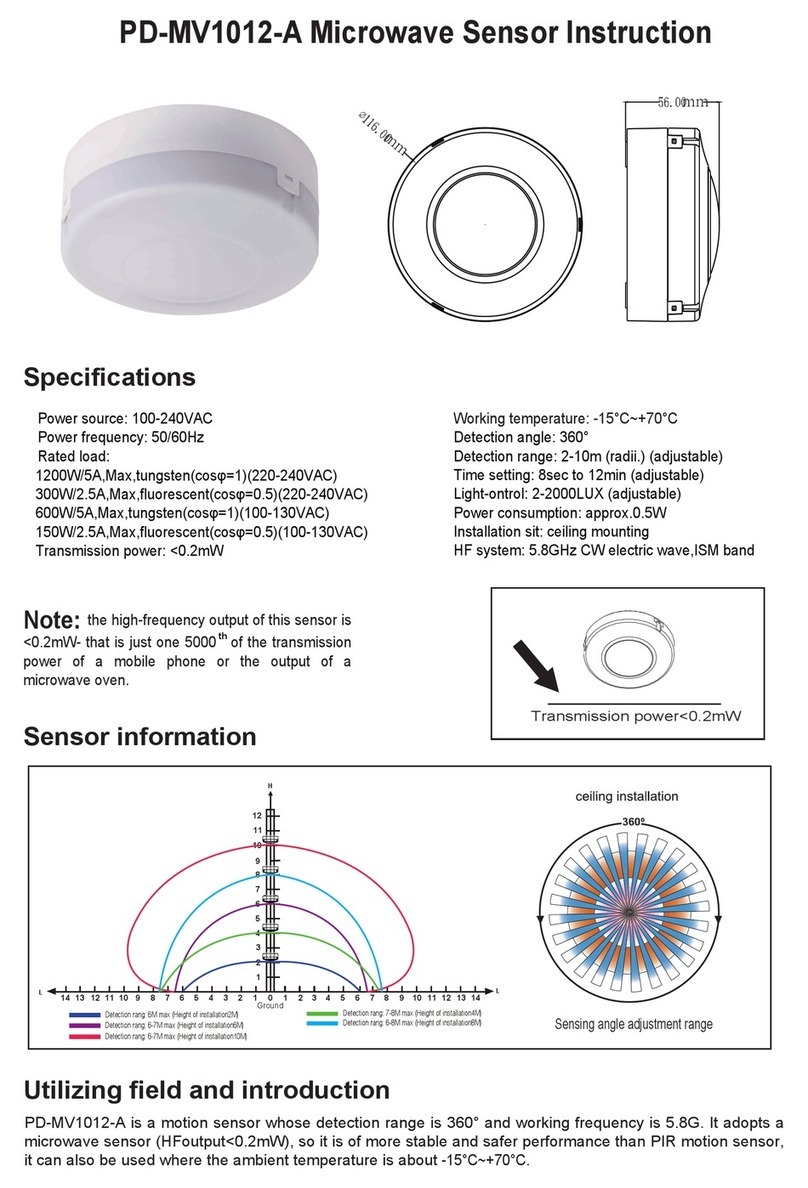

pdlux PD-MV1012-A User manual

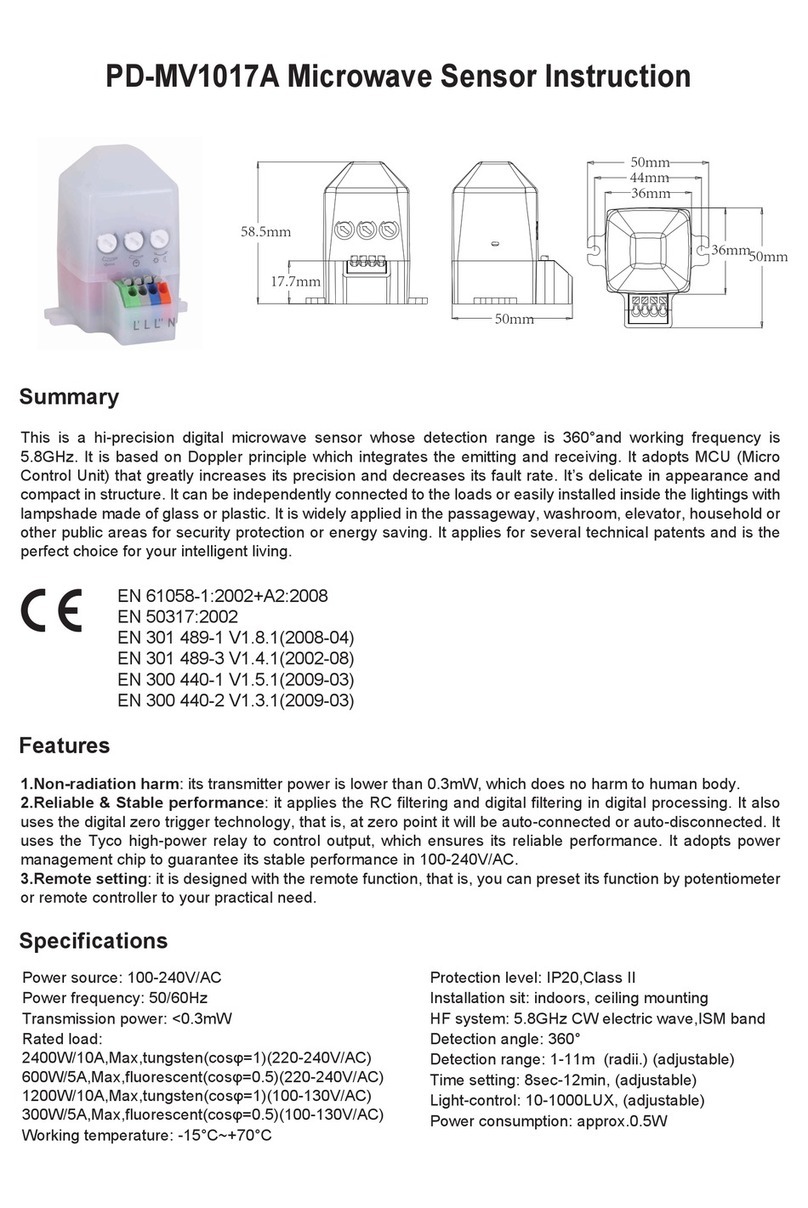

pdlux

pdlux PD-MV1017A User manual