PDX.GOLD VaporSmartz iQ 150 User manual

@pdx.gold

contact@pdx.gold

503.783.6550

www.pdx.gold

20209 SW 95th Ave. Tualatin, OR 97062

WELCOME 3

PRECAUTIONS & SAFETY 4

SPECIFICATIONS 5

INSPECTION & RECEIVING 6

SYMBOLS & WARNINGS 7

PRODUCT OVERVIEW 8

EVAPORATION PRESSURES 10

THE FILTER DRYER 11

INSTALLATION 12

OPERATION 14

MAINTENANCE 16

CERTIFICATION 17

WARRANTY 19

TABLE

OF

CONTENTS

Hello and welcome to the PDX.GOLD family. We understand there are a lot of choices

in the marketplace for botanical recovery systems, so we are delighted you have

chosen to invest in us.

We designed our Solvent Transfer and Recovery pumps with you in mind and sincerely

hope you notice the difference in quality and safety standards that set us apart from

our competitors. We built this machine to last and want you to enjoy the benefits of its

durability for years to come.

Sincerely,

PDX.GOLD

3

WELCOME

4

!

WARNING:

THE VaporSMARTZ iQ150 IS DESIGNED FOR HIGH VOLUME RECOVERY AT PRESSURES BELOW

150PSI (VaporSMARTZiQ120 BELOW 120PSI). IT HAS SAFETY PRESSURE SWITCHES TO LIMIT THE

SYSTEM PRESSURE TO 150 / 120 PSI.

DEADHEADING YOUR PUMP FOR ANY SIGNIFICANT TIME AGAINST PRESSURES AT OR ABOVE

150PSI (120PSI for iQ120) GENERATES EXCESSIVE HEAT AND WILL DAMAGE THE PUMP OVER

TIME. ALWAYS ENSURE YOUR SOLVENT RECOVERY TANK HAS CAPACITY TO RECOVER THE

SOLVENT IN THE SYSTEM. WE RECOMMEND A PRESSURE BELOW 80PSI AT STARTUP.

ADJUSTING OR ATTEMPTING TO ADJUST ANY SAFETY OR SYSTEM REGULATING HARDWARE

IS DANGEROUS AND VOIDS ALL WARRANTIES.

CAUSES OF EXCESSIVE RECOVERY PRESSURE INCLUDE: ENTRAPPED ATMOSPHERE IN

THE STORAGE VESSEL AND INSUFFICIENT POST PUMP HEAT CONTROL, RESULTING IN A

TANK TEMPERATURE RISE.

HIGHER PRESSURE CAUSES THE EQUIPMENT TO WORK HARDER. ANY TIME YOU ENCOUNTER

SIGNIFICANT MACHINE VIBRATION, TURN OFF THE SYSTEM IMMEDIATELY AND REMEDY THE

CONDITION CREATING THE VIBRATION BEFORE PROCEEDING ANY FURTHER!

! Unit must be installed in a lab designed to accommodate explosive atmospheres.

R600 / R600a / Propane must be handled in compliance within all federal, state and local

safety and environmental requirements.

1. Do not use this recovery system without reading this manual in its entirety.

2. Always perform the “Pre-Flight Check”, outlined in the Operations section of this

manual prior to using the recovery system.

3. Always confirm that there is ample space in the recovery vessel prior to solvent

recovery. Due to the relatively low density of these gases, internal float switches often

do not work, so an electronic scale is required.

4. Do not attempt to overfill the recovery tank.

5. Always utilize proper ventilation with explosion proof fans and exhaust systems.

6. Do not allow liquid or gaseous solvent to come into contact with exposed skin,

mucous membranes or eyes.

PRECAUTIONS & SAFETY

!

5

General Specifications

Maximum Output Pressure (VaporSmartz iQ150) 150 PSI

Maximum Output Pressure (VaporSmartz iQ120) 120 PSI

Motor Size (VaporSmartz iQ150) 2 Hp

Motor Size (VaporSmartz iQ120) 1 HP

Noise Level 78 dB

Free Air Displacement (VaporSmartz iQ150) 6.5 CFM

Free Air Displacement (VaporSmartz iQ120) 5.2 CFM

Pressure Shut off Valve (VaporSmartz iQ150) 150 PSI

Pressure Shut off Valve (VaporSmartz iQ120) 120 PSI

Applicable Media Butane, Propane, Propane blends.

Electrical

Requirements

115v / 208-230v Installation 50 / 60Hz, 30 Amps

230v / 460v Installation 50 / 60Hz, 30 Amps

Watts 1,500

Plumbing

Connections

Pump Input 0.5” JIC

Pump Output 0.5” JIC

Physical

Characteristics

Shipping Weight 375 lbs

Machine Weight 300 lbs

Shipping Dimensions 57” Length x 40.5” Width x 48.5” Height

Operating Dimensions 20” Length x 28” Width x 36” Height

SPECIFICATIONS

6

UNPACKING AND INSPECTING

Do not proceed if there is any evident shipping damage. Stop at

once and photograph the unit and packaging materials.

1. Once visual inspection has verified no obvious damage has occurred during

shipment, carefully uncrate the unit.

2. If the unit looks damaged, stop at once and call PDX.GOLD Customer Service.

3. Remove the unit from the pallet.

4. Use two people to lift the unit off the pallet, then roll it into position and lock wheels in place.

5. If not already shown below, record the model number and serial number of your unit in the

space provided and maintain this record for future reference.

Use this space below to record the identification plate information of your specific unit. The

identification plate is located on the baseplate and can viewed by looking through the

ventilation screen on the left side of the unit. Use blank spaces to record your internal

information if required eg: sales order, purchase order number, installer initials, etc.

UNIT

INFORMATION

Model Number

Serial Number

Certification Number

Date of Purchase

Notes

INSPECTION

&

RECEIVING

STOP

7

This recovery system pumps Butane and Propane, both

flammable gases. This machine must be kept in an explosion-

proof lab that meets environmental, safety and other regulations.

Explosion Hazard: NO smoking, NO open flames, NO sparks

Do not use VaporSmartz iQ150 / VaporSmartz iQ120

without proper ventilation.

Eye protection is strongly encouraged while using this machine.

Protective clothing: Fire resistant coveralls or jumpsuit is highly

recommended. Although working with a CLE (closed loop extractor)

drastically cuts down the risk of an explosive environment, we still

strongly suggest that anyone operating the VaporSmartz iQ150 /

VaporSmartz iQ120 wears fire resistant clothing due to the flammable

nature of Butane and Propane.

SYMBOLS & WARNINGS

8

Key Components

1. Power switch / Enclosure

2. Stainless Worktop

3. Input Connection

4. Output Connection

5. High Pressure / Low Pressure Gauges

6. Locking Casters

7. CycloneDry™ (add-on item)

8. Power Cord

Theory of Operation

The PDX.GOLD VaporSmartz iQ150 / VaporSmartz iQ120 is a single-switch operation. This solvent

transfer and recovery system transfers solvent gas within a closed loop extractor and returns it,

under pressure (up to 150 psi / 120psi), to a recovery tank for isolation and storage. The

VaporSmartz requires a dedicated 115V / 230V, 30AMP circuit and must be connected to a power

source by a licensed electrician. The internal components are all food grade and are comprised of

aluminum, stainless steel, iron, and Viton and Buna-N elastomers.

5

1

6

PRODUCT

OVERVIEW

4

3

8

7

2

9

Component Overview

The main power switch is pictured here in the OFF position. When the switch is in the “ON”

position, the pump will be fully engaged and operational. There are no other switches or valves

to manage.

The Input Connection is located on the back of the unit labeled “input”.

The Input Connection is 0.5”JIC.

The Output Connection is located on the back of the unit labeled

“output” and is also 0.5”JIC.

Pressure Control System: The VaporSmartz iQ150 / VaporSmartz iQ120 is rated to

accommodate 150 / 120 PSI internal pressure. If the pressure in the system exceeds 150 / 120

PSI, the pressure control switch will activate and shut off the motor. The system also has a

Pressure Relief Valve back-up in the event of a pressure switch failure. If the unit shuts off,

resolve any issues that caused the shut off and cycle the switch back to the OFF position to

reset the switch. Turn the switch to ON to re-start the unit.

There are two gauges on the VaporSmartz:

Located on the gauge panel, above the worktop you will find both pressure gauges. On the

right you will see the Output gauge. The Output gauge reads in PSI and displays a range of

0-200PSI (0-160PSI for iQ120). During normal operation, the gauge should read “0” when not

in use, and between 40 - 80 PSI when moving solvent.

On the left you will see the Input gauge. The Input gauge reads in PSI as well as in-Hg (inches

of mercury). The Input gauge displays a range of 0-160 PSI (0-100 PSI for iQ120) and 0-30 in

Hg. The Input gauge will read into the negative range when the pump has fully evacuated the

solvent from the extractor.

IMPORTANT NOTE: The recovery system may begin to draw negative pressure as the

extractor evacuates. While this is normal and is part of the design operation of the pump – it is

NOT INTENDED AS A VACUUM PUMP. Continued use of the system at vacuum levels greater

than 15 in-Hg will result in damage to the seals and drawing atmospheric air into the system

Many factors will influence the actual gauge readings during processing:

- Temperature variance between input gas and output recovery vessel will have

a dramatic impact on recovery speed.

- Type of solvent used. This machine runs butane, propane, and blends of the two.

Recovery speed varies based on the solvent you choose.

PRODUCT OVERVIEW

10

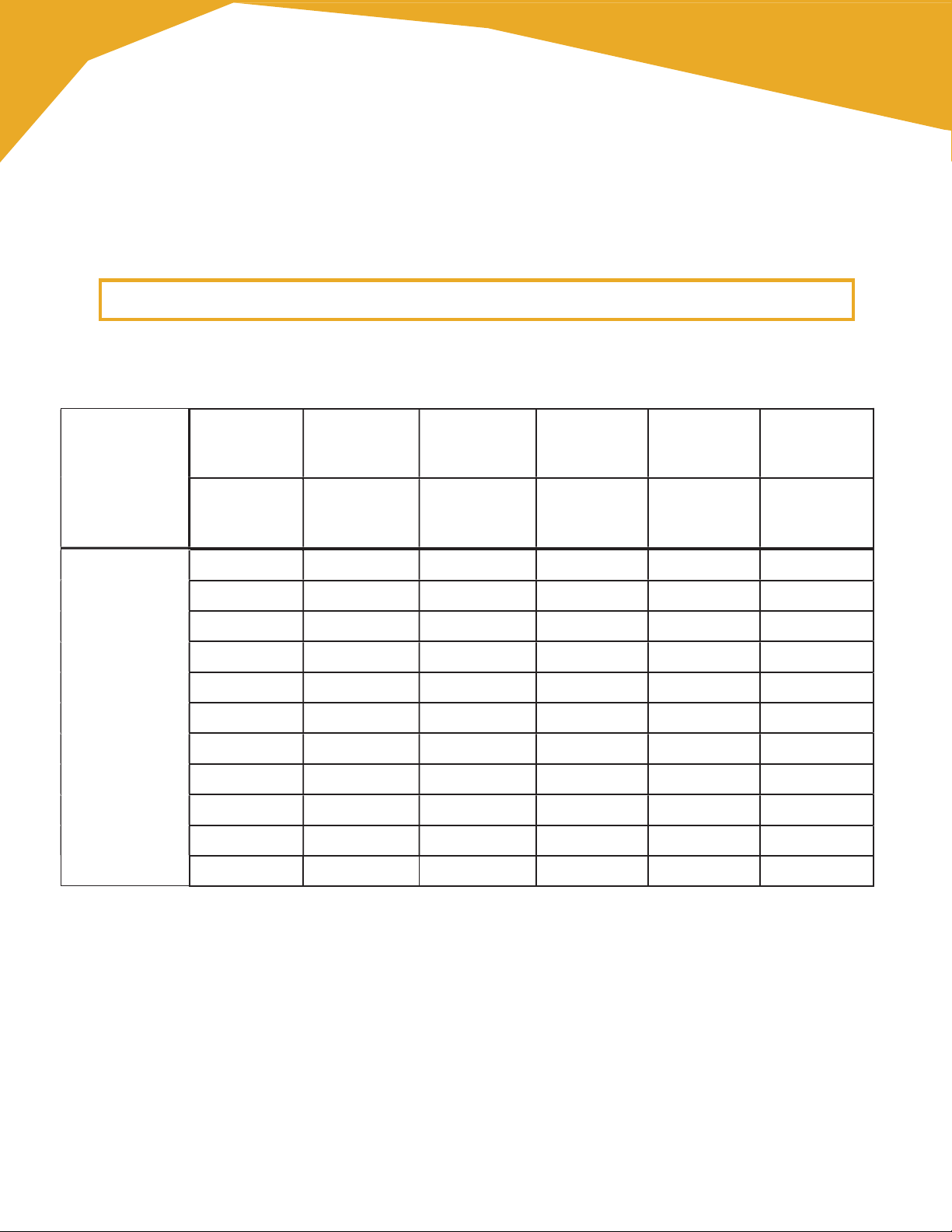

TEMPERATURE

MIXTURE

Propane

C3 H8

100

70

50

30

0

Butane

C4 H10

0

30

50

70

100

˚F -44 0 0 0 0 0

-30 6.8 0 0 0 0

-20 11.5 4.7 0 0 0

-10 17.5 9 3.5 0 0

0 24.5 15 7.6 2.3 0

10 34 20.5 12.3 5.9 0

20 42 28 17.8 10.2 0

30 53 36.5 24.5 15.4 0

40 65 46 32.4 21.5 3.1

50 78 56 41 28.5 6.9

60 93 68 50 36.5 11.5

Vapor Pressure

(psig)

EVAPORATION

PRESSURES

11

Ingesting ANY substance other than solvent vapor into the compressor is not

considered normal or customary use. Foreign matter is considered contamination

(extracted oils / organic byproducts / dirt / etc.), may damage the pump and void your

warranty.

To ensure peak performance of your solvent transfer and recovery system, we strongly

recommend the user to install a molecular sieve / solvent filter dryer in the system before the

input of the pump.

The VaporSmartz series are high-performance solvent transfer and recovery pumps and may

overwhelm many types of filter dryers. PDX.Gold has designed our own filter dryer, the

CycloneDry, which may be configured for ANY size extraction system. CycloneDry is a

modular system - simply daisy-chain any number of CycloneDrys to your recovery system (via

stainless steel braided hoses) to keep up with your level of processing.

CycloneDry are available in 3 sizes with the input fitting, output fitting and a pressure relief

valve on the top of the unit. Units are constructed of stainless steel, assembled with explosion

proof tri-clamps and Viton or Buna-N gaskets. The CycloneDry is designed to accommodate

two, three or four desiccant filter cores (depending on the size selected) to absorb water vapor

or oil and works in two ways:

1. As the solvent is drawn in by the pump, the CycloneDry acts as a “cold trap” and

heavier constituents such as water vapor or oil are spun out of the gas, condense on

the sides of the unit and settle to the bottom.

2. The included desiccant filter cores absorb any remaining water vapor and / or

suspended oils and removes them from the solvent gas*.

Filter Core Recharging

During normal use, the filter cores can become saturated with moisture and lose

effectiveness. Cores can be re-conditioned in a vacuum oven and may be reused many times

before requiring replacement if they have not been contaminated with organic material. The

cores will catch vaporous oils on the surface of the cores, which often is visible as a “sheen”

on the desiccant surface. Visible contamination on the cores is an indication it is time to

discard them and replace with new cores. Failure to maintain the cores may allow

contaminants to migrate over time through the desiccant material and into the compressor.

* Reconditioning / replacement of the cores may be required to maintain effective operation if they become saturated or contaminated.

FILTER DRYER

12

Lifting & Handling

The VaporSmartz iQ150 / VaporSmartz iQ120 is a precision machine that should be

handled with care and respect.

1. Except for initial removal from the pallet, do not lift the VaporSmartz iQ150 /

VaporSmartz iQ120. Utilize the installed casters to roll the unit into place.

*** Highly recommended that you use two people to lift from pallet ***

2. Lock the casters once in place.

3. The unit is not intended to be moved after wiring and installation. Casters are for

positioning and transport during set-up and installation only.

Environmental Conditions of Operation

The VaporSmartz iQ150 / VaporSmartz iQ120 best functions in an environment that is between

50- 90°F. The VaporSmartz iQ150 / VaporSmartz iQ120 should remain dry at all times. Poor air

quality can result in shorter pump life. Protect your pump from air-borne dust and debris that can

impede ventilation.

Installation Location Requirements

The VaporSmartz iQ150 / VaporSmartz iQ120 is intended to be used indoors on a flat surface. The

laboratory environment should comply with all local and state regulations and safety standards.

Prior to installation, consider the power source, location of other equipment and operator comfort

and efficiency.

Power Source

The VaporSmartz iQ150 / VaporSmartz iQ120 requires hard-wired connection to a

power source. This installation must be performed by a licensed electrician if local

regulations require.

1. Verify the power switch is in the “OFF” Position.

2. Verify voltage and amperage on the datatag.

3. Verify voltage and amperage of the power source.

4. Connect VaporSmartz iQ150 / VaporSmartz iQ120 to the appropriate power supply.

INSTALLATION

13

The VaporSmartz iQ150 / VaporSmartz iQ120 does not have any manually

adjustable valves. Use the valves on your extractor to control the flow of

gas.

Connecting to the Extractor

1. Follow all instructions in this manual closely.

2. Follow all instructions associated with your closed loop extractor closely.

3. Close the Input and Output Valves on the Extractor.

4. Using a 0.5” JIC terminated hose, connect the Output of the Extractor to the Input of the

VaporSmartz iQ150 / VaporSmartz iQ120. The Input is located on the back panel, right

side and is labeled “Input”.

The valve associated with this connection will be referred to in this manual as

“Input Valve”.

5. Using a 0.5” JIC terminated hose, connect the Output of the VaporSmartz iQ150 /

VaporSmartz iQ120 to the Input of the solvent recovery vessel. The Output is on the

back panel, left side and is labeled “Output”.

The valve associated with this connection will be referred to in this manual as

“Output Valve”.

Optimal Operating Pressures

It is recommended that the Input pressure remains at or below 80 PSI and the Output

pressure remains at or below 150PSI / 120 PSI (VaporSmartz iQ150 / VaporSmartz

iQ120). If the Input pressure exceeds 80 PSI, the case may pressurize and cycle the

pressure relief valve.

!

INSTALLATION

14

The following operation instructions assume the unit has been properly installed in

accordance with all applicable municipal safety, regulatory and legal compliance.

Do not proceed until proper installation has been completed.

Pre-Flight Check

1. Verify all fittings and connections between your extractor and VaporSmartz have been

tightened appropriately.

2. Verify the CycloneDry / molecular sieve filter elements are in a new, or reconditioned

state.

* IMPORTANT NOTE: Using old or saturated filter elements will have a negative effect on the life of

your pump and the quality of your product. Drawing moisture and / or organic material into the pump

will void the warranty.

3. Verify both the input and output valves on the closed loop extractor are open BEFORE

turning on the pump. NEVER RUN THE PUMP WITH THE INPUT VALVES OR OUTPUT

VALVES CLOSED.

Power-Up

Once you have verified the installation and checked out the system, it is time to power up.

Activate the power switch to begin transferring solvent.

Power-Down

1. Close the output valve on the extractor.

2. Turn off the pump.

3. Close the input valve on the solvent recovery tank.

*Notice*

The recovery system may begin to draw negative pressure as the extractor evacuates. While

this is normal and is part of the design operation of the pump – it is NOT INTENDED AS A

VACUUM PUMP. Continued use of the system at vacuum levels greater than 15 in-Hg will

result in damage to the seals and drawing atmospheric air into the system

Safety Measures

The system will auto shut off at 150 / 120 PSI of the output pressure.

OPERATION

!

15

What to do if your VaporSmartz iQ150/VaporSmartz Auto Shuts-off

The VaporSmartz iQ150 / VaporSmartz iQ120 has an auto shut-off that engages if

any number of parameters are exceeded.

- Input vacuum is greater than -20” Hg

- Output pressure is greater than 150 psi (120 psi for iQ120)

- Motor amperage current is exceeded

There is no external indicator on the unit showing which condition caused the auto shut-

off to engage. You will need to examine the system to determine the reason.

1. Turn the ON / OFF control switch to “OFF”, this will reset the unit.

2. While scanning the gauges, turn the switch to “ON” and review if the operation

limits have been exceeded for the input or output pressures.

a. Maximum input vacuum -20 inHg

b. Maximum Output pressure 150 psi (120 psi for iQ120)

3. If either pressure limit is reached, the unit will auto shut-off again. Troubleshoot

your attached equipment to bring the operating conditions back to within the

pump’s operating parameters.

If neither gauge indicates a pressure limit has been reached, the motor controller circuit

may have disengaged to prevent excessive current draw.

1. Turn the ON / OFF switch to “OFF”, this will reset the unit.

2. Perform a visual inspection to ensure no debris or materials have become bound

up in the pump / motor / belt drive system.

3. If anything has fouled the drive system, disconnect and isolate the unit from

the power supply and clear any debris from the drive system.

4. Turn the pump / motor / belt system by hand to confirm free rotation.

5. Reconnect the unit to the power supply.

6. Turn the control switch to “ON” and observe unit.

Continuing auto shut-off events NOT associated with pressures near the operating limits

may indicate pump contamination and / or motor damage. Contact PDX.GOLD for

assistance.

OPERATION

16

WARNING: Disconnect the unit from power supply prior to doing any

maintenance on the VaporSmartz.

General Maintenance

When cared for and operated properly according to this manual, the unit is essentially

maintenance free and will provide years of dependable service.

THE MOST IMPORTANT THING THE USER CAN DO TO REALIZE A LONG,

TROUBLEFREE PUMP LIFE IS TO TRANSFER CLEAN AND DRY SOLVENT.

EVERY piston pump on the market will be adversely affected by ingestion of contaminants

and ours is no exception to this rule.

This recovery system is an oilless design and requires no oil changes.

Preparing for Shipment

1. Disconnect the pump from the closed loop extractor.

2. Disconnect the molecular sieve / CycloneDry. Clean and store per the

instructions recommended by the manufacturer.

3. Properly package the unit in a shipping container, ensuring the unit is secure inside

the container to prevent movement during shipping.

4. Attach to a standard shipping pallet and band / secure the unit to the pallet for shipping

5. Alternately, store in a dry, clean environment for future use.

MAINTENANCE

!

17

VaporSmartz is certified by the third party engineering group, 3PCertz. 3PCertz specializes in

certifying cannabis extraction machines and the rooms in which they reside.

If you have purchased a certified unit, your VaporSmartz will have a serial tag provided by

3PCertz attesting to the fact your machine has been reviewed and held to the utmost standards

in cannabis extraction technology.

PDX.GOLD and 3PCertz offer certification for 14 states and the District of Columbia in the United

States. If your location is not listed, give us a call and we can review getting your location added

to our certification list!

- Arizona

- California

- Colorado

- District of Columbia

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Nevada

- New Mexico

- Oklahoma

- Oregon

- Vermont

- Washington

180043

Certification Report Number

Certified States

CERTIFICATION

18

Electrical

Part Manufacturer Description

Motor

VaporSmartz iQ150

Leeson NEMA 7, 2 HP, 1725 rpm.

Motor

VaporSmartz iQ120

Leeson NEMA 7, 1 HP, 1725 rpm.

Switch Enclosure Sprecher-Schuh NEMA 7 switch housing, includes

motor controller and shunt circuit.

Pressure Switches Ashcroft NEMA 7, 1/4” FNPT

Fittings &

Hoses

Part Manufacturer Description

Fittings SSP 1/2” 2600 psi working pressure,

Swagelok compatible.

Hoses Detroit Flex Stainless Steel braided hoses:

Certified high pressure PTFE, smooth

bore hoses, specifically designed for

applications requiring strength, reli-

ability, and long term performance.

Specifications

VaporSmartz iQ150: Leeson - 2 HP

VaporSmartz iQ120: BRP-1, 1 HP

- UL Class 1, Division 1

- Maximum pressure: (VaporSmartz iQ150) 150 psi. (VaporSmartz iQ120) 120 psi

- Maximum vacuum of 20” Hg

CERTIFICATION

19

LIMITED USA AND CANADA WARRANTY POLICY – PDX.GOLD warrants products sold against

defects in material or workmanship as follows: PDX.GOLD, at its option, unless otherwise agreed, will replace

or repair any defective product unit or defective part of the product unit at no charge, provided that:

1. The warranty claim is made in writing within the period of time specified in the catalog or in

information enclosed with the product packaging (6 months); and

2. The proof of purchase by bill of sale or receipted invoice is submitted concurrently with the claim

and shows that the product is within the applicable warranty period to Customer Service of

PDX.GOLD; and

3. The purchaser complies with Procedures for Returns listed under the General Terms and

Conditions contained herein; and

4. The purchaser complies with all the manufacturer’s requirements. The warranty is in force from the

date of shipment from PDX.GOLD’s manufacturing facility. The warranty period begins on the day the

customer receives the product, but not later than 90 days after the date of shipment from

PDX.GOLD’s manufacturing facility. PDX.GOLD reserves the right, at its discretion, to fulfill warranty

claim with refurbished or reconditioned parts or units.

This warranty shall not apply to:

a) Defects or damages resulting from (1) misuse of the product, (2) use of the product in other than

its normal and customary manner, (3) accident or neglect, (4) improper testing, operation,

maintenance, service, repair, installation, or storage, (5) unauthorized alteration or modification, (6)

damage determined to be the result of freight or shipping after the product has left the factory; or

b) Normal tear and wear of the product, its components, or parts; or

c) Post-expiration dated material

Other limitations

This warranty is the exclusive remedy of the purchaser, and PDX.GOLD disclaims all other warranties,

whether express, implied or statutory, including without limitation, warranties of merchantability and fitness for

particular purpose. No employee, agent, or representative of PDX.GOLD is authorized to bind PDX.GOLD to

any other warranty. In no event shall PDX.GOLD be liable for incidental or consequential damages.

All express and implied warranties, including the implied warranty of merchantability and the implied warranty

of fitness for a particular purpose, are expressly disclaimed and shall not apply to any products sold or services

rendered hereunder. PDX.GOLD shall not be liable for consequential, incidental, special, or other direct or

indirect damages resulting from economic loss or property damage sustained by you or any end user from use

of the products sold or services rendered hereunder.

WARRANTY

This manual suits for next models

1

Table of contents

Other PDX.GOLD Test Equipment manuals

Popular Test Equipment manuals by other brands

PeakTech

PeakTech 1145 Operation manual

Sunlight Electronics Laboratory

Sunlight Electronics Laboratory 7116C Operation manual

Agilent Technologies

Agilent Technologies 81101A quick start guide

Tektronix

Tektronix TBS2102 user manual

Alcofind

Alcofind AF-100S user manual

Hamron

Hamron 010933 operating instructions