Peak Scientific Hydrogen Detector User manual

Hydrogen Detector

User Manual

2021 © Peak Scientific – Rev 5– 12/10/2021

H²Detector User Manual

Page 2

Contents

Change History 3

How to use this Manual 3

Introduction 4

Warranties and Liabilities 5

Safety Notices 6

Symbols 6

Safety Notice to Users 6

Declaration of Conformity 7

Environmental Declaration 8

Technical Specification 9

Environment 9

Detector Inlets 9

Default Configuration 9

Electrical Requirements 9

General 9

Unpacking 10

Installation 11

Detector Environment 11

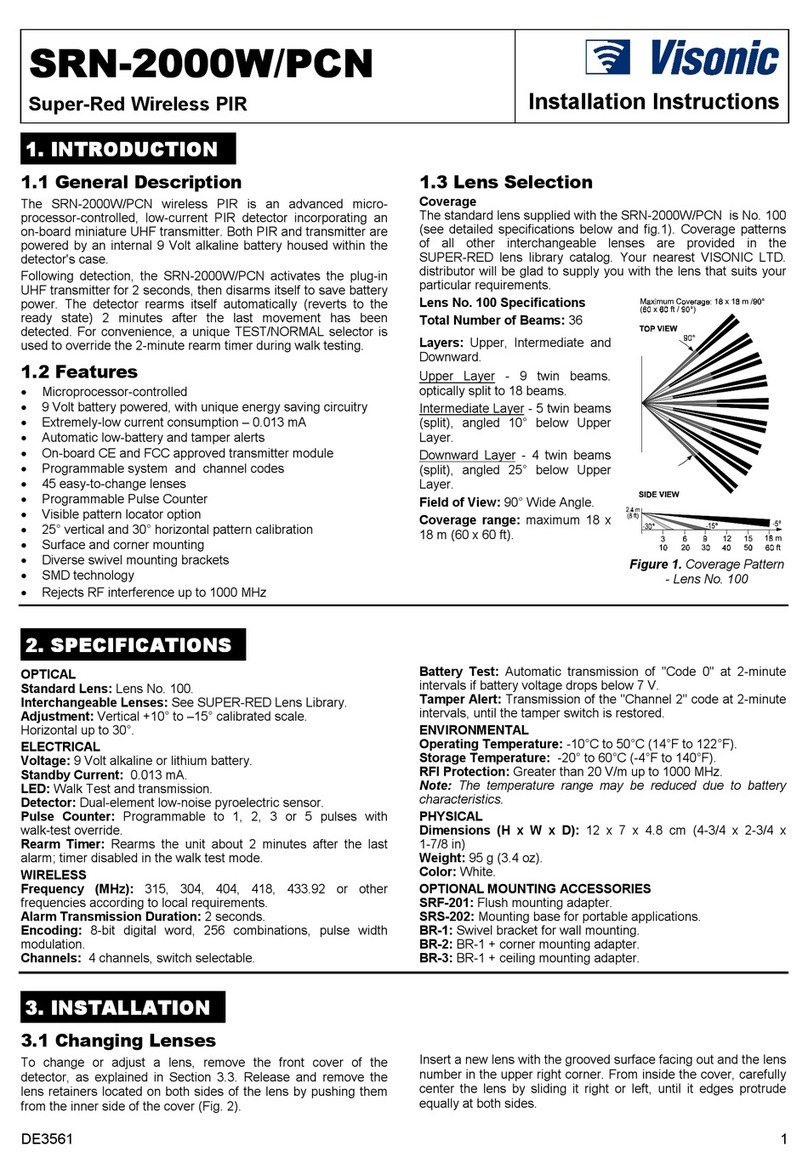

General Dimensions 12

Rear Connections 13

Fittings Kit 13

In Line Filter 13

Connecting to the GC 14

Tubing Lengths 15

Electrical Connection 16

Sensor Cartridge Installation 17

Start-up Sequence 19

IMPORTANT DOCUMENT

S

20

Service Requirements 21

Service Schedule 21

Trouble Shooting 21

H² Detector User Manual

Page 3

Change History

Rev.

Comment

Name

Date

1 D.O.C. Altered Liam Couttie 17/09/12

2

Connection Image Altered

Liam Couttie

31/10/12

3

GC Connection Info Added,

Liam Couttie

14/05/13

4

Fittings Kit Additions

Liam Couttie

03/09/13

How to use this Manual

This manual is intended for end users and has been written so that it can either

be read as a step by step guide to installation and usage or as a reference

document where you can skip to the relevant information.

Users of a hard copy version can refer to the contents page to find the relevant

information. Users of the soft copy version can use the hyperlinks from the

contents page as well as the hyperlinks between sections.

Please review each of the following sections carefully.

Thank you for selecting Peak Scientific to meet your Gas Detection needs, and

should you require any further assistance or support please do not hesitate to

contact Peak Scientific or Peak Partner from which you purchased your

Detector.

H² Detector User Manual

Page 4

Introduction

The Peak Scientific Hydrogen Detector is an extractive gas sampling system

that draws a sample locally from your GC Oven to a sensor cartridge that is

located inside the detector’s chassis.

Our Hydrogen Detector is wall mountable and displays gas concentration,

alarm, fault and status information via its backlit LCD and LEDs. A simple to use

4-button keypad located under the display provides the facility to set-up,

review, operate and make changes to the detector’s configuration.

H² Detector User Manual

Page 5

Warranties and Liabilities

1. The Company warrants that it has title to the Goods.

2. Subject to the provisions of this clause the Company warrants that the

Goods shall comply in all material respects with any specification

referred to in the Order Confirmation (as the same may be amended)

and shall, subject thereto, be free from defects in material and

workmanship for the lesser of a period of twelve months from the date

of delivery or thirteen months from the date of dispatch from the

factory.

3. Save as provided in this clause and except where the Goods are sold to

a person dealing as a consumer (within the meaning of the Unfair

Contract Terms Act 1977) all warranties, conditions or other terms

implied by statute or common law are hereby expressly excluded save

to the extent they may not be lawfully excluded. When the Goods are

sold to a consumer within the meaning of the Unfair Contract Terms Act

1977 their statutory rights are not affected by the provisions of this

clause.

4. In the event of the Customer making a claim in respect of any defect in

terms of clause 2 hereof the Customer must.

1. Reasonably satisfy the Company that the Goods have been

properly installed, commissioned, stored, serviced and used and

without prejudice to the generality of the foregoing that any

defect is not the direct or indirect result of lack of repair and/or

servicing, incorrect repair and/or servicing, use of wrong

materials and/or incorrect spare parts

2. Allow the company to inspect the Goods and/or any installation

and any relevant packaging as and when reasonably required by

the Company.

5. Subject to the Company being notified of any defect as is referred to in

sub-clause 2 hereof within a reasonable time of it becoming apparent

and subject always to the terms of sub-clause 4 hereof, the Company

shall, in its option, replace or repair the defective Goods or refund a

proportionate part of the Price. The Company shall have no further

liability to the Customer (save as mentioned in sub-clause 6 hereof).

6. The Company shall be liable to indemnify the Customer in respect of

any claim for death or personal injury to any person in so far as such is

attributable to the negligence or breach of duty of the Company or any

failure by the Company to comply with the provisions of sub-clause 2

hereof.

7. Save as provided in sub-clause 2 hereof the Company shall not be liable

in respect of any claim by the Customer for costs, damages, loss or

expenses (whether direct, indirect, consequential or otherwise) or

indemnity in any respect howsoever arising including, but not by way of

limitation, liability arising in negligence (other than pursuant to clause 6

above) that may be suffered by the Customer or any third party.

H² Detector User Manual

Page 6

Safety Notices

Symbols

This manual uses the following symbols to highlight specific areas important to

the safe and proper use of the detector

Safety Notice to Users

These instructions must be read thoroughly and understood

before installation and operation of your Peak Hydrogen

Detector. Use of the Detector in a manner not specified by

Peak Scientific MAY impair the SAFETY provided by the

equipment.

When handling, operating or carrying out any maintenance,

personnel must employ safe engineering practices and

observe all relevant local health and safety requirements and

regulations. The attention of UK users is drawn to the Health

and Safety at Work Act 1974, and the Institute of Electrical

Engineers regulations.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment

maybe impaired.

A WARNING notice denotes a hazard. It calls attention to an operating procedure,

process or similar, which if not correctly performed or adhered to, could cause

personal injury or in the worst case death. Do not proceed beyond a WARNING notice

until the indicated conditions are fully understood or met.

A CAUTION notice denotes a hazard. It calls attention to an operating procedure,

process or similar, which if not correctly performed or adhered to, could cause damage

to the Detector or the Application. Do not proceed beyond a CAUTION notice until the

indicated conditions are fully understood or met.

Caution, risk of electric shock. Ensure power to the Detector has been removed before

proceeding.

EU Declaration of Conformity

We Peak Scientific Instruments Ltd.

Of Fountain Crescent, Inchinnan, Renfrewshire, PA4 9RE

Hereby declare that, this declaration of conformity is issued under the sole

responsibility of the manufacturer.

Equipment: Hydrogen Detector

Model: Hydrogen Detector

To which this declaration relates, is in conformity with the following applicable EU

Directives, harmonized standards, and other normative requirements.

• Low Voltage Directive 2014/35/EU

EN 61010-1: 2010 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use.

• Electromagnetic Compatibility Directive 2014/30/EU

EN 61326-1: 2013 Electrical Equipment for Measurement, Control and Laboratory Use

– EMC Requirements. (Class A)

• Restriction on the use of certain hazardous substances in electronic equipment

(RoHS) Directive 2011/65/EU as amended by EU 2015/863.

• FCC 47 CFR Part 15 class A

Unintentional radiators; Conducted and Radiated emissions limits.

Signed for and on behalf of Peak Scientific by

Signed:

Name: Fraser Dunn

Position: Design Engineering Manager

Peak Scientific Instruments ltd,

Inchinnan, Renfrew, Scotland, PA4 9RE, UK.

Date: 10th August 2021

UK Declaration of Conformity

We Peak Scientific Instruments Ltd.

Of Fountain Crescent, Inchinnan, Renfrewshire, PA4 9RE

Hereby declare that, this declaration of conformity is issued under the sole

responsibility of the manufacturer.

Equipment: Hydrogen Detector

Model: Hydrogen Detector

To which this declaration relates, is in conformity with the following applicable UK

Statutory Instruments, Standards and other normative requirements.

• The Electrical Equipment (Safety) Regulations 2016 (SI 2016 / 1101) as amended.

BS61010-1:2010 Safety Requirements for Electrical Equipment for Measurement

Control and Laboratory Use.

• The Electromagnetic Compatibility Regulations 2016 (SI 2016 / 1091) as amended.

BS61326-1:2013 Electrical Equipment for Measurement , Control and Laboratory Use

– EMC Requirements.

• The Restriction of the Use of Certain Hazardous Substances in Electrical and

Electronic Equipment Regulations 2012 (SI 2012 / 3032) as amended.

Signed for and on behalf of Peak Scientific by

Signed:

Name: Fraser Dunn

Position: Design Engineering Manager

Peak Scientific Instruments ltd,

Inchinnan, Renfrew, Scotland, PA4 9RE, UK.

Date: 10th August 2021

WEEE Compliance Statement

The Waste Electrical and Electronic Equipment (WEEE) Regulations SI 2013 No 3113

and or the Waste Electrical and Electronic Equipment (WEEE) Directive 2012/19/EU

apply to all electrical and electronic equipment placed on the market in the UK and EU

covered by the scope of regulations which can be found in the Government Guidance

Notes (PDF) produced by the Department for Business Innovation and skills for the UK

and here for Europe.

All PEAK products that are subject to the WEEE directive are compliant with the

WEEE marking requirement. Such products are marked with the “crossed-out wheelie

bin” symbol (shown below) in accordance with European standard EN50419. All

old electrical equipment can be recycled. Please do not dispose of any electrical

equipment (including those marked with this symbol) in general rubbish bins. Please

contact your dealer or distributor for clarity.

H² Detector User Manual

Page 9 2013 © Peak Scientific – Rev 4 – 03/09/1

Technical Specification

Environment

Minimum operating ambient temperature

0°C (40°F)

Maximum operating ambient temperature 40°C (104°F)

Maximum relative humidity 90% Non-Condensing

Minimum storage temperature* 0

o

C (40

o

F)

Maximum storage temperature* 40

o

C (104

o

F)

*NOTE – When taken out of storage the Detector should be allowed to acclimatize at

room temperature for a minimum of 3 hours before operation.

Detector Inlets

Mass Flow Rate

500 cc/min(10in/H

2

O max pressure/vacuum)

Transport time 2-30 seconds maximum

Ambient Point In line air filter required (supplied)

Default Configuration

Current source with:

1.0mA Fault

2.0mA Inhibit

3.0mA Maintenance Fault

4.0 to 20.0mA Gas Reading (normal operation)

21mA Over range

Toxic Gas

Flammable Gas

Oxygen

Full Scale(FS) Typically 4 x Threshold Limit

Value (TLV)

100% Lower

Explosive Limit

(LEL)

25% Volume

(v/v)

Lowest Alarm Level (LAL)

Typically ½ TLV

10% LEL

5% v/v

Lower Detectable Level

(LDL)

Typically 0.4 TLV 9% LEL 0% v/v

The LDL is the minimum level that is reliably distinguishable from zero.

Alarm 1 (Relay 1)

½ TLV

10% LEL

23.5% v/v (rising)

Normally de-energized, energizes on alarm. Contact Normally Open (NO),

Closes on alarm.

Alarm 2 (Relay 2)

TLV

20% LEL

19.5% v/v (Falling)

Normally De-energized, de-energizes on alarm. Contact Normally Open

(NO), closes on alarm.

Fault (Relay 3)

Normally energized, de-energizes on fault. Contact normally open (NO).

Instrument Fault only.

Latching

Latching Alarm and fault relay DO NOT automatically reset when reading

falls below alarm thresholds. Relays MUST be manually reset.

Pass Code

No pass code set.

Electrical Requirements

The Detector has its power supplied by the Precision 500 generator

General

Detector dimensions in cm W x D x H 6.3 x 16.2 x 20 (2.5” x 6.4” x 7.9”)

Detector weight 1.8 kg (3.9 lb.)

Shipping crate dimensions in cm W x D x H 40 x 40 x 15 (15.7” x 15.7” x 5.9”)

Shipping weight 3 kg (6.6 lb.)

H² Detector User Manual

Page 10 2013 © Peak Scientific – Rev 4 – 03/09/1

Unpacking

Although Peak Scientific takes every precaution with safe transit and

packaging, it is advisable to fully inspect the unit for any sign of transit

damage.

Check ‘SHOCKWATCH’ label for signs of rough handling prior to un-packing –

Any damage should be reported immediately to the carrier and Peak

Scientific or the Peak Partner from where the unit was purchased.

Please save the product packaging for storage or future shipment of the

Detector.

Note: Included with the Detector is a “Fittings Kit” containing the

communication cable for connecting the detector to the generator also all the

required fittings. Be careful not to discard these with the packaging.

H² Detector User Manual

Page 11 2013 © Peak Scientific – Rev 4 – 03/09/1

Installation

Detector Environment

The Detector is designed for use indoor safe non- explosive

atmospheres only. It should be installed at a suitable height

adjacent to the Gas Chromatograph it is connected to. Please

see the Tubing lengths section for further details on maximum

distances from the GC for maximum performance of the

detector.

Performance of the Detector (like all sophisticated

equipment) is affected by ambient conditions. Note should

also be taken to the proximity of Air Conditioning outlets.

These can sometimes give rise to “pockets” of air with high

relative humidity. Operation of the unit within such a pocket

could adversely affect its performance. Please refer to the

drawing below for the general dimensions of the unit.

Maximum Ambient Conditions: 40°C (dry bulb) 90%RH (Max) Non-Condensing

Location

The detector can be located on a flat surface or wall mounted for operation -

this will ensure that you can locate it within the maximum distance required for

the unit to successfully monitor for Hydrogen leaks.

The Peak Hydrogen Detector is supplied with a bracket to allow a simple way

to mount the unit to a wall near the GC.

Use 2 x M4 Screws or equivalent (not supplied) for mounting the bracket to the

wall. You will then be able to lower the detector unit onto the wall bracket. The

wall mounting has been specially designed to allow greater serviceability by

enabling the unit to be taken down off of the wall for service and maintenance

work to be carried out, without having to remove the wall bracket.

H² Detector User Manual

Page 13 2013 © Peak Scientific – Rev 4 – 03/09/1

Rear Connections

Fittings Kit

Supplied in the Fittings Kit are all the fittings required to connect the Hydrogen

Detector to the Generator. The contents of the Fittings Kit are as follows:

1. Communications Cable × 1

2. In Line Filter × 4

3. Cartridge x 1

4. ¼” Push Fit Barbed Fitting × 2

5. ¼” OD x ⅛” THK Exhaust Tubing × 1.5m

6. ¼” OD x 3/16” THK Input Tubing × 1.5m

7. ⅛” OD Stainless Steel Tubing x 1m

8. Bulkhead Reducer Fitting x 1

9. Tygon Filter Tubing x 1m

10. Hex Key x 1

11. Hose Clips x 2

12. Wall Mounting Bracket x 1

13. Installation Guide– Hydrogen Detector × 1

14. User Manual CD– Hydrogen Detector × 1

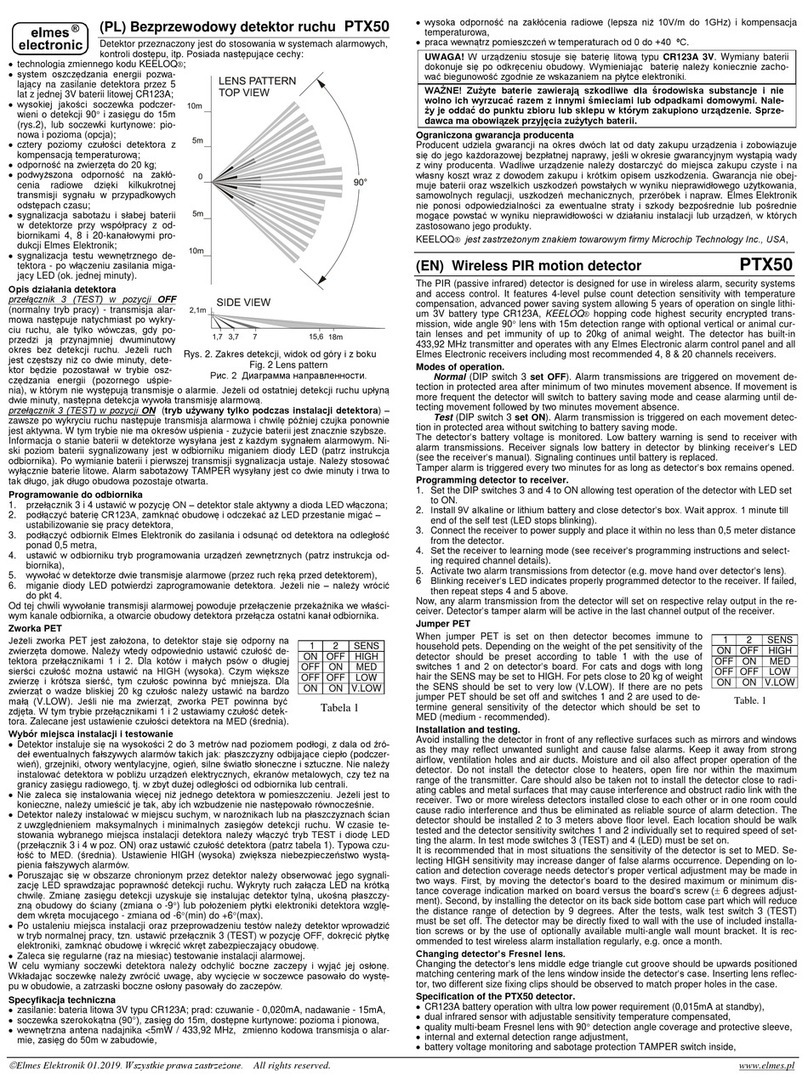

In Line Filter

The In Line filter should be fitted, as close to the instrument as possible, on the

end of the tubing which is connected to the Input port at the rear of the

Detector, as shown below.

¼” Barbed Fitting

Hose Clamp

Inlet Filter

Input Tubing

Tygon Tubing

H² Detector User Manual

Page 14 2013 © Peak Scientific – Rev 4 – 03/09/1

Connecting to the GC

1. First remove the plastic cover on the top of the GC.

2. Locate the cut-out hole on the aluminium plate directly above the rear

hole on the GC oven.

3. Make a hole through the insulation material, through to the oven. The

stainless steel tubing from the detector can now be pushed through the

hole, and secured in place using more insulation material.

4. Once the stainless steel tubing has been pushed through and secured,

the end of the tubing should be aimed at the inlet of the GC column.

H² Detector User Manual

Page 15 2013 © Peak Scientific – Rev 4 – 03/09/1

5. Position the end of the tubing as close to the inlet as possible, without

limiting access for column changes and inlet maintenance.

6. The detector is now fully connected and will take samples continuously

and both the detector and the H2 generator will sound an alarm if

dangerous levels of Hydrogen are detected. The generator will then shut

down.

Tubing Lengths

The length of the tubing which will be connected to the Input

Port of the Detector is important and is determined by the

Hydrogen cartridge used by the detector. Failure to follow

these recommendations could lead to the Hydrogen Detector

failing to operate efficiently.

Inlet Sample Specifications:

Maximum

Tubing Length, m (ft.)

30 (100)

20 (66)

10 (33)

0

Transport Time (Sec)

28

19

10

1

Tubing OD, mm (in)

6.35 (0.25)

Tubing ID, mm (in)

3.18 (0.125)

H² Detector User Manual

Page 16 2013 © Peak Scientific – Rev 4 – 03/09/1

Electrical Connection

Connect the Detector to the Peak Scientific Precision 500 Generator using the

communication cable provided.

This unit is plugged, from the ‘In’ port at the rear on the detector, into the ‘H2

Detector’ port at the rear of the generator, as shown below. This connection

will provide the detector unit with power and allows communication between

the Precision 500 and the detector unit.

The detector will take samples continuously and both the detector and the

Precision 500 will alarm if dangerous levels of hydrogen are detected, the

Precision 500 will then shut down.

Multiple detectors can be connected to one Precision 500. If this is desired,

connect the first detectors ‘Out’ port to the second detectors ‘In’ port, as

illustrated below. Please take into consideration when working with multiple

Hydrogen Detector Units that a minimum required distance between units is

82mm (3.23in).

H

2

Detector

Port

In Port

Out Port

Precision 500

H

2

Detector

H² Detector User Manual

Page 17 2013 © Peak Scientific – Rev 4 – 03/09/1

Sensor Cartridge Installation

The pre-calibrated smart sensor cartridges can easily be fitted or replaced as

they simply plug into the detector without the need for any tools. The sensor

cartridge is firmly held in place by two locking tabs. Some cartridges are

shipped with a protective cap to shield them from contaminants during

shipping. This cap must be removed before inserting the cartridge into the

Detector unit, failure to do so may damage the transmitter. Switch the power

switch on the terminal module to the ‘on’ position and the re fit the

Sensor warranty is void if the sensor cartridge is opened by unauthorised user.

*The cartridge has an ‘activate by’ date that must be adhered to.

H² Detector User Manual

Page 18 2013 © Peak Scientific – Rev 4 – 03/09/1

In a first-time start up, an F49 or F88 fault code may be displayed; there is

no actual fault and the fault message can be cleared by depressing the “X”

button for a few seconds.

To properly activate the Detector with the cartridge for the first time:

1. When “ChAngE gAS” or “FIrSt CELL” scrolls on the display, hit the

“✓”on the Detector front panel.

2. When the “reboot” completes then press and hold the “X” to clear

any latched fault(s).

3. Confirm that the green LED is flashing.

4. Confirm that the yellow and red LEDs are off.

5. Confirm the display shows a concentration of zero (as appropriate).

The cartridge has now been accepted by the Detector as the correct type.

If the above steps were not performed at initial start-up, the remove the

cartridge and cycle power. Once the Detector has completed the “reboot”

process, install the cartridge and repeat the steps above.

H² Detector User Manual

Page 19 2013 © Peak Scientific – Rev 4 – 03/09/1

Start-up Sequence

CHECK:

1. Ensure power cable is correctly connected between the Hydrogen

Generator and the Hydrogen Detector.

2. Hydrogen Generator is turned on.

3. After applying power to the Peak Scientific Hydrogen Detector the unit

will run go through a start-up test routine illuminating in sequence all

LEDs, icons and digits of the display. The unit will then display the

messages “WAIT” and “LOAD” as it checks for the cartridge data,

typically less than 180 seconds.

4. When complete, the detector will enter normal monitoring mode

indicated by the icon on the display cycling through three states (2

rings, 3 rings, 4 rings). The measured gas concentration will be shown

on the display. The green LED will flash once every second indicating

power and the sample flow rate indicator will be displayed. If monitoring

is interrupted due to a fault, a test or calibration process or a user

requested inhibit, the display will flash, please refer to the

Troubleshooting section for guidance. (See Figure 1)

Figure 1: Normal Operation

Table of contents

Popular Security Sensor manuals by other brands

Inficon

Inficon XL3000flexRC Translation of the original operating instructions

Lince

Lince GR868DT Installation, operation and maintenance manual

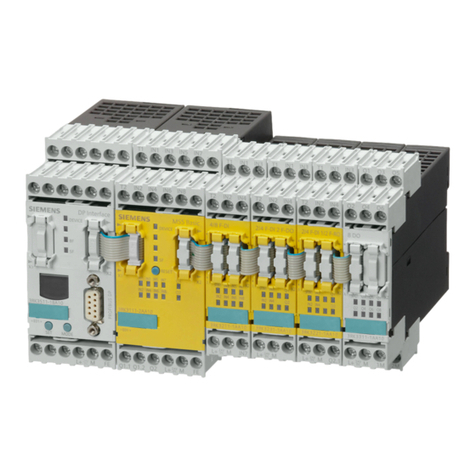

Siemens

Siemens SIRIUS 3RK3 System manual

Visonic

Visonic SRN-2000W/PCN installation instructions

Agilent Technologies

Agilent Technologies 1260 Infinity user manual

Cooper

Cooper 1803 LED CG-S Fitting and operating instructions