PCAN-Router DR – User Manual

5

1 Introduction

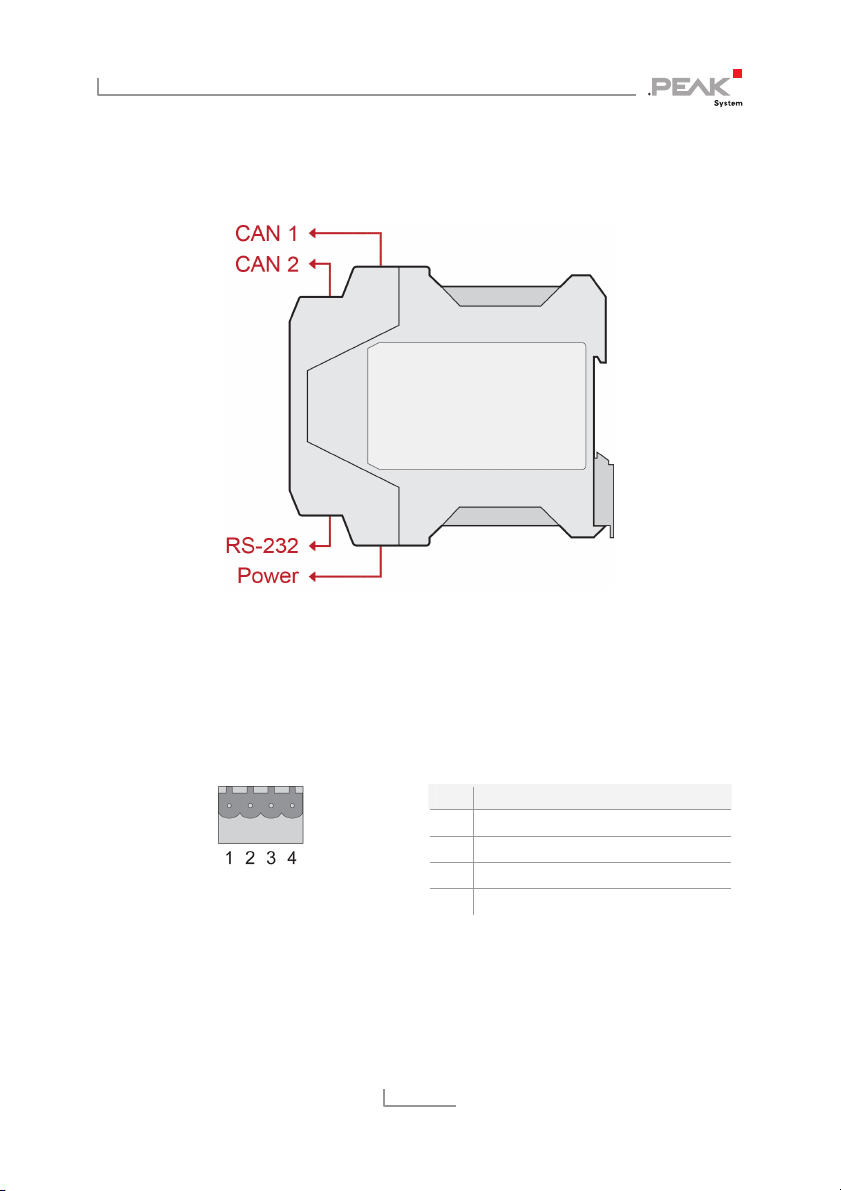

The PCAN-Router DR has two High-speed CAN channels. Their bit

rate is adjusted with a rotary switch on the device front. The module

forwards the message traffic bi-directionally 1:1 between both

connected CAN buses.

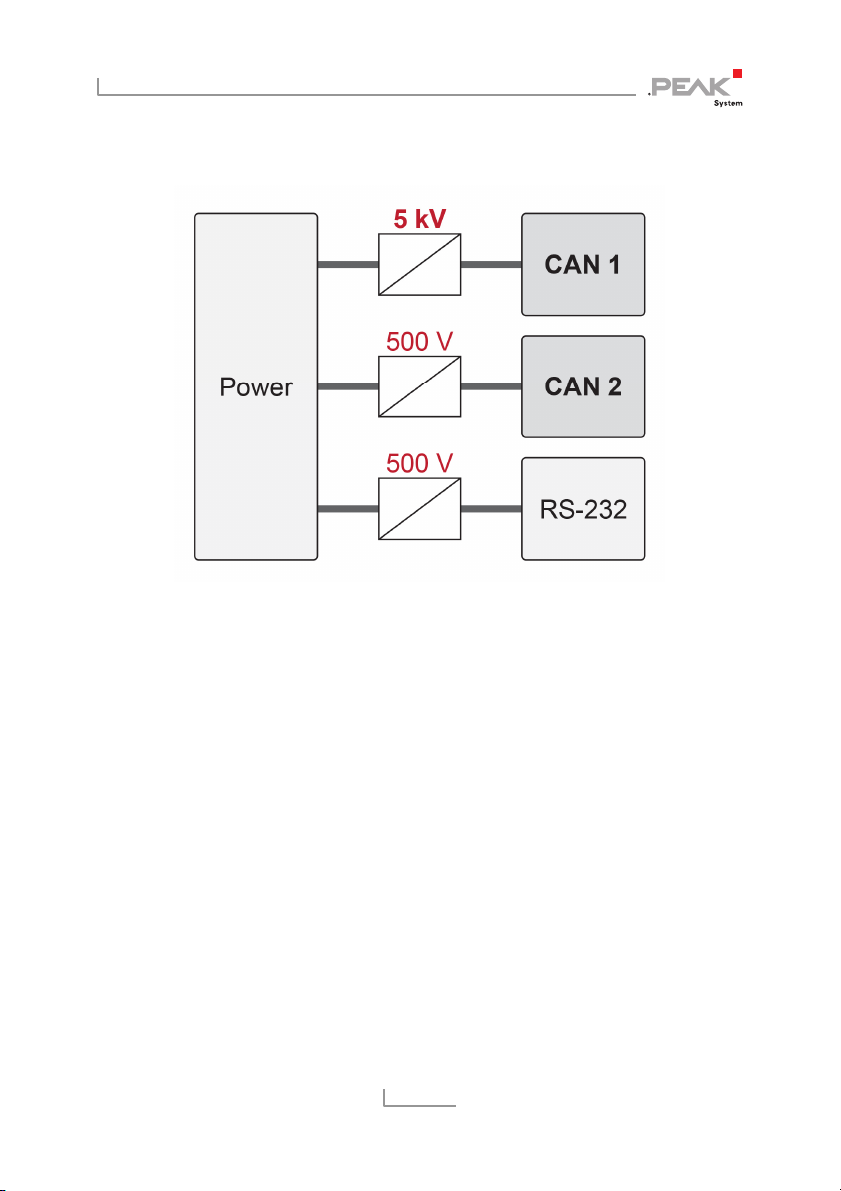

The ports of the device are isolated against each other and against

the power supply with at least 500 V. Furthermore, CAN 1 has a

separation voltage of up to 5 kV conforming with IEC 60601-1. With

its DIN rail casing and the support of the extended temperature

range, the module is suitable for use in an industrial environment.

Just like the PCAN-Router in the aluminum casing, the PCAN-Router

DR can be freely programmed. A corresponding development

package is included in the scope of supply.

1.1 Properties at a Glance

NXP LPC21 series microcontroller (16/32-bit ARM CPU)

32 kbyte EEPROM

Two High-speed CAN channels (ISO 11898-2)

Complies with CAN specifications 2.0 A/B

NXP PCA82C251 CAN transceiver

Bit rates from 5 kbit/s up to 1 Mbit/s, adjustable with a rotary

switch

Reset of the device with a push button

Switchable termination for each CAN channel

Status indication via LEDs for the module status, both CAN

channels, and the power supply