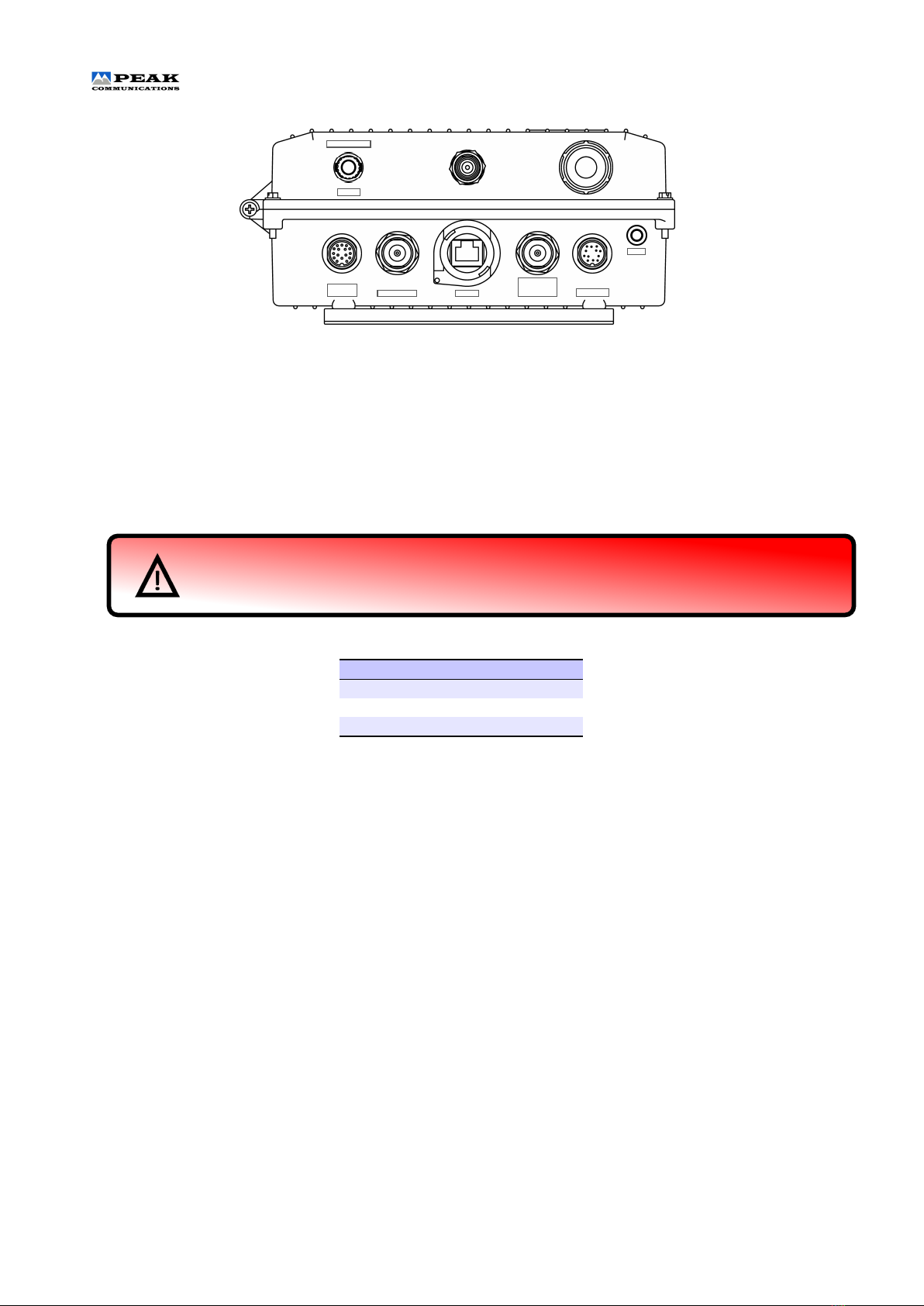

Installation and Operating Handbook

List of Tables

1.1 Ethernetresetsettings............................................ 2

1.2 Power/Remote/Alarmspinout ...................................... 3

1.3 Relayratings ................................................. 3

1.4 Redundancypinout ............................................. 3

1.5 Wiredinterfacecontrol............................................ 3

1.6 StatusLED .................................................. 4

4.1 P7xxxprotocol ................................................ 8

4.2 Deviceinstructionlist ............................................ 9

4.3 Device status request message format (instruction 20) . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Device status response message format (instruction 21) . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5 Device change request message format (instruction 22) . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.6 Remote/localinstructionlist ........................................ 13

4.7 Remote / Local Change Request message format (instruction 24) . . . . . . . . . . . . . . . . . . . 14

4.8 Unitinstructionlist .............................................. 15

4.9 Unit status request message format (instruction 40) . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.10 Unit status request response message format (instruction 41) . . . . . . . . . . . . . . . . . . . . . . 17

4.11Redundancyinstructionlist ......................................... 18

4.12 Redundancy status request message format (instruction 45) . . . . . . . . . . . . . . . . . . . . . . 19

4.13 Redundancy status response message format (instruction 46) . . . . . . . . . . . . . . . . . . . . . 20

4.14 Redundancy change request message format (instruction 47) . . . . . . . . . . . . . . . . . . . . . . 21

4.15 Serial communications settings instruction list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.16 Serial Communications Settings Change Request message format (instruction 26) . . . . . . . . . . 23

4.17 Ethernet Settings instruction list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.18 Ethernet Status Request message format (instruction 4, sub instruction ’1’) . . . . . . . . . . . . . . 25

4.19 Ethernet Status Response message format (instruction 5, sub instruction ’1’) . . . . . . . . . . . . . 26

4.20 Ethernet Change Request message format (instruction 6, sub instruction ’1’) . . . . . . . . . . . . . 27

4.21 TCP Port Settings instruction list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.22 TCP Port Status Request message format (instruction 4, sub instruction ’2’) . . . . . . . . . . . . . . 29

4.23 TCP Port Status Response message format (instruction 5, sub instruction ’2’) . . . . . . . . . . . . . 30

4.24 TCP Port Change Request message format (instruction 6, sub instruction ’2’) . . . . . . . . . . . . . 31

PBU2000 Peak Communications Ltd. v