A qualied electrician must perform all

the wiring.

1. GENERAL INFORMATION

1.1. Read this Instruction Manual thoroughly prior to any work.

Work should be undertaken by qualified persons only.

ATTENTION!

Important information for installers of this

equipment!

This equipment is intended for installation by technically qualified

personnel. Failure to install it in compliance with national and

local electrical codes, and with motor suppliers recommenda-

tions, may result in electrical shock or fire hazard, unsatisfac-

tory performance, and equipment failure. Installation information

is available from pump manufacturers and directly from motor

suppliers. Retain this information sheet with the equipment for

future reference.

WARNING

Serious or fatal electrical shock may result from failure to

connect the motor, control enclosures, metal plumbing, and all

other metal near the motor or cable, to the power supply ground

terminal using wire no smaller than motor cable wires. To reduce

risk of electrical shock, disconnect power before working on or

around the water system.

1. LOCATION

The pump should be installed in a dry, accessible place not

subject to freezing temperatures. If installed in a pump pit or

other location subject to dampness, proper ventilation must be

provided to avoid moisture damage to the electrical equipment.

2. PIPING

Galvanized steel or plastic pipe is recommended. If copper or

other dis-similar metal piping is used, a di-electric union or

bushing is recommended where the piping is connected to the

pump body. The pipe used should be cleaned and free of scale.

Ream ends of pipe to remove burrs. Check threads to see that

they are clean and not damaged. Horizontal runs of suction

pipe must slope upwards from the well to the pump to avoid air

pockets in the line which will make it difficult, if not impossible, to

prime the pump. The recommended slope is one inch in ten feet.

If pump must be offset an appreciable distance from the well,

the size of horizontal pipe should be increased to reduce

friction losses.

If using di-electric bushing, hand start bushing into female end of

pump housing (or other female connection) first. Use a six-sided

socket to tighten the bushing.

The bushing should be fully inserted into the female connec-

tion. After the male end of the bushing is fully installed, hand

start pipe (or other male connection) into the female end of the

bushing.Failuretofollowtheseguidelinesmaydamagethebushing.

Caution should be taken to not cross-thread the bushing.

3. FLUSHING

If the pump discharge line is connected to pressure tank or

house service, disconnect it and flush and clean the system by

* Time delay fuses and circuit breakers (Single Phase).

For distances of 100 feet and over from meter to motor, larger

wire than shown may be required.

5. MOTORS

Motors are equipped with sealed ball bearings and require little

attention.

If motor repeatedly stops, cools off, and starts again, the cause

or trouble must be located and corrected. Do not cover motor

with canvas or other material that may interfere with proper air

circulation and cause over-heating.

CAUTION

!

temporarily wasting the water outdoors or to drain. The pump

should be operated until the water runs clear, without sand, mud

or rust.

This procedure will eliminate the danger of pumping dirty water

into the pressure tank and home appliances. When water runs

clear, re-connect discharge line to tank and service.

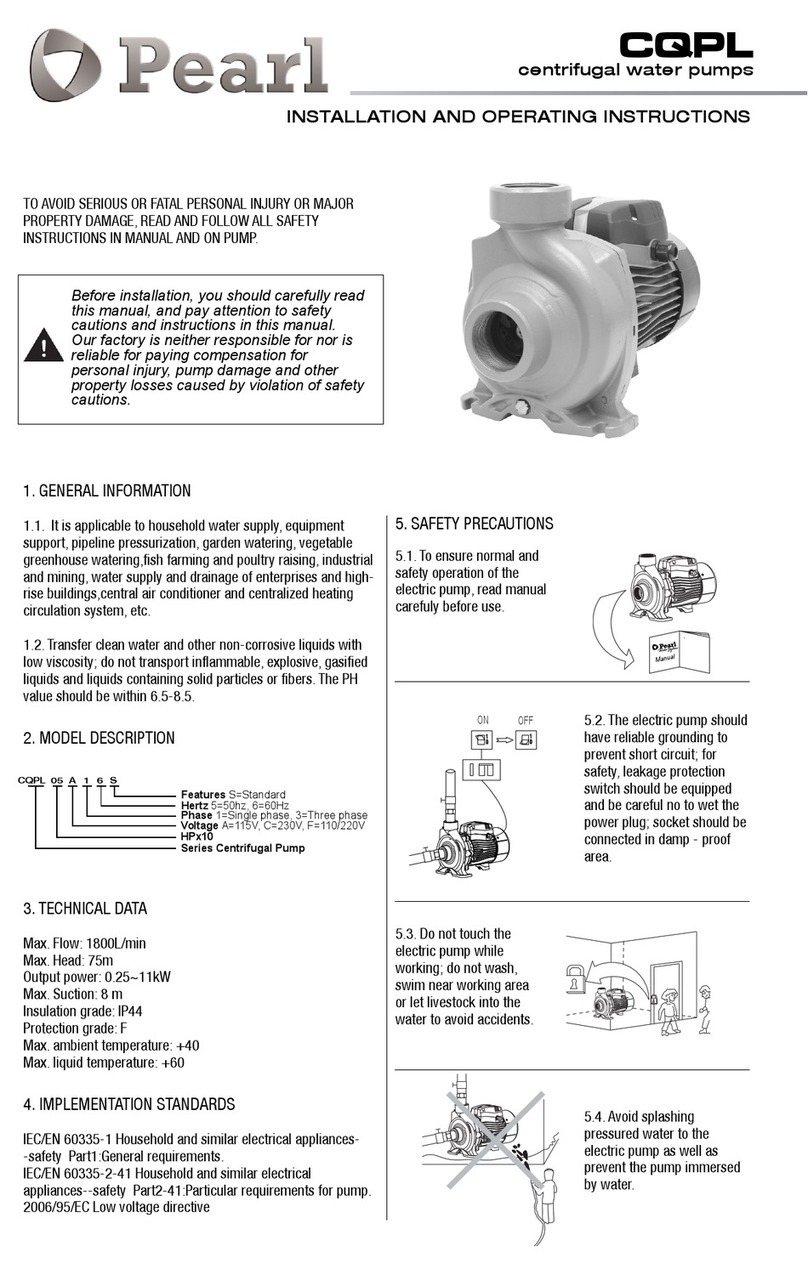

4. WIRING (Use copper conductors only)

Be certain that wire and fuses of correct size are installed. Be

certain the phase, voltage, and cycles of the supply circuit are

the same as that shown on the motor name plate.

It is strongly recommended that a separate electric line, well pro-

tected against fire, be run from electrical service to the pump,

with a fused switch box at the pump.

In the event of fire, this precaution will permit continuous opera-

tion of your pumping system. For added safety, the pump and

motor should be properly grounded to the well casing or to a

separate ground rod driven eight feet into the ground.

NOTE: For proper fuse, circuit breaker and wire sizes in your

area, follow local codes. Otherwise:

Wire Gage and Standard Fuse Sizes

MOTOR

SIZE

WIRE SIZE *FUSETRON *CIRCUIT BRKR

115 V 230 V 115 V 230 V 115 V 230 V

1 HP 8 12 30 amp 20 amp 35 amp 20 amp

1.5 HP 6 10 35 amp 25 amp 40 amp 20 amp

2 HP 8 8 - 30 amp - 25 amp