4

English (US)

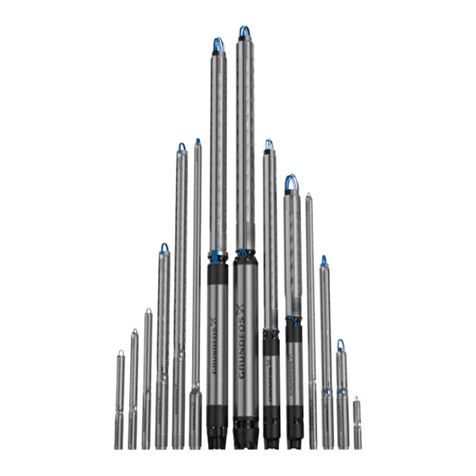

5.1.3 Installation depth

Pumping sand or well sediment can occur when

the pump motor is installed lower than the top of

the well screen or within 5 ft of the well bottom.

This can reduce the performance and life

expectancy of the pump and should be avoided.

If the pump is to be installed in a lake,

containment pond, tank or large diameter well,

the water velocity passing over the motor must

be sufficient to ensure proper motor cooling.

The minimum recommended water flow rates

which ensure proper cooling are listed in section

9.1 Minimum water flow requirements for sub-

mersible pump motors on p. 13.

5.1.4 Electrical supply

The motor voltage, phase and frequency

indicated on the motor nameplate should be

checked against the actual electrical supply.

5.1.5 Wire cable type

The wire cable used between the pump and

control box or panel should be approved for

submersible pump applications. The conductor

insulation should have a continuous Teflon®

jacket with no splices and must be suitable for

use with submersible pumps.

5.2 Mechanical installation

5.2.1 Riser pipe or hose

The riser pipe or hose should be properly sized

and selected based on estimated flow rates and

friction-loss factors.

A back-up wrench should be used when

attaching a riser pipe or metallic nipple to the

pump. The pump should only be gripped by the

flats on the top of the discharge chamber. The

body of the pump, cable guard or motor

should not be gripped under any

circumstance.

5.2.2 If a steel riser pipe is used

An approved pipe thread compound should be

used on all joints. Make sure the joints are

adequately tightened in order to resist the

tendency of the motor to loosen the joints when

stopping and starting.

After the first section of the riser pipe has been

attached to the pump, the lifting cable or

elevator should be clamped to the pipe. Do not

clamp the pump.

When raising the pump and riser section, be

careful not to place bending stress on the pump

by picking it up by the pump-end only.

The drop cable should be secured to the riser

pipe at frequent intervals to prevent sagging,

looping or possible cable damage.

5.2.3 If plastic or flexible riser pipe is used

Use the correct compound recommended by the

pipe manufacturer or specific job specifications.

Make sure that joints are securely fastened.

Besides making sure that joints are securely

fastened, the use of a torque arrester is

recommended when using these types of pipe.

Do not connect the first plastic or flexible

riser section directly to the pump.

Always attach a metallic nipple or adapter

into the discharge chamber of the pump.

When tightened, the threaded end of the

nipple or adapter must not come in contact

with the check valve retainer in the discharge

chamber of the pump.

The drop cable should be secured to the riser

pipe at frequent intervals using an approved clip

or tape to prevent sagging, looping and possible

cable damage.

Leave enough slack between tie points to allow

for this stretching. This tendency for plastic and

flexible pipe to stretch will also affect the

calculation of the pump setting depth. If the

depth setting is critical, check with the

manufacturer of the pipe to determine how to

compensate for pipe stretch.

When these types of pipe are used, it is

recommended that a safety cable be attached to

the pump to lower and raise it. The discharge

piece of SPE submersibles is designed to

accommodate this cable; see fig. 1.

Fig. 1 SPE submersible with safety cable

attached

When tightened, the first section of

the riser pipe must not come in

contact with the check valve

retainer in the discharge chamber

of the pump.

Make sure that the electrical cables

are not cut or damaged in any way

when the pump is being lowered in

the well.

Important — plastic and flexible

pipe tend to stretch under load.

This stretching must be taken into

account when securing the cable to

the riser pipe.

TM05 0853 1711

SPE_ US.book Page 4 Thursday, May 5, 2011 8:18 PM