Pearl 4MWP Series User manual

Table of contents

Other Pearl Water Pump manuals

Pearl

Pearl CSP User manual

Pearl

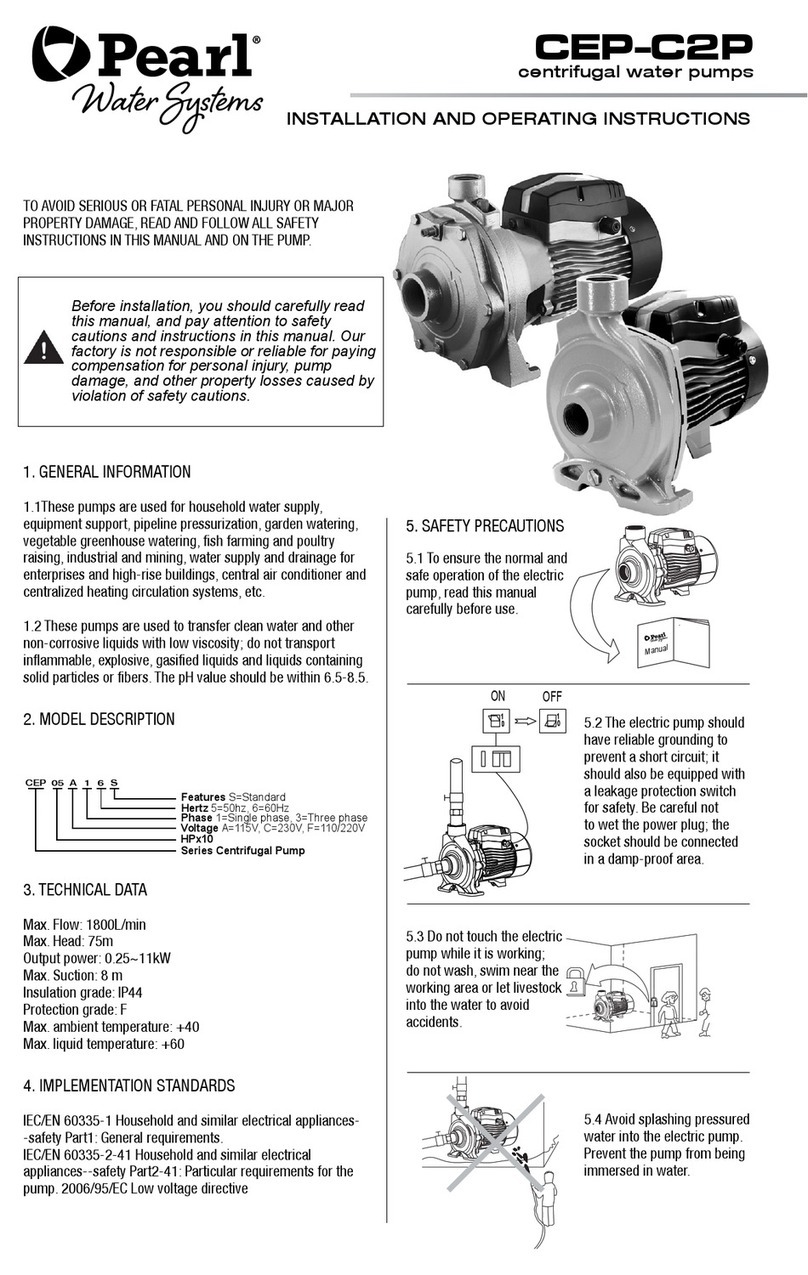

Pearl CEP-C2P User manual

Pearl

Pearl JCC Series User manual

Pearl

Pearl JACKY User manual

Pearl

Pearl JCCH Series User manual

Pearl

Pearl THOR 10 User manual

Pearl

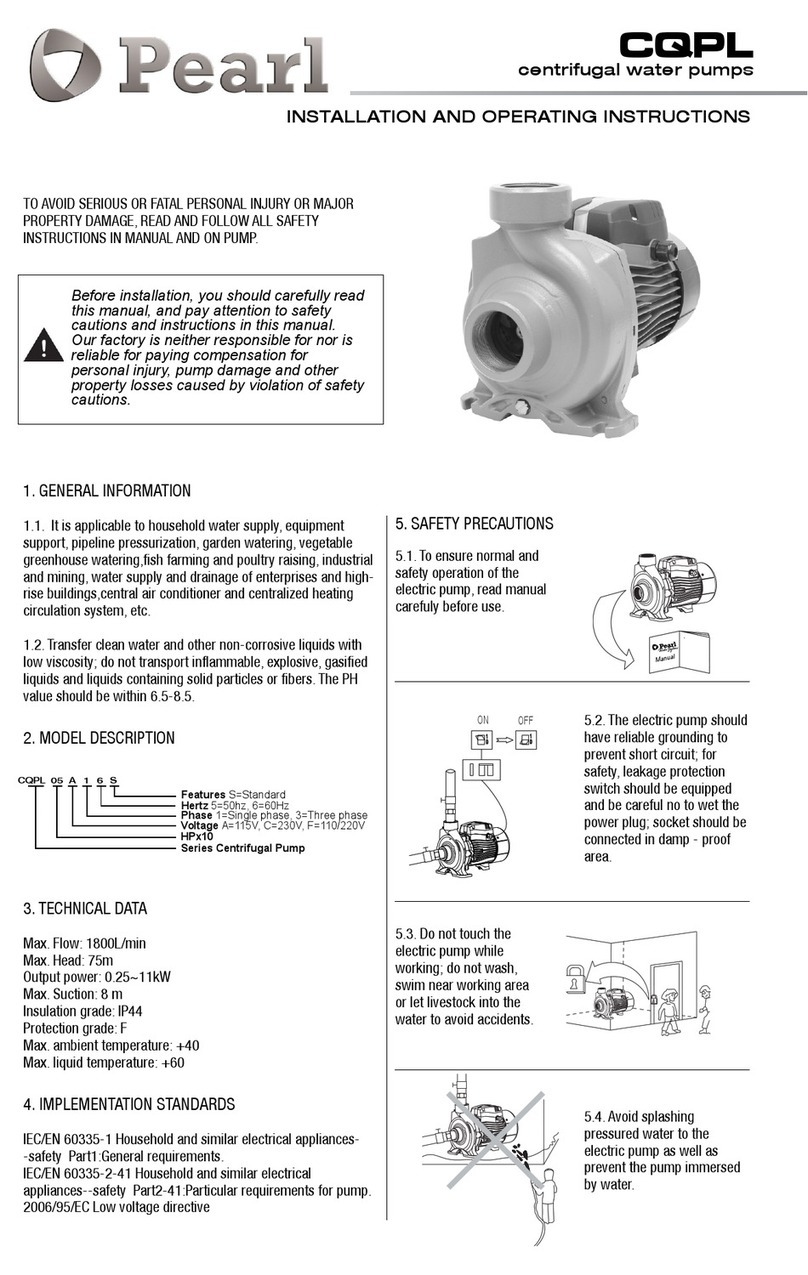

Pearl CQPL Series User manual

Pearl

Pearl Iron Jet IRONJ 05 User manual

Pearl

Pearl CEP BIG User manual

Pearl

Pearl CEP-C2P User manual

Popular Water Pump manuals by other brands

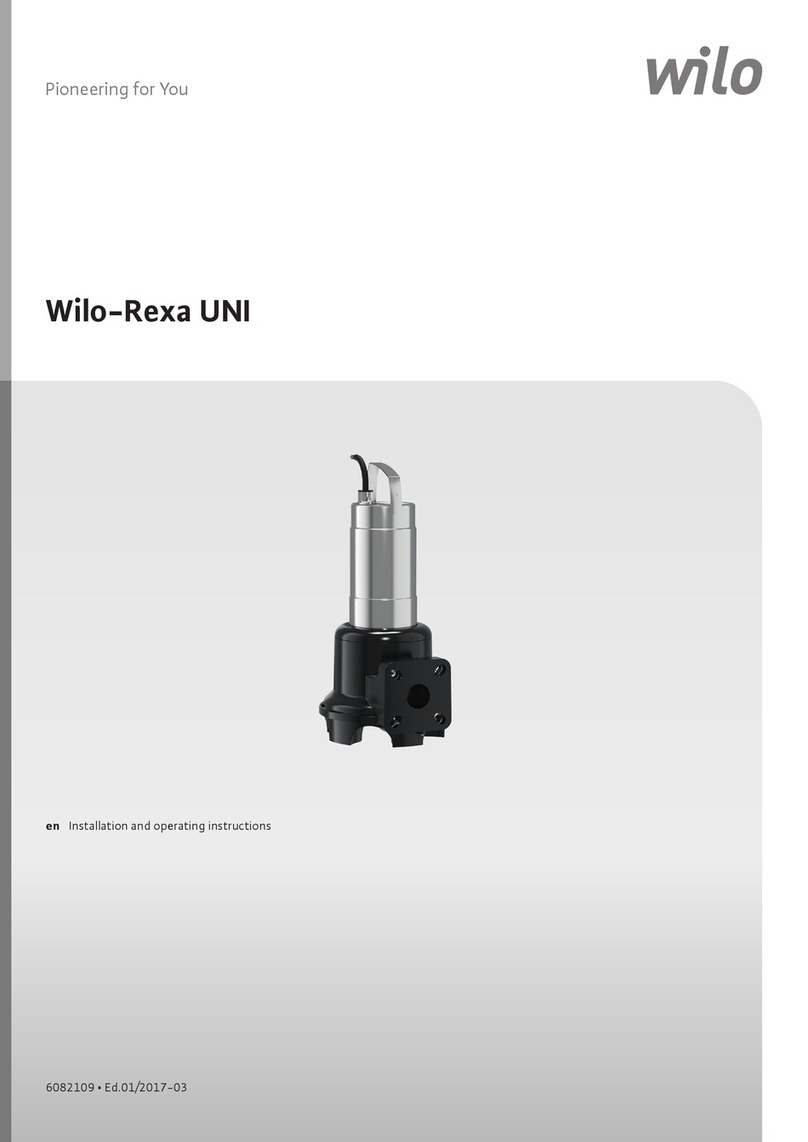

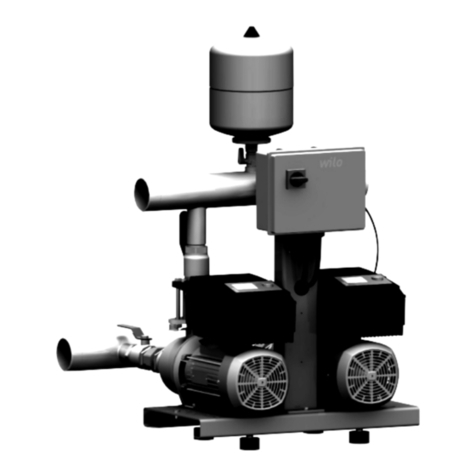

Wilo

Wilo COR MHIE Series Installation and operating instructions

Tallas Pumps

Tallas Pumps P1 330W Instruction for installation and maintenance

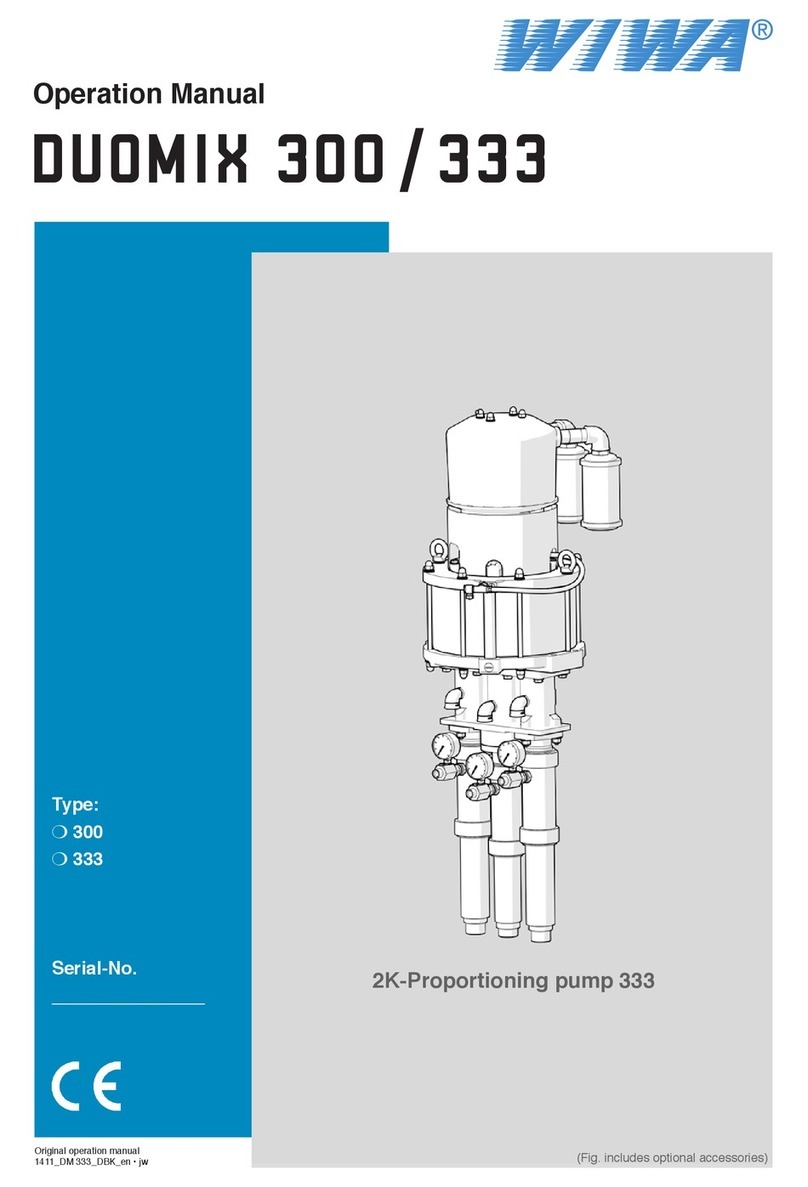

wiwa

wiwa 300 Operation manual

Lowara

Lowara DOMO Quick start up guide

Dover

Dover Wilden Original Series Engineering, operation & maintenance

Henden

Henden HPHDB Installation & owner's manual

EINHELL

EINHELL GC-DP 3730 Original operating instructions

KNF

KNF OEM TRANSLATION OF ORIGINAL OPERATING AND INSTALLATION INSTRUCTIONS

Barnant Company

Barnant Company PK15 operating manual

XPOtool

XPOtool CGP Operation manual

Desmi

Desmi GP user manual

Pfeiffer Vacuum

Pfeiffer Vacuum HiPace 30 operating instructions