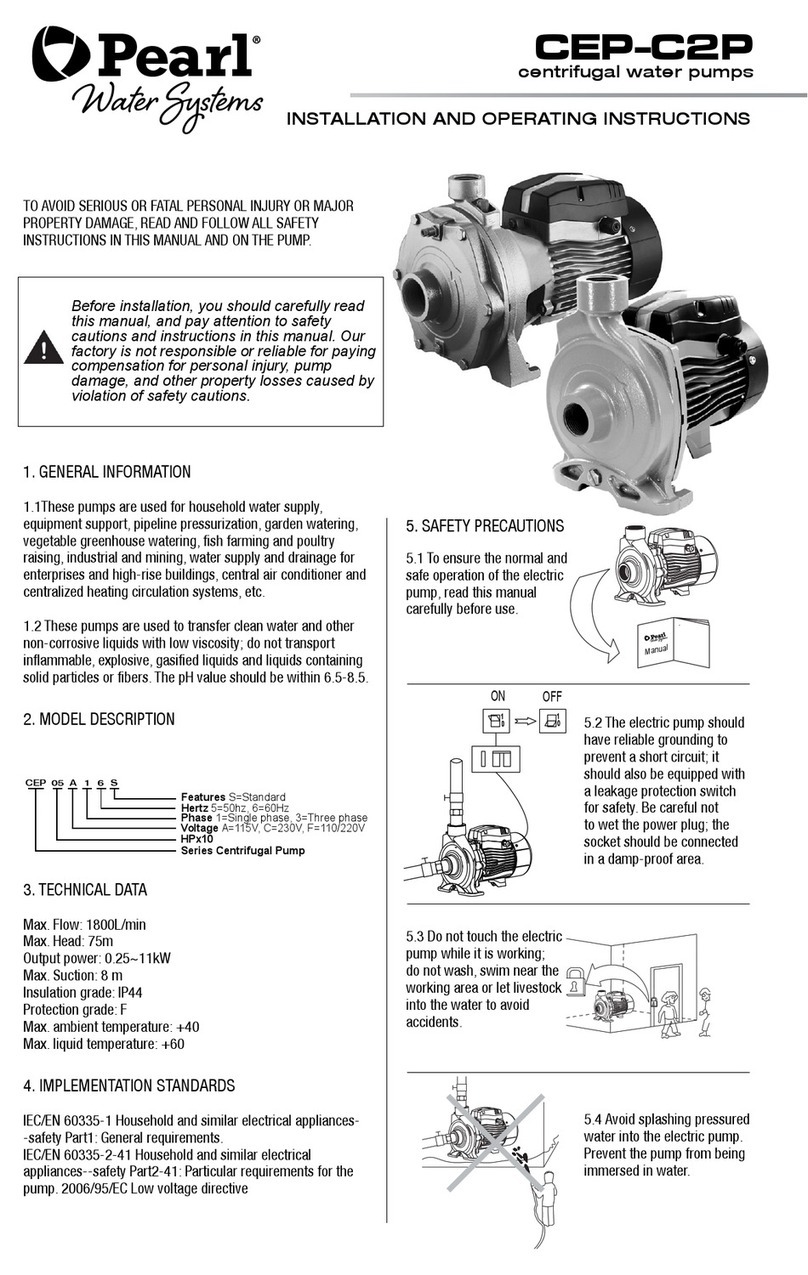

Pearl CEP BIG User manual

centrifugal pumps

CEP BIG

INSTALLATION AND OPERATING INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR MAJOR

PROPERTY DAMAGE, READ AND FOLLOW ALL SAFETY

INSTRUCTIONS IN MANUAL AND ON PUMP.

Before installing and using the pump, read the

following instructions carefully.

The manufacturer declines all responsibility in case

of accident or damage due to negligence or lack of

observance of the instructions described in this booklet

or in conditions that differ from those indicated on the

nameplate; it also declines all responsibility for damage

caused by improper use of the pump.

1. APPLICATIONS

1.1. CEP BIG standard pumps are qualified to handle clean

water or liquids similar to water in physical and chemical

properties. The PH value of the transmission liquids shall be

between 6.5 and 8.5.

1.2. It is widely used for farm irrigation and drainage in facto-

ries, mines, schools, hospitals, hotels and cities. It can also be

used as circulation pump for central air-conditioning and central

heating system. With impeller of welding stainless steel or

casting copper, it can be used as pumps for fire fighting system

and spraying system.

2. MODEL DESCRIPTION

3. TECHNICAL DATA

Flow rate: 0 - 60 m3/h

Head: 25 - 105 m

Speed: 3500 rpm

Insulation class: F

Protection class: IP54(4-7.5kW), IP55(11-15kW)

Max. operating pressure: 10 bar

Max. ambient temperature: +40°C

Max. liquid temperature: +75°C

4. IMPLEMENTATION STANDARDS

- 73/23/CEE

- 89/392/CEE

- 89/336/CEE

- Mechanical seal in compliance with DIN 24960

- Inlet and outlet DN in compliance with EN 733 and UNI 7467

5.1. To ensure normal and

safety operation of the

electric pump, read manual

carefuly before use.

5.2. To avoid electric shock,

make sure that the pump is

safely grounded and equipped

with an earth leakage

circuit breaker. Do not get the

plug wet and do not use any

socket in an area with high

humidity.

5.3. Do not touch the

electric pump while work-

ing; do not wash or swim

near the working area or

let livestock into the water

to avoid accident.

5.4. Avoid splashing pres-

sured water to the electric

pump.

Standard

Hz

Phase

Voltage

Rated Hp x 10

Close Coupled End Suction Centrifugal Pump

CEP 50 H 3 6 S

Manual

5. SAFETY PRECAUTIONS

7. INSTALLATION

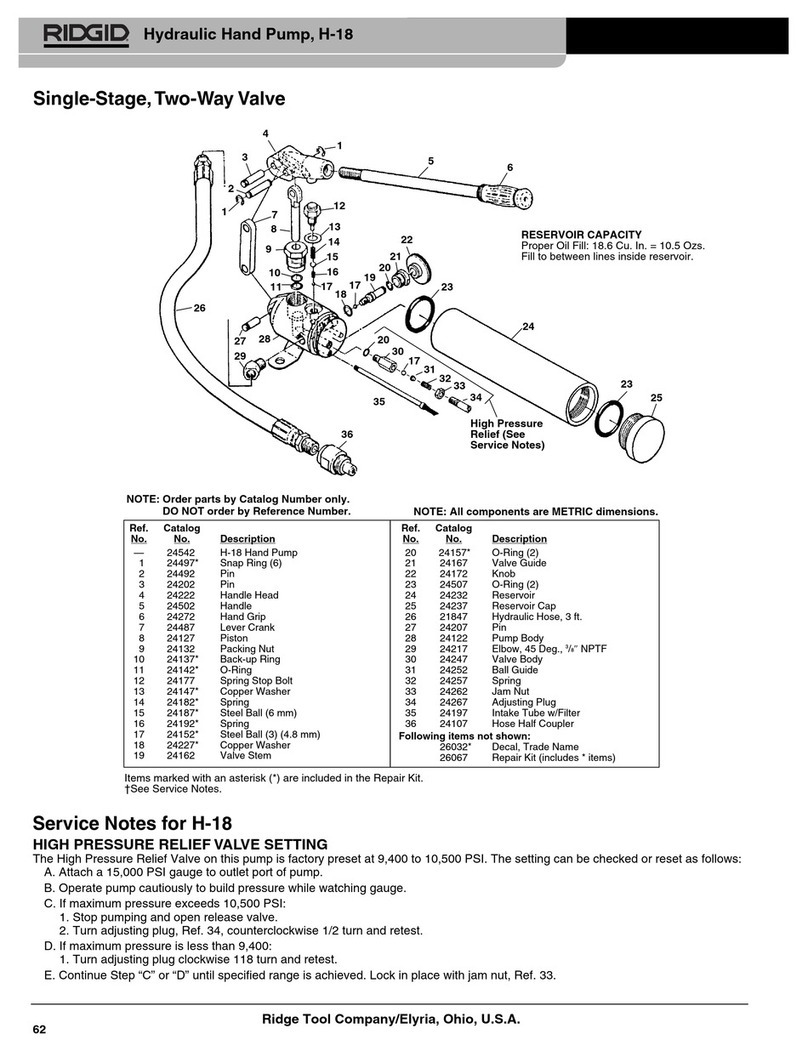

6. PRODUCT STRUCTURE

PRODUCT STRUCTURE cont...

POS. PART

1 Pump body

2 Impeller

3 O-sealing ring

4 Motor connector

5 Motor

6 Terminal box

7 Coupling

8 Mechanical seal

9 Keys

POS. PART

1 Pump cover

2 Impeller

3 O-sealing ring

4 O-sealing ring

5 Pump body

6 Mechanical seal

7 Water proof ring

8 Bracket

9 Fan

5.5. Make sure the pump is

installed in a well-aired place.

5.6. Before carrying out

checks or doing any main-

tenance,

clear the system by

disconnecting the voltage,

and then remove the pump

plug from the socket.

5.7. Ensure the pump will not

be accidently turned on

while installing and

maintaining; if not used

for a long time, cut off the

power first and then turn off

valves in inlet and outlet of

the pump.

5.8. The pump must operate

with clean water. It is not

suitable for pumping

inflammable, gasified or

explosive liquids.

5.9. The power supply shall

be in accordance with the

voltage stated on the

nameplate.

4℃

1 2 3 4

56

7

8

9

1 2 3 4 5 6 7 8 9 10

11

12

13

14

1 2 3 4

56

7

8

9

1 2 3 4 5 6 7 8 9 10

11

12

13

14

DNM B

h1 h2

h

aw

L

DNA

m1

s

n

n1

m

DNM

DNA

a

L

B

h1 h2

h

m1

m

b

s

n

n1

b

MODEL DNM DNA a h2 w x b c h1 m m1 n n1 s B Hmax L

CEP 50

50 50

70 210 258 127 50 12 136 100 70 240 190 14 255 346 450

CEP 75

137 210 263 180 60 15 160 22 70 272 212 14 308 370

570

CEP 100 591

CEP 150

93 252 309 245 65 20 160 260 210 314 254 15 322 412 787

CEP 200

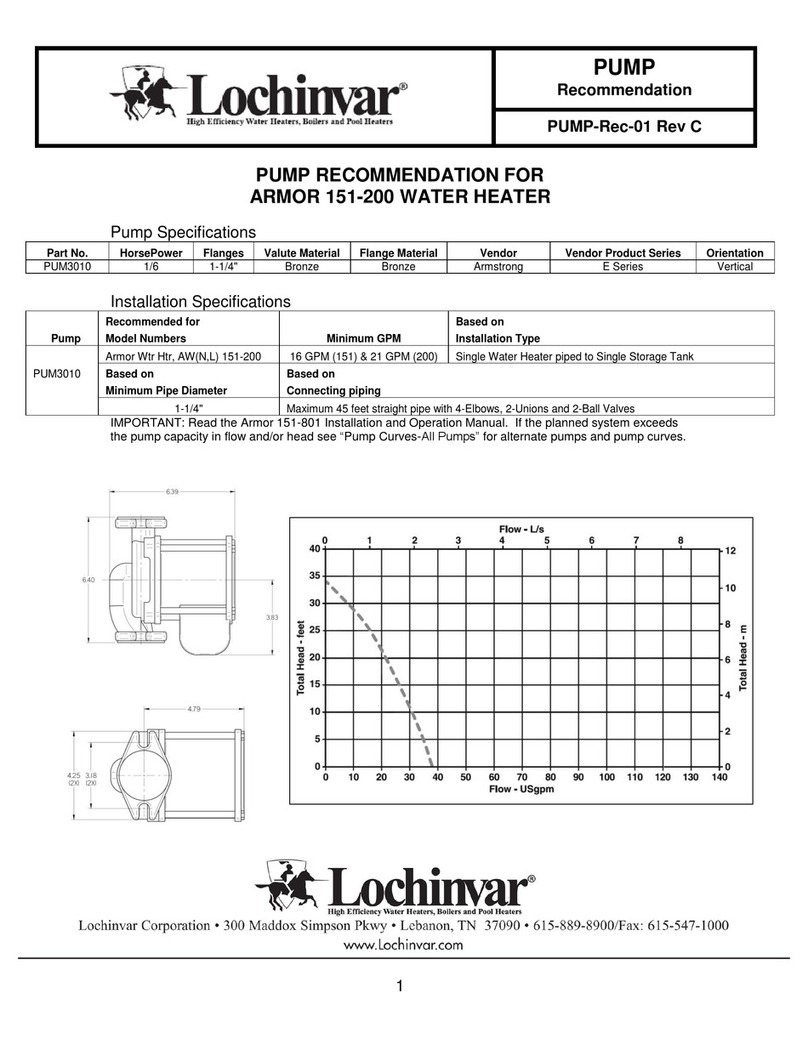

8. PERFORMANCE DATA

MODEL speed

(r/min) Rated flow

(m3/h) Rated flow

(m) Power

(kW)

CEP 50

3500

24 38 4

CEP 75 16 61 5.5

CEP 100 19 75 7.5

CEP 150 31 60 11

CEP 200 35 70 15

9. PRIOR TU USE

During installation apply all the safety regulations

issued by thecompetent authorities and dictated by

common sense.

9.1.With the appropriate bolts secure the pump to flat and solid

surfaces toavoid vibrations. The resistance of the motor shall be

more than 50MΩ.

9.2. Before startup, check if the pump turns freely by rotating

the fan. Remove the filling plug and fully fill the pump chamber

with clean water, then tighten the filling plug.

9.3. In case the electric pump is far from the power supply, it’s

necessary to use a thicker cable. Otherwise the pump cannot

work properly due to the big voltage drop.

9.4. Do not use soft rubber tube for inlet pipeline during

installation. A foot valve shall be vertically installed with a

distance of at least 30 cm from the water bottom to avoid

suction of sediment.

9.5. Pay attention to the water level during operation. The foot

valve shall not be above the water surface.

9.6. If the pump is not be used for a long time, it is advisable to

empty it completely, wash it with clean water and store it in a

dry, well-ventilated

place.

This product shall be installed and maintained by a

qualied person who is procient with this instruction.

The installation and operation must be in accordance

with local regulations and the recognized operation

criteria. Install the pipeline properly according to the

requirement of this instruction, and protect it from

freezing.

CORRECT INSTALLATION

A DIAGRAM

CORRECT INSTALLATION

B DIAGRAM

1. Discharge plug

2. Electric pump

3. Outlet pipeline

4. Joint

5. Filling plug

6. Inlet pipeline

7. Foot valve

8. Support

NOTES FOR INLET PIPELINE INSTALLATION:

1. Do not use too soft rubber tube for the inlet pipeline during

pump installation.

2. The foot valve should be vertically installed 30cm from water

bottom to avoid suction of sediment (A)

3. All connections of the inlet pipelines must be sealed.

To ensure water suction, it’s necessary to reduce the quantity

of bents of the pipelines.

4. The diameter of the inlet pipe must not be less than that of

the pump inlet to avoid big hydraulic loss and small water flow.

5. Pay attention to the water level during operation. The foot

valve shall not be above the water surface (B).

6. In case the inlet pipe is longer than 10m in length or over 4m

in hoisting height, the pipe diameter should exceed diameter of

water inlet of the pump.

7. The pipelines should be anchored so that no stresses

whatsoever is transmitted to the pump.

8. It is recommended to install a filter on inlet pipeline to avoid

incoming of solid particles to the electric pump.

NOTE FOR OUTLET PIPELINE INSTALLATION:

The diameter of the outlet pipeline shall be not less than that of

the pump outlet to reduce the pressure drop, high flow rate and

noise to the lowest level.

10. ELECTRICAL CONNECTIONS

Make sure that there is no voltage at the line wire

terminals before connecting.

The electric pump shall be grounded reliably to avoid

electric leakage and an earth leakage circuit breaker

shall be equipped.

The electrical connection shall be carried out according to the

local regulations.

Check that the pump operates within the specied range on the

nameplate.

Connect up the pump (making sure that there is an efcient

grounding circuit) according to the diagram on the nameplate on

the motor.

The correct direction of rotation for three-phase motors is

clockwise, looking at the pump from the motor fan side. If this is

not the case, invert two of the phases.

switch

fuse

pressure

switch

magnetic

thermal

switch

switch

fuse

pressure

switch

magnetic

thermal

switch

Direct ConnectionY /

Connection

L

1

L

2

L

3

M

3~

M

3~

L

1

L

2

L

3

M

3~

M

3~

L

1

L

2

L

3

L

1

L

2

L

3

T

1

T

2

T

3

T

1

T

2

T

3

DIRECT CONNECTION Y

11. STARTUP AND MAINTENANCE

Do not operate the pump unless the pump chamber is

fully lled with clean water.

Dry operation of the pump will cause damage to the

mechanical seal.

Do not touch the electric pump unless the power of

pump is cut off for over 5 minutes.

Do not remove the pump bonnet unless the water in

pump chamber is completely drained.

Rotate the fan with a screwdriver to check if the pump rotates

flexibly before startup. Remove the filling plug and prime the

pump chamber fully with clean water, then tighten the filling

plug.

PROBLEM POSSIBLE CAUSE SOLUTION

The pump

does not

start

Low voltage Regulate voltage variation between +/-10%

Impeller blocked Clean the impeller by removing it

Cable broke or one phase disconnected Check out outlet box and replace the cable

Stator winding burnout Replace the stator winding

Insufficient

liquids

pumped

Excessive head Choose appropriate standard pump according to the scope

of application

Foot valve clogged or filter screen blocked Clean up the float grass

Suction pipe leakage Tighten the adaptor of suction pipe evenly

Mechanical seal damage Replace mechanical seal

Stator

winding

burnout

Wrong grounded circuit or phase failure of power

Fix the problems by removing the winding, re-embedding,

the winding, re-embedding, drying it by heat.

Seal box broken and the coil burns out

Long time of dry operation

Impeller blocked or long-time running

Cable broke and winding exposed to moisture

12.TROUBLESHOOTING

3000 W. 16 Ave. Miami, FL 33012

Tel: (954) 4749090 | Fax: (954) 8890413

Keep the valve narrow opened during startup. When the pump

runs normally, adjust the valve to the required flow.

When not using the pump and the ambient temperature is

below 4, empty the pump completely for frost and freeze

protection. The priming procedure must be repeated to restart

the pump.

Attention! If the appliance or the supply cord is

damaged, it must be repaired by manufacturer, its

service agent or qualied person.

CONNECTION

L1 L2 L3

GY

PE

WE

BK

PK

CE

BE YW RD

W2 U2 V2

U1 V1 W1

440~480V

L1 L2 L3

PK GY

BK

WE

CE

LB Y W R D

PE

W2 U2 V2

U1 V1 W1

2

220~240V

L1 L2 L3

GY

PE

WE

BK

PK

CE

LB Y W R D

W2 U2 V2

U1 V1 W1

440~480V

L1 L2 L3

PK

GY

BK

WE

CE

BE Y W RD

PE

W2 U2 V2

U1 V1 W1

2220~240V

BK

CE

WE

RD

YW

GY

PE

PK

BE

- black

- coffee

- white

- red

- yellow

- grey

- purple

- pink

- blue

BK

CE

WE

RD

YW

GY

PE

PK

BE

- black

- coffee

- white

- red

- yellow

- grey

- purple

- pink

- blue

BK

CE

WE

RD

YW

GY

PE

PK

BE

- black

- coffee

- white

- red

- yellow

- grey

- purple

- pink

- light blue

BK

CE

WE

RD

YW

GY

PE

PK

BE

- black

- coffee

- white

- red

- yellow

- grey

- purple

- pink

- light blue

L1 L2 L3

GY

PE

WE

BK

PK

CE

BE YW RD

W2 U2 V2

U1 V1 W1

440~480V

L1 L2 L3

PK GY

BK

WE

CE

LB Y W R D

PE

W2 U2 V2

U1 V1 W1

2

220~240V

L1 L2 L3

GY

PE

WE

BK

PK

CE

LB Y W R D

W2 U2 V2

U1 V1 W1

440~480V

L1 L2 L3

PK

GY

BK

WE

CE

BE Y W RD

PE

W2 U2 V2

U1 V1 W1

2220~240V

BK

CE

WE

RD

YW

GY

PE

PK

BE

- black

- coffee

- white

- red

- yellow

- grey

- purple

- pink

- blue

BK

CE

WE

RD

YW

GY

PE

PK

BE

- black

- coffee

- white

- red

- yellow

- grey

- purple

- pink

- blue

BK

CE

WE

RD

YW

GY

PE

PK

BE

- black

- coffee

- white

- red

- yellow

- grey

- purple

- pink

- light blue

BK

CE

WE

RD

YW

GY

PE

PK

BE

- black

- coffee

- white

- red

- yellow

- grey

- purple

- pink

- light blue

Other Pearl Water Pump manuals

Pearl

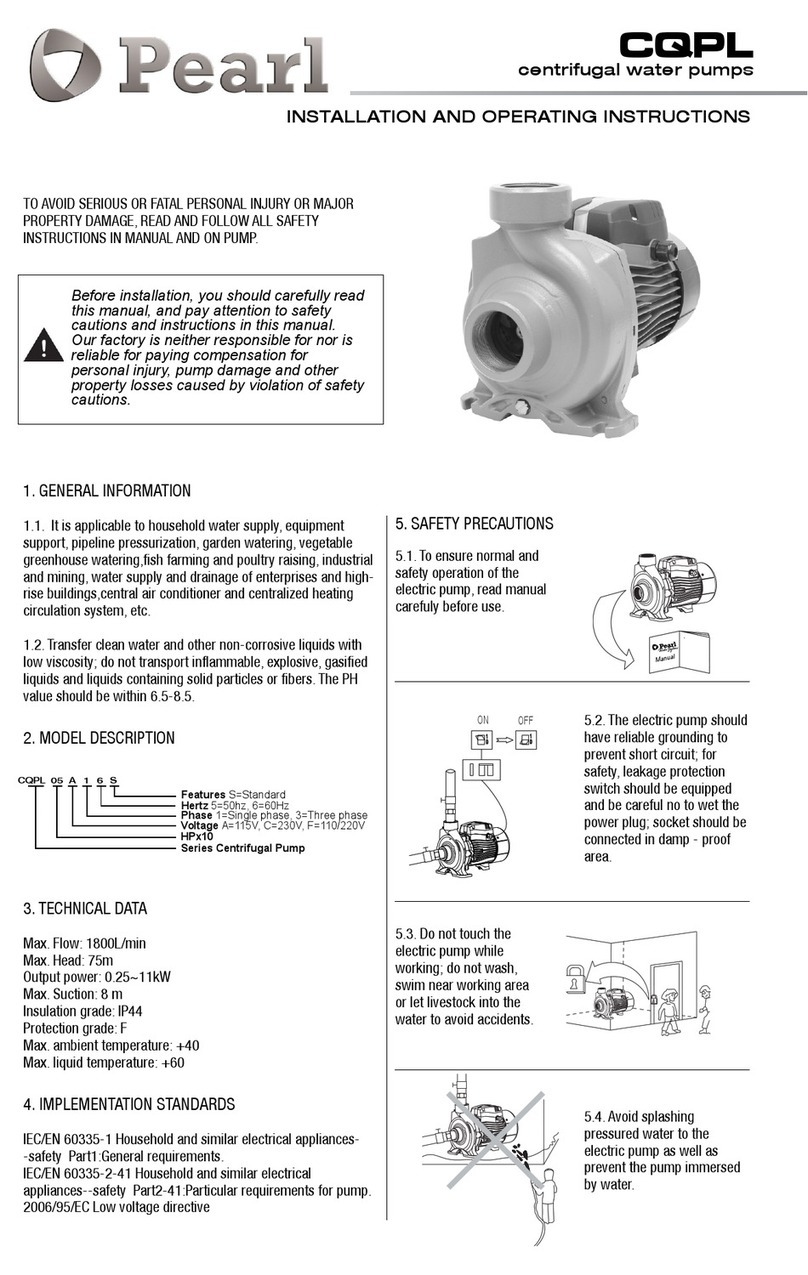

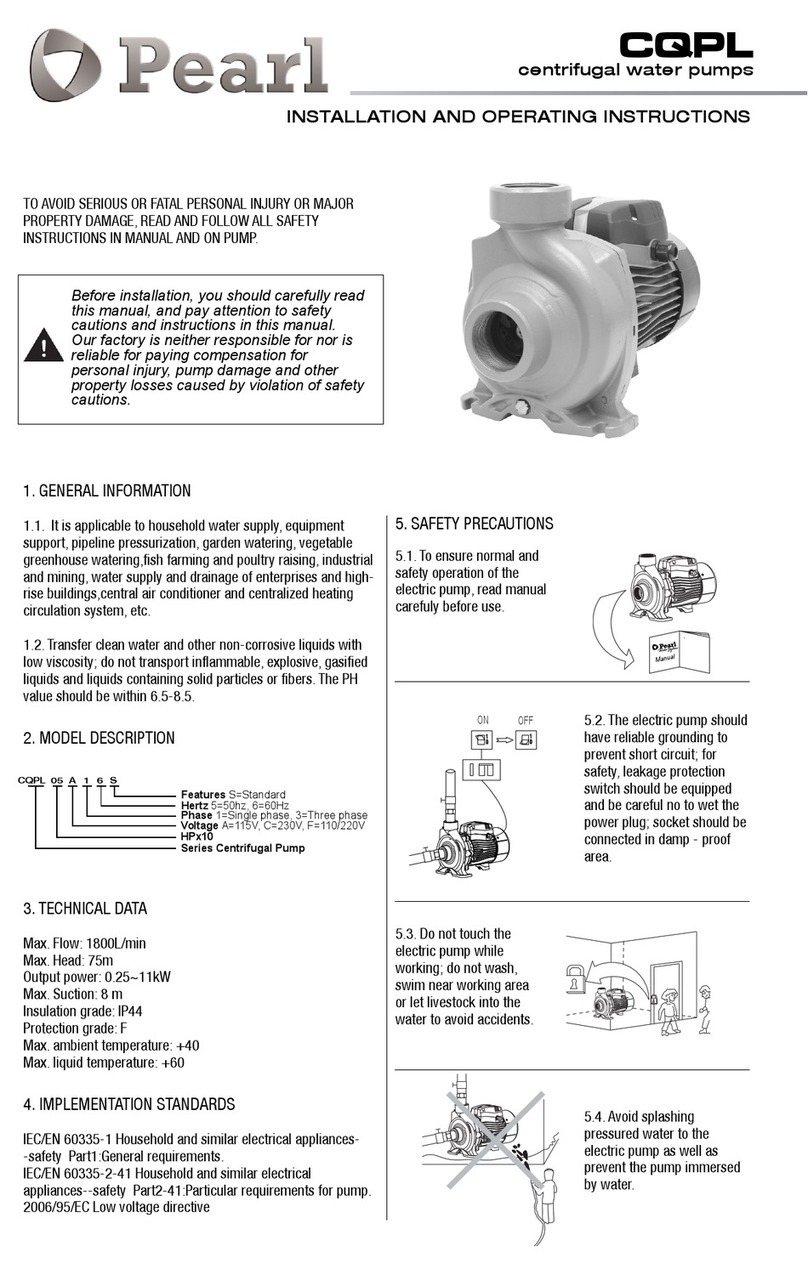

Pearl CQPL User manual

Pearl

Pearl Iron Jet IRONJ 05 User manual

Pearl

Pearl CQPL Series User manual

Pearl

Pearl JACKY User manual

Pearl

Pearl CSP User manual

Pearl

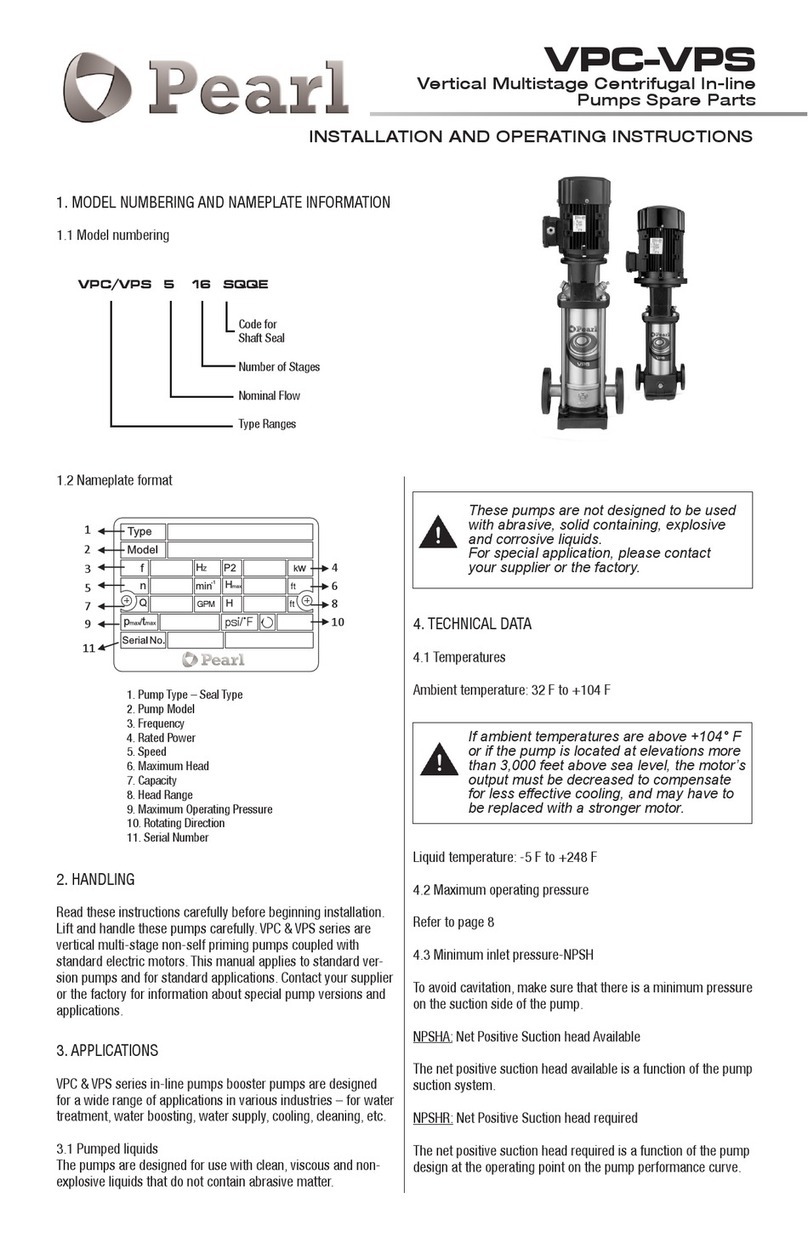

Pearl VPS 1 User manual

Pearl

Pearl JCP User manual

Pearl

Pearl JCCH Series User manual

Pearl

Pearl 4MWP Series User manual

Pearl

Pearl MXA Series User manual

Popular Water Pump manuals by other brands

Black & Decker

Black & Decker BXGP800XE Original instructions

Graco

Graco Husky 3300 repair parts

APEC PUMP

APEC PUMP ST Series Installation and operation manual

Pentair

Pentair Myers SHA Series Installation and service manual

Desmi

Desmi Modular S-N Series Operation and maintenance instruction

Xylem

Xylem Goulds SHV Series Installation, operation and maintenance instructions