Pearl CEP-C2P User manual

Other manuals for CEP-C2P

1

Table of contents

Other Pearl Water Pump manuals

Pearl

Pearl MXA Series User manual

Pearl

Pearl THOR 10 User manual

Pearl

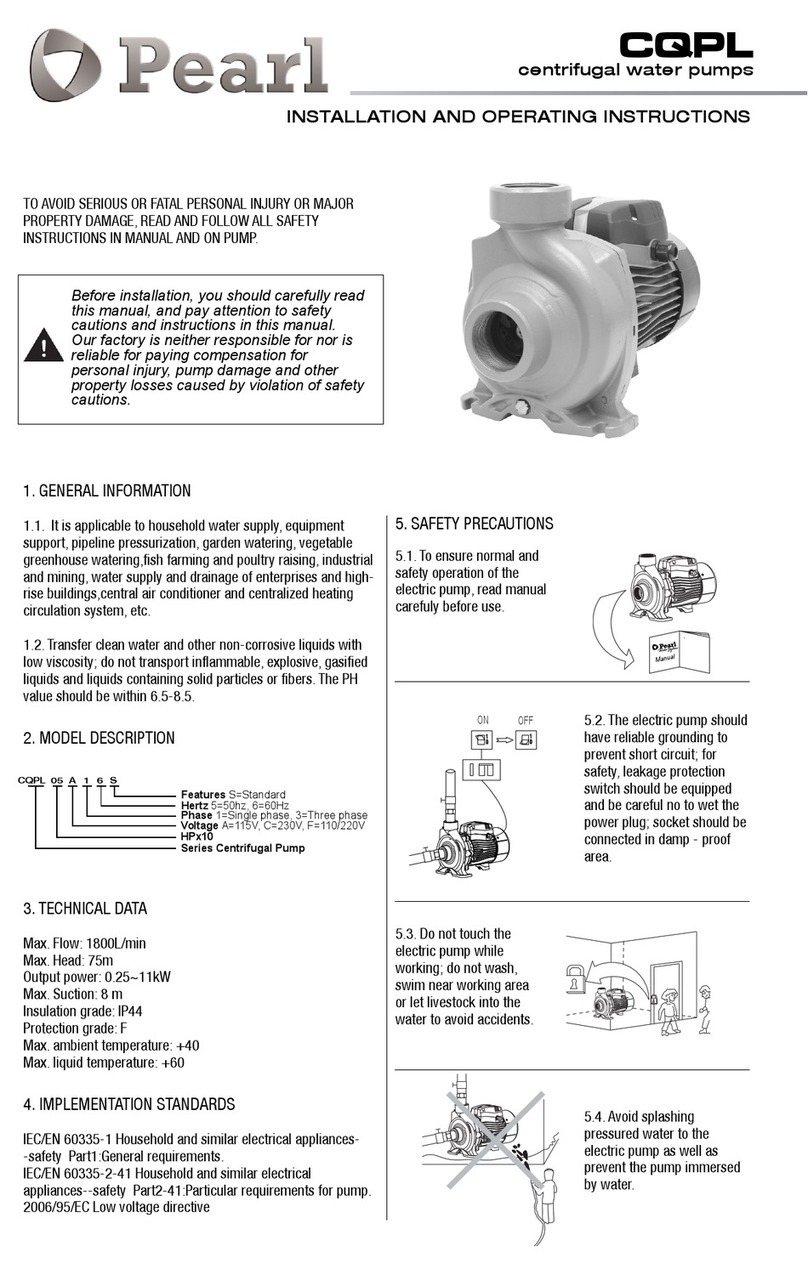

Pearl CQPL User manual

Pearl

Pearl JCP User manual

Pearl

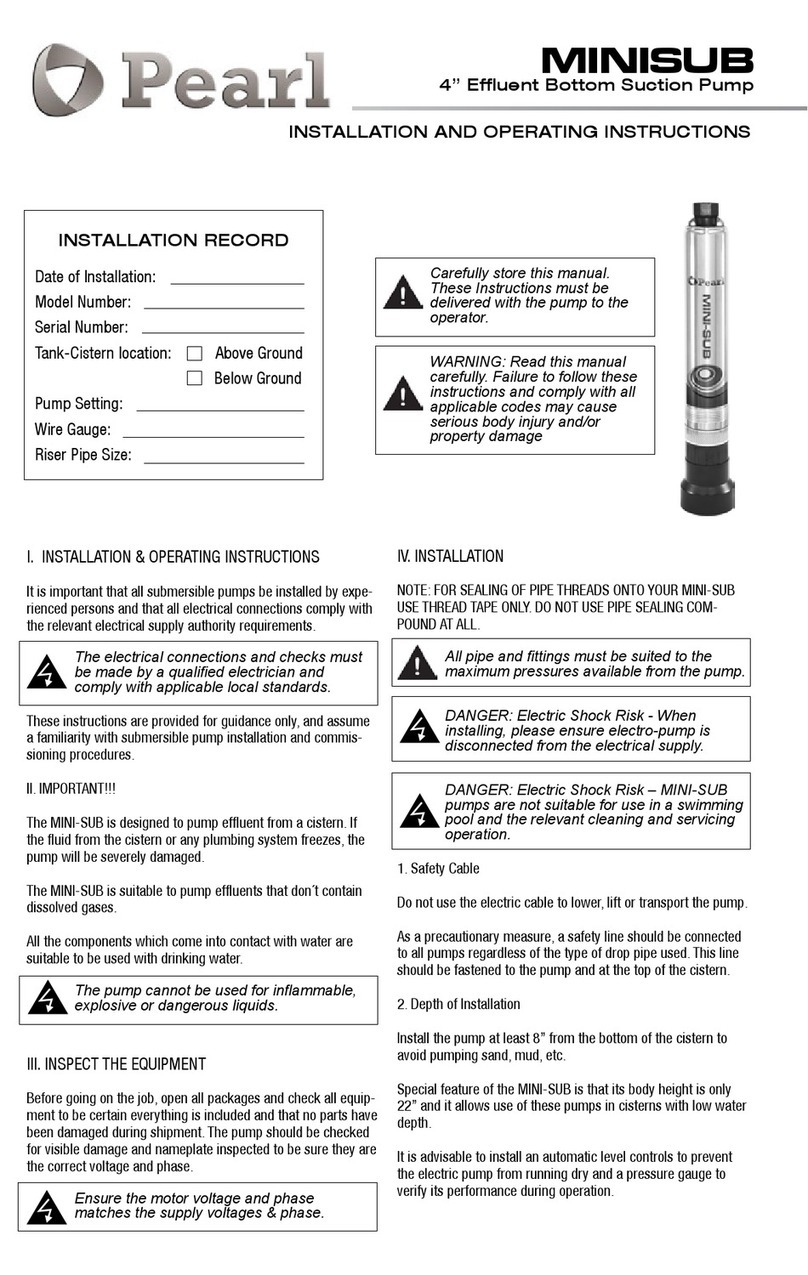

Pearl MINISUB User manual

Pearl

Pearl JCC Series User manual

Pearl

Pearl Iron Jet IRONJ 05 User manual

Pearl

Pearl CEP BIG User manual

Pearl

Pearl CQPL Series User manual

Pearl

Pearl JACKY User manual

Popular Water Pump manuals by other brands

BJM Pumps

BJM Pumps SKG FAHRENHEIT Series Installation, operation & maintenance manual

Liberty Pumps

Liberty Pumps ProVore PRG Series installation manual

Hanna Instruments

Hanna Instruments BL1.5 instruction manual

Warren rupp

Warren rupp SANDPIPER HP10 Service & operating manual

Grundfos

Grundfos PF Series Installation and operating instructions

HERTELL

HERTELL KD Series quick guide

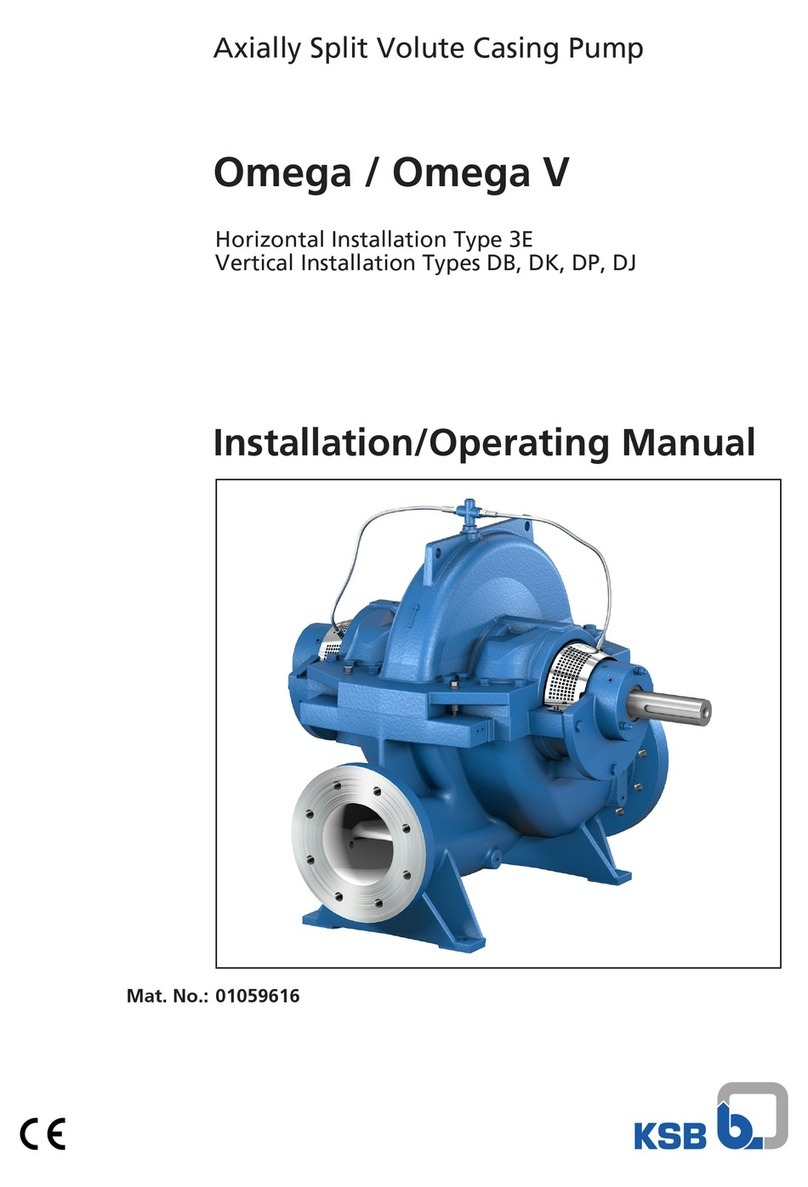

KSB

KSB Omega Installation & operating manual

LR-Cal

LR-Cal LSP 1000-BM operating instructions

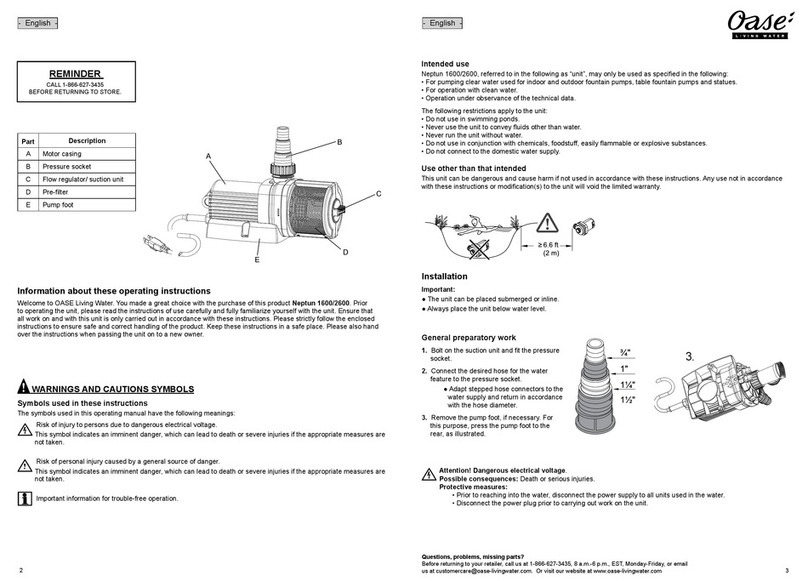

Oase

Oase Neptun 2600 Installation

SHURflo

SHURflo NG7V Operating Instructions, Performance, Specifications and Parts Manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 82E52-B Installation, operation, and maintenance manual with parts list

Wilo

Wilo Wilo-E 15/1-5 Installation and operating instructions

Varian

Varian TV 141 Navigator RS485 instruction manual

Dover

Dover WILDEN PRO-FLO P1 Series Engineering, operation & maintenance

AxFlow

AxFlow Aturia ND Series Operation & maintenance manual

Gardner Denver

Gardner Denver GD-250 Operating and service manual

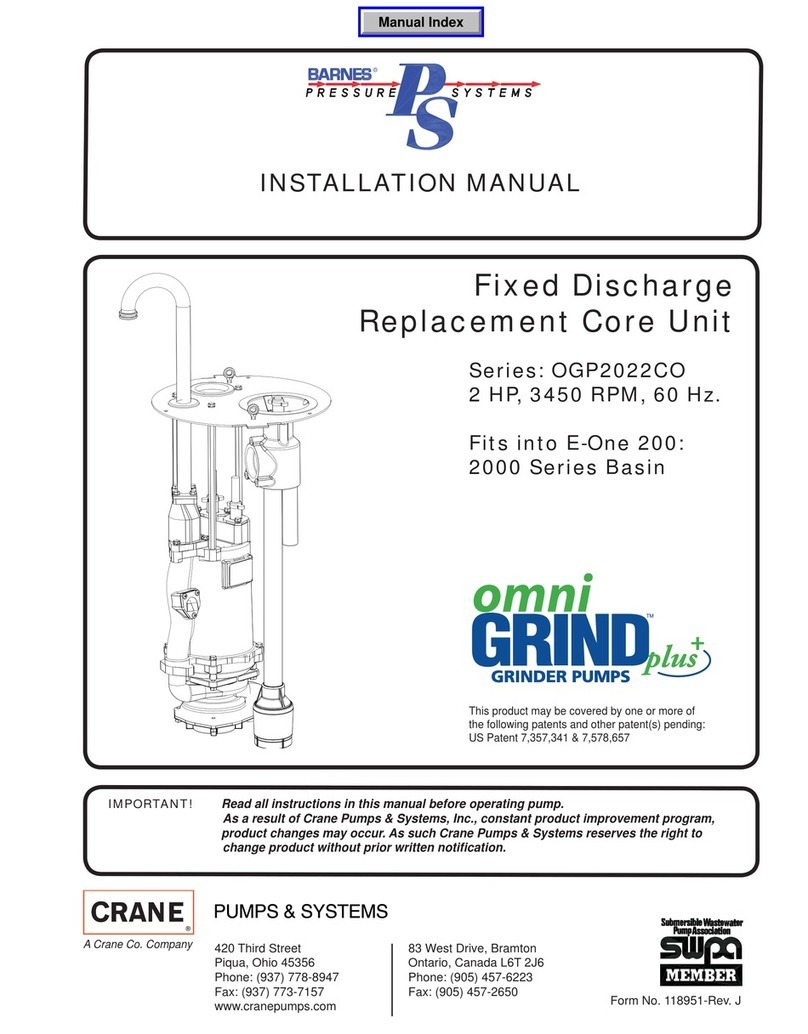

Crane

Crane Barnes PS Omni Grind Plus OGP2022CO Series installation manual

WOERNER

WOERNER GMG-K Translation of the original operation manual