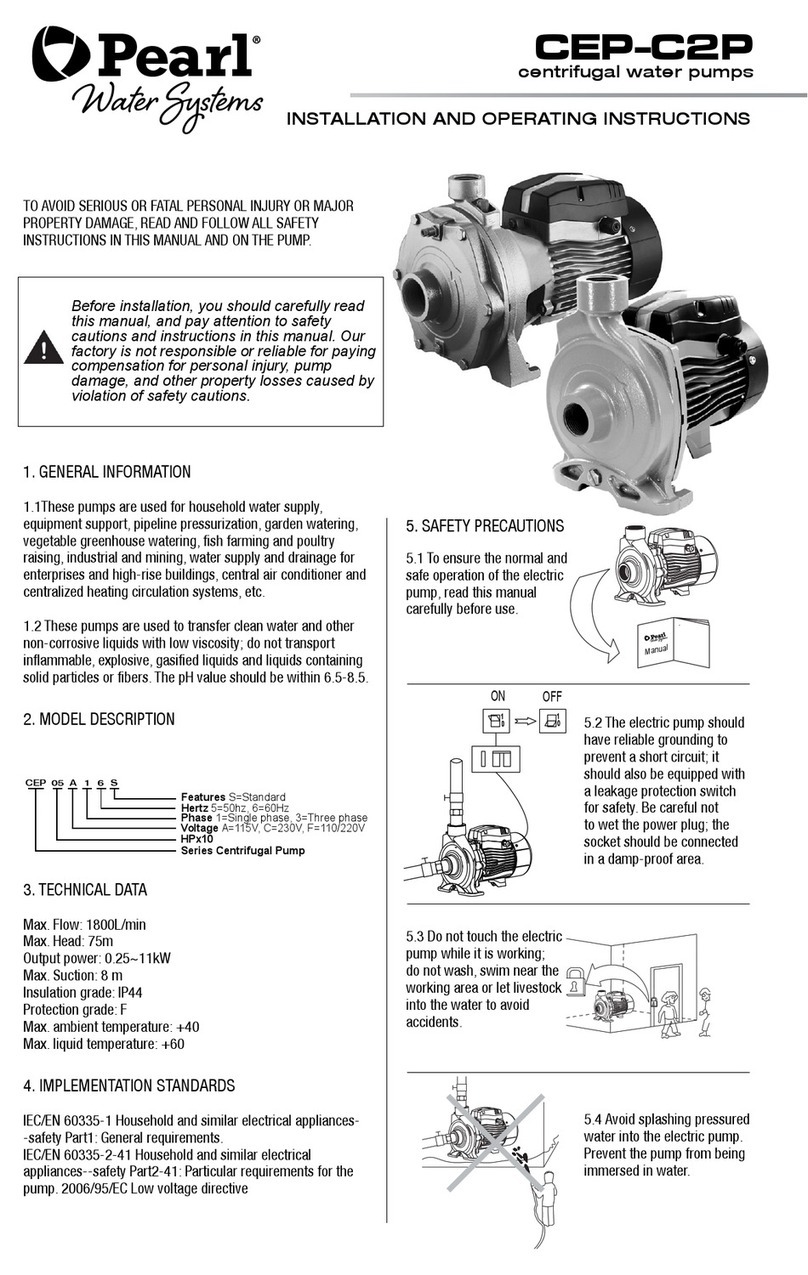

This pump has been evaluated for use with

water only.

Risk of electric shock – this pump is supplied

with a grounding conductor and grounding-

type attachment plug. To reduce the risk of

electric shock, be certain that it is connected

only to a properly grounded, grounding-type

receptacle.

NOTICE: This pumps has been designed for working in presence

of water for cooling and lubrication. Working without water will

cause severe damage to the pump.

A qualied electrician must perform all the

wiring.

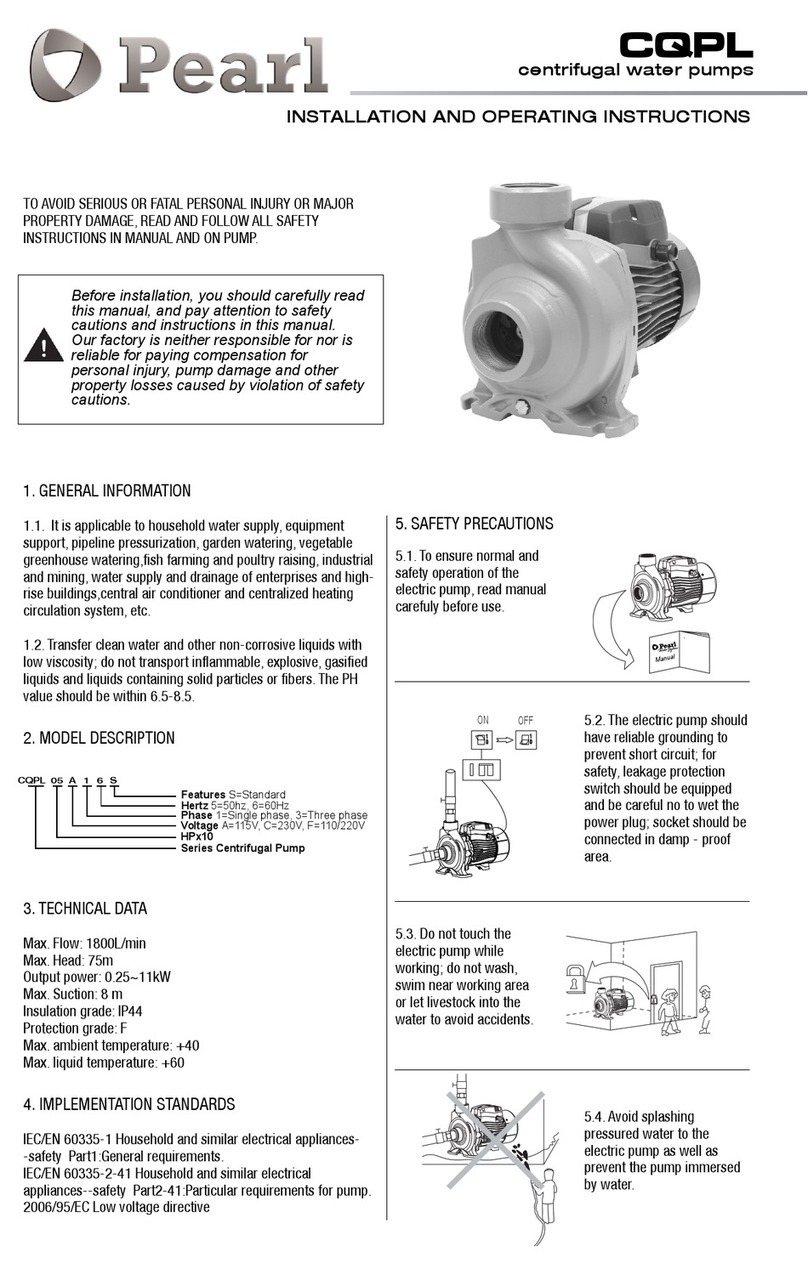

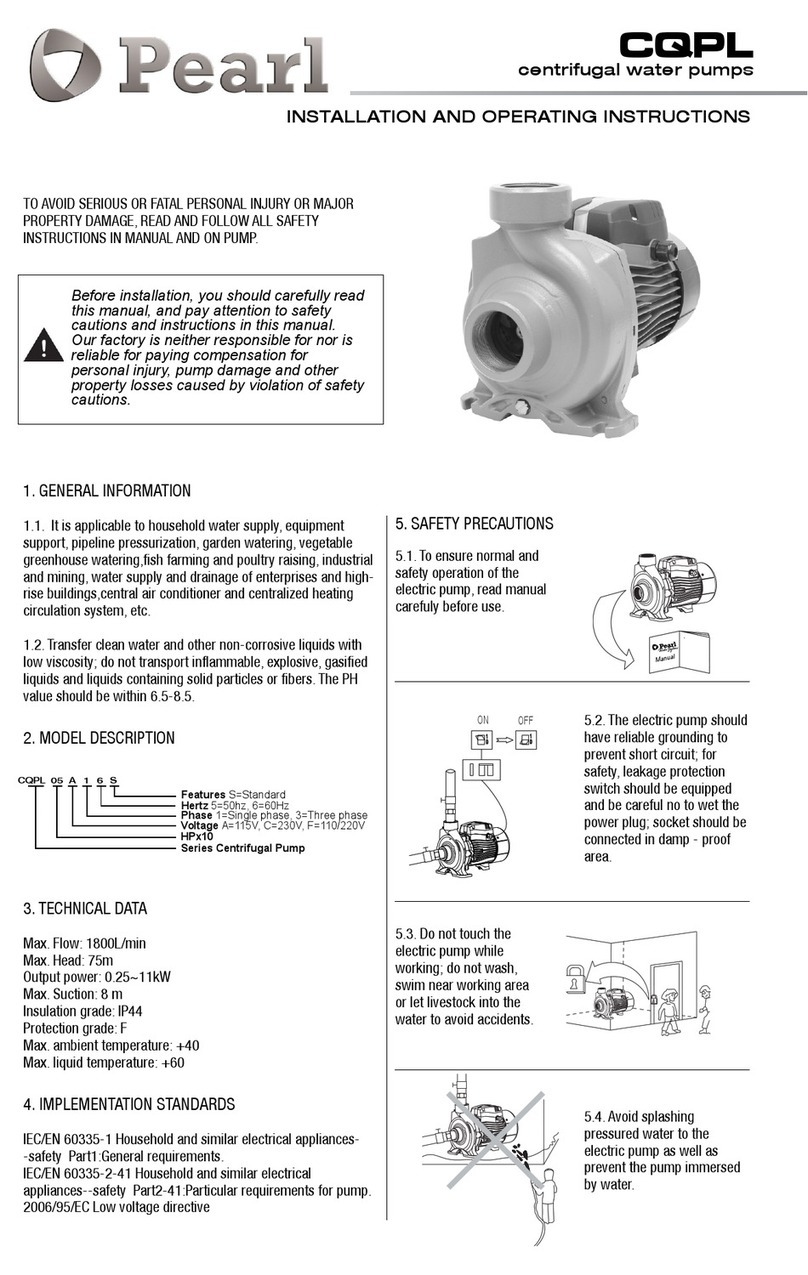

1. GENERAL INFORMATION

1.1. Read this Instruction Manual thoroughly prior to any work.

Work should be undertaken by qualified persons only.

1.2. Sump pumps are designed to operate intermittently and

usually seasonally. It is recommended that you test the pump

before your rainy season begins to insure that the pump

and switch are operating properly.

1.3. We suggest installing a high water alarm system and a

battery back-up pump system for finished basements or areas

where flooding will cause property damage. A back-up

generator is another option you can discuss with your pump

installer. Most power outages occur during rain storms, just

when you need your sump pump the most! Pump manufac-

turer’s warranties cover only the pump. Labor and incidental

damage such as flooding is not covered.

2. PRE-INSTALLATION CHECKS

2.1. Open all cartons and inspect for shipping damage. Report

any damage to your supplier immediately.

2.2. Verify that all equipment is the correct voltage. Warranty

does not cover damage caused by connecting pumps and

controls to incorrect voltage.

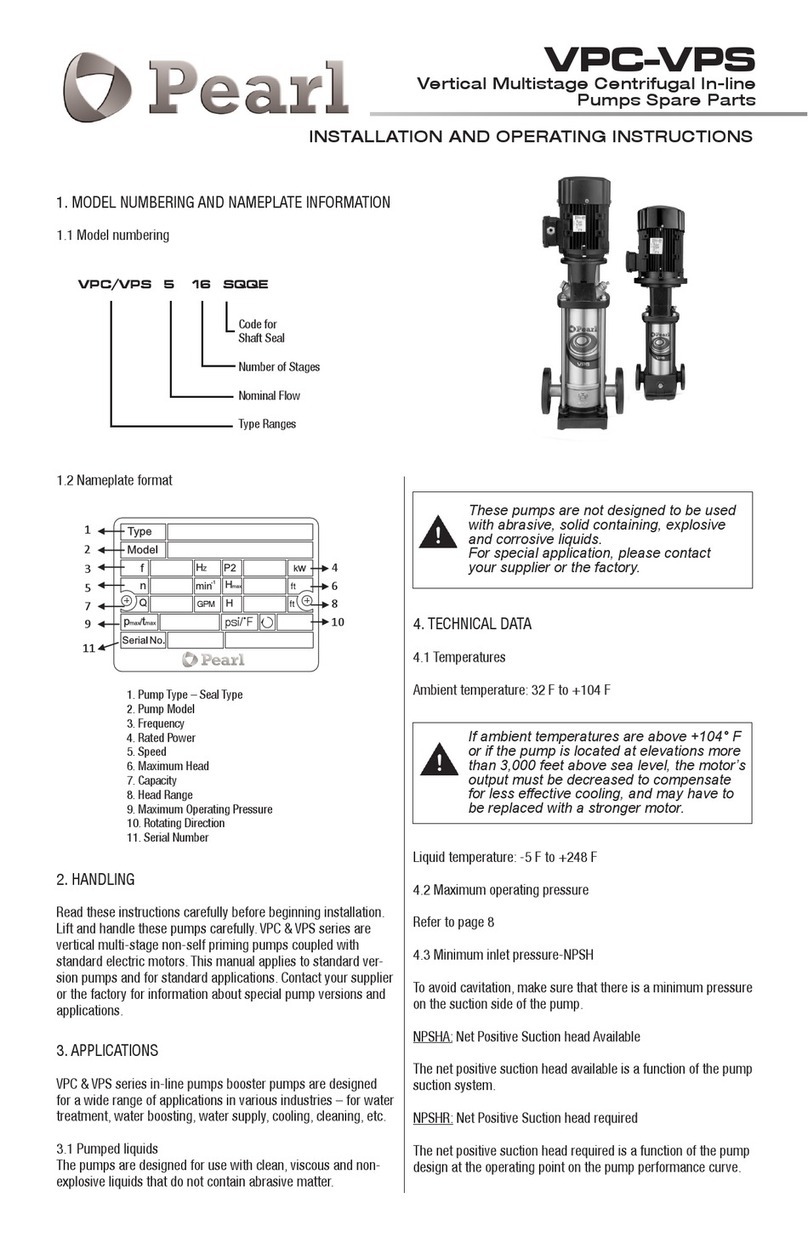

2.3. Is your basin sized correctly and the proper type for the

location?

Diameter - It must be wide enough to allow the pump and

switch to physically fit and provide room for the float switch to

operate freely. The vertical float switch models typically require

less diameter than the wide-angle float models. See “min. basin

diameter” in Chart 1.

Depth - It must be deeper than the minimum depth at

which the switch turns the pump On. As an example,

if the pump turns on at 7.50” you want to use a basin

deeper than 7.50”.

See “On level” in Chart 1.

Style - There are several sump basin styles

available. The location of the sump deter-

mines if you require a cover and what type

you require. It is important to keep debris from

entering the sump and clogging the pump.

An open sump in a trafc area such as a

basement is dangerous. If children or pets will

be playing in the area a bolt-on or child-proof

cover is recommended.

Do not use the power cord or discharge hose

to carry or handle the pump. Doing so may

cause severe damage to the power cord

connector, the power cord or discharge hose.

Use the carrying handle

supplied with the pump.

It is strongly recommended to use a “Ground

Fault Circuit Interrupt” GFCI device on

this pump. This GFCI (ground fault circuit

interrupter) should be listed by Underwriters

Laboratories (UL). This is required by many

local codes and enforcement agencies. It is

strongly recommended as it provides a safer

installation and will reduce possible injury

from electrical shock.

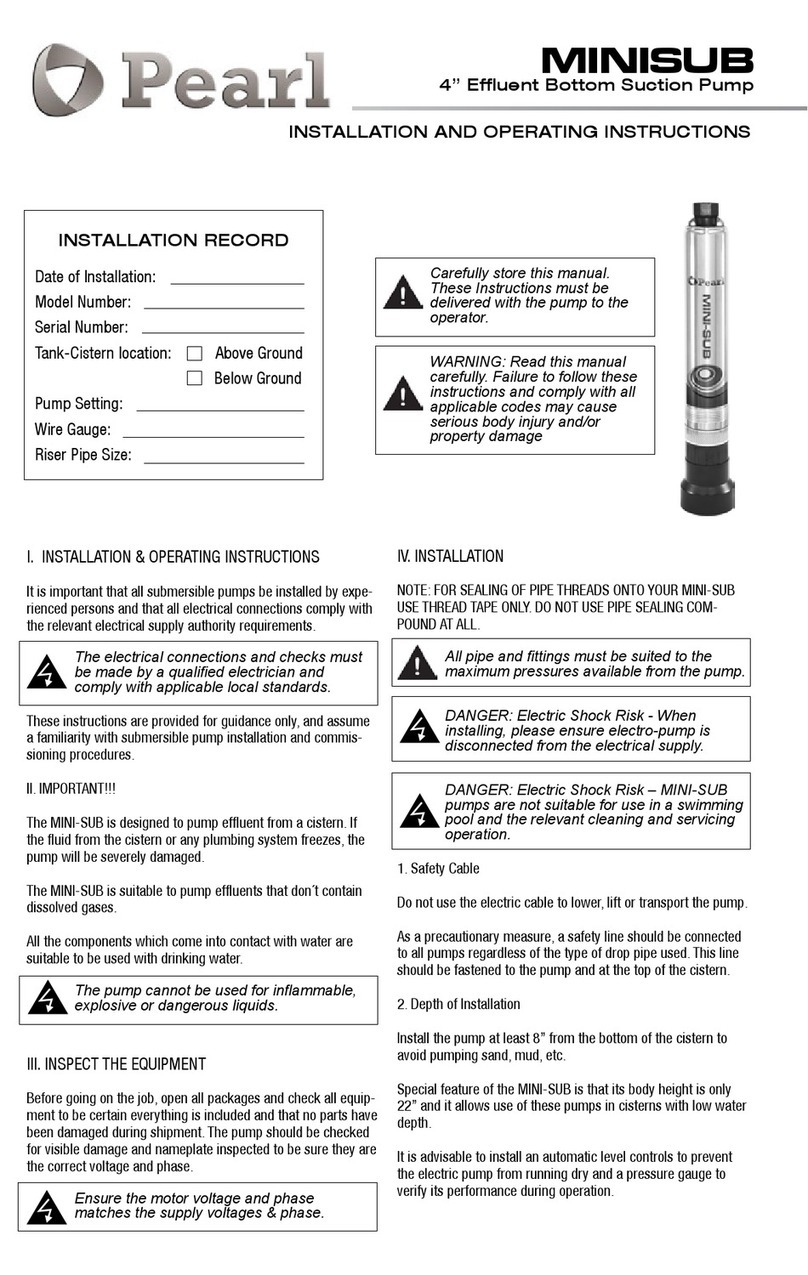

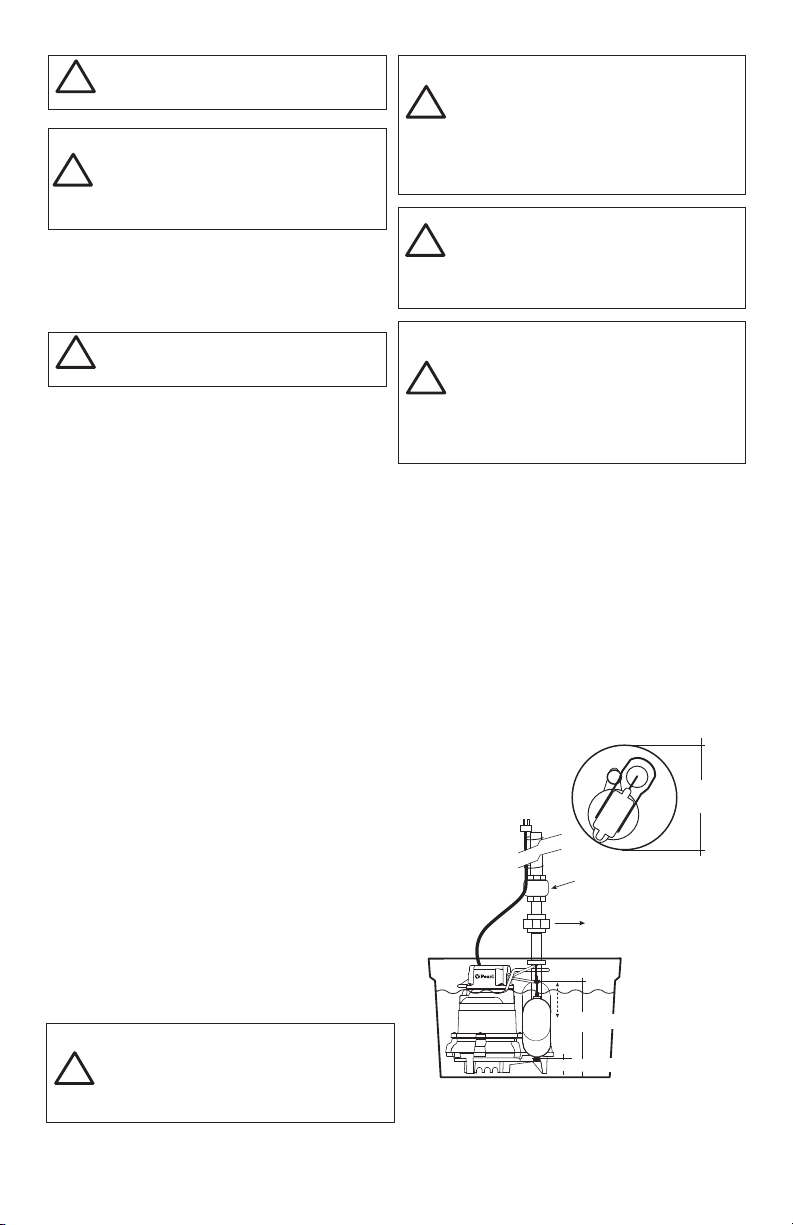

3. PIPING

3.1. The discharge pipe should be the same size as the pump

discharge (11/4”) to insure optimum performance. Using

undersized pipe will reduce the flow. Your pump supplier can

suggest the correct pipe for your installation.

3.2. Install a threaded pipe adapter, matched to the pipe type

you are using, into the threaded pump discharge. A union

installed just above the sump or basin cover will facilitate future

maintenance and replacement. See Chart 1 for discharge size.

3.3. Recommended to install a line check valve just above the

union to prevent backflow of water after each pump cycle.

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

WARNING

!

WARNING

!

WARNING

!

check valve

union

Chart 1

Min. OFF level 3 ½”

Min. ON level 7 ½”

Minimum basin

diameter 12”

4. INSTALLATION IN SUMP

4.1. The pump can be placed directly on the bottom of a poly or

fiberglass sump basin or a concrete sump bottom. The pump