- 2 -

PEC MACC DC Power Supply

Index

Section and Title Page

1. INTRODUCTION .................................................................................................................... 4

1.1 Scope............................................................................................................................................4

1.2 General Description of the MACC ..............................................................................................4

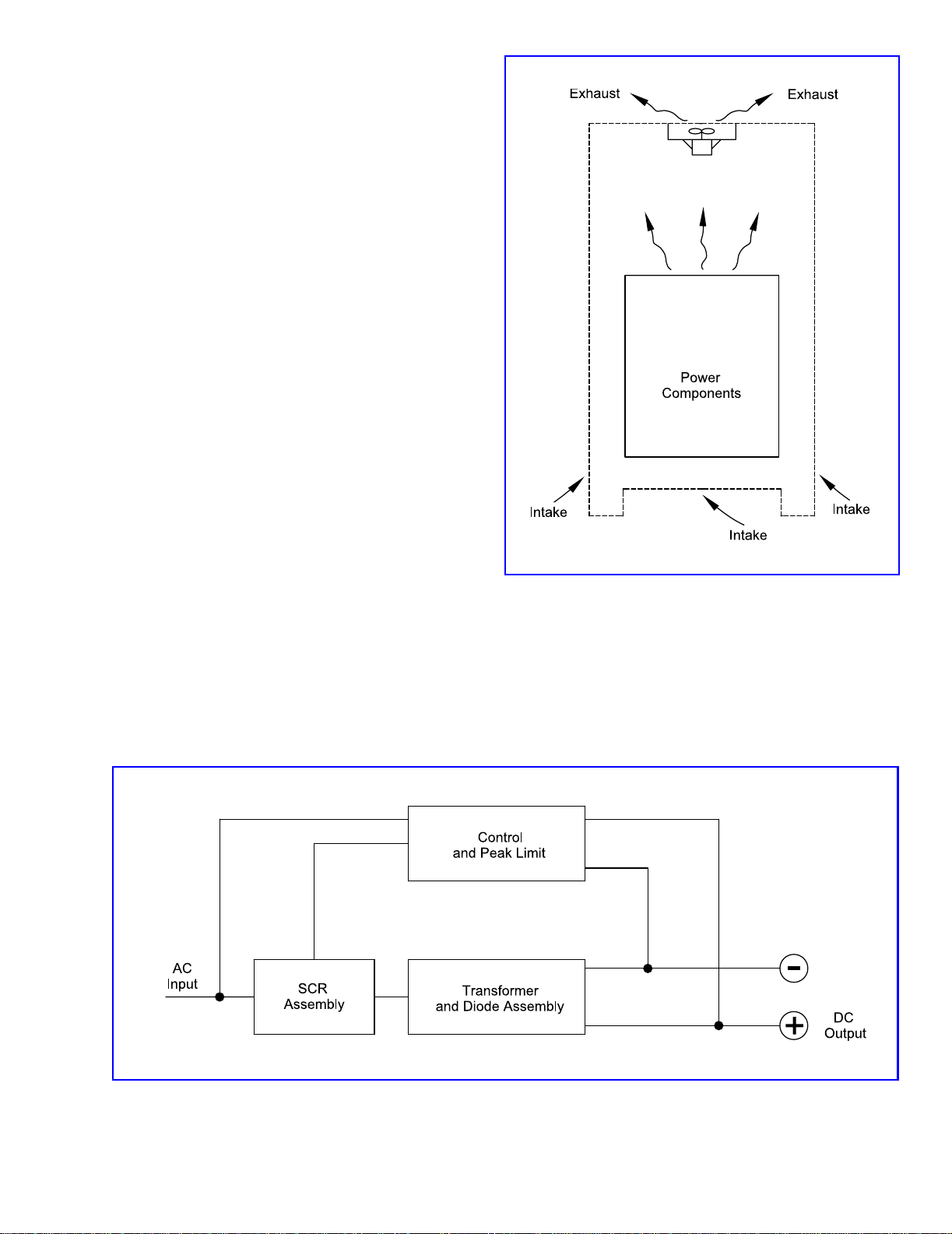

1.2.1 Power Conversion System...................................................................................................4

1.2.2 Cooling System ...................................................................................................................4

1.2.3 Control System ....................................................................................................................4

2. INSTALLATION ...................................................................................................................... 5

2.1 Inspection and Storage.................................................................................................................5

2.2 Handling the MACC ....................................................................................................................6

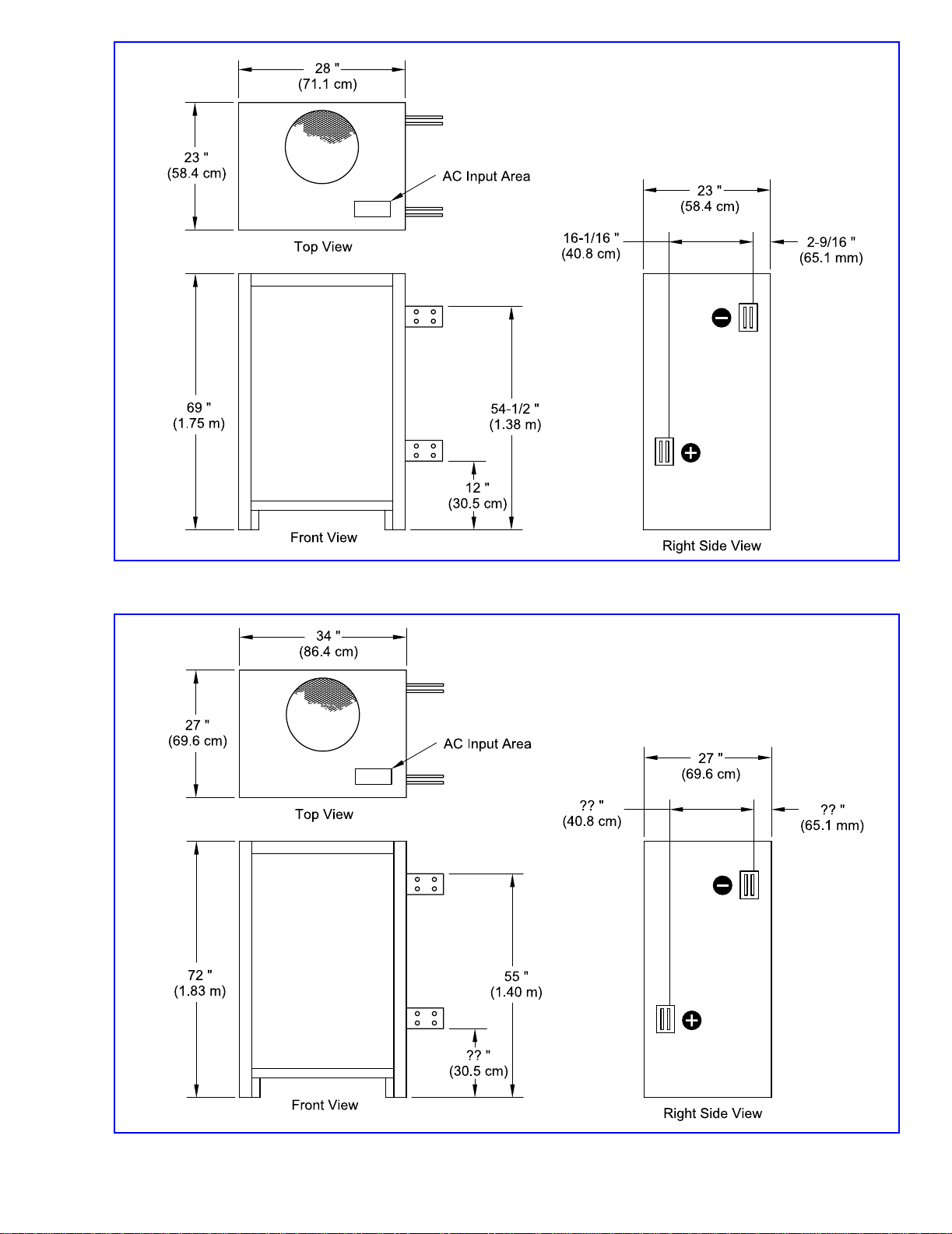

2.3 Cabinet Size, Weight, and Input KVA.........................................................................................6

2.4 Location ........................................................................................................................................6

2.4.1 Air-Cooled Converter..........................................................................................................8

2.5 Electrical ......................................................................................................................................8

2.5.1 A.C. Input Connection.........................................................................................................8

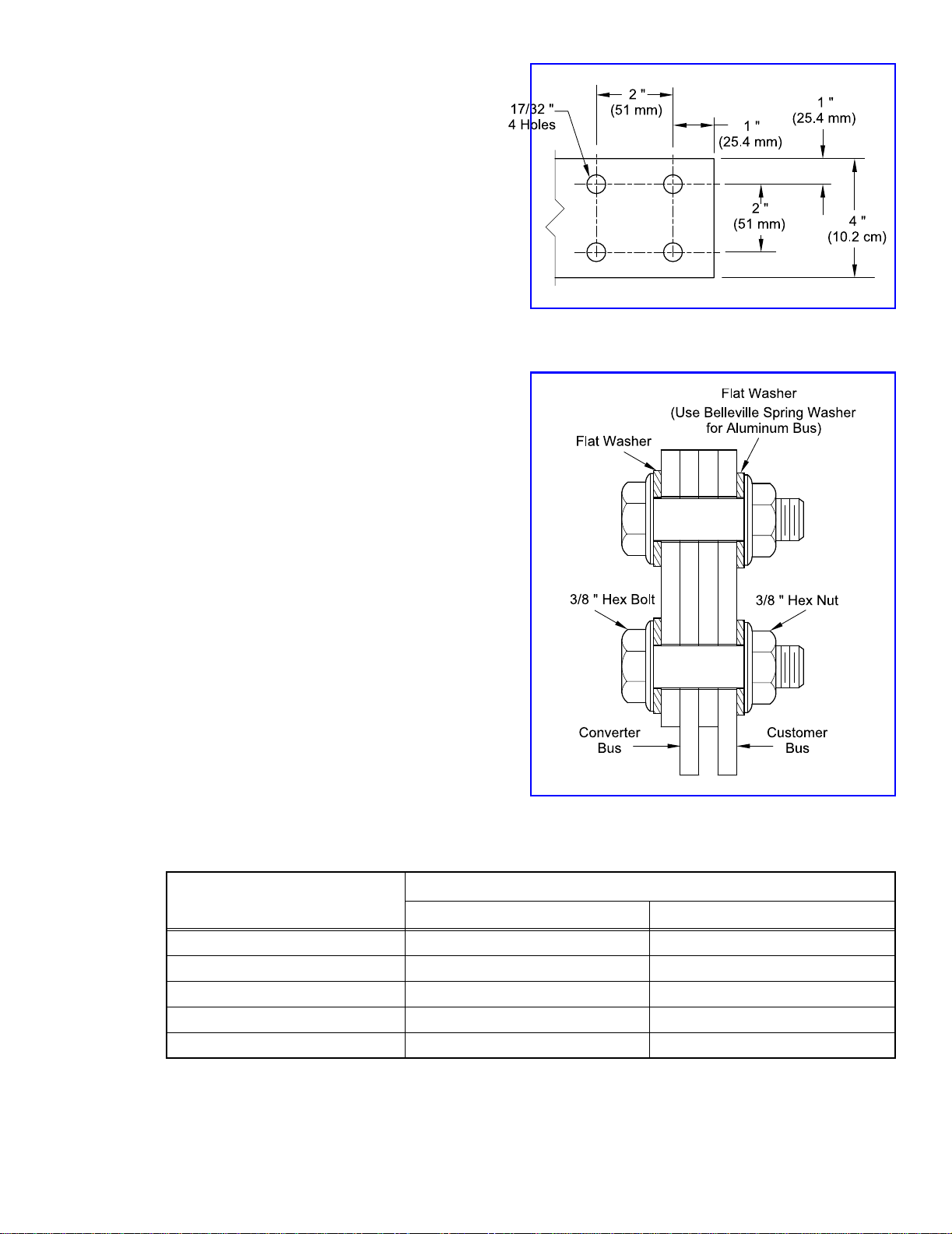

2.5.2 DC Output Connections ......................................................................................................9

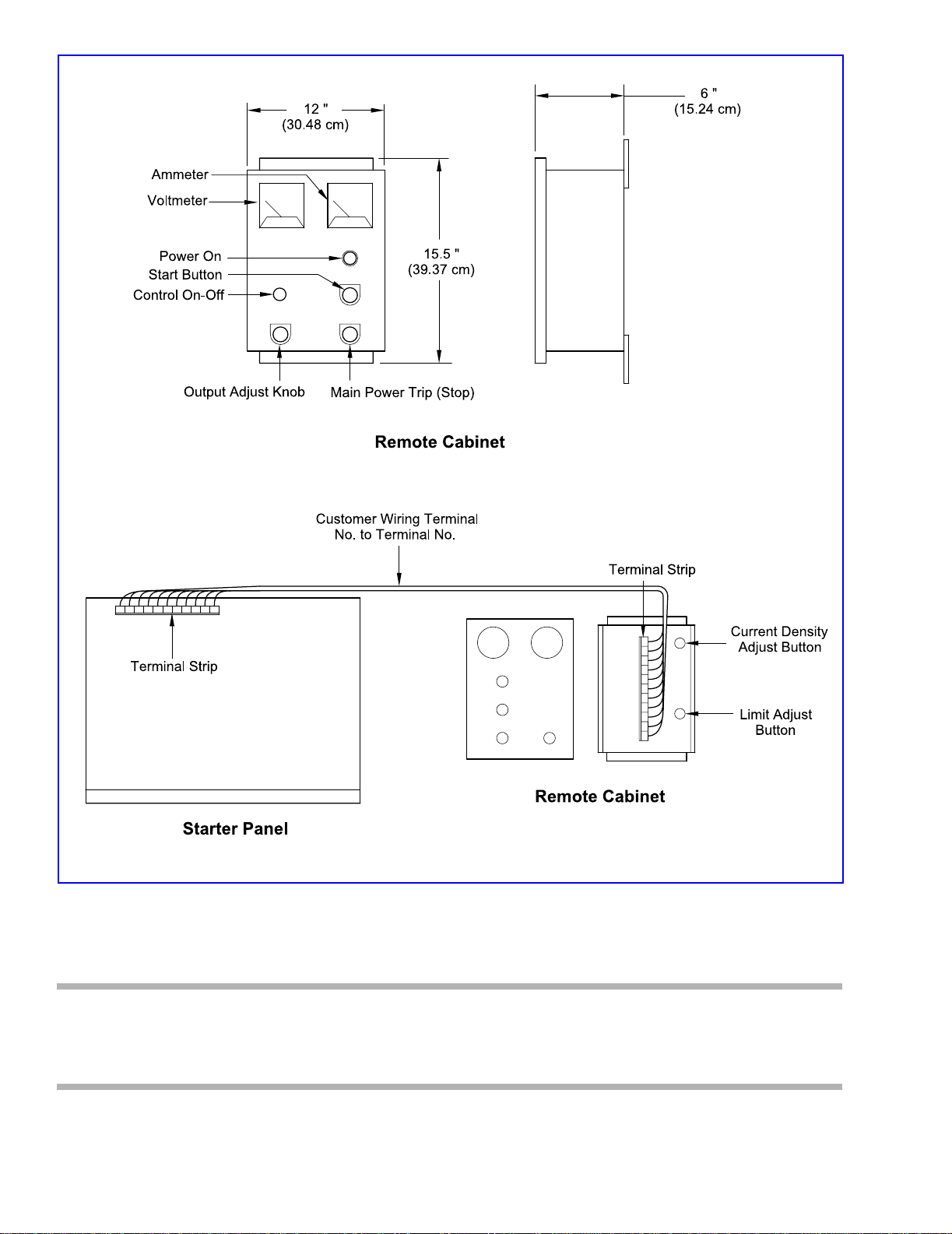

2.5.3 Connections for Remote Control Converter........................................................................9

3. OPERATION ...........................................................................................................................11

3.1 Component Operation ...............................................................................................................11

3.1.1 Magnetic Starter ................................................................................................................11

3.1.2 Line Current Transformers ................................................................................................11

3.1.3 Silicon Controlled Rectifier...............................................................................................12

3.1.4 Main Transformer..............................................................................................................13

3.1.5 Diode Assembly ................................................................................................................14

3.1.6 Control Transformer..........................................................................................................14

3.1.7 Protective Devices .............................................................................................................14

3.2 Cooling System..........................................................................................................................15

3.2.1 Control Operation..............................................................................................................15

3.2.2 Control Function................................................................................................................15

3.3 Converter Operation...................................................................................................................17

3.3.1 Turn-On Procedure............................................................................................................17

3.3.2 Automatic Voltage with Current Limit Operation Adjustment Procedure .......................17

3.3.3 Automatic Average Current Density Control with Current Limit Adjustment Procedure18

3.3.4 Automatic Current Control with Voltage Limit Adjustment Procedure ...........................19

3.3.5 Conversion to Current Mode of Control ...........................................................................19

3.3.6 Turn-Off Procedure ...........................................................................................................19