ISO 9001

PEGAS 235 AUTOMAT CNC - 7 - tel.-fax : 00420-544 221 125

9. Make sure, that the machine is well installed and that is well connected to the

electricity. ( It can be done only by a qualified person.

10. Controll and repair of el. instalation can be done only by a qualified person.

11. Never switch on the machine when all protecting parts are nor well closed and fixed,

12. Keep safety distance form all moving parts ( saw-blade, engine, ...)

13. Keep the machine clean.

14. The working room keep free of tools.

15. After finishing your work, switch off the main switch and take out power point from

plug.

16. When solving problems with machine, follow the using instructions or feel free to call

our technics.

17. When manipulate with saw-blade, saw-discs, when doing maintenance tasks switch

off the main switch and take out power point from plug.

18. When the saw-blade is moving, no part of your body can be in its working zone.

19. When having any problem, breakdown, press immediately CENTRALSTOP.

20. When the machine is working, it can not be manipulate with other parts of machine.

21. Use only recommended saw- blades, saw- discs.

22. Support long rods in front of the machine and also behind it.

23. It is prohibited to cut material that is bigger than a cutting capacity of machine, this

machine is only for cutting steel, metals and plasts.

24. Be very carefull espacially when cutting and taking away short pieces.

25. Never put material to the machine when it is working.

26. Before starting cutting cycle, you must test one cycle without material to make sure,

that the machine is well set.

27. Check good work of machine, from time to time check the work of machine when

working on its maximum ( max. speed of saw-blade, saw-disc, max. feed rate, max.

feed).

28. Check, if the vice is well set before fast tightening (tolerance 1-5 mm), if the material

is well tightened.

Allways work very carefully and avoid all dangerous situations.

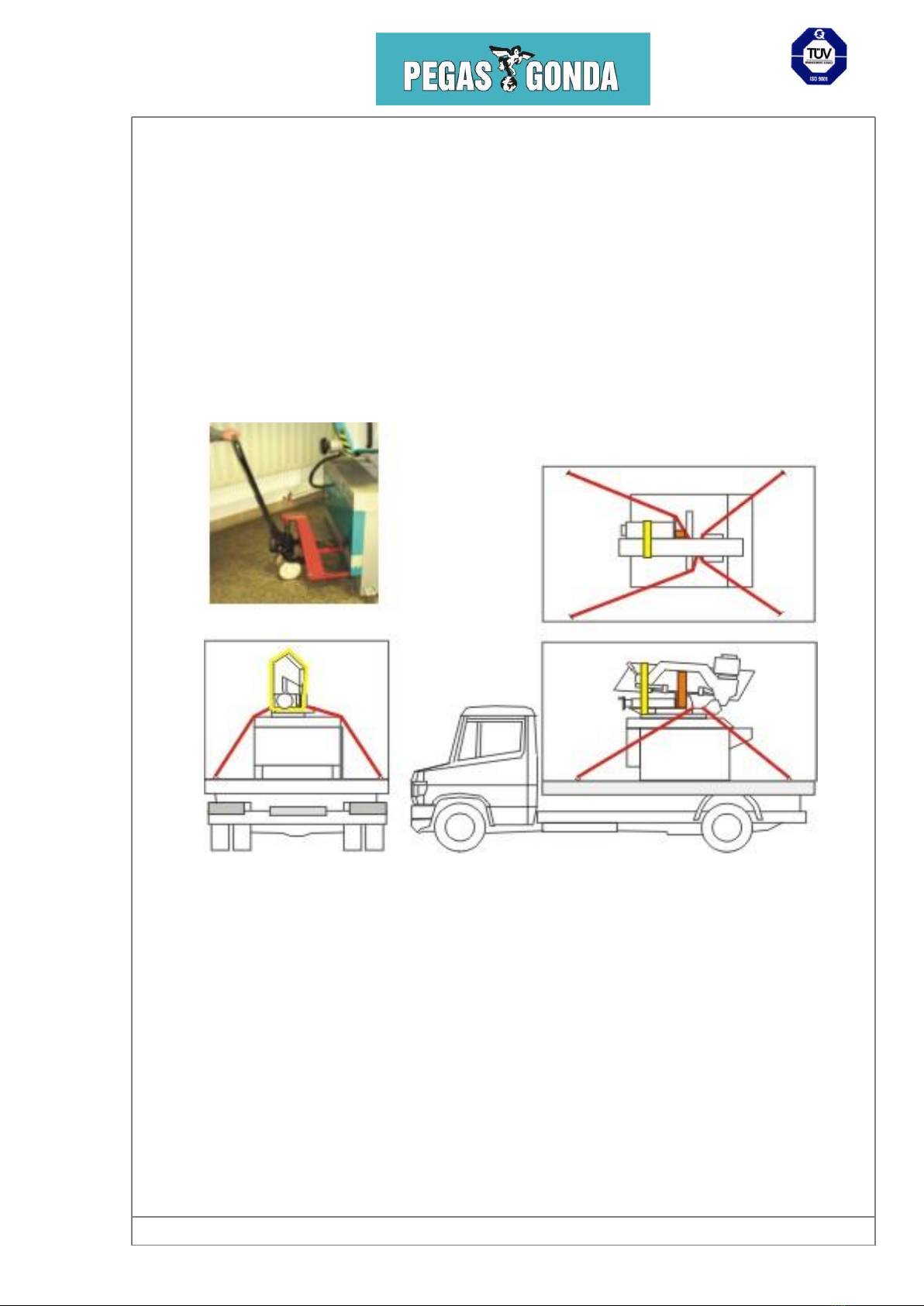

DESCRIPTION OF PICTOGRAMS

Clamping of material to vice

- when clamping material nobody can manipulate in a

working zone of the vice jaws.

- after manipulating with a movable part of jaws, check

the right clamping of material

The sence of direction of saw-blade when cutting

- when connecting the machine to the electricity, pay

attention to the right working direction of saw-blade

- when changing saw-blade pay attention to the right

sence of direction of teeth