Engine speed adjustment

Use the throttle handle for the engine speed

adjustment

.

During operation

• Avoid getting limbs into rotating parts of the

snowcutter.

• Observe safety precautions when working

on or crossing gravel roads, sidewalks and

the roadway. Be careful when driving on the

roadway.

• If a foreign object got into the rotating parts

of snowcutter, stop the engine, disconnect the

wire terminals from the battery, disconnect the

high-voltage wire from the spark plug, make a

full check of moving parts of the snowcutter

for damage; repair the cutter before starting

the engine and operating the snowcutter.

• If the engine starts to vibrate abnormally, stop

working immediately and check for possible

causes of the vibration. The vibration usually

indicates a problem.

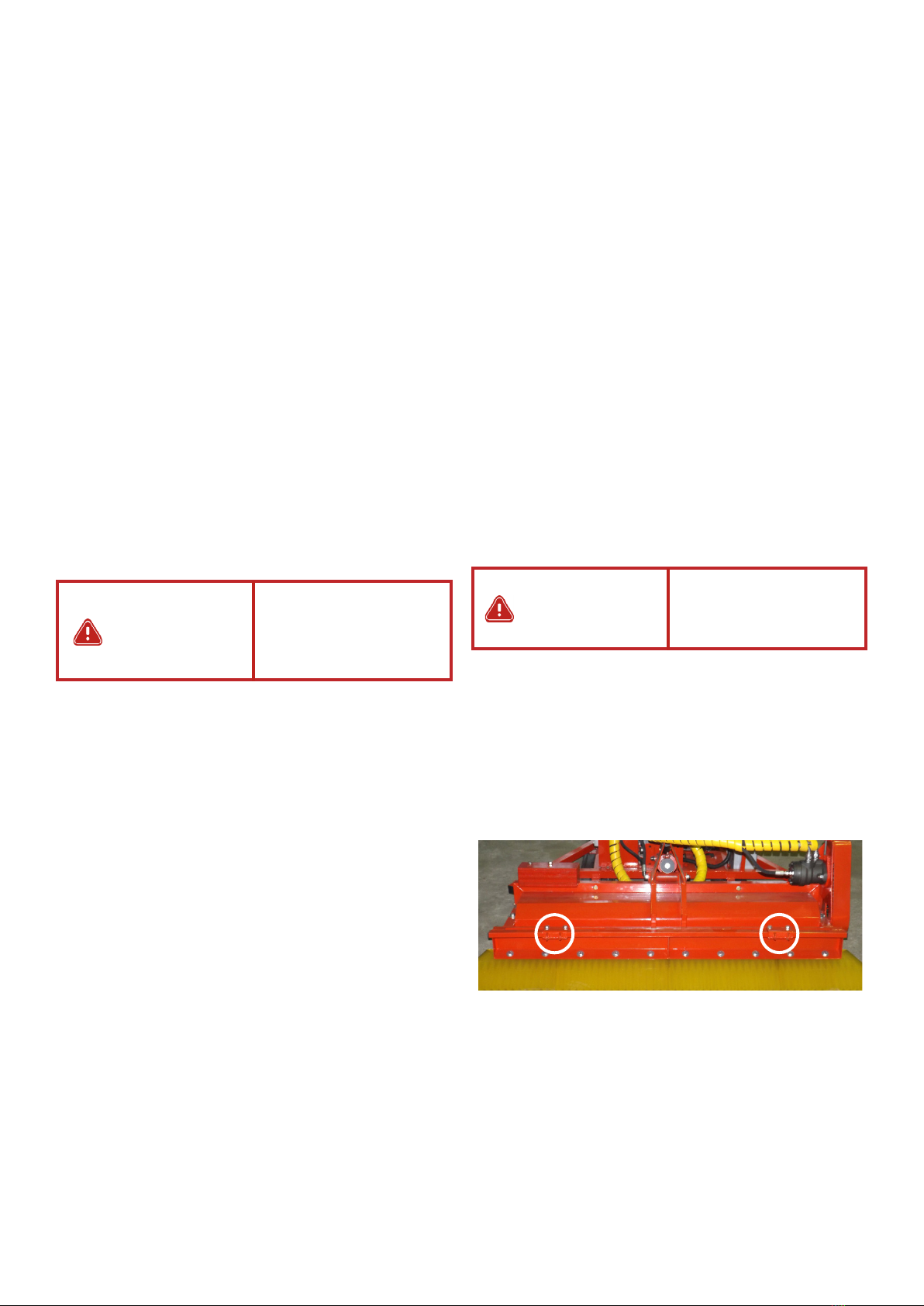

Track setters installation

Fastenings for the track setter installation are

shown in image 5. To install the track setters,

insert them into the fastening slots and tighten

the bolts.

Storage and maintenance

Image 5. Track setters fastenings

• Keep the snowcutter rotary shaft and

accessories in good working condition.

• Check the tightening of the engine mounting

bolts and other bolts at regular intervals.

• Never store the snowcutter with fuel in it

indoors or near possible ignition source.

Page 8

Recommended warm up time:

• from 0 °C to -10 °C is 3 minutes;

• from -10 °C to -20 °C is 7-8 minutes;

• from -20 °C and below is 10-15 minutes.

Recommended hydraulic oil working temperature

is from + 5 °C to + 80 °C.

Use lever 1 to lift the cutter rotor up. Use lever 3 to

set the minimum cutting angle. Use lever 2 to turn

on the rotor rotation.

Move the throttle lever on 2/3 turn.Lower the cutter

rotor by switching lever 1 to the self-regulation

position. Use lever 3 to correct the depth of the

cutter rotor. Proceed with the surfacing.The driving

speed is 4-8 km/h.

Do not use carburetor

choke when starting

already warm engine.

ATTENTION ATTENTION Snowcutter towing in

reverse is forbidden.

• Turn off the engine whenever done workingwith

the cutter.

• Observe safety precautions when leaving

thesnowcutter unattended.

• Stop the engine and make sure that all

rotatingparts are stopped before cleaning,

repairing orinspecting the snowcutter.

• Do not start the engine being inside.

• Make sure that all safety devices are inplace

and xed.

• Do not work with the snowcutter inconditions

of poor visibility and bad light.

• Be careful when digging up hard snow or ice—

the cutter can move forward. Do not lowerthe

cutter boom without coupling a tractorrst.