9

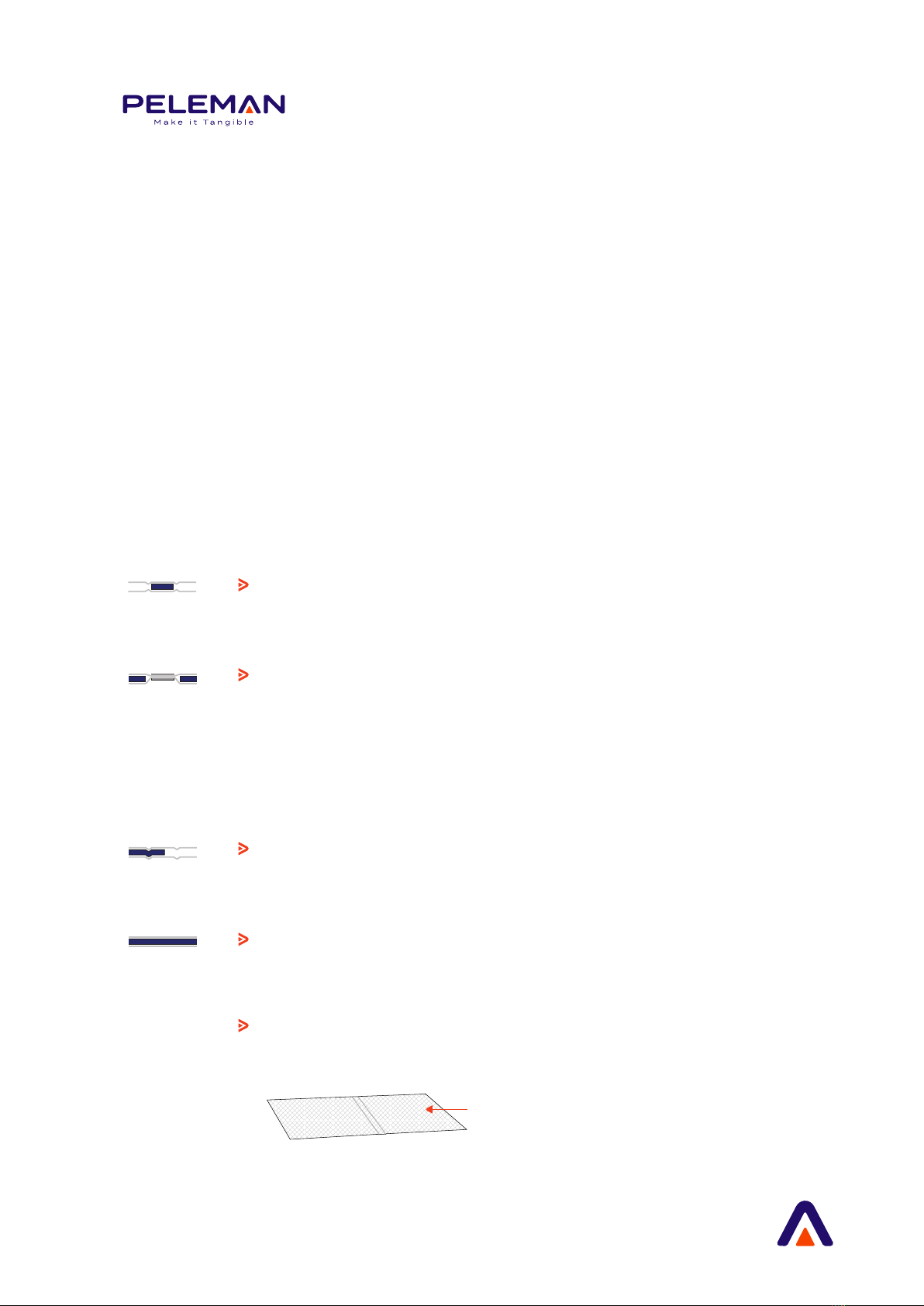

The 3-pieces Hard Cover Basic with 3 pieces of 2,7mm thick

greyboard.

For traditional bookbinding and casing-in.

The 3-pieces Hard Cover Basic with 2 pieces of 2,7mm thick

greyboard and the middle piece in 0,3mm thick steel sheet

covered with 2 resins: the binding resin and the casing-in

resin. To use with the Mirror Sheet to finish the inner side of

the book.

For binding with Resin SteelBinding.

The one-piece Hard Cover Basic with 2 creases in the

2,7mm thick greyboard. To use with the Mirror Sheet.

For ring binders, folders, portfolios...

The one-piece Hard Cover Basic in 2,7mm thick greyboard.

To use with the Mirror Sheet.

For displays, top cards, game boards...

For the Hard Cover Basic Box in combination with the Clips:

2.7mm thick cardboard.

We are able to provide 4 differents Hard Cover Basic types:

Required Materials

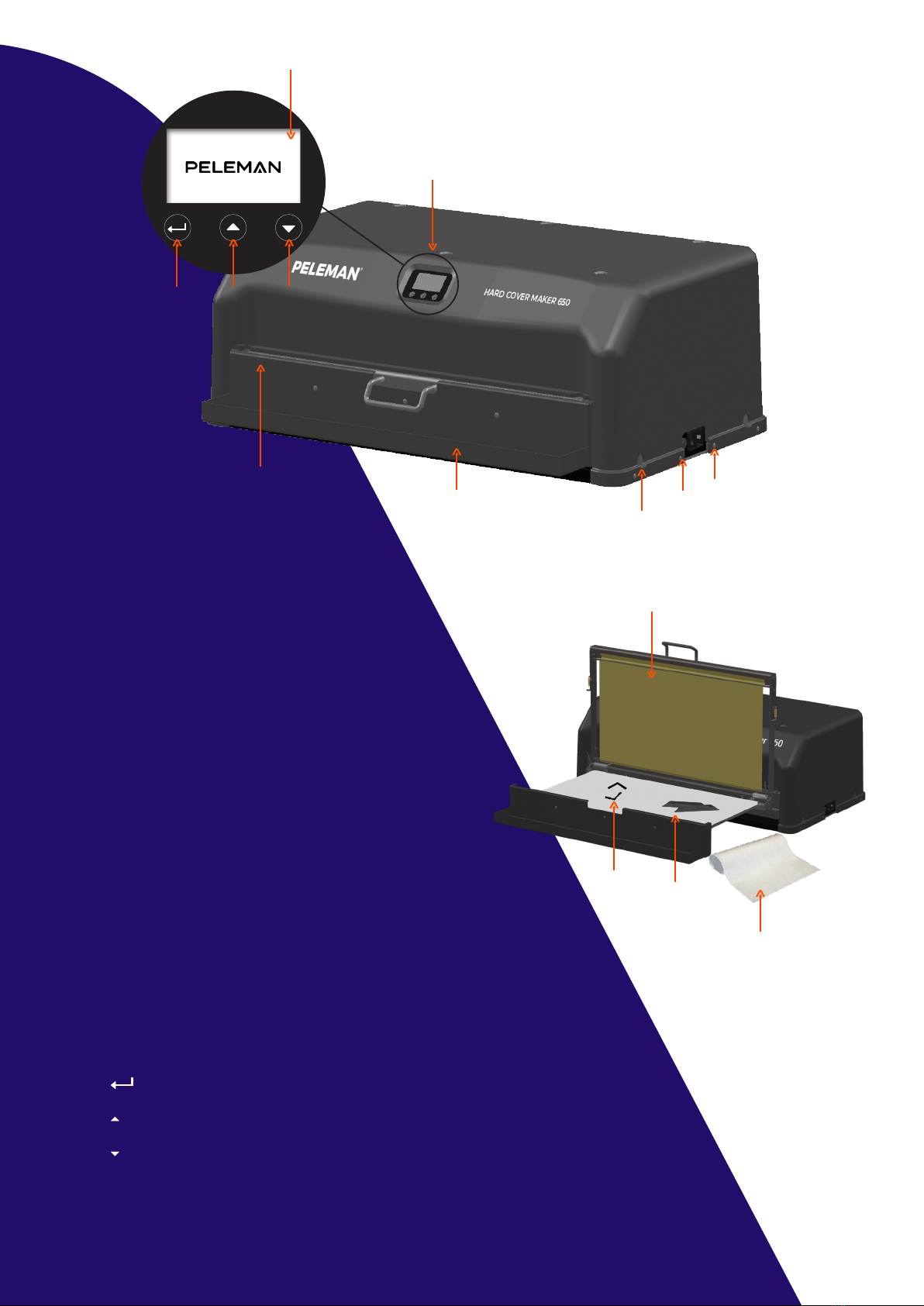

The Hard Cover Maker 650 uses a unique and patented way of casing and

wrapping in. It is an environmentally friendly solution which requires low

maintenance and helps cutting costs. Such a unique casing-in system asks

for some unique components and products.

Hard Cover Basic

The Hard Cover Basic is an in-house designed innovative and patented

pre-made cover de¬veloped for use with the Casemaking systems. The

Hard Cover Basic is covered with a thin layer of hotmelt on the outside and

inside.

Our summer at the beach!

Our summer at the beach!

glossy side = hot melt side