3049336 R02

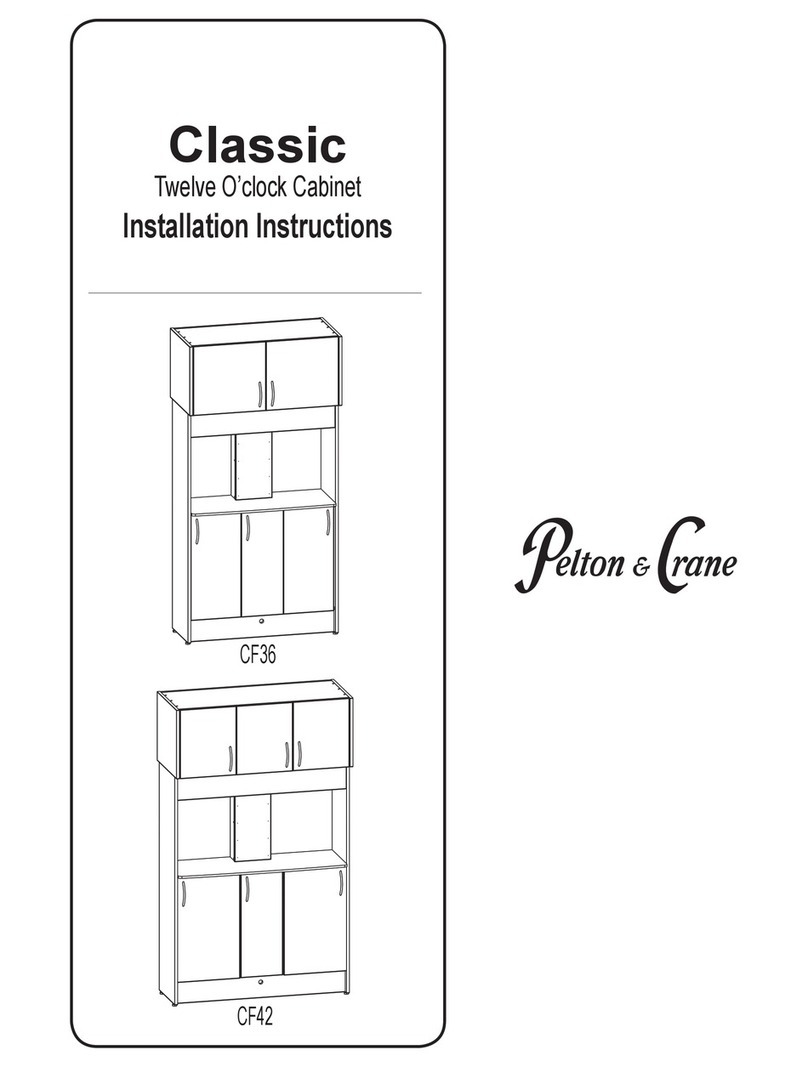

OVERVIEW

Charlotte NC, U.S.A.28273,

11727 Fruehauf Dr.

MN

SN

MO

YR

120VAC, 12A, 60Hz

OPERATORY CABINET

34488

ETL CLASSIFIED

Product Name and

Electrical Rating

Model and Serial numbers

Date of Manufacture

IEC Type and Class

Safety Standard Information

Certification Mark and other

Symbols when Applicable

046820 Rev. 04 08/07/13

PRODUCT DISPOSAL

Contact your local authorized dealer for proper disposal

of the device to ensure compliance with your local

environmental regulations.

INTERFERENCE WITH ELECTROMEDICAL DEVICES

To guarantee the operational safety of electromedical

devices, it is recommended that the operation of mobile

radio telephones in the medical practice or hospital be

prohibited.

Strong EMI sources such as electro surgery units or x-ray

units may affect performance. If performance problems

occur, move the unit to another electrical circuit or physical

location.

INCOMPATIBLE UNITS OR ACCESSORIES

To guarantee the operational safety and function of this

device, the use of unapproved units or accessories is not

advised. Doing so could result in potential hazard. Using

accessory equipment not complying with the equivalent

safety requirement of this equipment may lead to a

reduced level of safety of the resulting system. Connecting

electrical equipment to multiple socket outlets effectively

leads to creating an ME SYSTEM, and can result in a

reduced level of safety. All congurations shall comply with

the system standard IEC 60601-1-1 or IEC 60601-1:2005.

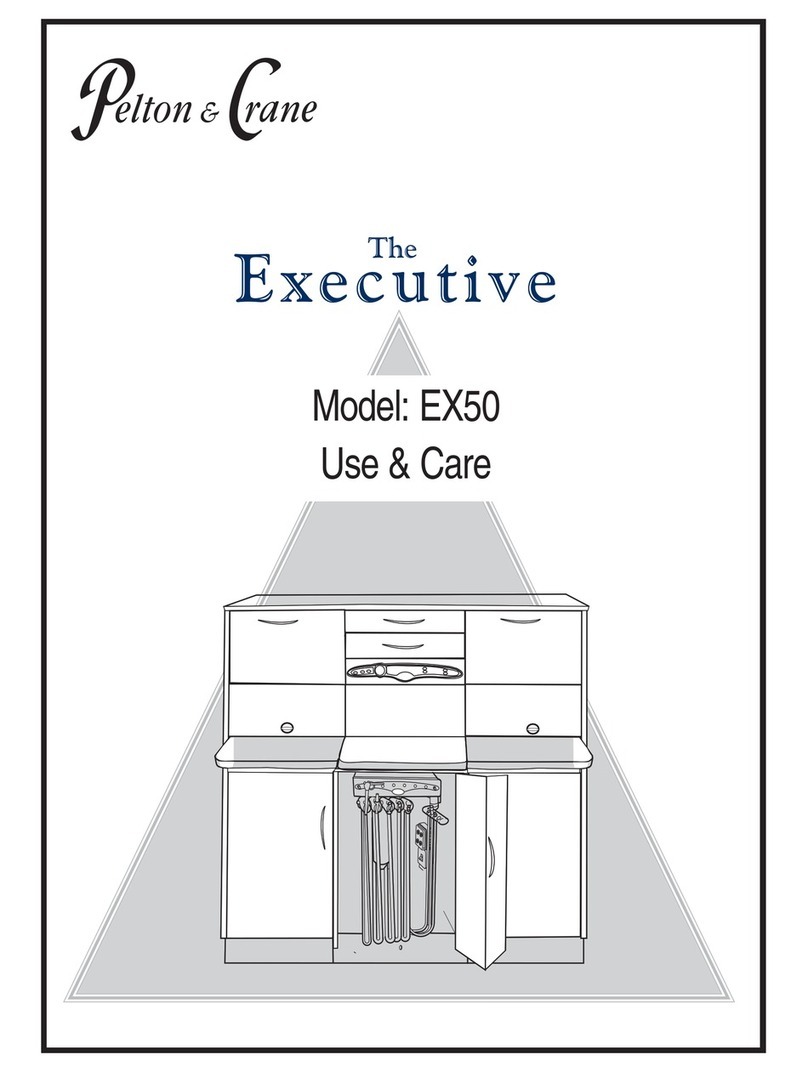

PRODUCT IDENTIFICATION

This product can be identied by its product label. This

label states the unit model and serial number, electrical

specications, manufacture date and safety classication.

Note the SAMPLE labels shown below.

DEFINITION OF SYMBOLS

The following symbols and terms may be used throughout

this manual and your equipment:

WARNING: Failure to carefully follow the

described procedure may result in damage

to the equipment and/or injury to the patient/

operator.

Risk of electrical shock present.

Make sure power is disconnected before

attempting this procedure.

See operating instructions.

(AC) Alternating current.

Protective earth (Ground)

Manufacturing Date

Waste Electrical and Electronic Equipment.

Type B Applied part.

Indicates conformity to General Requirements for

Safety is certied by Intertek Testing Services.

General mandatory action required, important to

follow instruction. Not a caution.

Warning, strong magnetic eld.

Off

On

Light Switch

Authorized Representative:

Medical Device and QA Services (MDQAS)

Spring Court, Spring Road, HALE, Cheshire, WA14 2UQ

United Kingdom

Tel: +44 (0) 845 527 5078 FAX: +44(0) 161 903 9787

WORKING ENVIRONMENT:

The unit is to be used in an ofce environment only

Ambient Temperature: 68°F to 76°F (20°C to 25°C)

Relative Humidity: 20% to 60% non-condensing

Atmospheric Pressure: 13.1 to 15.3 PSI (900 to 1050hPa)

STORAGE AND TRANSPORTATION

Temperature : -68°F to 122°F (-55°C to 50°C)

Relative Humidity : 10% to 90% non-condensing

LONG PERIODS OF NON-USE

If the device is not to be used for sometime, ensure the

water line is disinfected and ushed with air before the

master switch is switched off.

Technical Description

Model Designation: Caseworx Side Cabinet

Power Supply: 120V-50-60HZ, 12A

Protection against harmful ingress of water:

Ordinary Equipment

Mode of Operation: Continuous