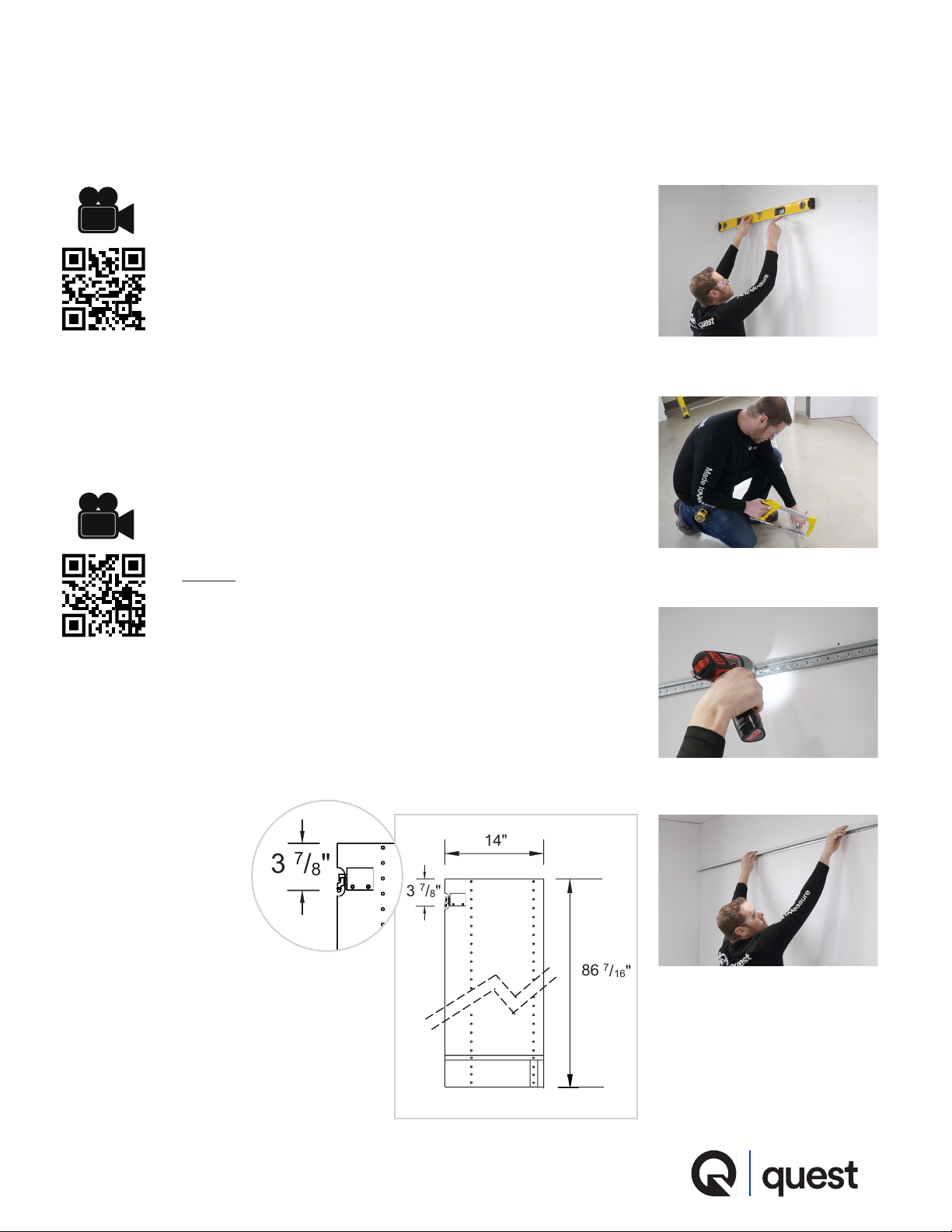

2. Layout the closet sections

▪Your closet design will need a small gap on each end, typically between 1” and 2”. This

is to ensure that the closet system can be assembled without the constraints of imperfect

wall conditions.

▪Determine overall wall dimension, then subtract the

designed closet overall width. Leave about half of that

balance on the far right of the closet, and the other half

on the far left of the closet. Keep in mind that the overall

designed width of the closet may increase slightly as you

assemble the closet.

▪Layout the vertical partition locations. (Figure 5)

3. Organize the closet components

▪According to your closet design, locate the appropriate closet components near their

installation location, beginning with the vertical partitions.

▪Next, organize the xed shelves near the vertical partition locations.

▪No need to organize the adjustable shelves, clothes rods, drawers, or any other

accessory at this time.

Figure 5

Figure 6

Figure 8

CLOZX

Closet Installation

Figure 7

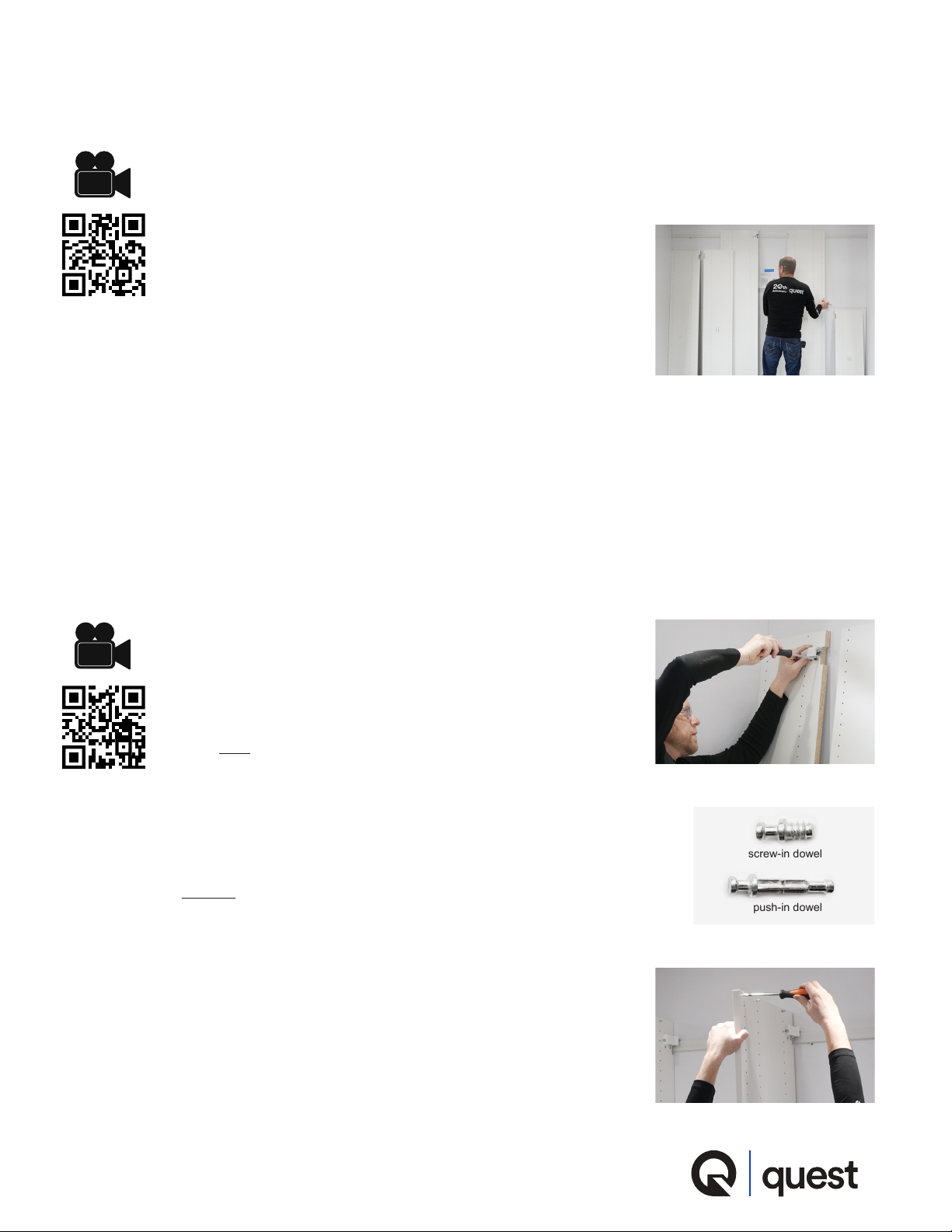

4. Install the vertical partitions

▪Begin from the far right or far left of each wall. If you have a

wall with an open-ended system run, begin against the wall.

▪Each vertical partition will require a panel hanger. (Figure 6)

The panel hangers are attached near the top of the partition,

and fastened with 2 – 5mm Euro-Screws. NOTE: There are

right and left-handed panel hangers, use according to the

requirements on your design.

▪Please reference the individual module instructions for

further information.

▪Hang the partitions.

▪Do not adjust the panel hanger at this time, unless you must

due to extreme wall variations.

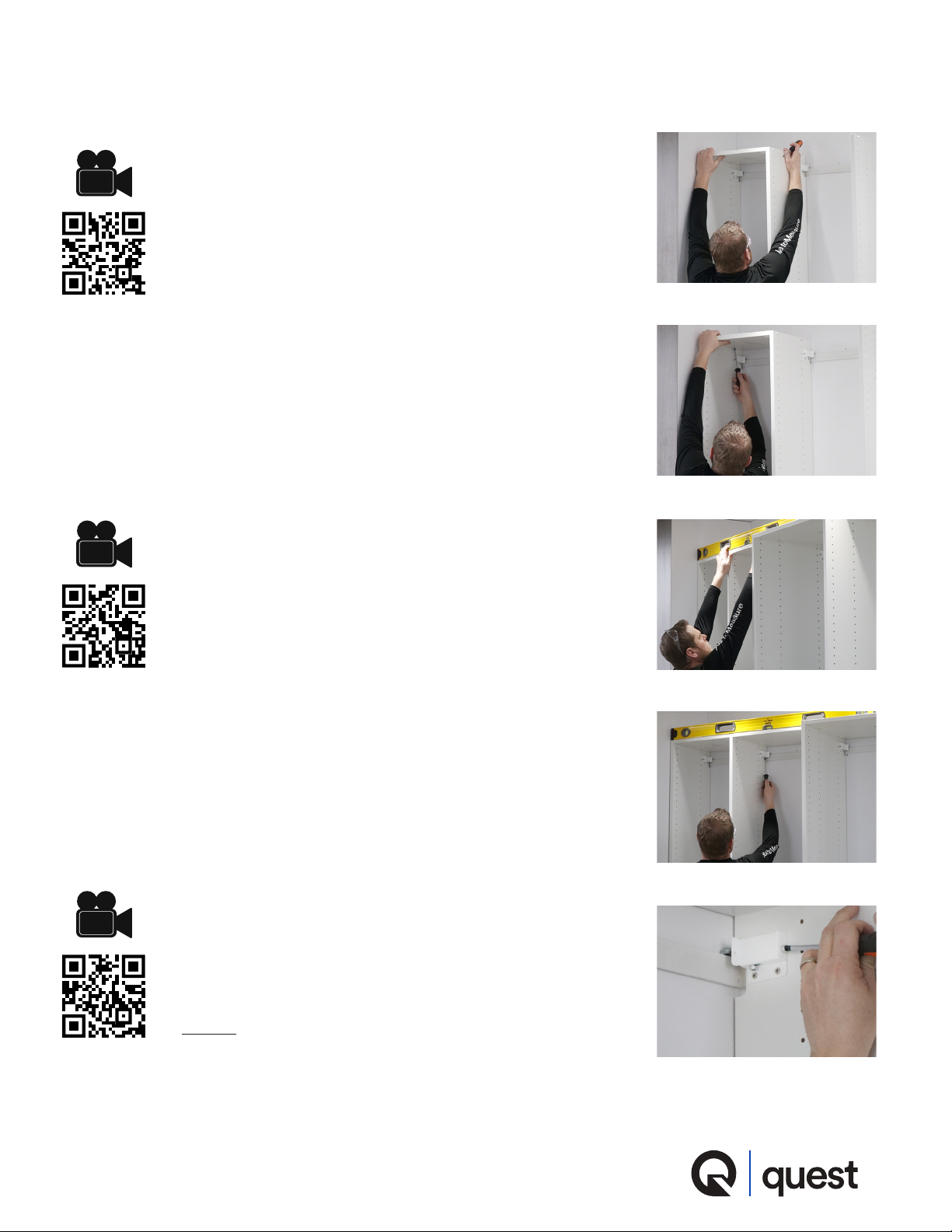

▪There are 2 different connector dowels used in assembly (Figure 7):

◦The screw-in dowel is used when a common shelf is not

required, or at the rst or last partition.

◦The push-in dowel is used when a common shelf is

present; where there is a shelf in the same location on

each side of the vertical partition (such as the top).

▪You will want to pre-assemble any connectors required on

the partition. This will be determined by the module type. (Figure 8)

2

4

screw-in dowel

push-in dowel

VIDEO 2

VIDEO 4