8www.PennBarry.com

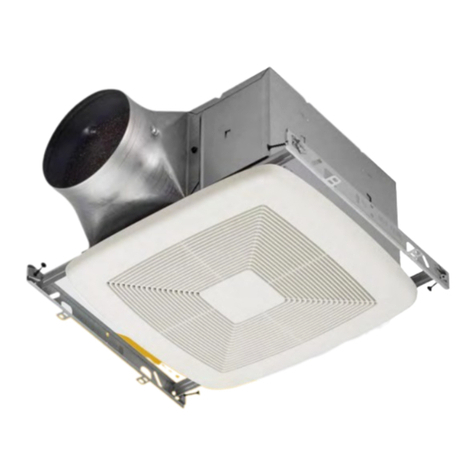

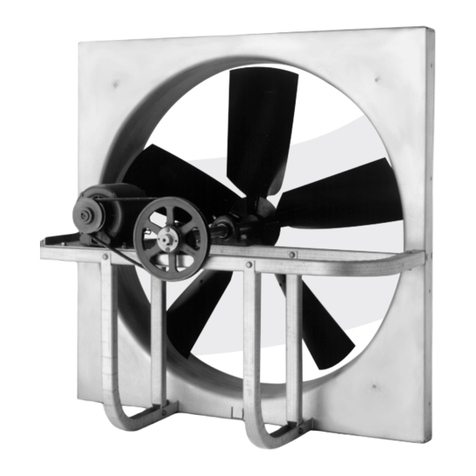

INSTALLING THE WALL DAMPER

When required, level and fasten the wall damper through the mounting holes provided in the damper mounting ange. Consult

Figure 1 for the proper mounting arrangements. Secure the damper to the wall opening without undo twisting which may distort the

frame. Check for free operation. If dampers are motor operated type, ascertain the proper voltage is present on motor terminals.

The fan is now ready for service.

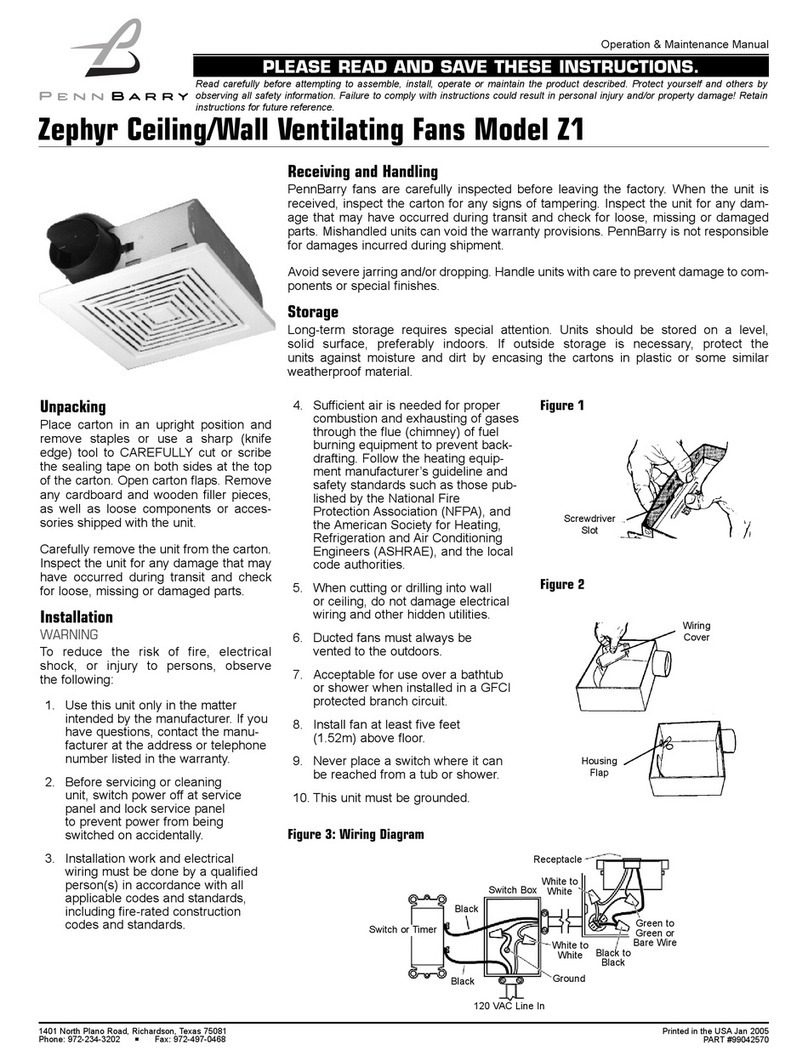

Replacement Switch Wiring Diagrams (1 Phase)

The 4 pole reversing switch is shipped from the factory, even as a replacement part, pre-wired for a Marathon brand motor. If you

are using this switch as a replacement on a unit having an A.O. Smith motor, your unit almost certainly has a 3 pole reversing switch.

Counting the number of terminals on the switch (nine for a 3 pole, or 12 for a four pole) is an easy method to determine which switch

you have.

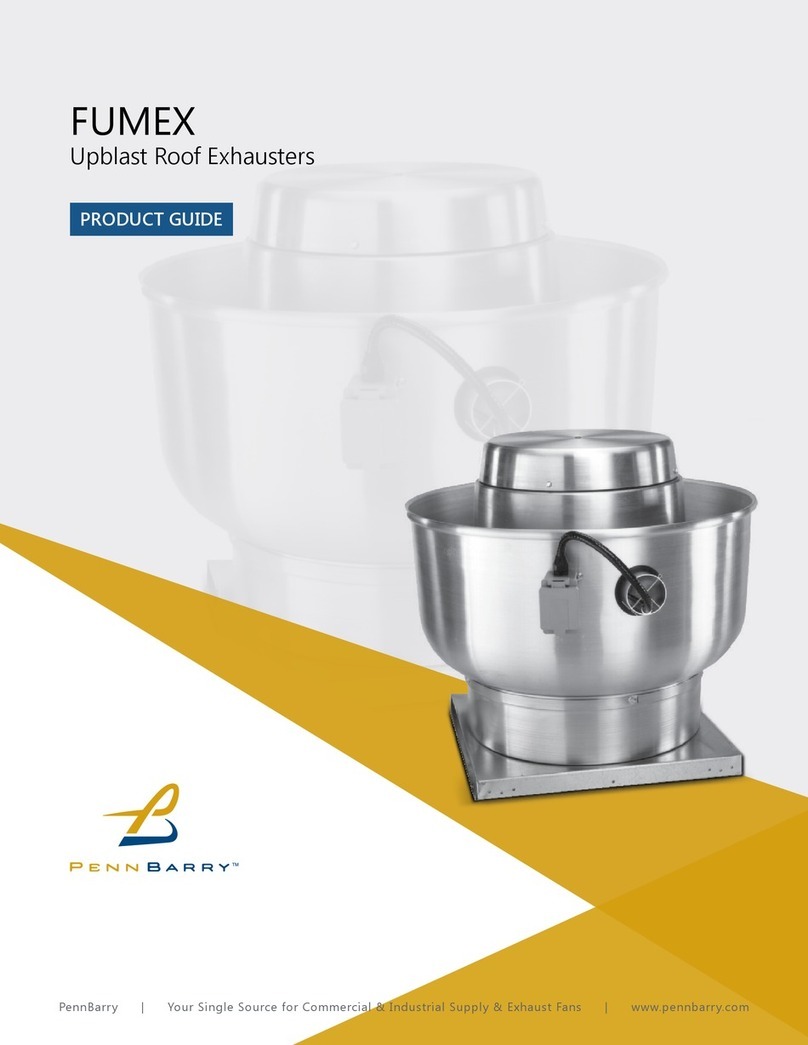

If you have a 3 pole switch, you MUST RECONFIGURE the 4 pole switch which has been supplied.

There are two ways to approach this task:

The rst is easiest to explain, but requires careful attention. Simply stated, remove & discard all the wires from the 4 pole switch

and move all the wires from the 3 pole switch to the 4 pole switch in exactly the same arrangement. Move only one wire at a time.

You can match the wires to the same terminal numbers (the 3 pole switch has no connections for #7, 8 & 9). Cap any unused wires.

Verify that the end result matches the diagram labeled “RECONFIGURED 4 POLE SWITCH”.

The second method is to follow the detailed instructions below. To do this, use only pins 1-9 of the switch; pins 10-12 remain unused.

1. Disconnect & cap the blue wires on pin #12 & 7, they are not used.

2. Remove the terminals with black wires from pin #8 & 6. Connect the terminal with the long black wire to pin #6 and the other

terminal to pin #7.

3. Remove the terminal with the long red wire from pin #11 and connect it to pin #9.

4. You will have to connect pin #8 to neutral in the eld. A wire is not provided.

Figure 2: Recongured 4 pole reversing

switch for use with A.O. Smith motors

CAUTION: Make certain that the power source is disconnected before attempting to service or disassemble any components!

If the service switch is out-of-sight, lock it in the OFF position and tag to prevent application of power.

Periodically clean any guards, dampers, motors and props to prevent decrease in airow and overheating of the motor, and

make sure all bolts are tight.

CAUTION

MAINTENANCE

Figure 1: 4 pole reversing switch for use

with Marathon motors