4www.PennBarry.com

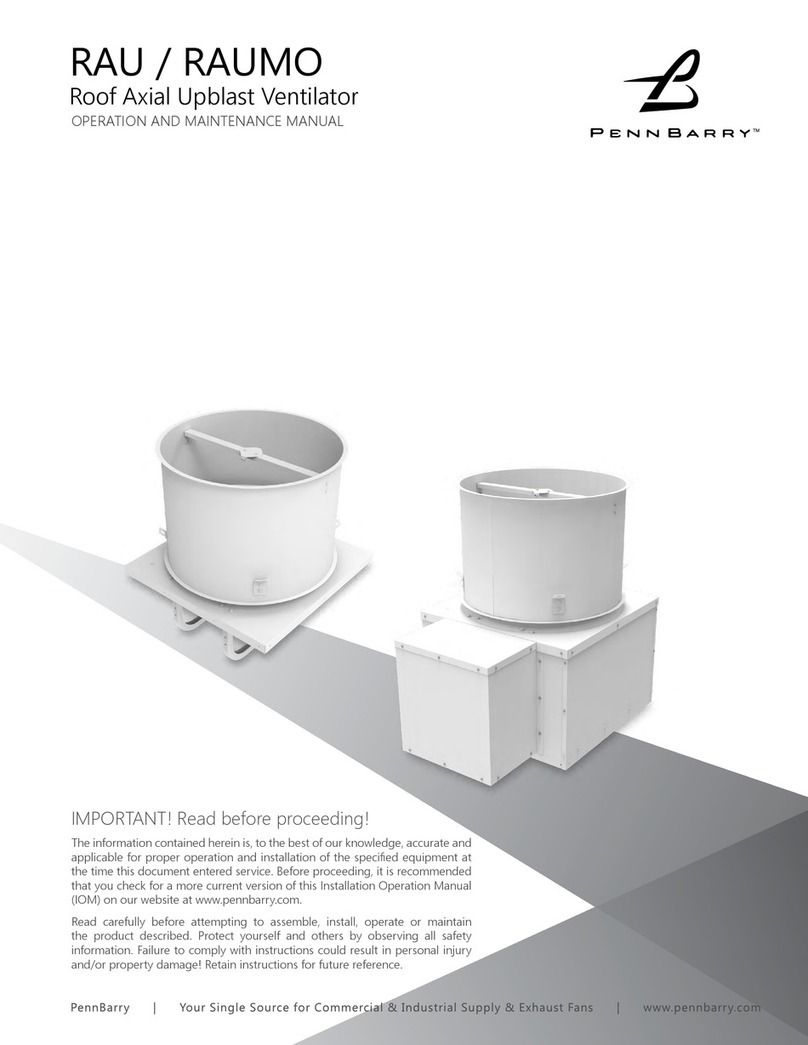

INSTALLATION

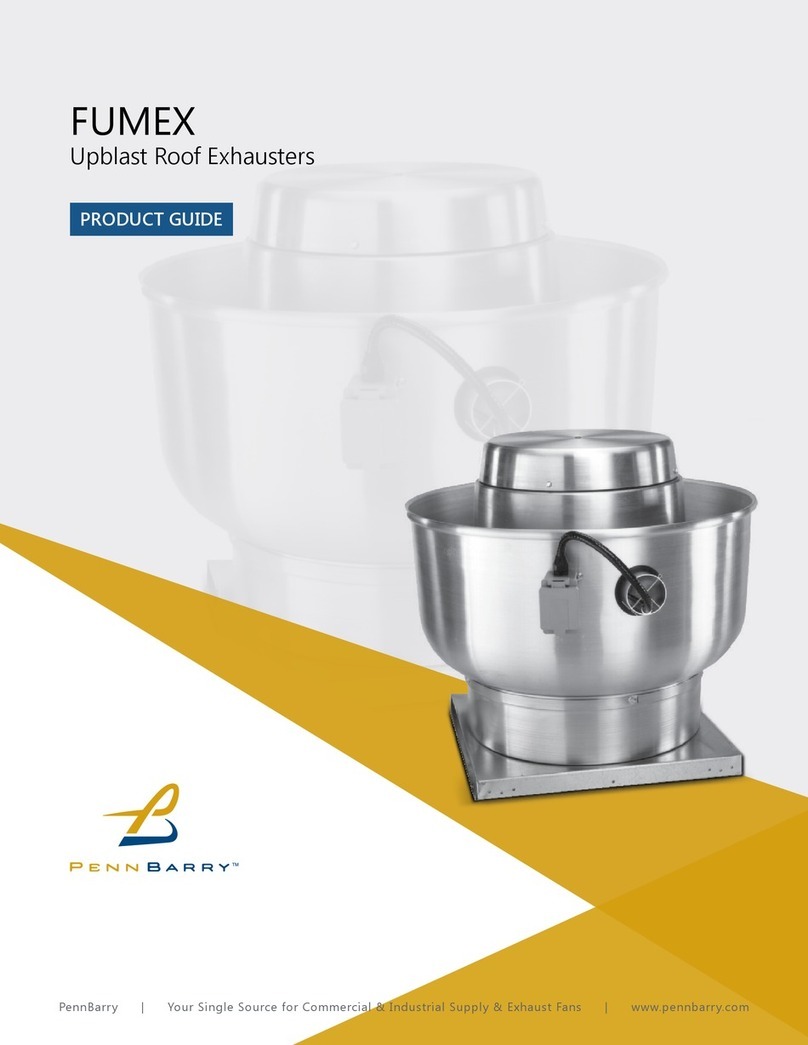

For all units, determine the minimum safe oor or roof loading requirement for proper support, by multiplying the total weight of the

unit by two. Follow local codes and good practices to ensure proper anchoring of roof top units. A minimum of 12” clearance should

be provided for adequate heat dissipation. For these units, ex pads and other isolators are available to reduce the transmission of

vibration to the surrounding areas. See suggested ductwork installations and the dimensional information on page 9 and 11. Blowers

suitable for Restaurant Exhaust Appliances (YZHW) are accordingly labeled. These units require installation according to NFPA96

Standards, local codes and general practices. For curb mounting, to ensure a positive seal, apply a high temperature gasket material

on the roof curb.

Installing Dampers

When required, install dampers prior to mounting the unit on the curb or frame. Secure dampers to the inside of the curb without

undue twisting, which may distort the damper frame. Damper frame must be reasonably level on all sides. Check for free operation.

If dampers are motor operated type, ascertain that proper voltage is impressed on motor terminals.

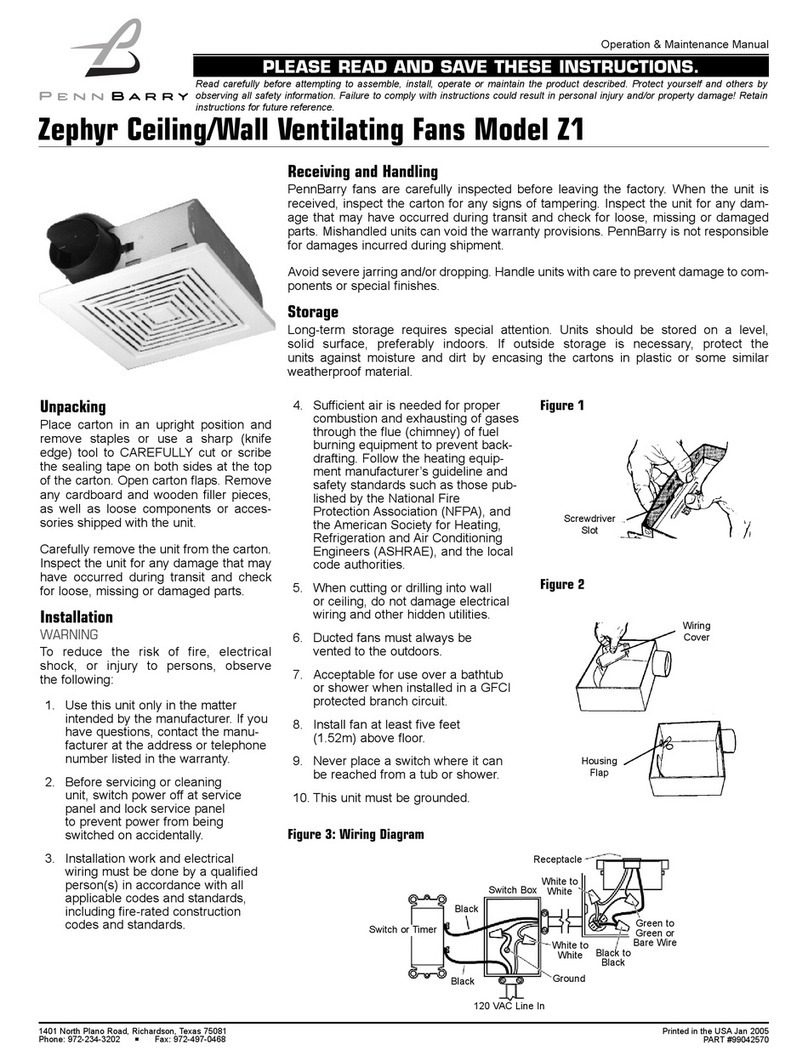

Positioning and Running Power Lines

Power is normally brought from within the building and placed inside one corner of the curb. Feed power line through the clearance

hole provided in the damper and in turn through the electrical conduit hole provided in the base of the exhauster (fed through

rubber grommets on smaller units). If local codes require special electrical wire of unusually large size, then remove and discard the

electrical conduit (or grommets).

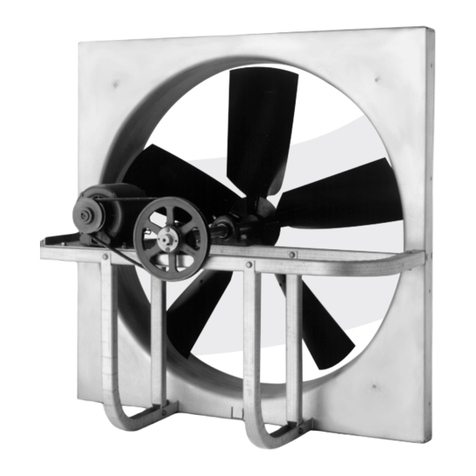

Installing the Fan

For access to motor and drive assembly, simply remove or lift access hood and make necessary power connections to motor

(through service switch if required). Provide a generous amount of slack in power line between motor and service switch to allow for

motor deections and to permit movement or motor for belt tension adjustments.

Anchoring or Securing the Unit

Whenever possible, anchor the fan by fastening through the vertical portion of the mounting ange. The type of fastener depends

upon curb construction, and using two fasteners per side constitutes adequate anchoring under normal conditions. If code or

specication prescribes fastening through the top (horizontal portion) of the mounting ange, use neoprene or lead washers under

the head of each fastener to prevent water leaks.

To complete the re-assembly of the unit, secure hood to frame by replacing all spacers, washers and nuts exactly as they were found

prior to removal. The unit is now ready for service.

Apply power and check rotation as indicated by arrow in motor compartment. The rotation of all centrifugal ventilators is

counterclockwise when viewing the unit from above the motor compartment.

Guy down large units installed in areas subject to high winds or unusual eld conditions.

CAUTION