4www.PennBarry.com

INSTALLATION

Any accessories which have been provided “knocked-down” can be assembled per illustrations provided (pages 9 - 11).

Remove internal protective shipping trays and llers. Check for and remove any loose hardware or particles from the inside of the

fan housing. Disconnect motor cord and plug from internal terminal box and receptacle.

Avoid severe jarring and/or dropping. Handle units with care to prevent damage to components or special nishes.

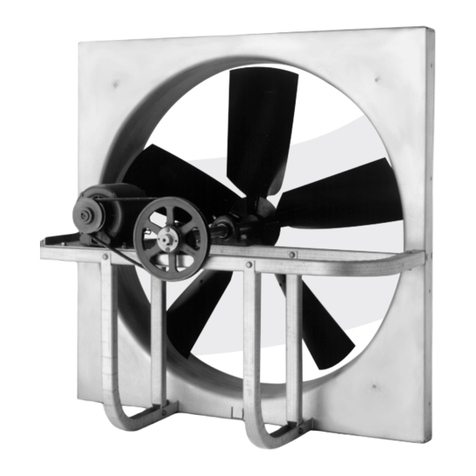

LOCATION AND GUARDS

All fans have moving parts which require guarding in the same way as other moving machinery. Where the fan is accessible to

untrained personnel or the general public, use maximum safety guards, even at the cost of some performance. Unprotected fans

located less than 7’ above the oor require guarding as specied in the Occupational Safety and Health Act (OSHA). UL listed fans,

to maintain their personal safety listing, must be installed not less than 10 feet above the oor. PennBarry recommends the use of

guards on all exposed non-ducted fans.

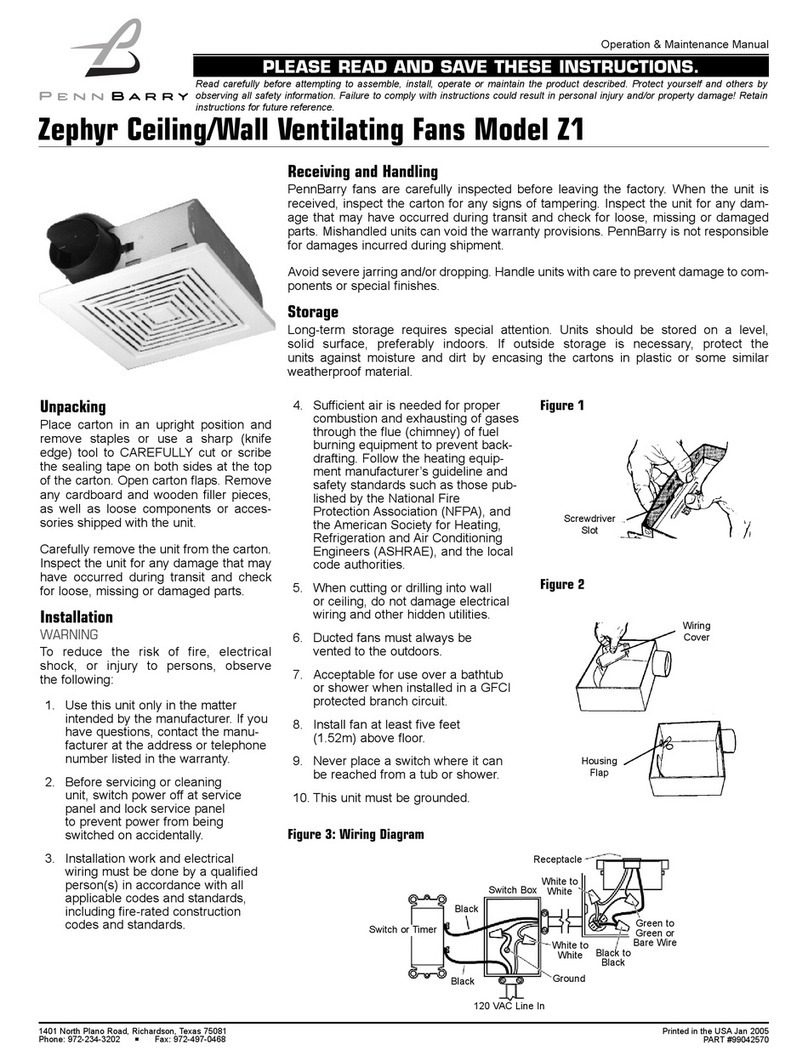

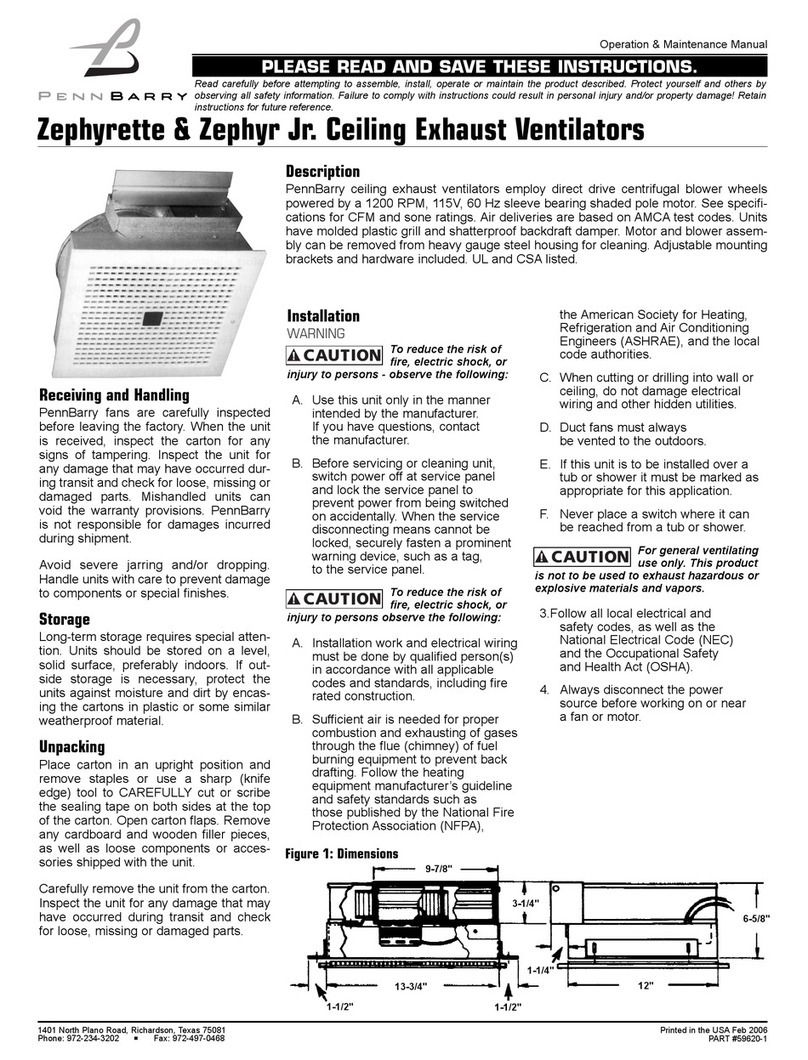

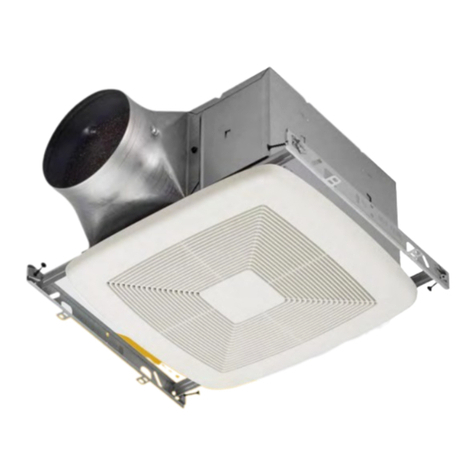

INSTALLING THE PANEL FAN

Wall openings must be square and must be a minimum of 1/2” greater than the outside dimension of the panel fan housing, when

recessed within the wall. Level and securely anchor the fan to the wall through holes pre-drilled in the mounting ange. Use the type,

size and number of fasteners suitable to the unit size and wall construction. If the contractor removes ventilator parts, reassemble

by placing all spacers, washers, nuts, bolts, fasteners and components exactly as they were prior to removal. Tighten and secure all

fasteners.

ELECTRICAL CONNECTIONS

1. Connect motor, per nameplate, to correct power supply.

2. Install all wiring, protection and grounding in accordance with national electrical code and local requirements.

3. Follow all local electrical and safety codes, as well as the National Electrical Code (NEC) and the Occupational Safety and Health

Act (OSHA).

4. In order to prevent motor failure when speed controller is used, unit must be started on high speed before turning to low speed.

POSITIONING AND RUNNING POWER LINES

Power is normally brought from within the building through proper conduit lines to the wall opening, and in turn to the (service

switch, if furnished, or to the) motor. When power lines are brought up to the unit, provide a generous amount of slack to allow for

motor adjustments and to permit movement of motor for belt tension adjustments. Ground motor adequately and securely. Protect

power lines from sharp objects. Do not kink power line or permit it to contact hot surfaces, chemicals, grease or oil. Use only UL

recognized electrical parts, rated for proper voltage, load and environment.

SWP is for general ventilating use only; do not use to exhaust hazardous or explosive materials and vapors.

CAUTION

Before attempting any repair or installation work, be certain that all power to the motor and electrical accessories is

turned o and locked in the o position.

CAUTION

Follow all local electrical, safety and building codes, the provisions of the National Electrical Code and the Occupational

Safety and Health Act.

CAUTION