Penny Hydraulics Ltd

Operating & Maintenance Manual – VME - SwingLift Cranes KJ, ML, F500, FV500, CC, MC & GBC

3

Table of Contents

Welcome .................................................................................................................................................2

Table of Contents.................................................................................................................................... 3

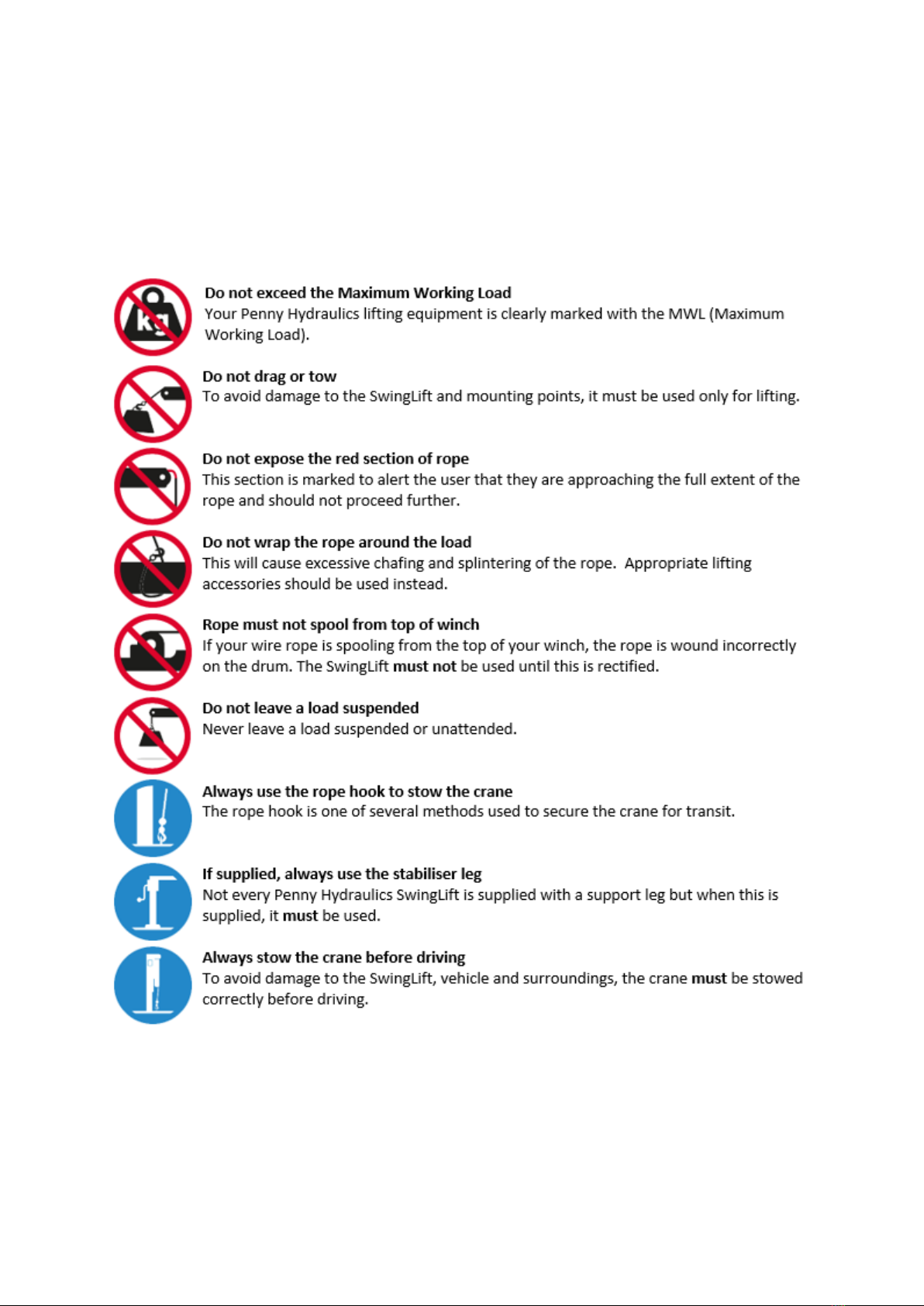

Safety Warning........................................................................................................................................6

Method of Operation.............................................................................................................................. 7

Fault Finding............................................................................................................................................8

Maintenance ...........................................................................................................................................9

Planned Maintenance Schedule ...........................................................................................................10

Load Test Procedure .............................................................................................................................11

Commissioning......................................................................................................................................12

Penny Hydraulics Limited Warranty Policy ...........................................................................................15

Service Contract.................................................................................................................................... 16

Typical Wiring Layout............................................................................................................................17

Overload Setting ...................................................................................................................................17

EC Declaration of Conformity ...............................................................................................................18

SwingLift Knuckle Joint Range...............................................................................................................19

KJ250/1 – Exploded View..................................................................................................................20

KJ250/1 – Parts List ...........................................................................................................................21

KJ250/1.5&2 Exploded View .............................................................................................................22

KJ250/ 1.5&2 Parts List .....................................................................................................................23

KJ250/2 RPT – Exploded View........................................................................................................... 24

KJ250/2 RPT – Parts List ....................................................................................................................25

Technical Data – KJ Series................................................................................................................. 26

SwingLift Mini-Loader Range ................................................................................................................27

ML250 - Exploded view.....................................................................................................................28

ML250 - Parts List..............................................................................................................................29

ML500 - Exploded view.....................................................................................................................30

ML500 - Parts List..............................................................................................................................31

Technical Data – ML Series ...............................................................................................................32

SwingLift F500 .......................................................................................................................................33

F500 – Exploded View....................................................................................................................... 35

F500 Parts List................................................................................................................................... 36

Technical Data – F500 .......................................................................................................................37

FV500 ....................................................................................................................................................38